Patents

Literature

133 results about "Thin film thermocouples" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

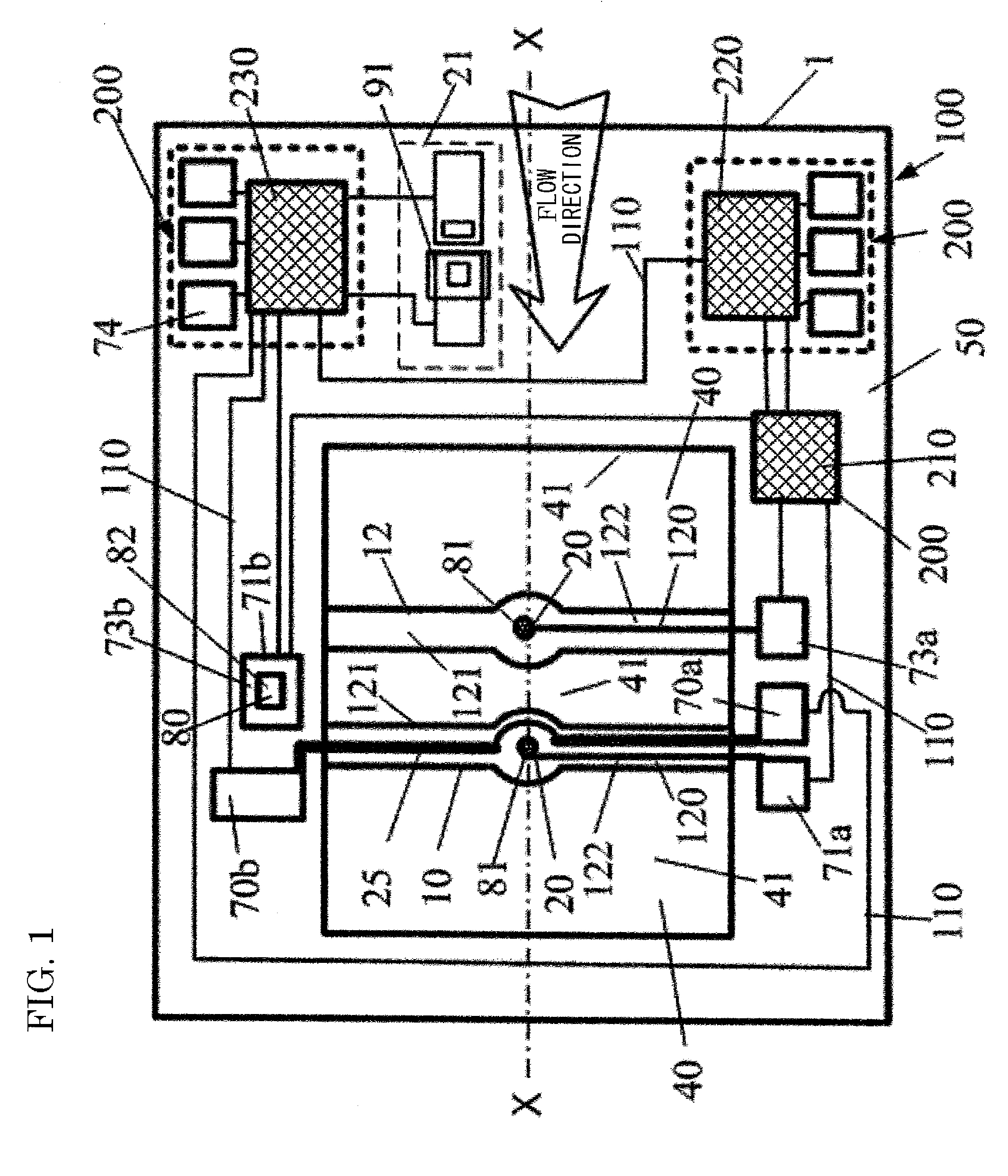

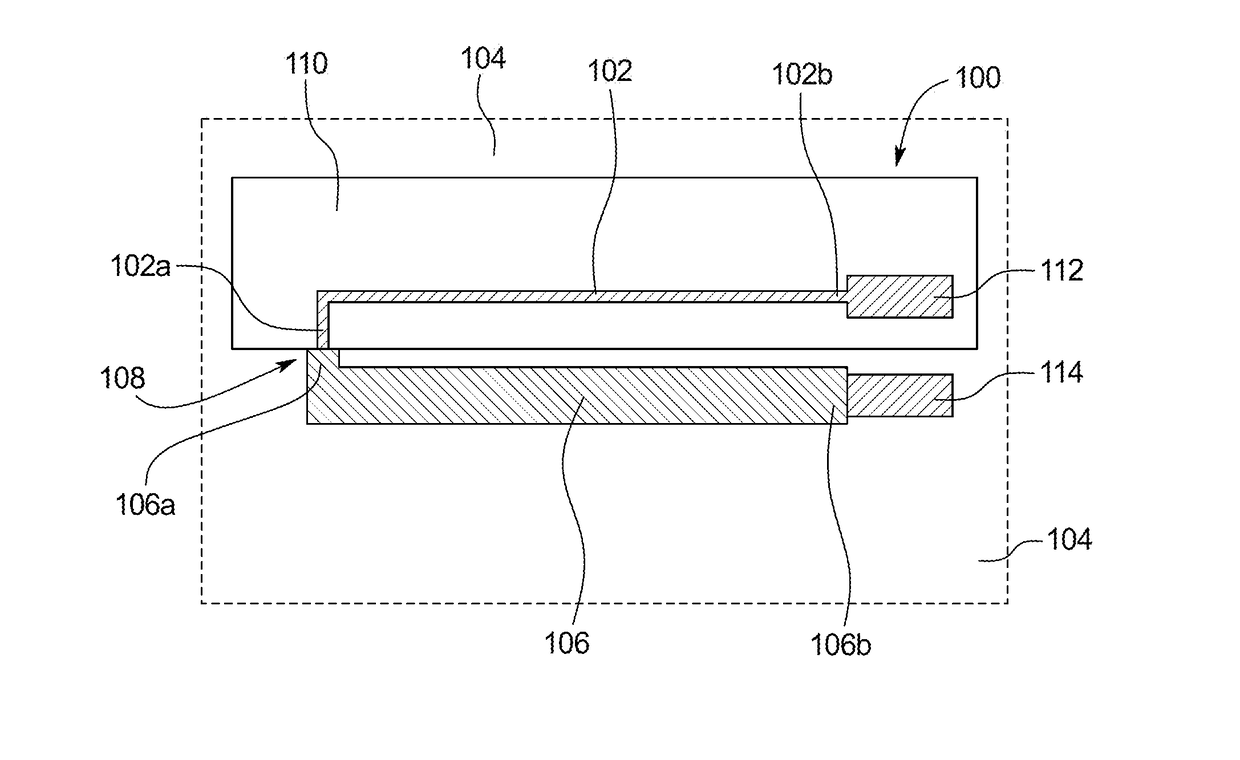

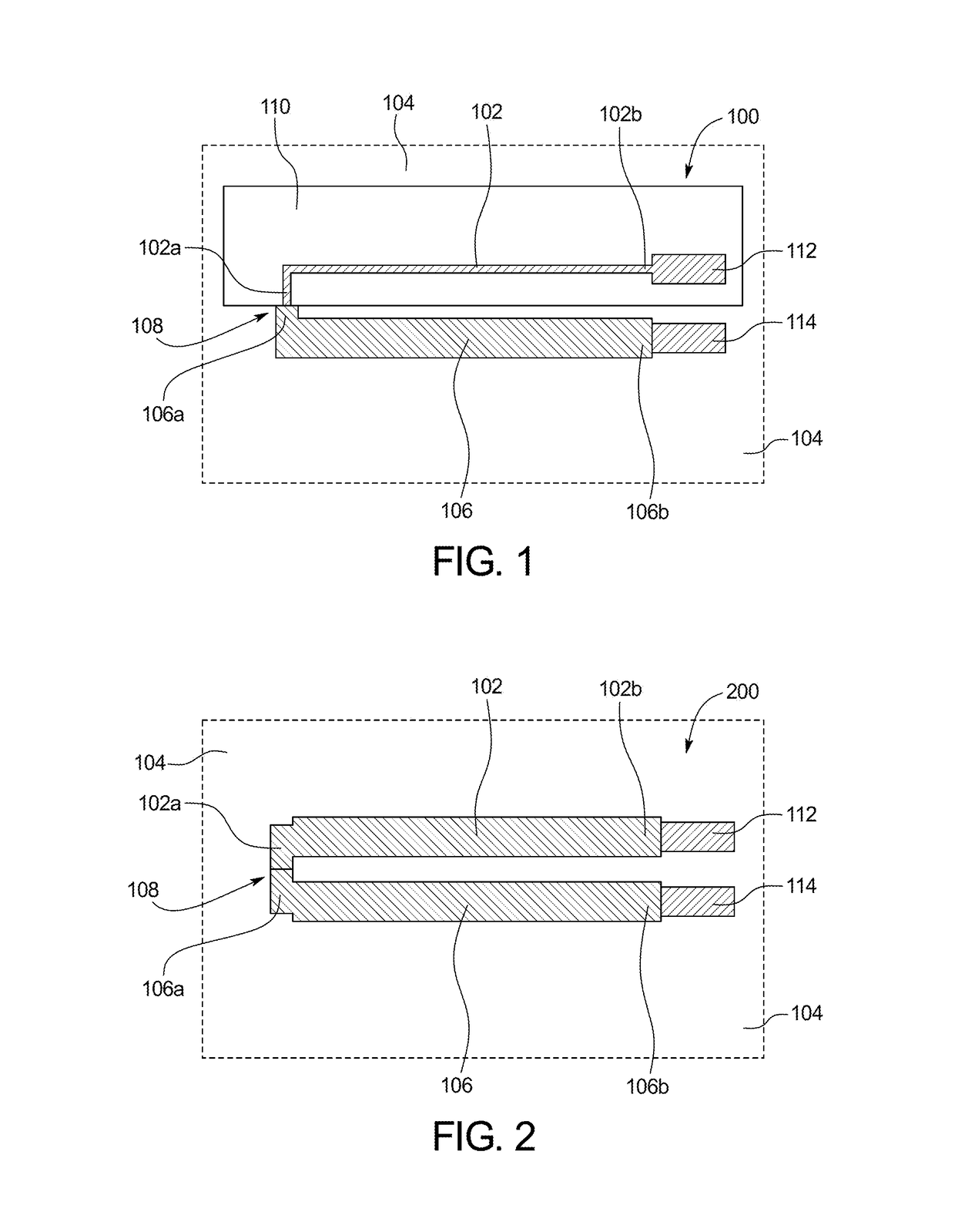

Heat conduction-type sensor for calibrating effects of temperature and type of fluid, and thermal flow sensor and thermal barometric sensor using this sensor

InactiveUS8667839B2Eliminate the effects ofWell formedVolume/mass flow by thermal effectsThermometer testing/calibrationThin film thermocouplesGas pressure transducer

