Photoluminescence organometallic complex microcapsule and preparation method thereof

An organometallic and photoluminescent technology, which is applied in the direction of microcapsule preparation, microsphere preparation, luminescent materials, etc., can solve the problems of oxidation, restriction of organometallic complexes, deterioration, etc., and achieve simple operation, poor weather resistance, and compatibility sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

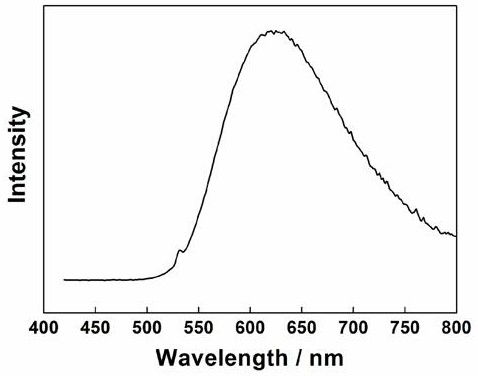

[0045] Preparation of tris(8-hydroxyquinoline-2-carbaldehyde)aluminum:

[0046] Weigh 2.04 g of aluminum isopropoxide and dissolve it in 50 mL of absolute ethanol, heat and stir, then add 5.20 g of 8-hydroxyquinoline-2-carbaldehyde, and continue the reaction for 2 h. After the reaction was completed, the solvent was removed, washed several times with n-hexane, and dried in vacuo to obtain an orange solid powder.

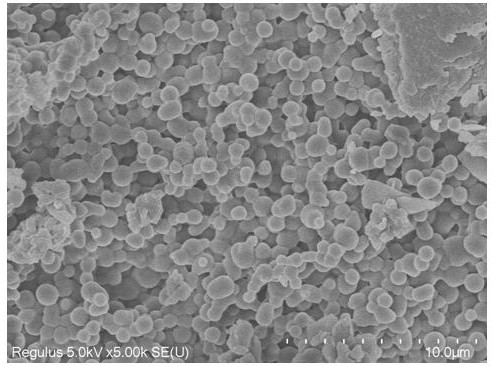

[0047] Preparation of tris(8-hydroxyquinoline-2-carbaldehyde)aluminum microcapsules:

[0048] Add 0.20 g of glutaraldehyde and 0.18 g of Tween80 into 3 mL of deionized water, stir until uniform, and adjust the pH to 2 with hydrochloric acid to form an internal aqueous phase; add 0.08 g of tris(8-hydroxyquinoline-2-carbaldehyde) aluminum, 1.00 g Span80 was added to 10 mL toluene to form an oil phase; 0.4 PVA-1788 and 5 g Tween80 were dissolved in 100 mL deionized water and heated to 60 o C, forming an external aqueous phase.

[0049] Add the inner water phase to th...

Embodiment 2

[0052] Preparation of (8-hydroxyquinoline)bis(8-hydroxyquinoline-2-carbaldehyde)aluminum:

[0053] Weigh 2.04 g of aluminum isopropoxide and dissolve it in 50 mL of absolute ethanol, heat and stir, then add 1.45 g of 8-hydroxyquinoline, react for 30 min, then add 3.46 g of 8-hydroxyquinoline-2-carbaldehyde, and continue the reaction 2 h. After the reaction was completed, the solvent was removed, washed several times with n-hexane, and dried in vacuo to obtain an orange solid powder.

[0054] Preparation of (8-hydroxyquinoline) bis(8-hydroxyquinoline-2-carbaldehyde) aluminum microcapsules:

[0055] Add 0.20 g of adipaldehyde and 0.2 g of sodium dodecylbenzenesulfonate into 4 mL of deionized water, stir until uniform, adjust the pH to 1.5 with hydrochloric acid to form an internal aqueous phase; add 0.08 g of (8-hydroxyquinoline) Bis(8-hydroxyquinoline-2-carbaldehyde) and 1.00 g Span85 were added to 10 mL toluene to form an oil phase; 0.4 PVA-1799 and 5 g sodium dodecylbenzene...

Embodiment 3

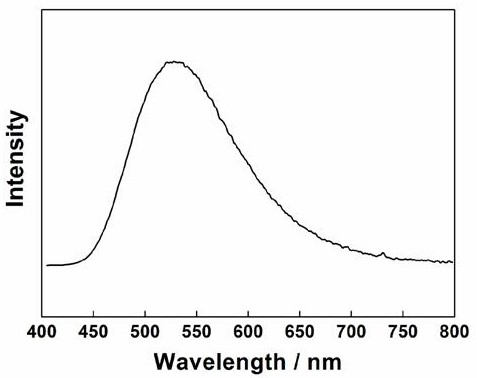

[0058] Preparation of bis(8-hydroxyquinoline)(8-hydroxyquinoline-2-carbaldehyde)aluminum:

[0059] Weigh 2.04 g of aluminum isopropoxide and dissolve it in 50 mL of absolute ethanol, heat and stir, then add 2.90 g of 8-hydroxyquinoline, react for 30 min, then add 1.73 g of 8-hydroxyquinoline-2-carbaldehyde, and continue the reaction 2 h. After the reaction was completed, the solvent was removed, washed several times with n-hexane, and dried in vacuo to obtain an orange solid powder.

[0060] Preparation of bis(8-hydroxyquinoline)(8-hydroxyquinoline-2-formaldehyde) aluminum microcapsules:

[0061] Add 0.30 g of succinic dialdehyde and 0.2 g of cetyltrimethylammonium bromide into 2 mL of deionized water, stir until uniform, adjust the pH to 1 with hydrochloric acid to form an inner aqueous phase; add 0.1 g of bis(8-hydroxy Quinoline) (8-hydroxyquinoline-2-carbaldehyde) aluminum, 1.00 g Span65 were added to 10 mL toluene to form an oil phase; 0.4 PVA-2088 and 6 g cetyltrimethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com