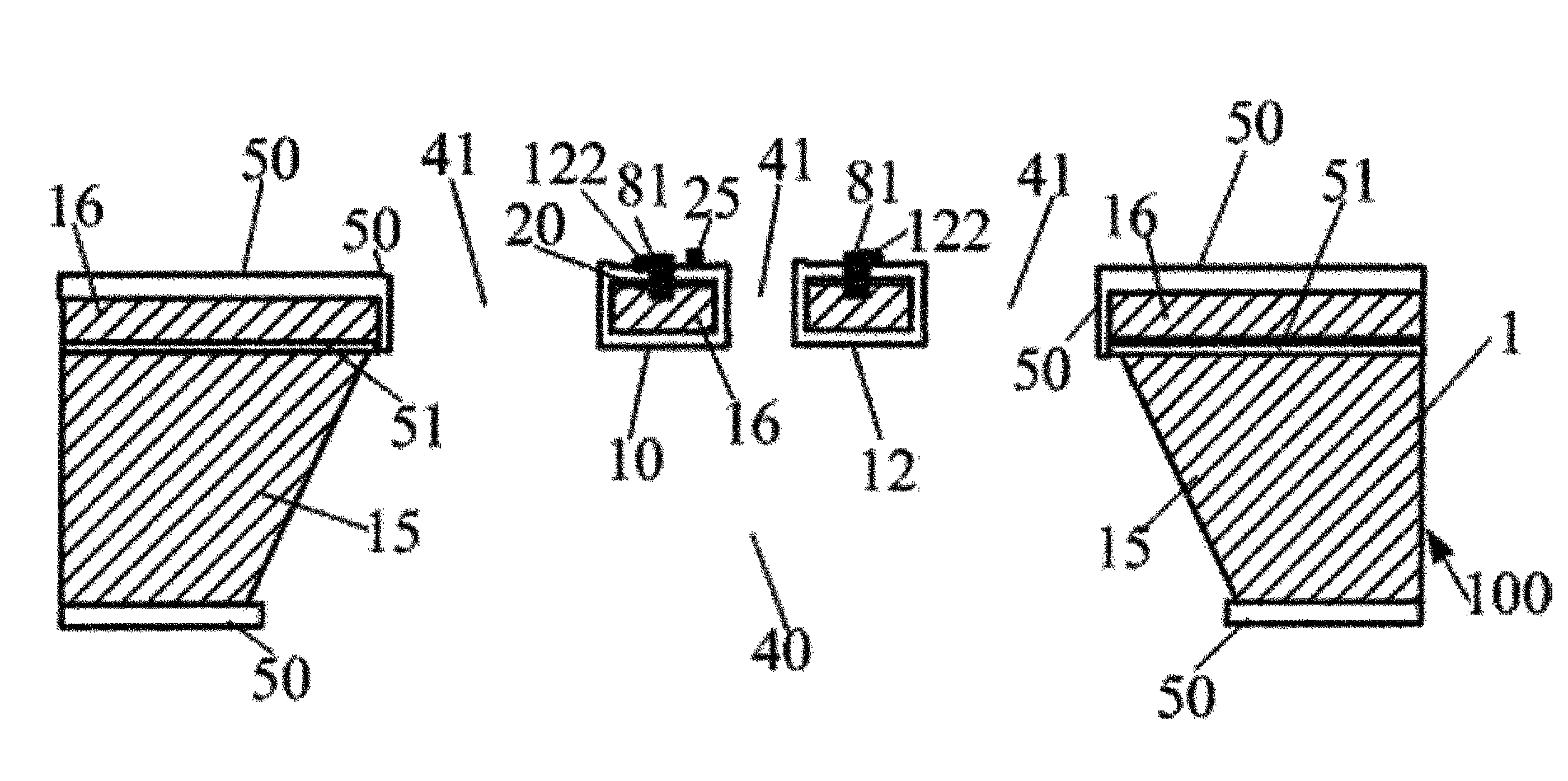

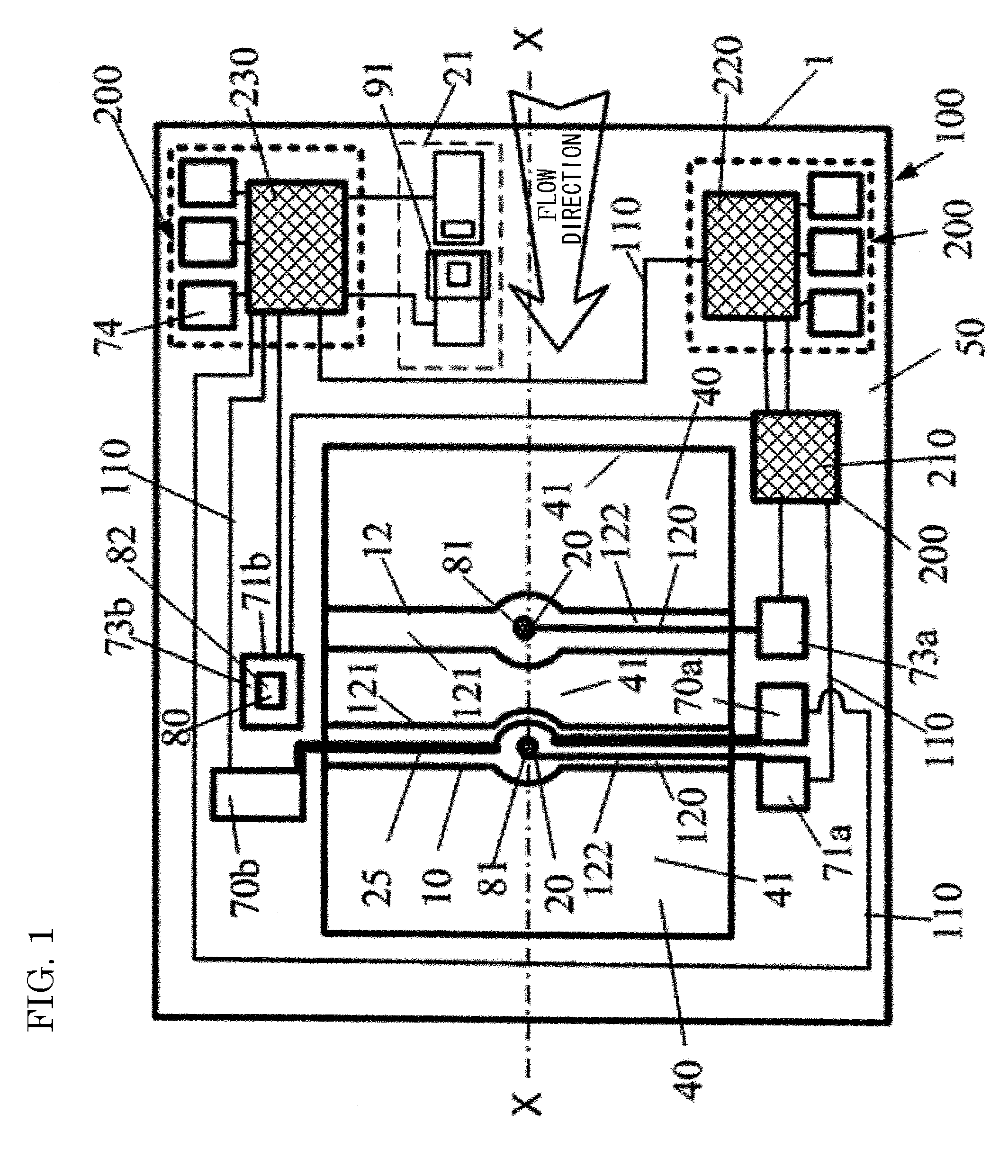

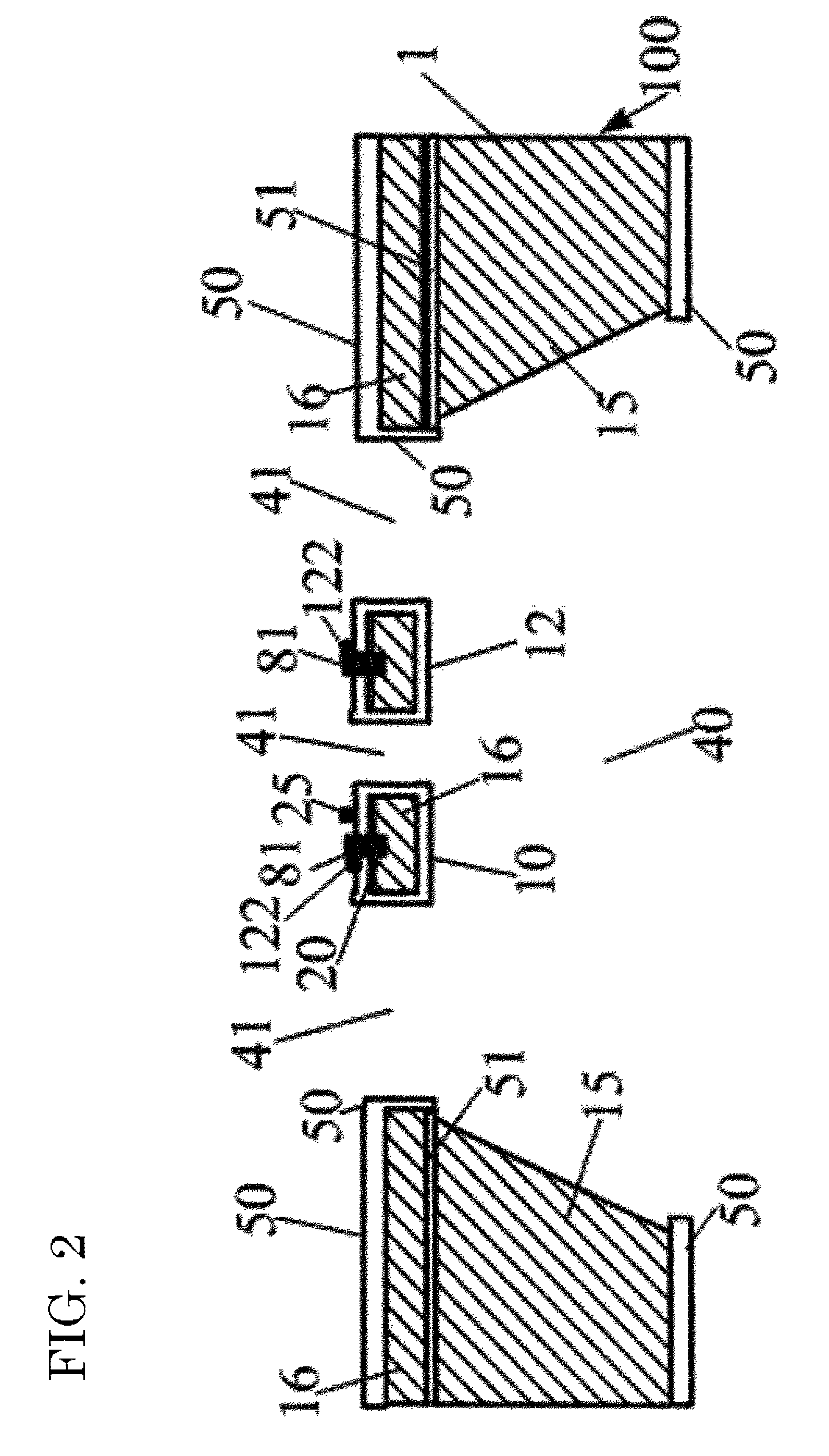

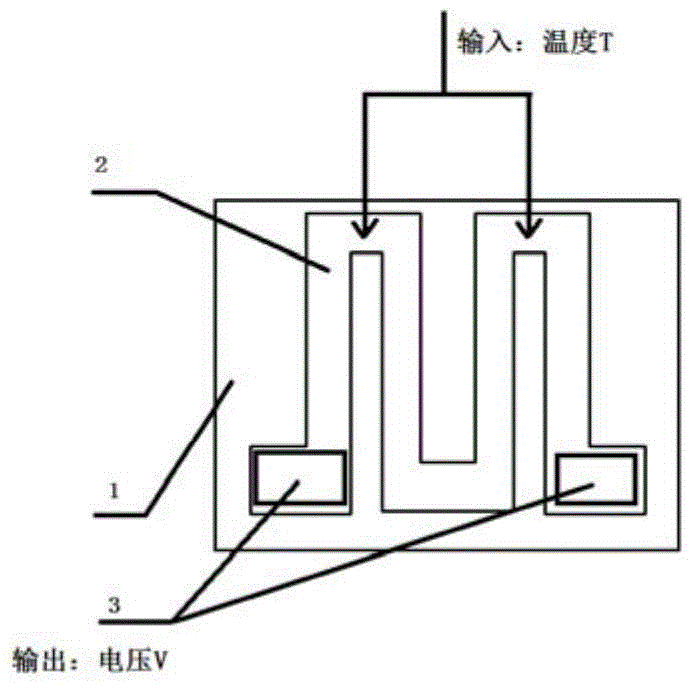

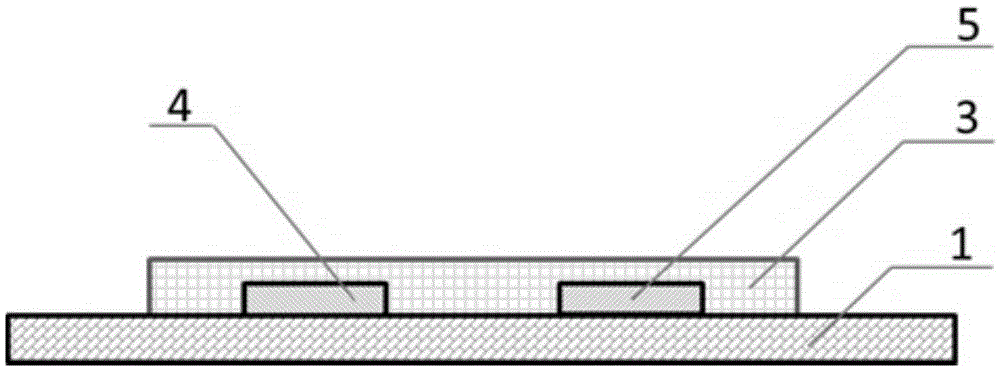

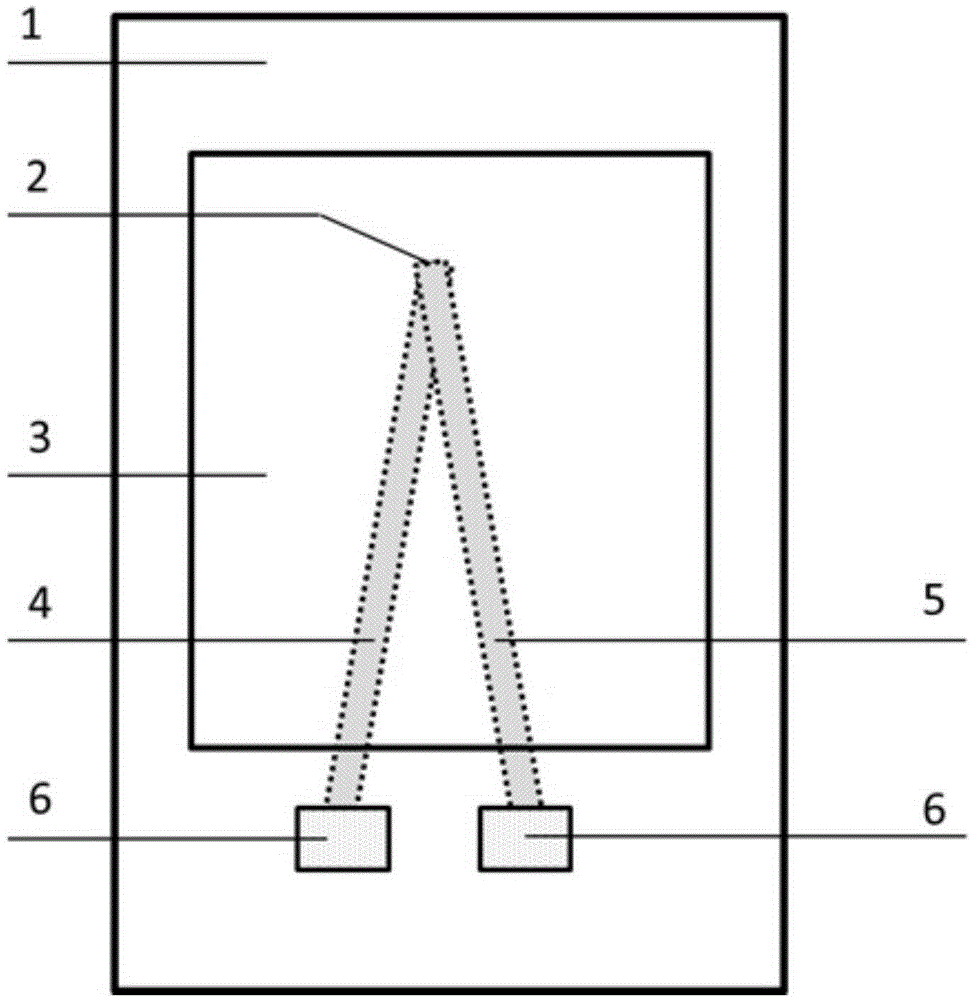

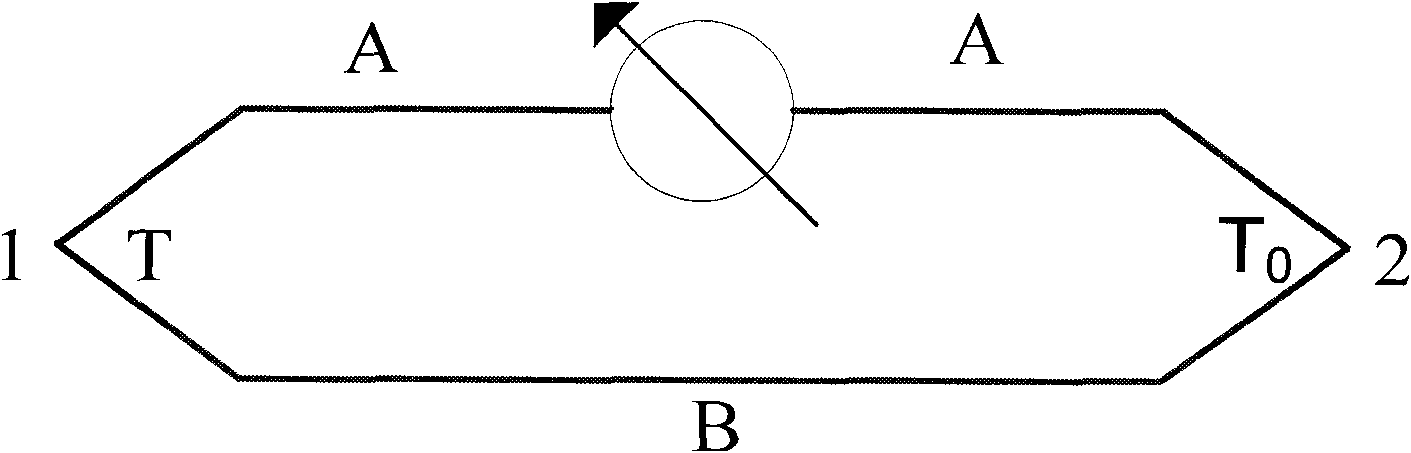

A heat conduction-type sensor corrects (calibrate) effects of a temperature of a measurement target fluid and a type of the fluid on a measurement value in measurement of a flow velocity, a mass flow, or an atmospheric pressure. Also provided is a thermal flow sensor and a thermal barometric sensor with this correcting function, high sensitivity, simple configuration, and low cost. At least two thin films that are thermally separated from a substrate through the same cavity are provided, one thin film comprises a heater and a temperature sensor, and the other thin film comprises at least one temperature sensor, the temperature sensors being thin-film thermocouples. The thin film is arranged in proximity so that it is heated only through the measurement target fluid by heating of the heater. A calibration circuit calculates and compares quantities concerning heat transfer coefficients of a standard fluid and the unknown measurement target fluid.

Owner:GAKUIN TOHOKU

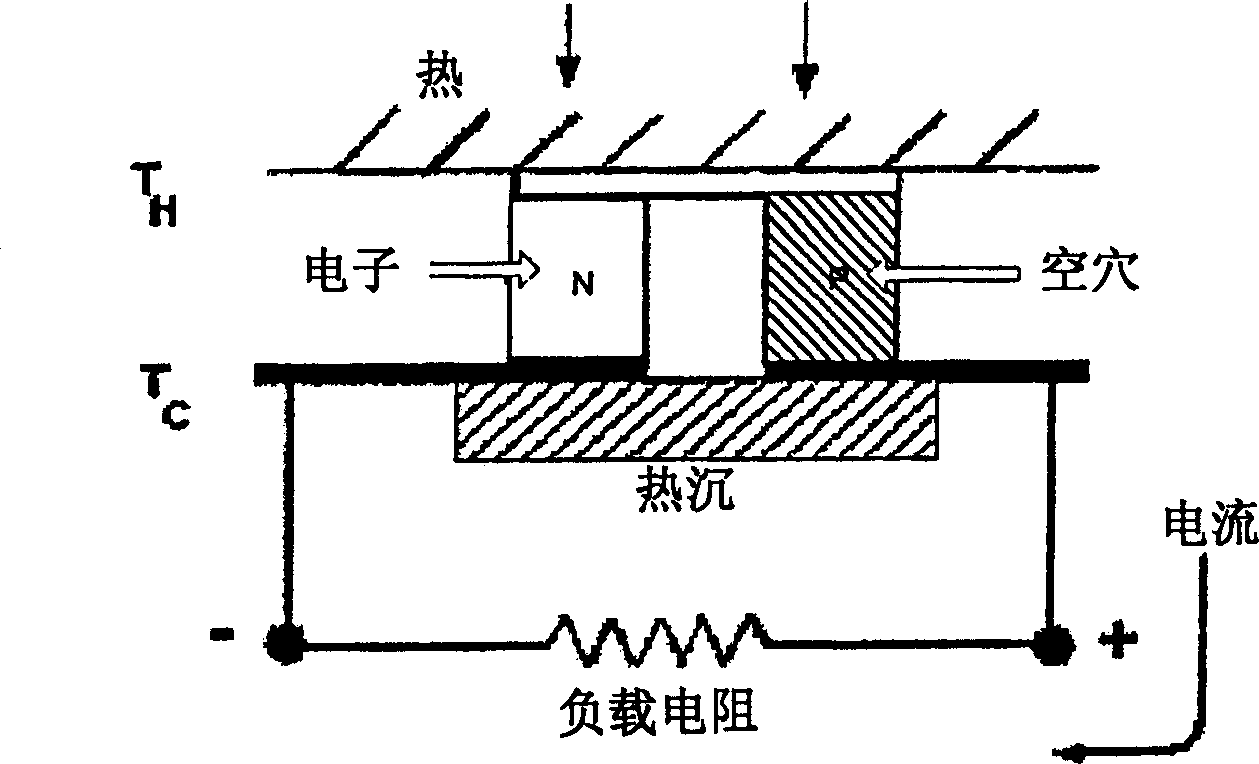

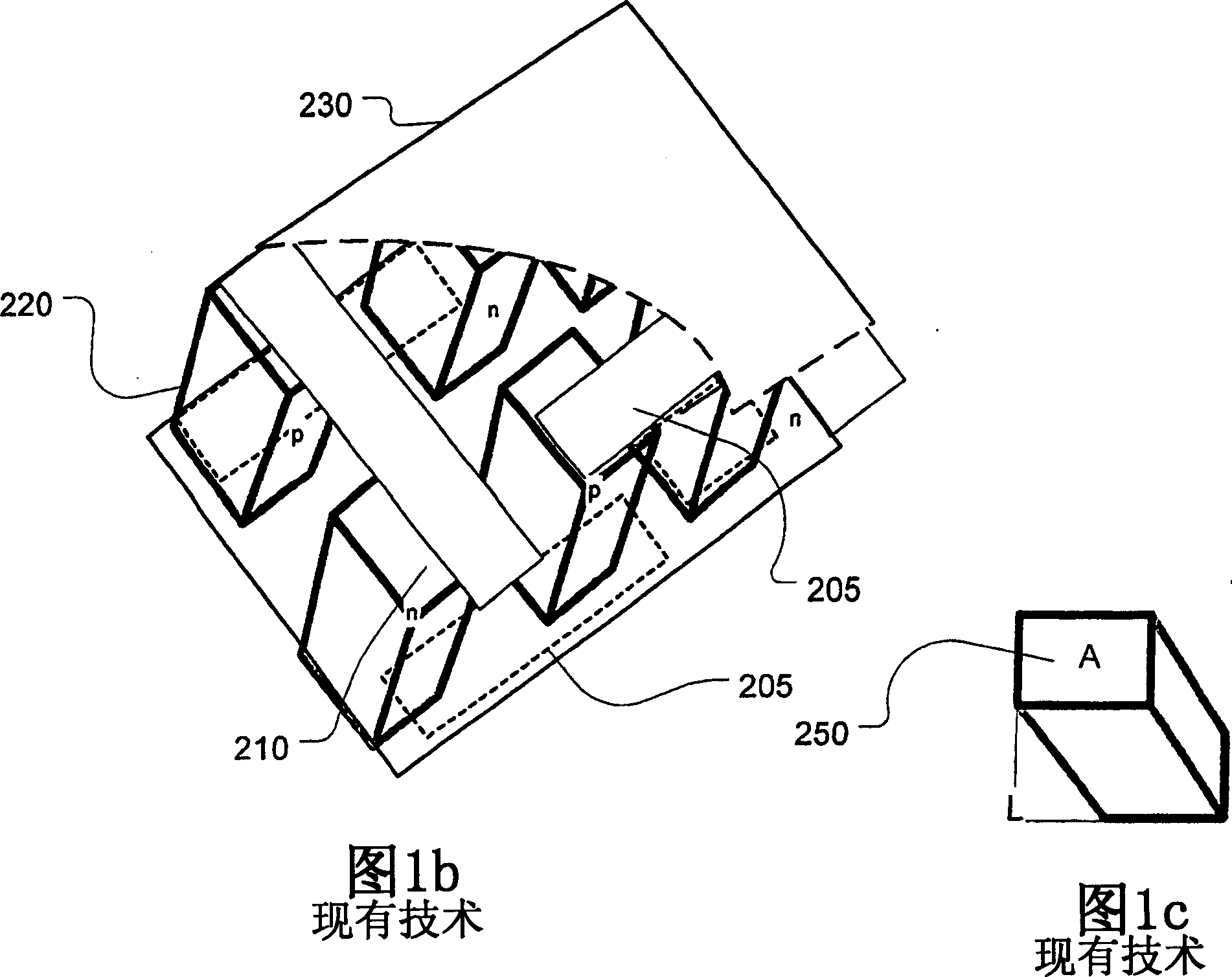

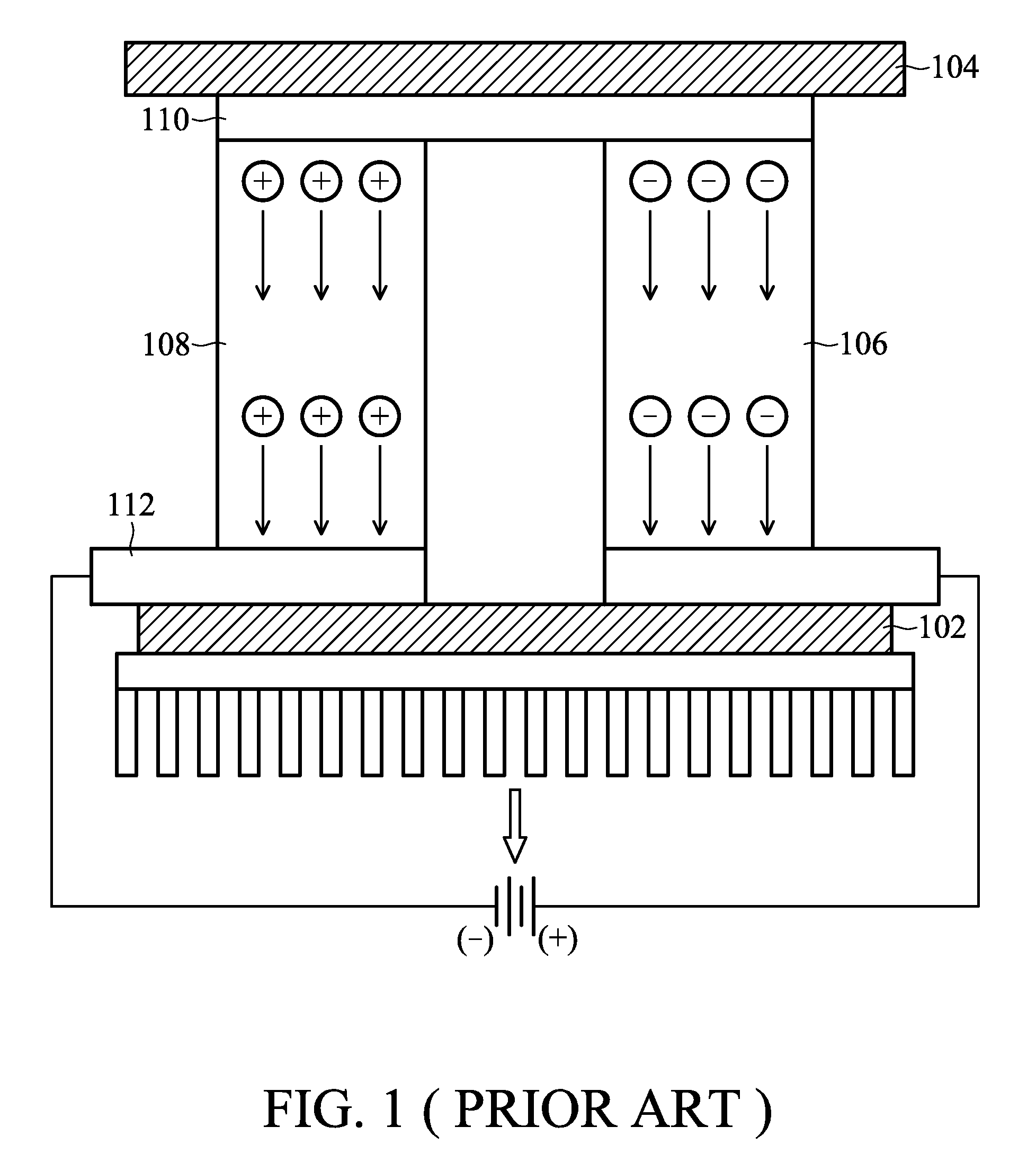

Thermoelectric devices and applications for the same

InactiveCN1890821AThermoelectric device with peltier/seeback effectThermoelectric device detailsThin film thermocouplesTemperature difference

Owner:BATTELLE MEMORIAL INST

Heat conduction-type sensor for calibrating effects of temperature and type of fluid, and thermal flow sensor and thermal barometric sensor using this sensor

InactiveUS20120318058A1Eliminate the effects ofWell formedVolume/mass flow by thermal effectsFluid pressure measurement by mechanical elementsThin film thermocouplesAtmospheric air

A heat conduction-type sensor corrects (calibrate) effects of a temperature of a measurement target fluid and a type of the fluid on a measurement value in measurement of a flow velocity, a mass flow, or an atmospheric pressure. Also provided is a thermal flow sensor and a thermal barometric sensor with this correcting function, high sensitivity, simple configuration, and low cost. At least two thin films that are thermally separated from a substrate through the same cavity are provided, one thin film comprises a heater and a temperature sensor, and the other thin film comprises at least one temperature sensor, the temperature sensors being thin-film thermocouples. The thin film is arranged in proximity so that it is heated only through the measurement target fluid by heating of the heater. A calibration circuit calculates and compares quantities concerning heat transfer coefficients of a standard fluid and the unknown measurement target fluid.

Owner:GAKUIN TOHOKU

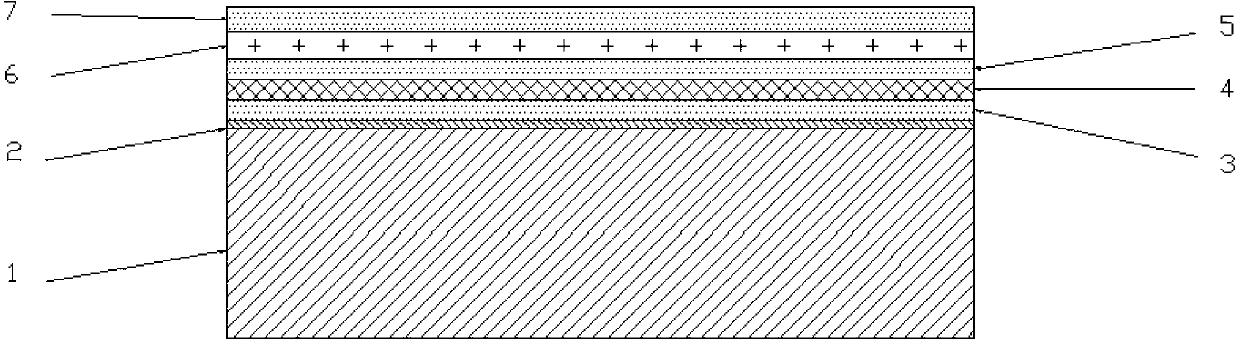

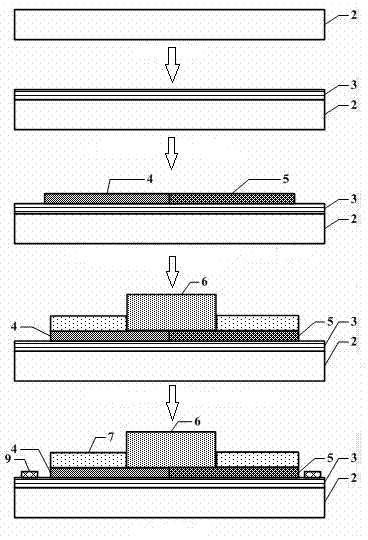

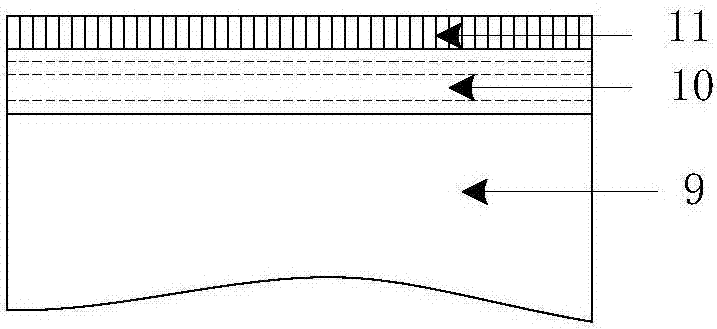

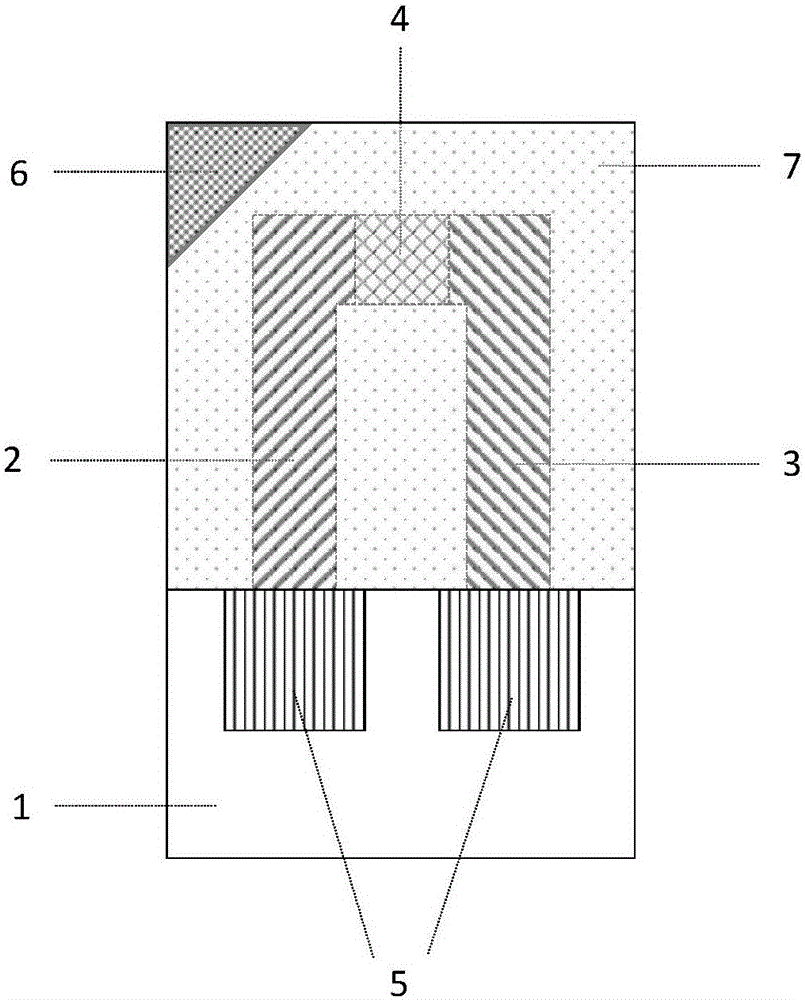

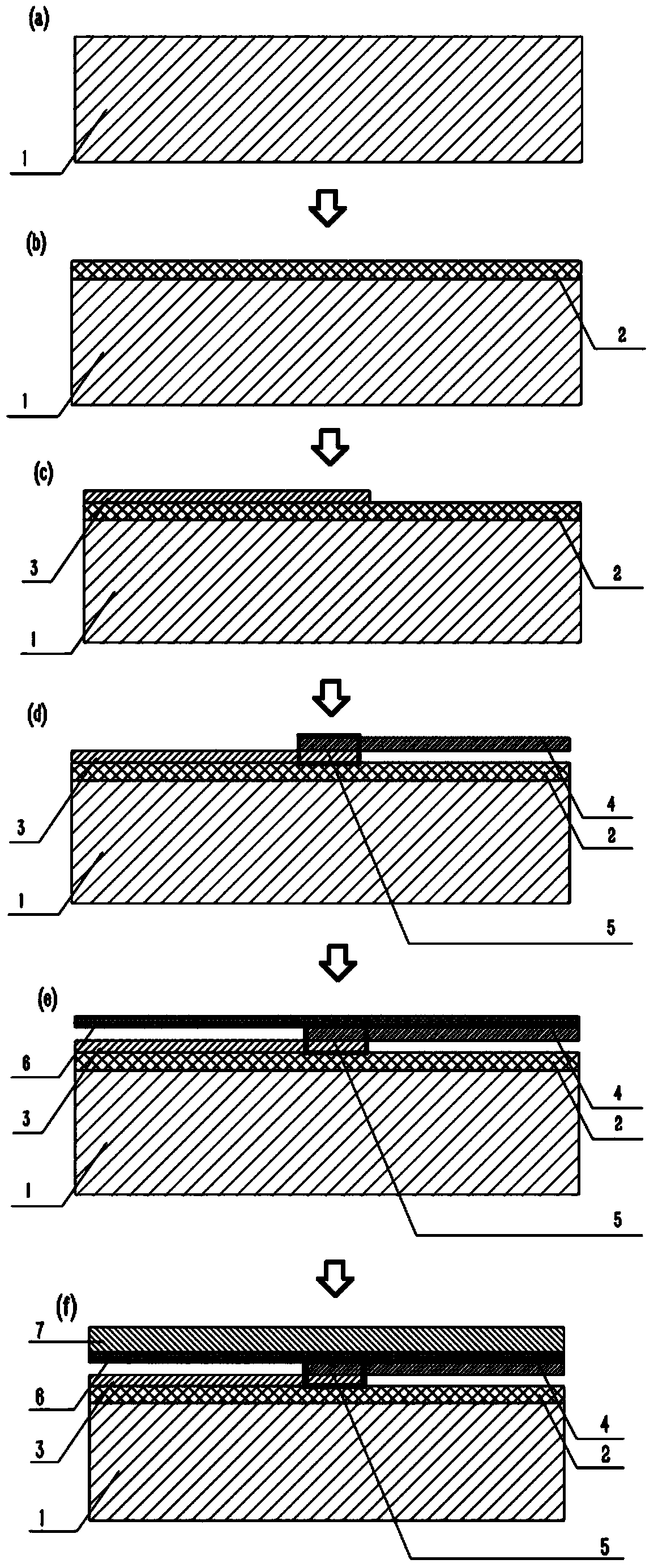

High-temperature ceramic base film thermocouple and manufacturing method thereof

ActiveCN103344350ALattice Mismatch ReliefImprove bindingThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThin film thermocouplesManufacturing technology

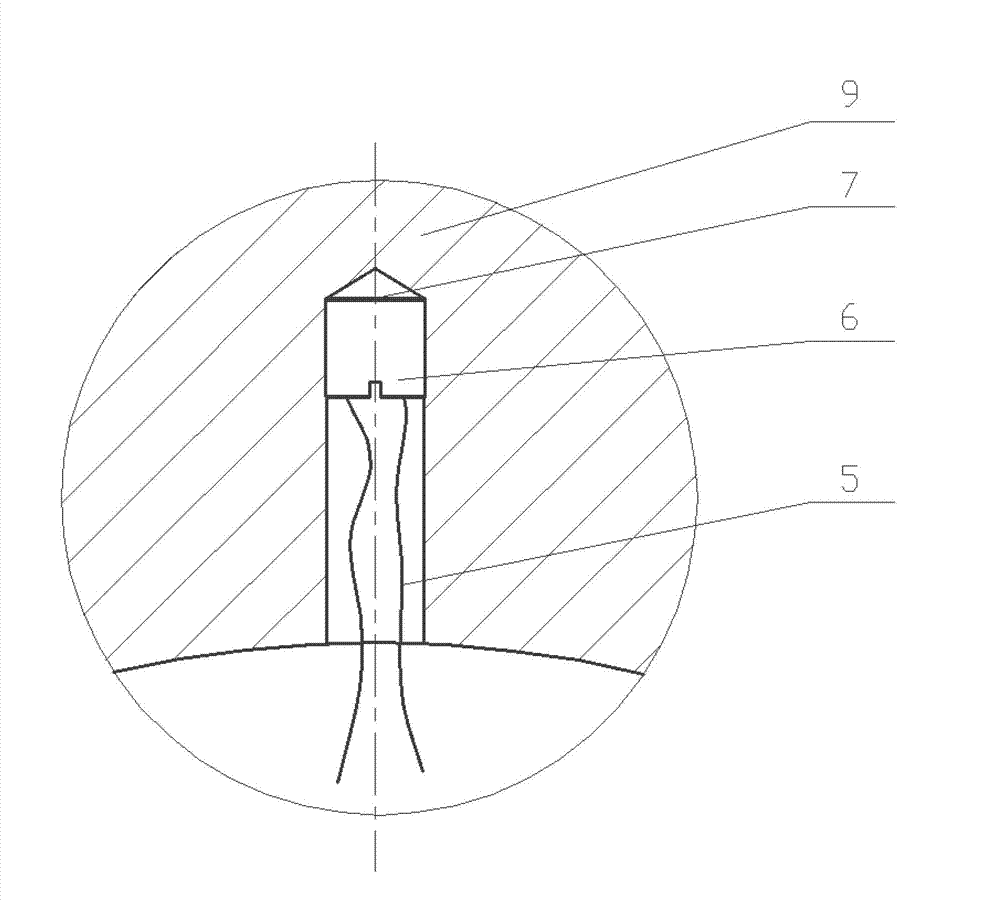

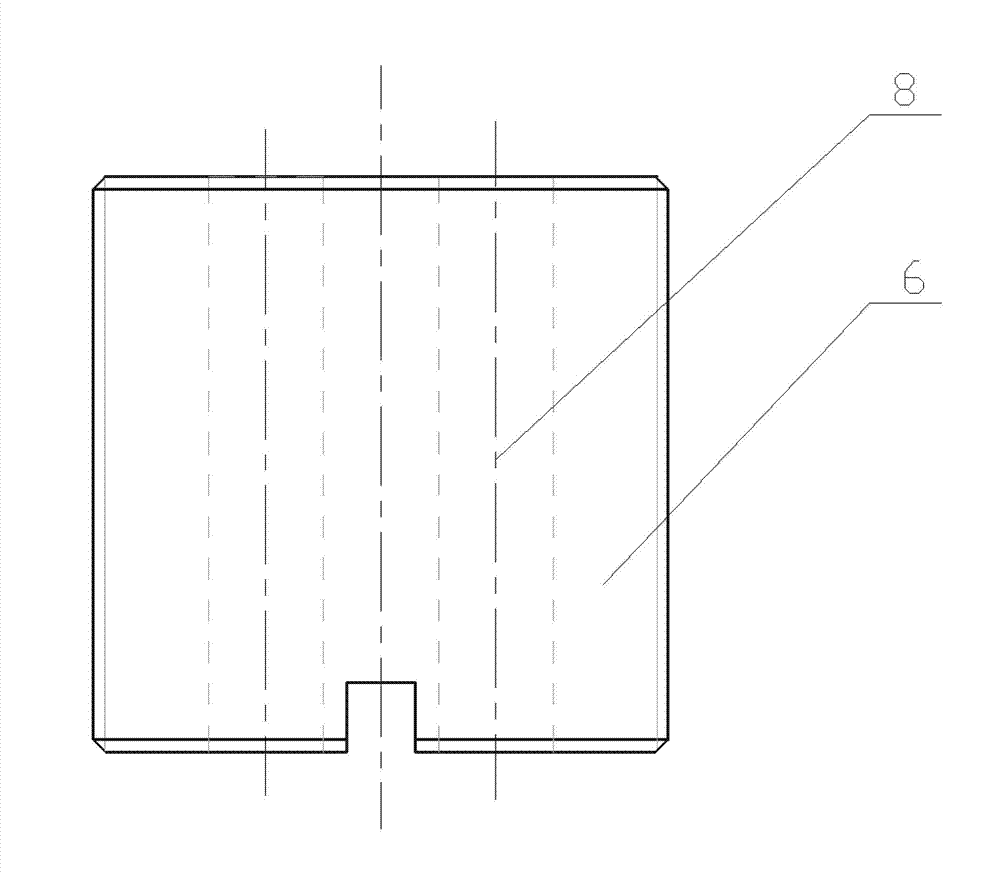

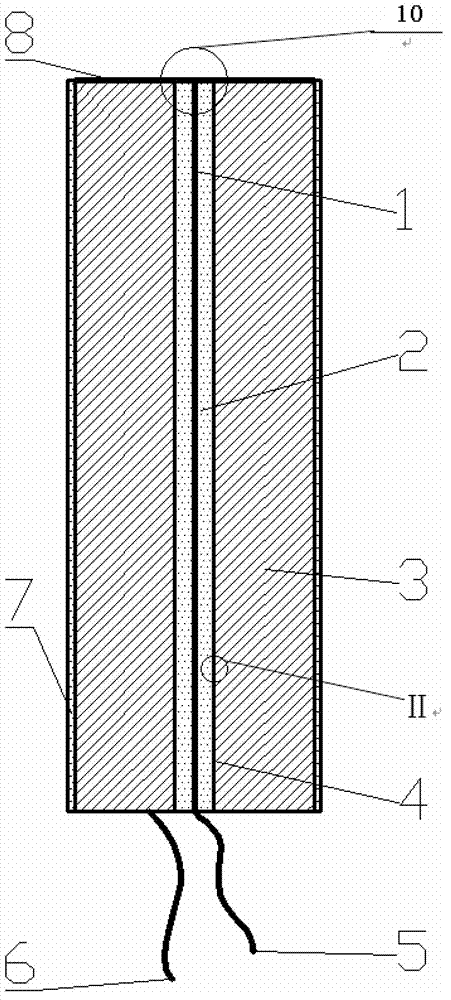

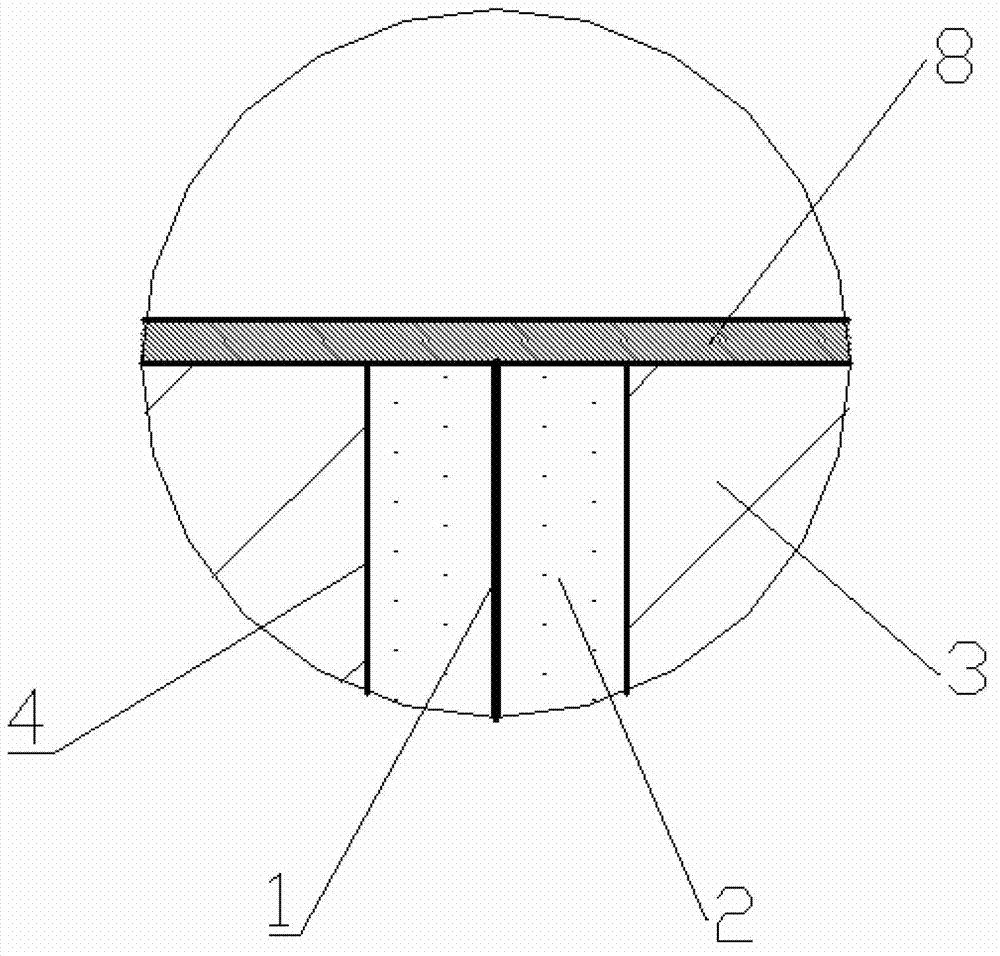

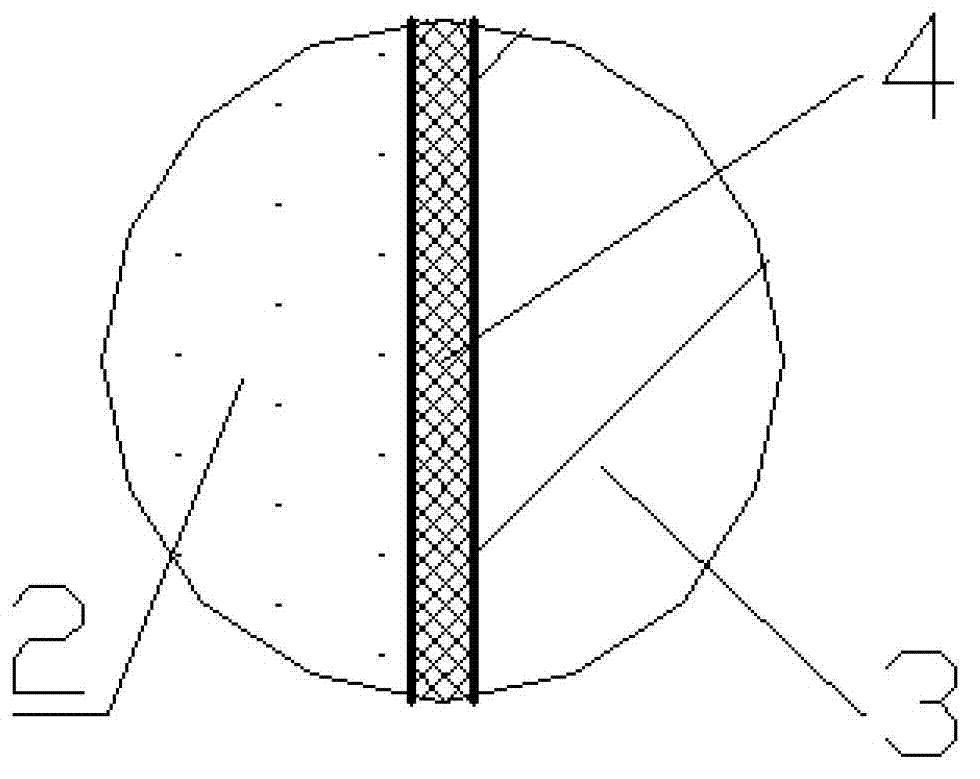

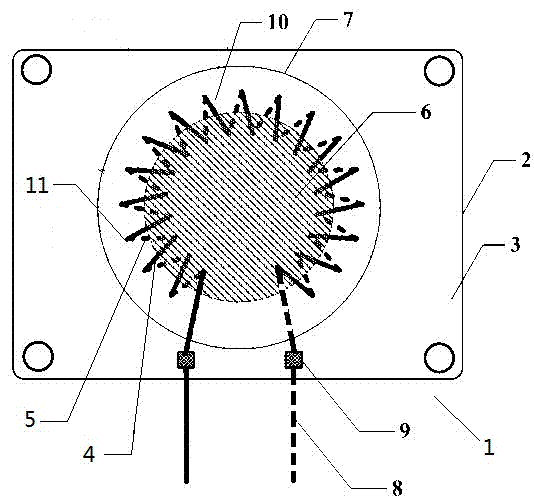

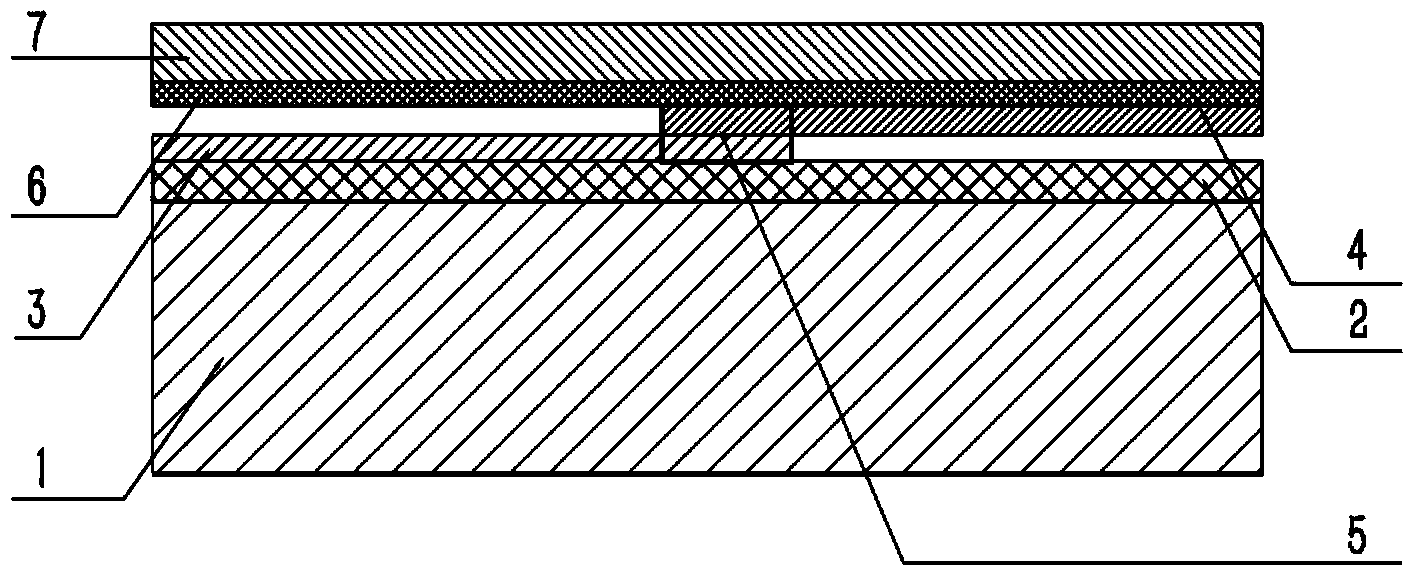

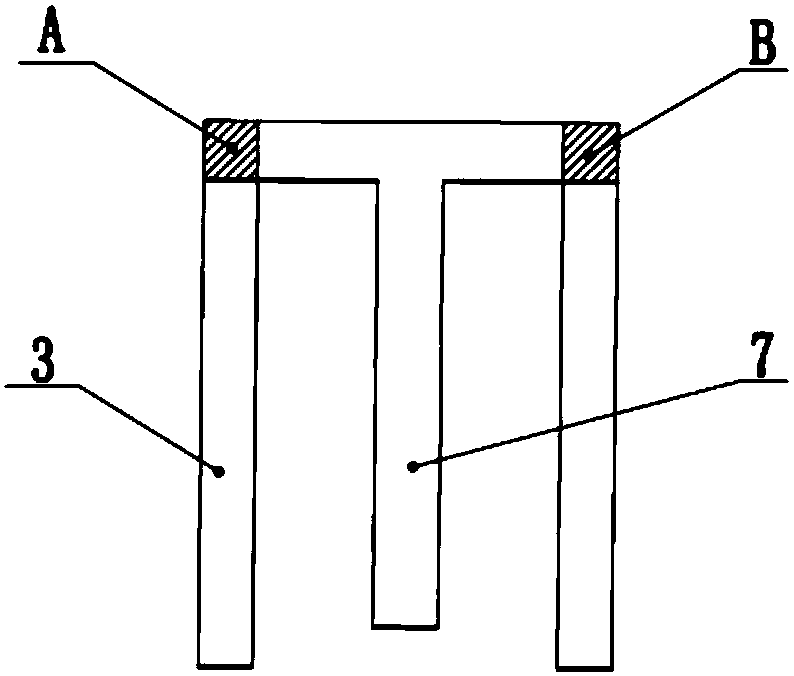

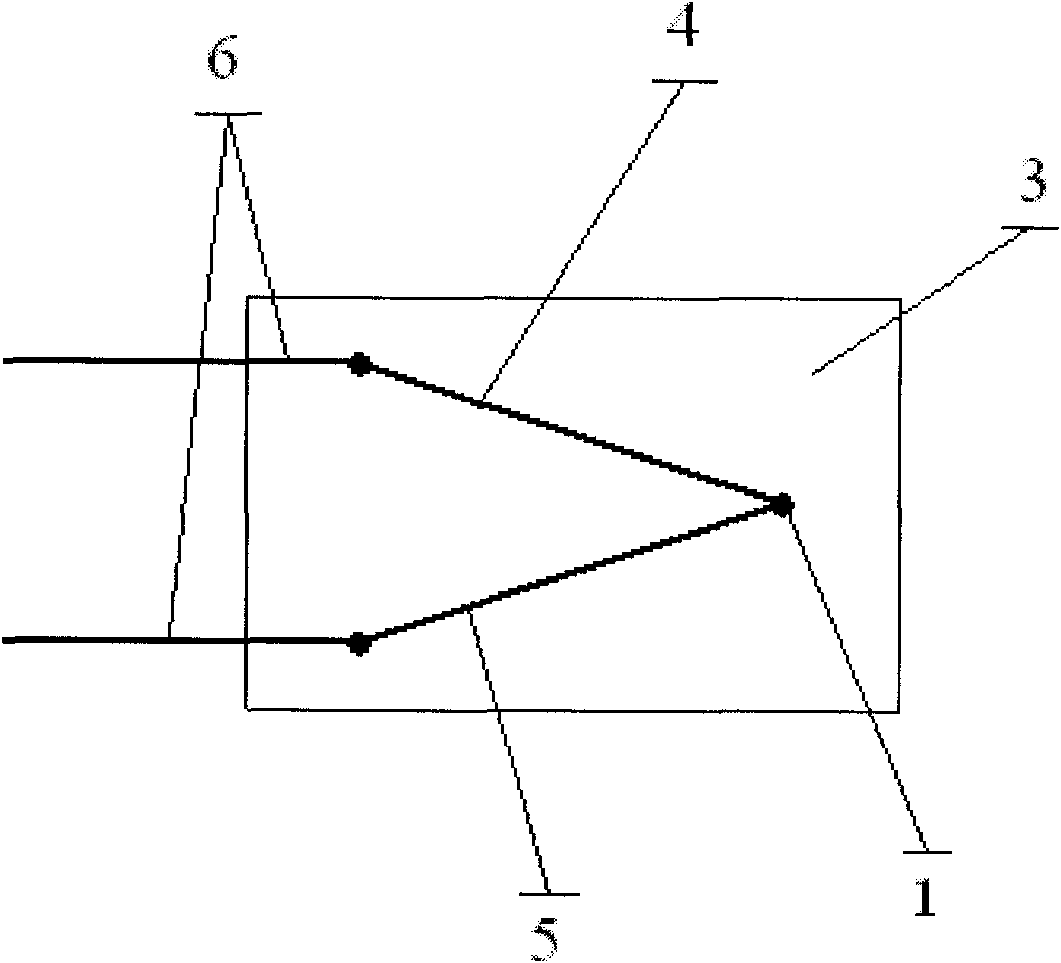

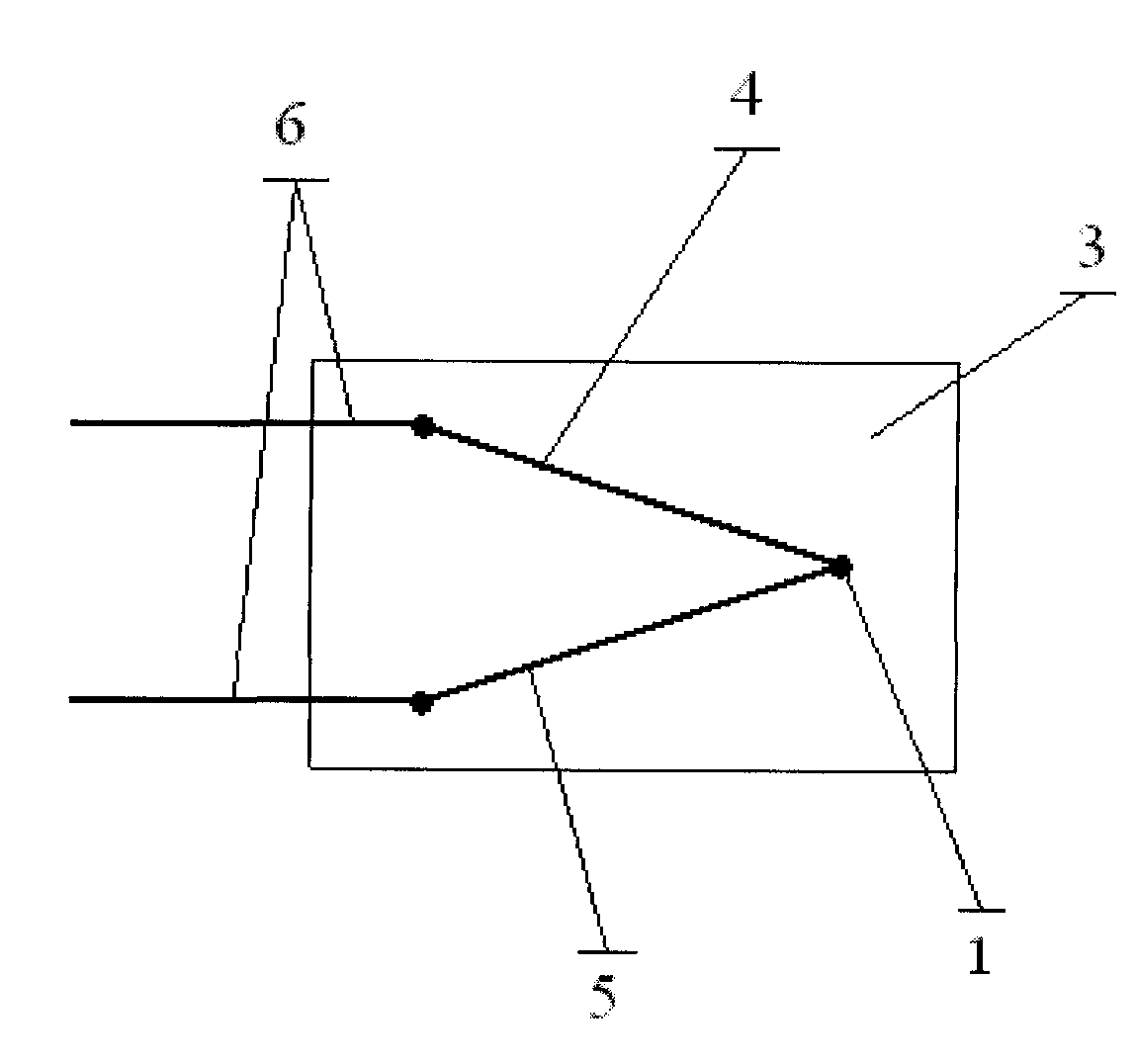

The invention discloses a high-temperature ceramic base film thermocouple and a manufacturing method of the high-temperature ceramic base film thermocouple, and belongs to the field of sensor manufacturing technologies and high temperature measurement technologies. The high-temperature ceramic base film thermocouple sequentially comprises a ceramic base 1, a SiO2 layer 2, a first A12O3 layer 3, an interlayer 4, a second A12O3 layer 5, a thermocouple layer 6 and a third A12O3 layer 7. The high-temperature ceramic base film thermocouple has the advantages that (1) the SiO2 transition layer is adopted, so that binding force on the interface between an insulating layer and the ceramic base is enhanced; (2) the A12O3-Si3N4 / A1N-A12O3 composite insulating layer is adopted, the excellent insulating performance is possessed, oxygen can be prevented from entering the high-temperature ceramic base film thermocouple, oxidization of a film on an inner layer is eliminated, and good dynamic response of a sensor is guaranteed; (3) thermal stress of the film caused by thermal loads is effectively reduced, and film forming quality and stability of the film are guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

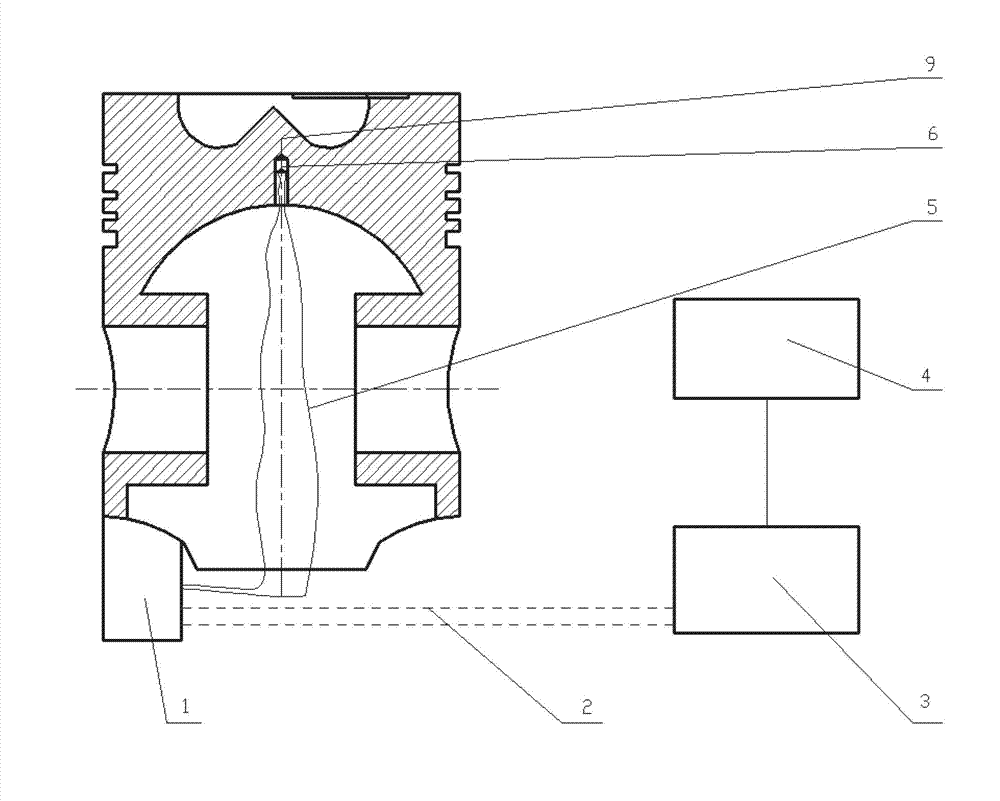

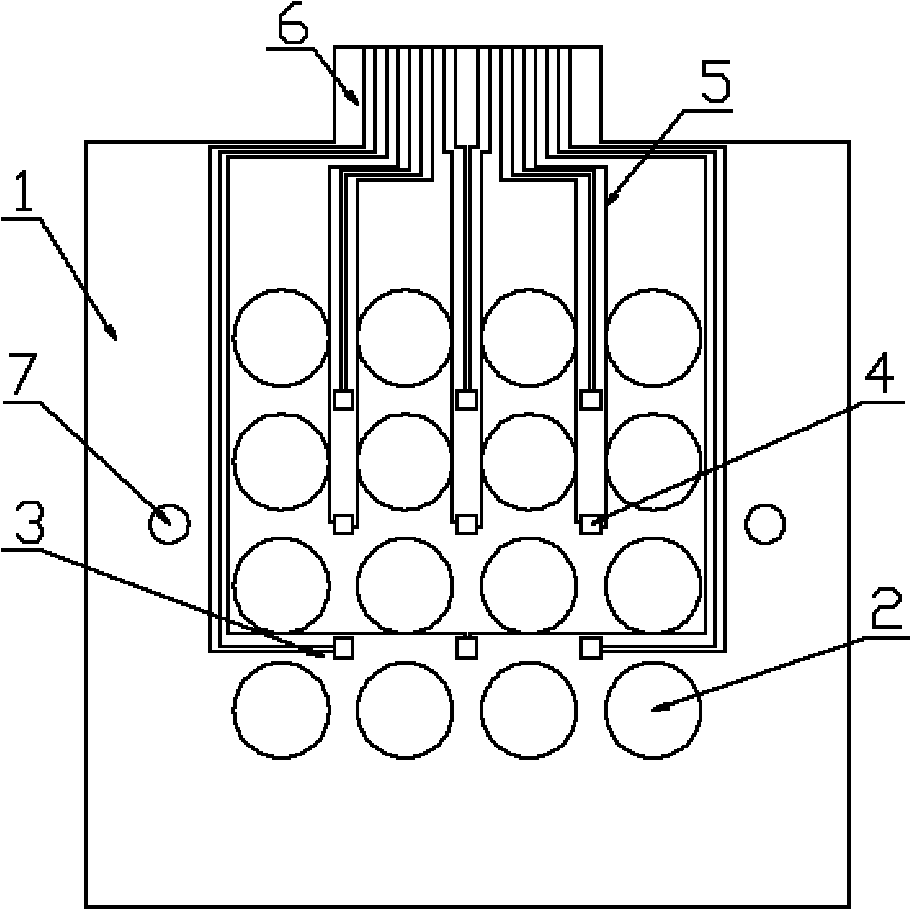

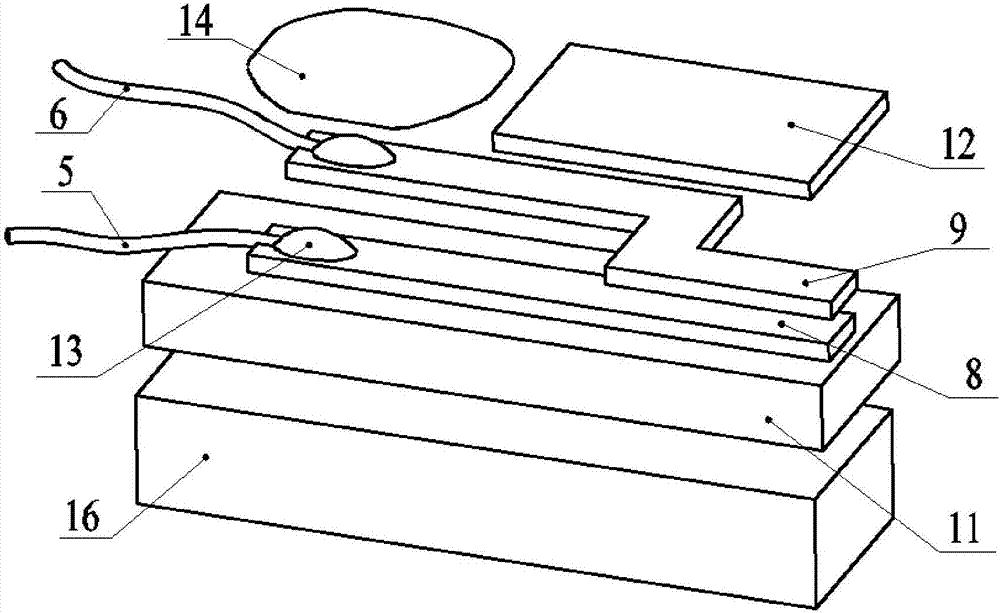

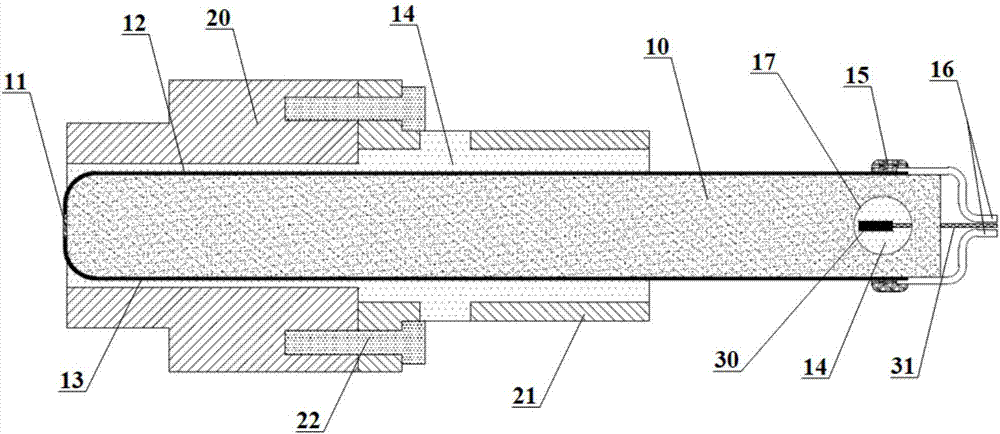

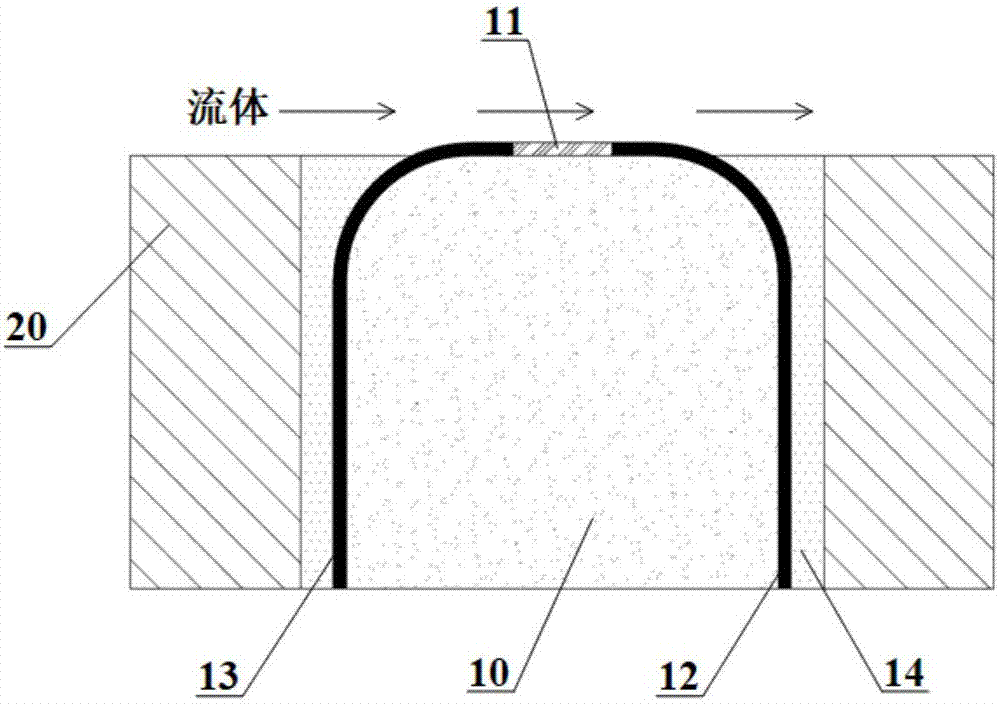

Transient temperature measuring system for diesel engine piston and measuring method thereof

ActiveCN102853930AEasy to manufactureEasy to placeThermometers using electric/magnetic elementsUsing electrical meansThin film thermocouplesContinuous measurement

The invention discloses a transient temperature measuring system for a diesel engine piston and a measuring method thereof. The system comprises a data acquiring, amplifying and transmitting device, a signal receiving device, a computer, a temperature measuring screw and a compensating lead, wherein the temperature measuring screw is connected with the data acquiring, amplifying and transmitting device through the compensating lead; the data acquiring, amplifying and transmitting device is connected with the signal receiving device through a wireless transmission signal; and the upper end face of the temperature measuring screw is provided with a film thermocouple. The method comprises the following steps of: making a mask and a mask clamp; making a temperature measuring screw; installing; and measuring. According to the measuring system, temperature is measured by using an advanced film thermocouple preparation technology, so that short dynamic response time is ensured, high temperature measuring accuracy is realized, and continuous measurement can be performed. Meanwhile, a small screw structure is adopted, and a sensor is easy to manufacture and can be placed on the piston easily; and the transient temperature measuring system is simple in structure, is convenient to replace, and can be produced in a standard way. Due to the adoption of the transient temperature measuring system and the measuring method thereof, the problems of temperature testing of the diesel engine piston in a severe working environment and the problem of lead connection of the film thermocouple are solved.

Owner:DALIAN JIAOTONG UNIVERSITY

Needle-like coaxial thin-film thermocouple for measuring transient temperature

ActiveCN103245430AThermometers using electric/magnetic elementsUsing electrical meansThin film thermocouplesThermodynamics

The invention discloses a needle-like coaxial thin-film thermocouple for measuring a transient temperature, and belongs to the technical field of sensors. The needle-like coaxial thin-film thermocouple comprises a thermocouple coaxial structure comprising a needle-like measuring end, thermal electrodes and an insulating layer, wherein the measuring end comprises a thermal electrode I and a thin-film coating, and the thin-film coating is arranged on the needle-like top surface of the thermocouple coaxial structure; the thermal electrode I is covered with the insulating layer; the insulating layer and a thermal electrode II are adhered with glue; the thin-film coating and the wire-shaped thermal electrode are connected to form a thermocouple thermal connection point which is the measuring end; a lead I is connected with the thermal electrode I, and a lead II is connected with the thermal electrode II; and the measuring end converts measured temperature signals into electrical signals and transmits the electrical signals to a cold junction compensation and signal conditioning module and a computer testing system through wires.

Owner:DALIAN JIAOTONG UNIVERSITY

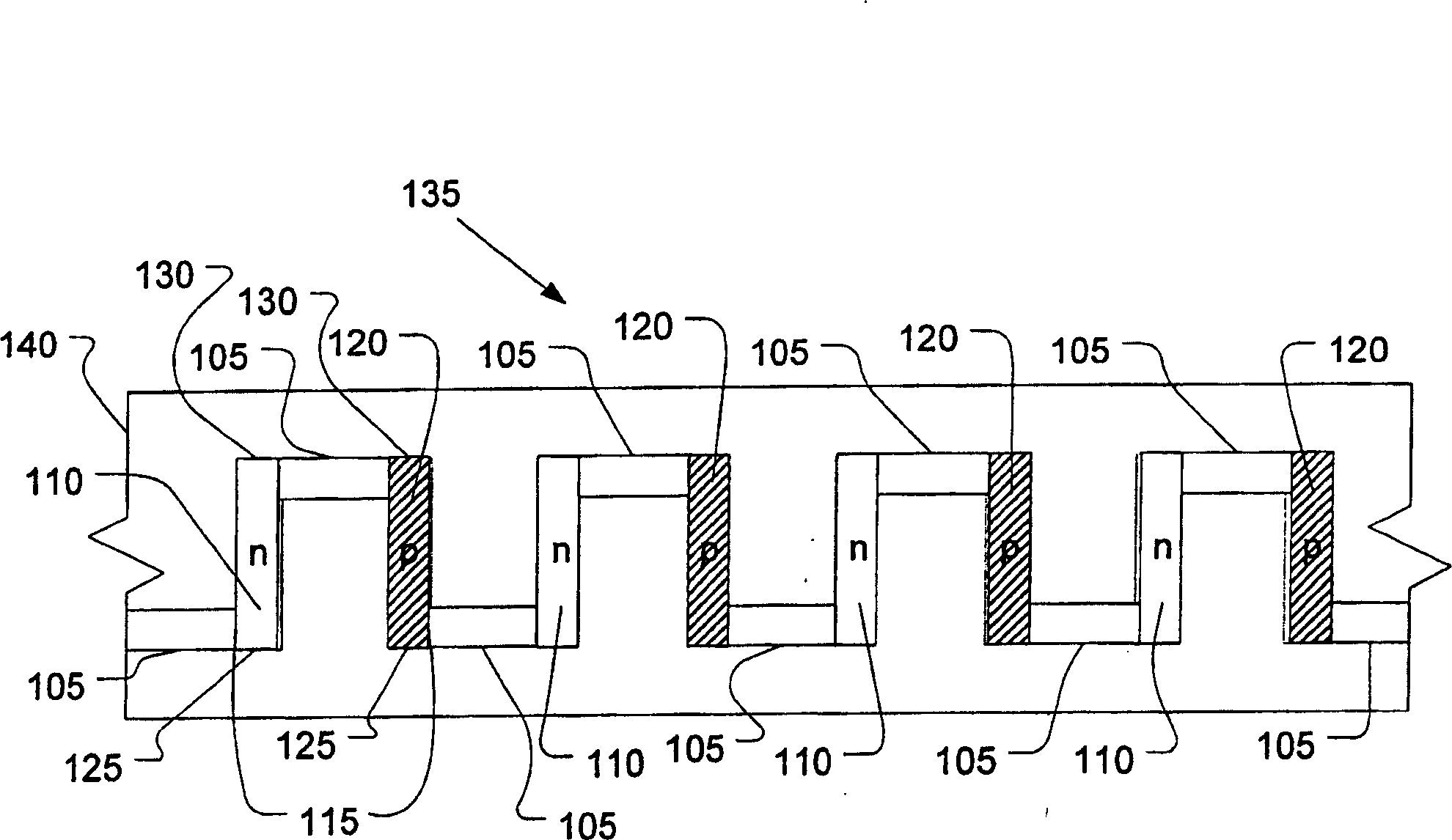

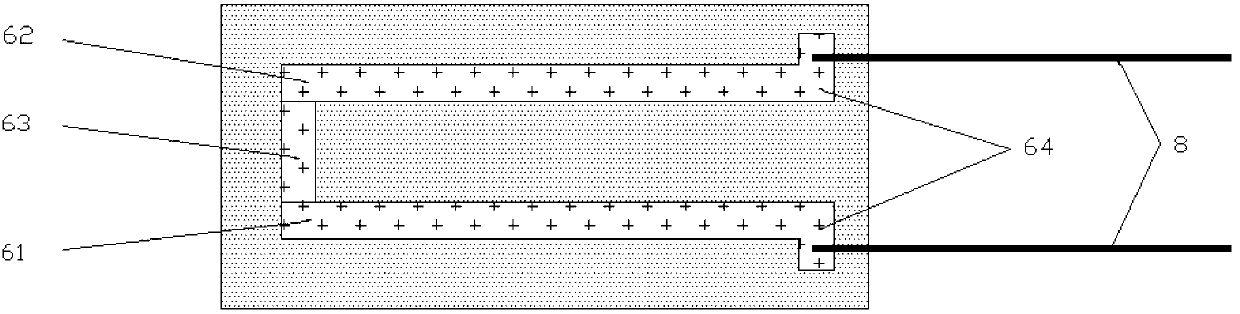

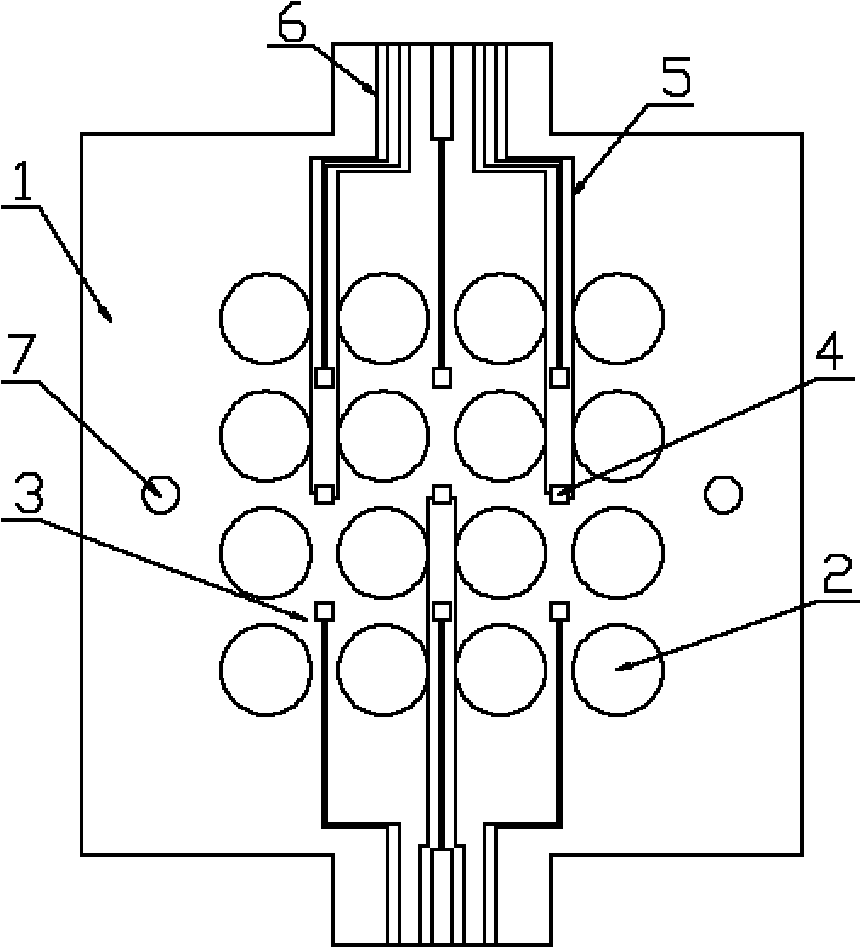

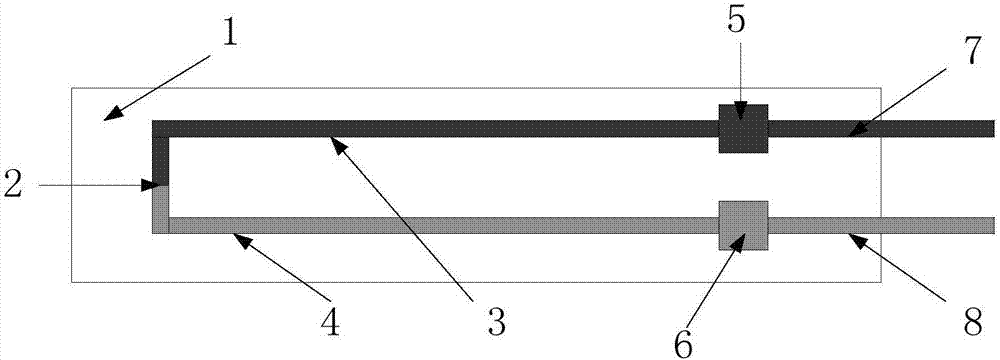

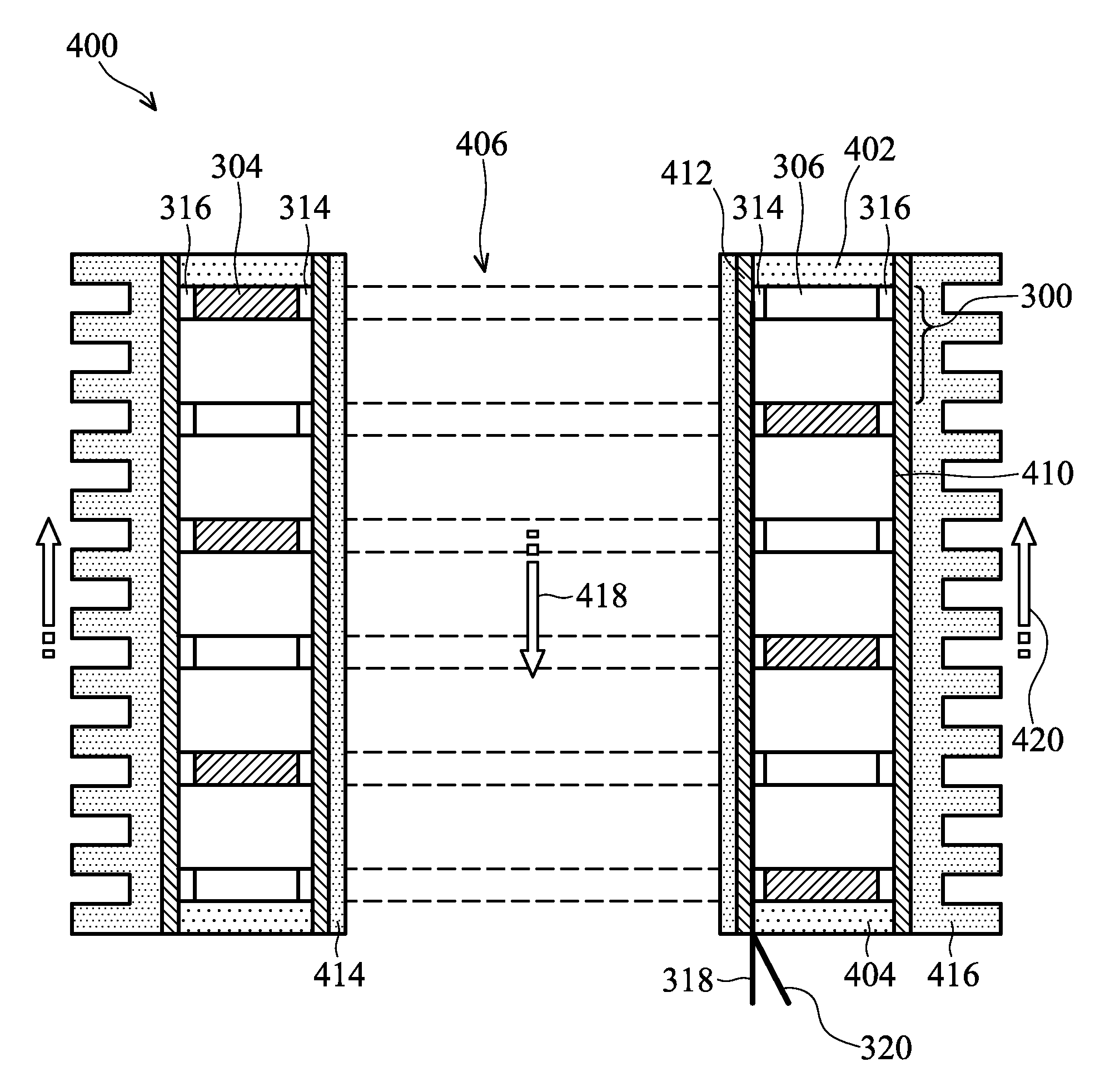

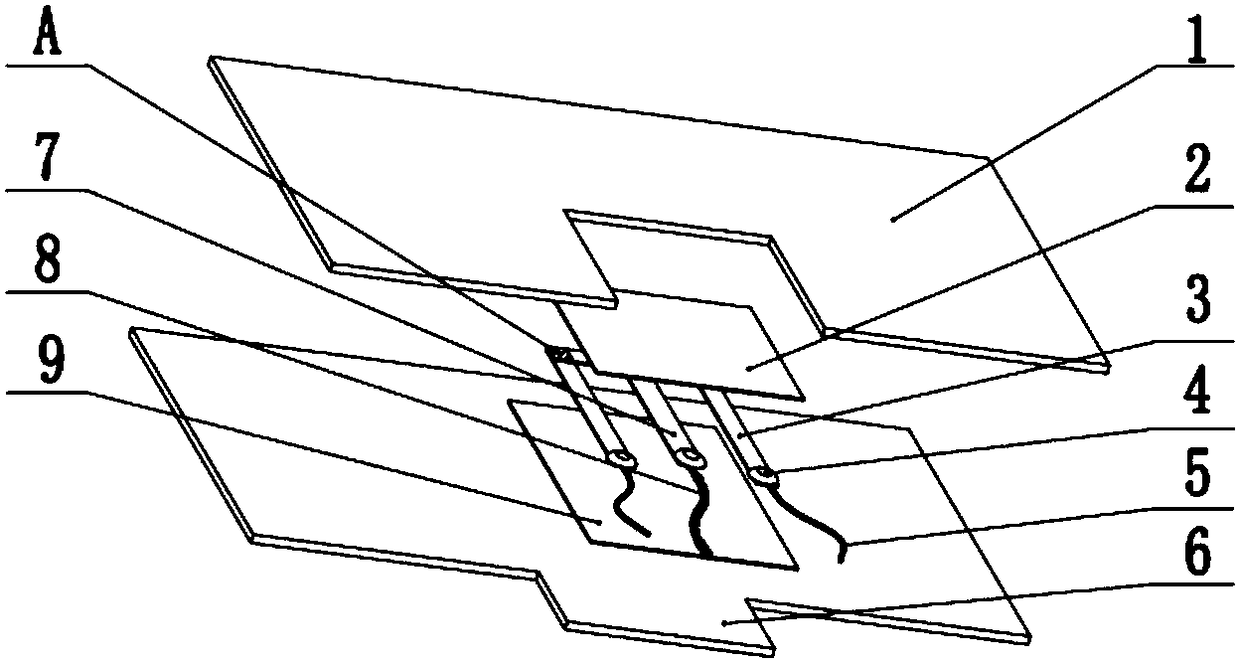

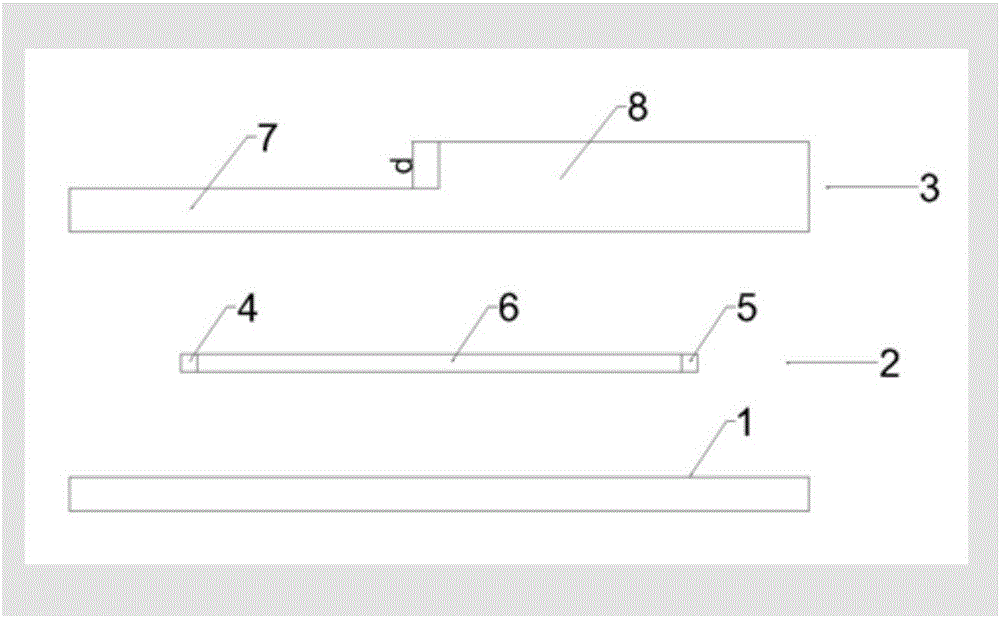

Insertion sheet for measuring internal temperature distribution of fuel cell

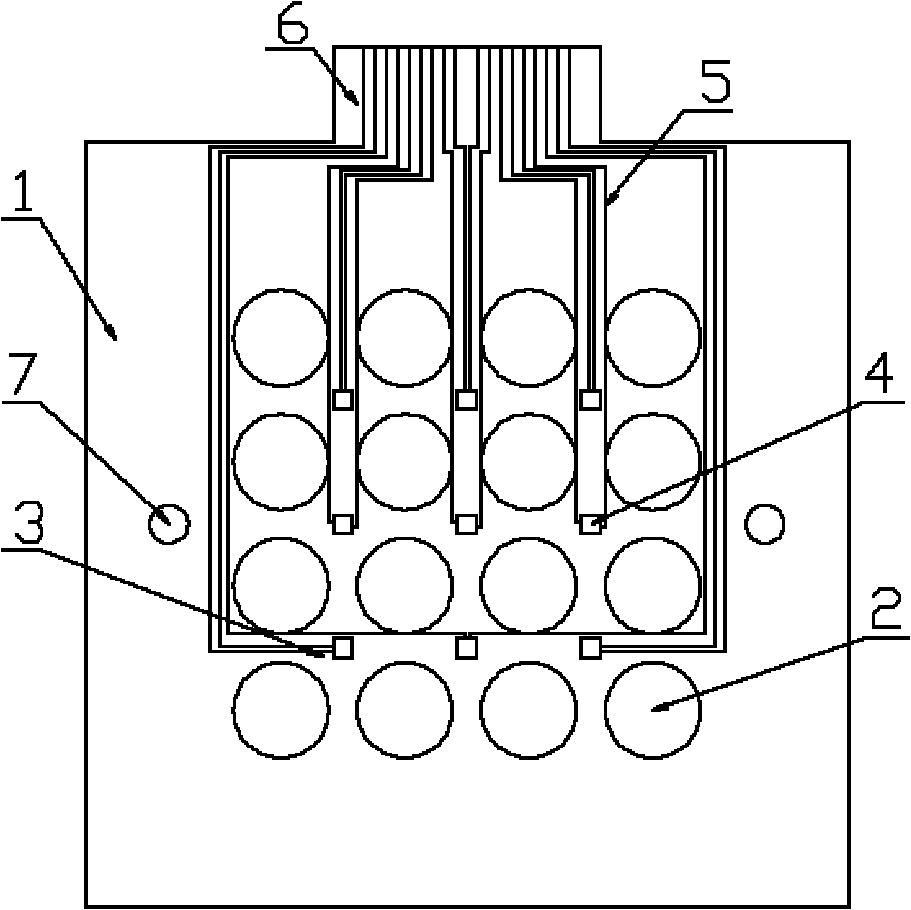

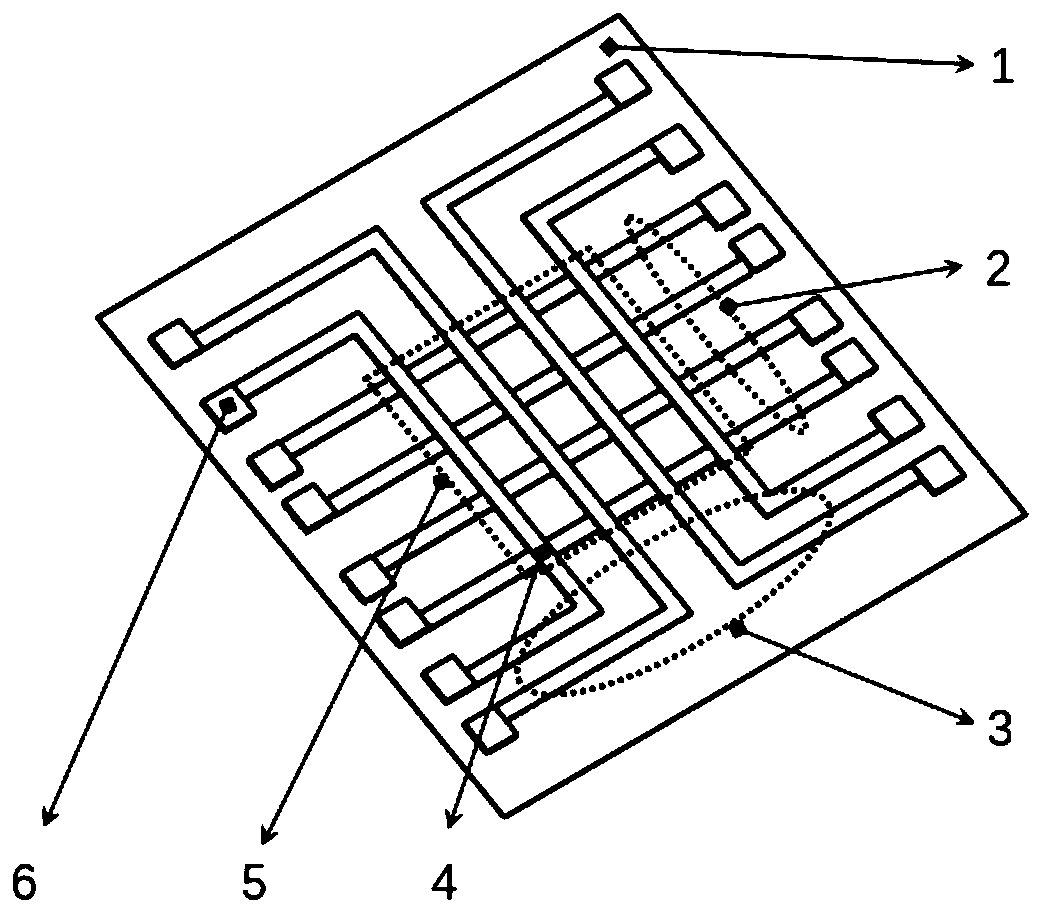

ActiveCN102116680ASimple structureSimplified steps for measuring temperature distributionThermometers using electric/magnetic elementsFuel cell auxillariesThin film thermocouplesFuel cells

The invention discloses an insertion sheet for measuring the internal temperature distribution of a fuel cell, which is a device for measuring the internal temperature distribution of a fuel cell. The insertion sheet comprises a stainless steel substrate with gold plated on two sides, a plurality of leak seams and ribs are arranged on the substrate, the size and the shape of the leak seams and the ribs are same with those of grooves and ridges on a flow field plate of the fuel cell to be measured, and the positions mutually correspond. The entire surfaces of the ribs between the leak seams are provided with a film thermocouple which is formed by plating four films through evaporation by using a vacuum plating technology. An outgoing line of a measuring head of the film thermocouple extends to the edge of the substrate by using a printed circuit method and is provided with a standard wiring port connected with an external circuit on the edge of the substrate. The insertion sheet for measuring the internal transient temperature distribution of the fuel cell is completely independent of an object to be measured, has a simple structure and a wide use range, is accurate for measurement and can be used for the online measurement of the internal temperature distribution situation of the fuel cell.

Owner:BEIJING UNIV OF TECH

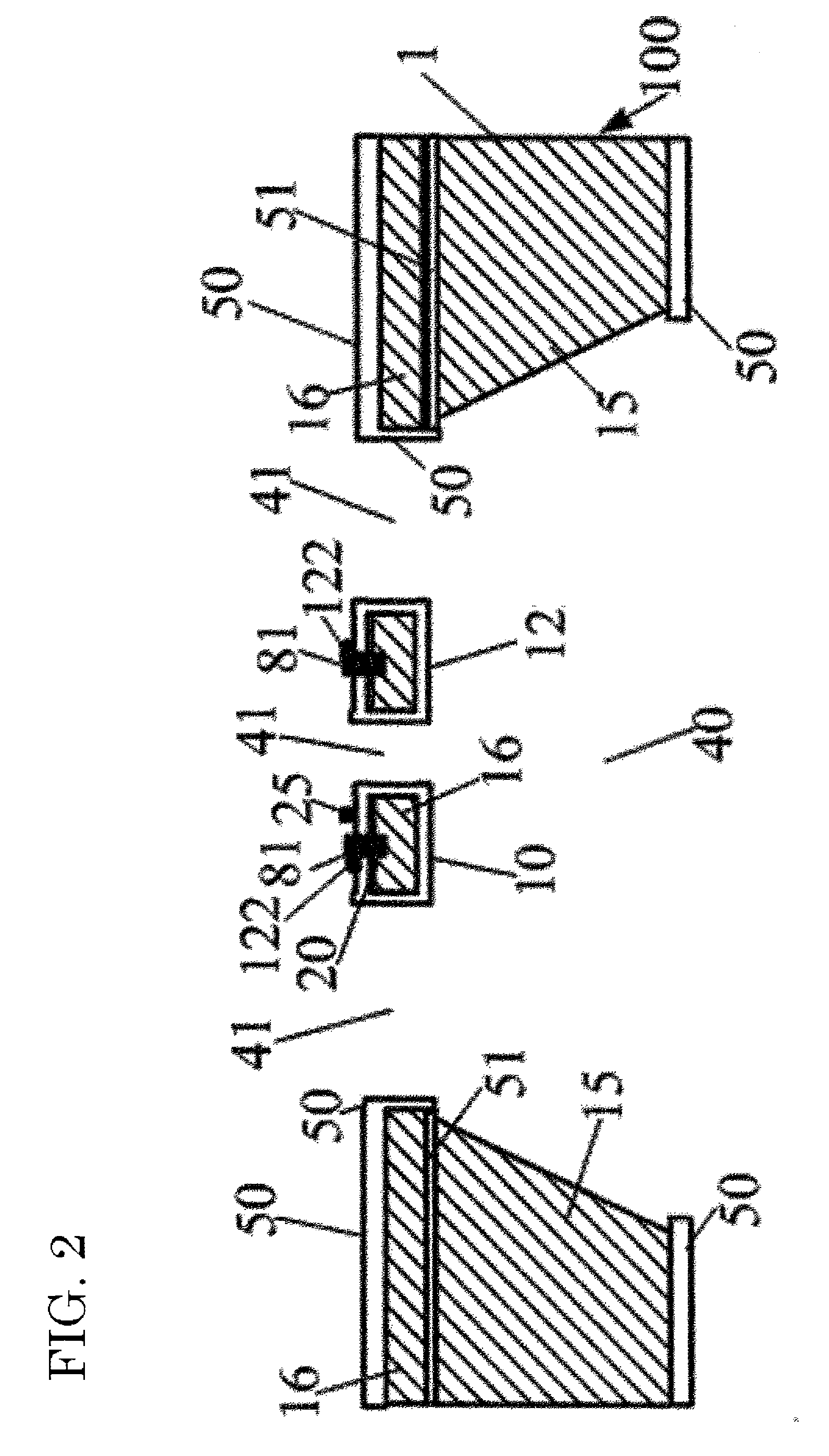

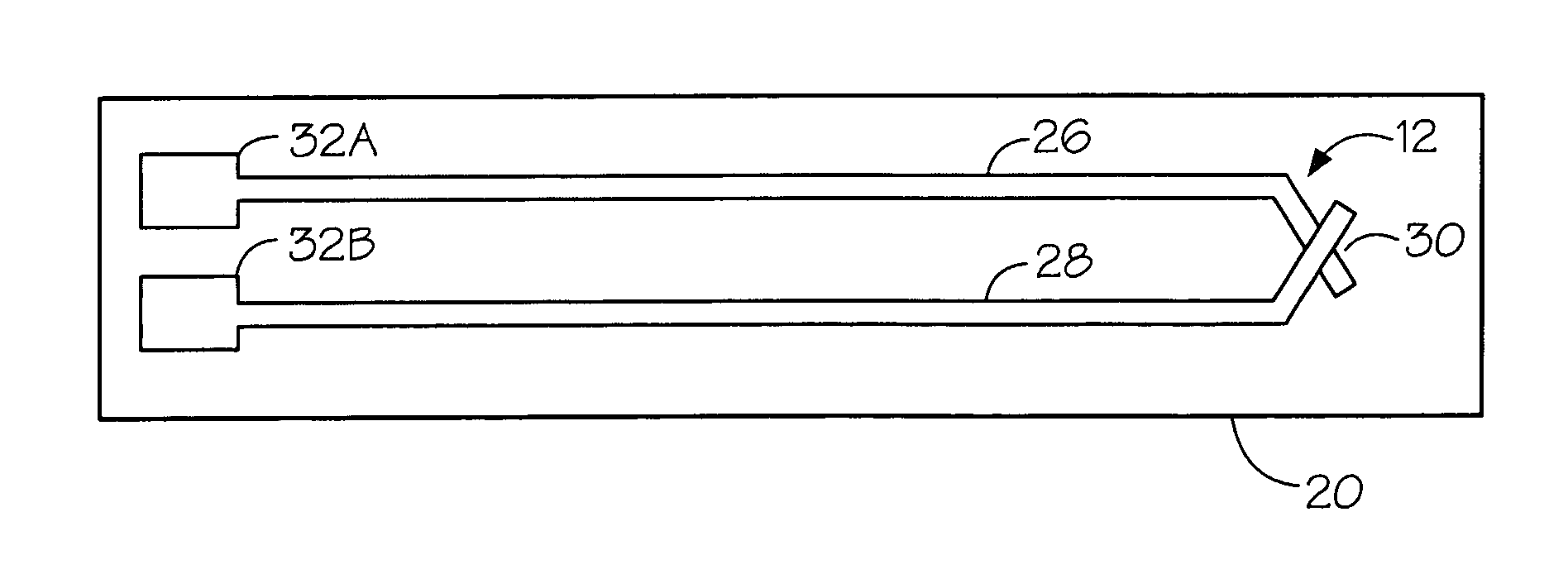

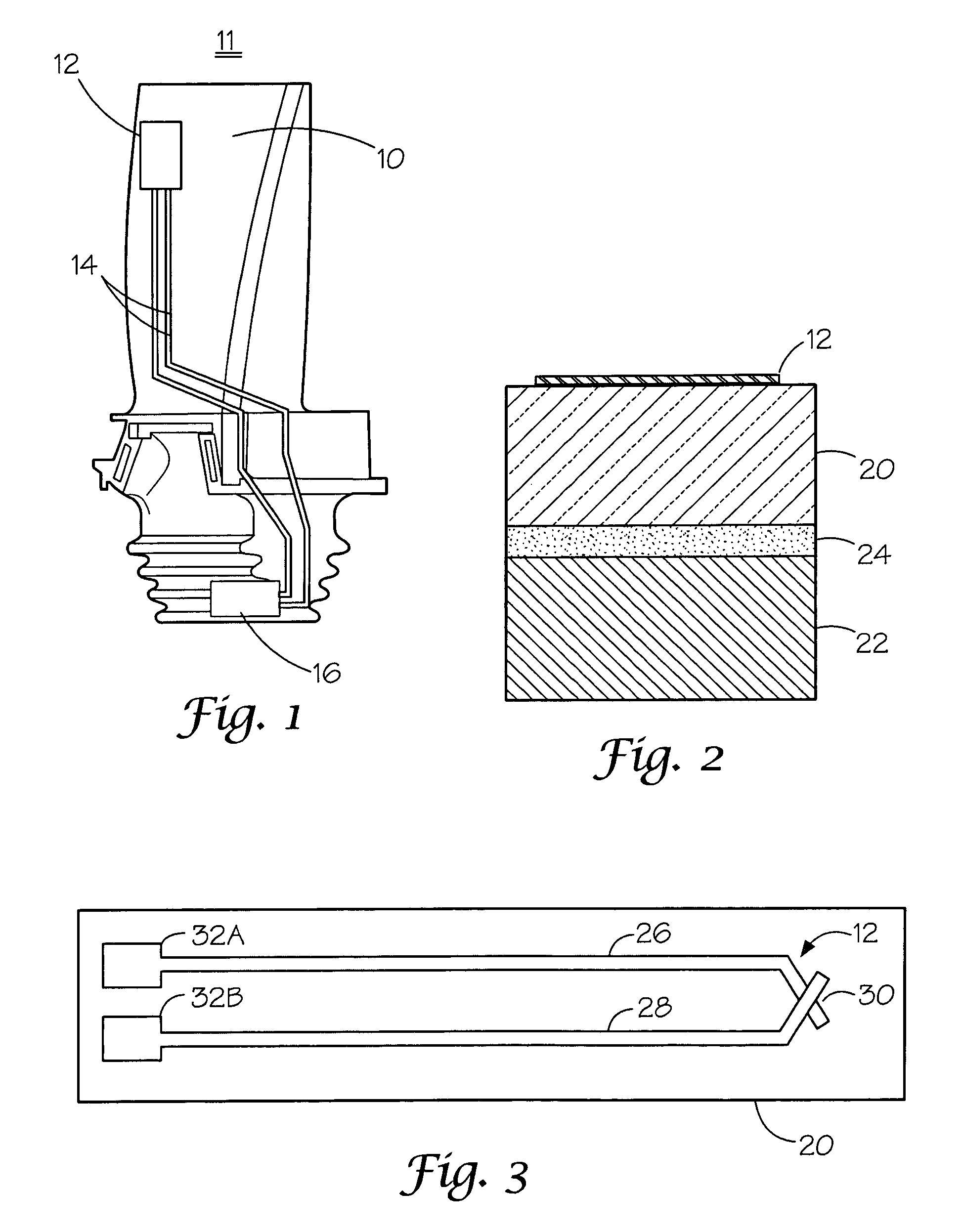

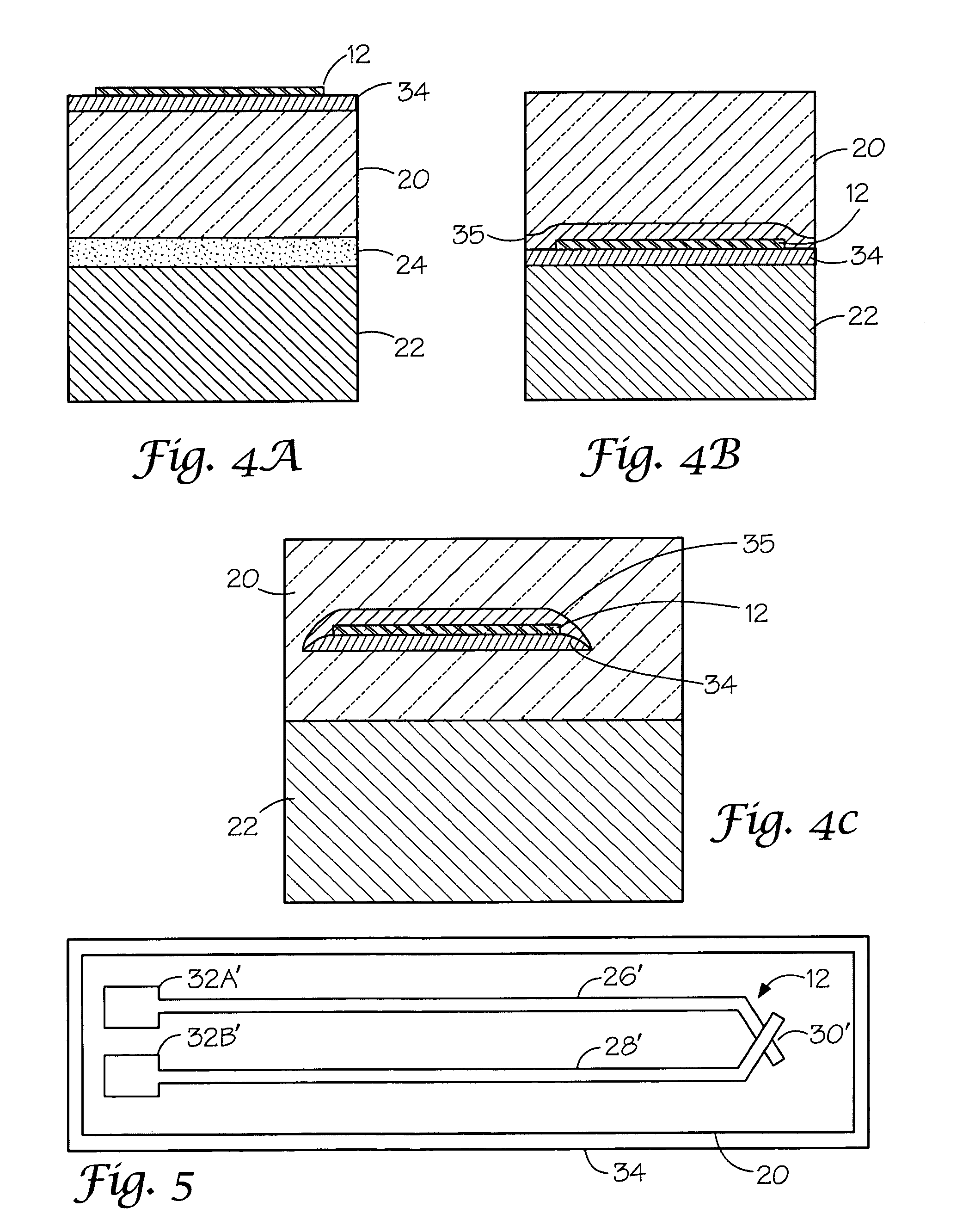

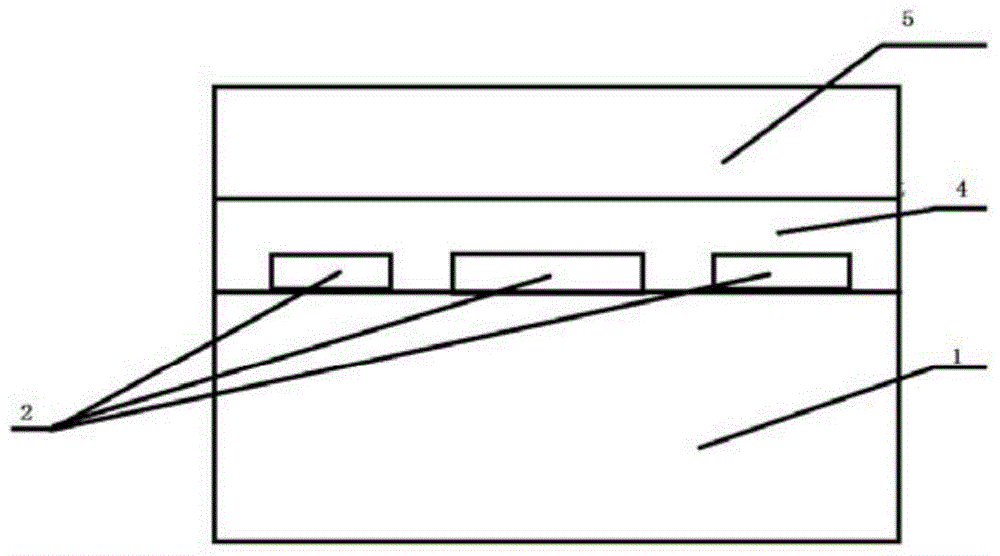

Thermocouple for Gas Turbine Environments

ActiveUS20100027584A1Thermometer detailsThermometers using electric/magnetic elementsThin film thermocouplesEngineering

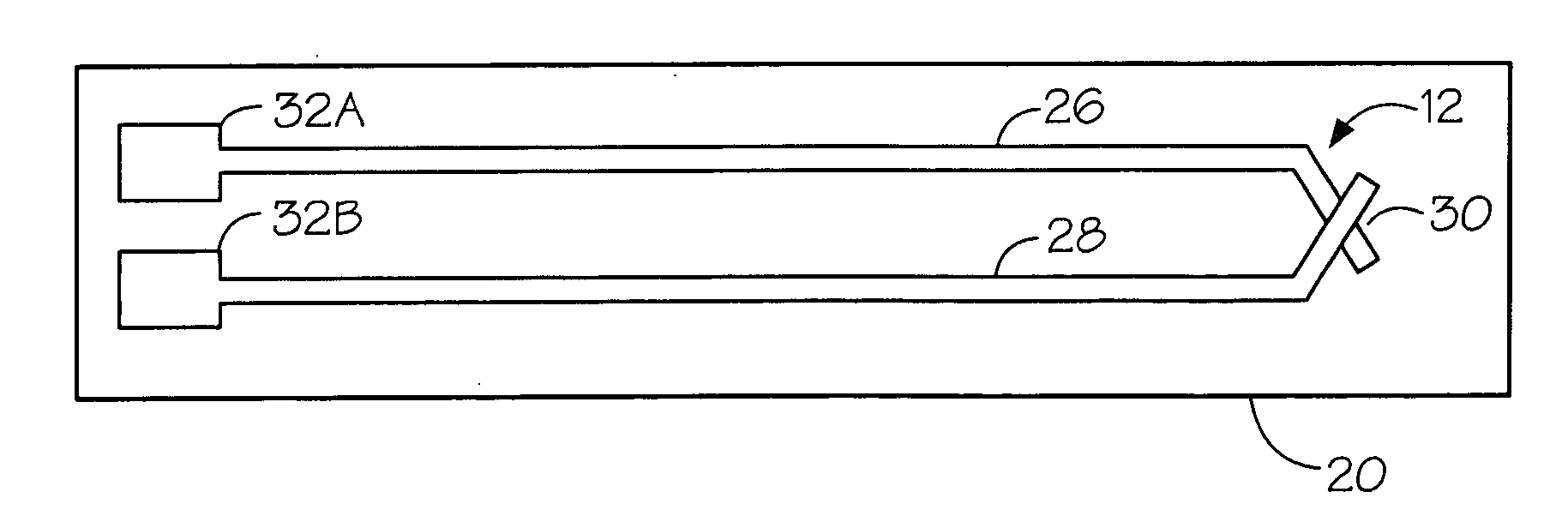

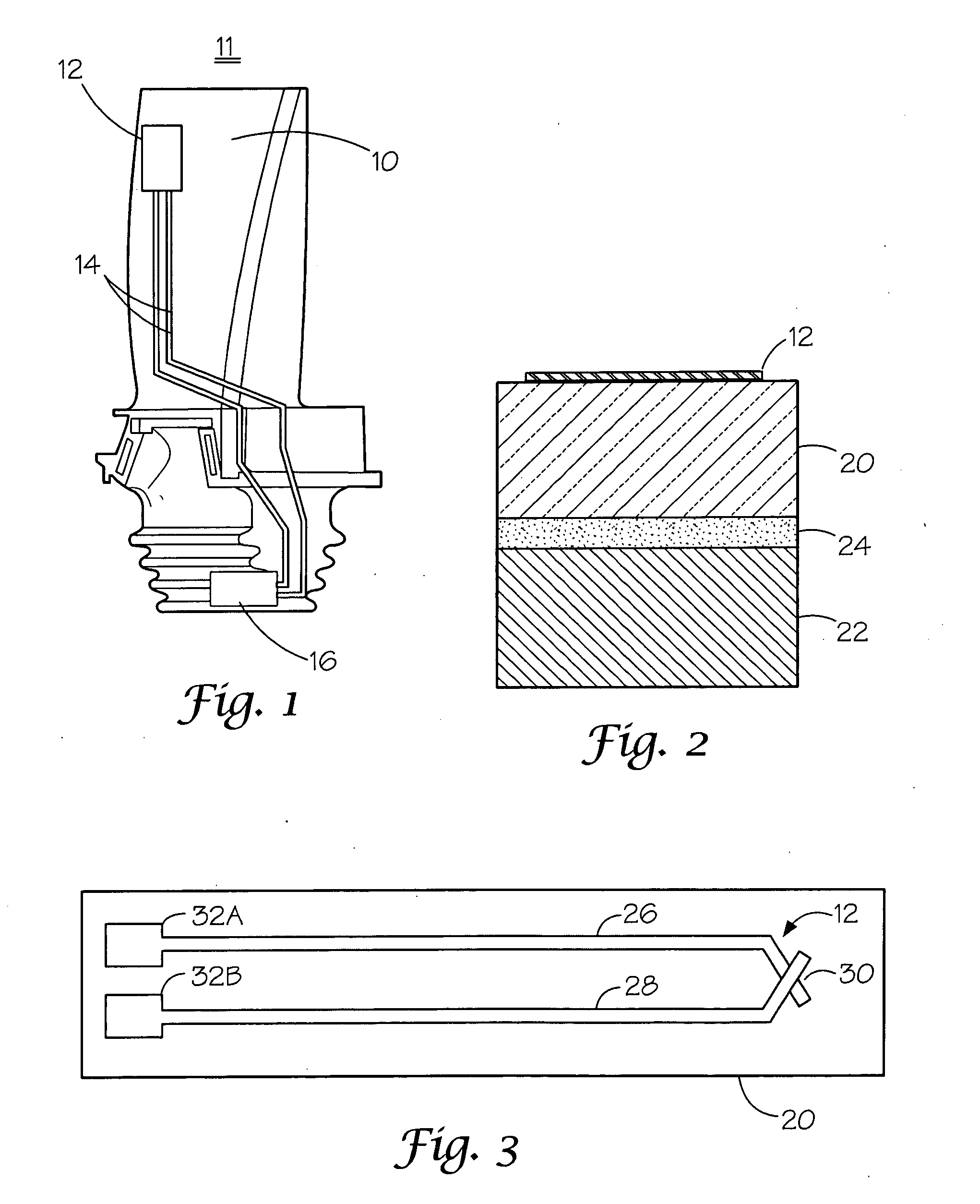

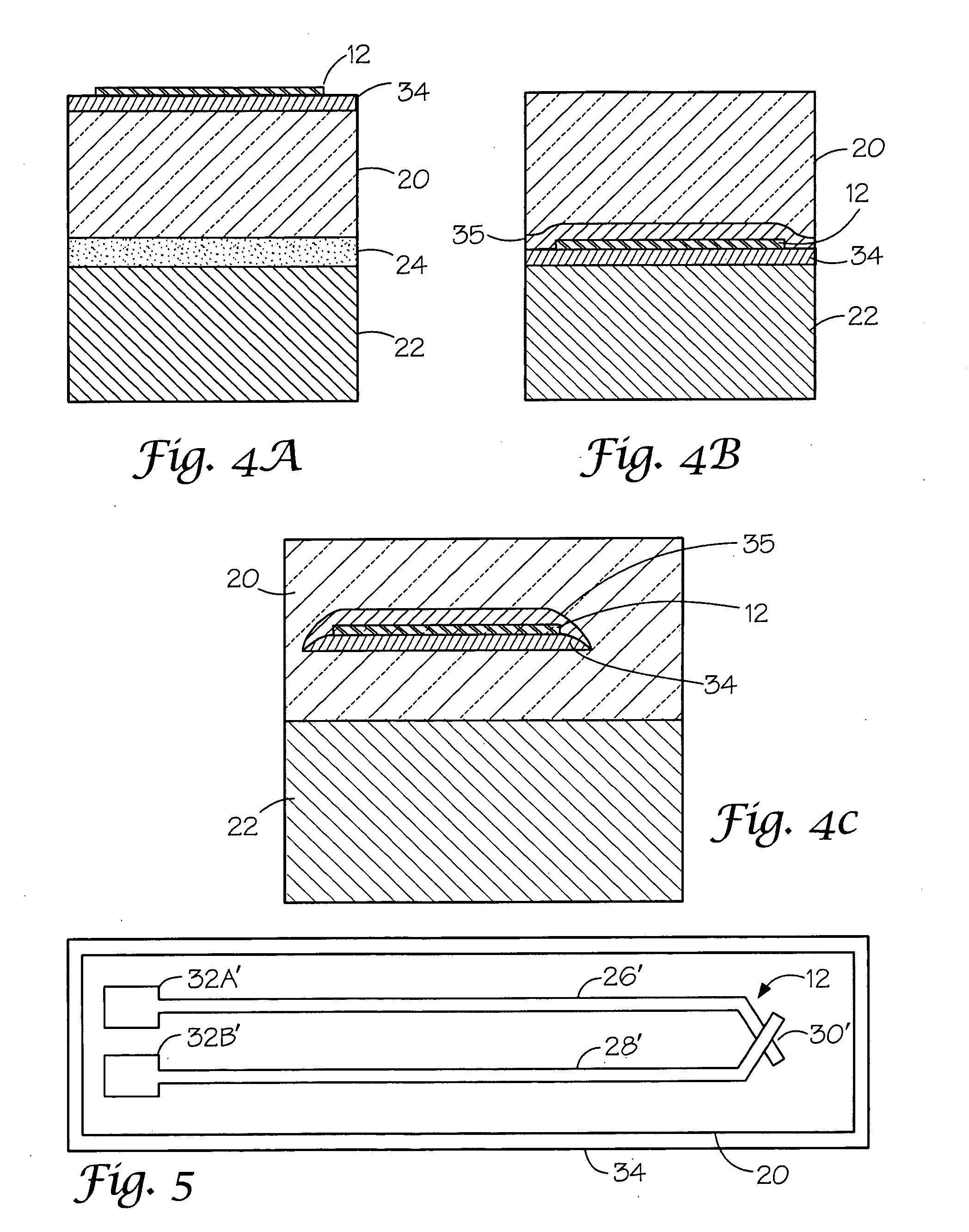

A thin-film thermocouple (12) is disclosed for use with a gas turbine component. The thermocouple may be formed on a non-planar substrate (22) having formed thereon an electrically insulating layer (34) capable of maintaining its insulating properties at gas turbine operating temperatures. A first thermocouple leg (26) made of pure platinum is then deposited on the dielectric layer (34). A second thermocouple leg (28) made of another pure metal or a transparent ceramic oxide is also formed on the dielectric layer (34) wherein the first and second thermocouple legs make ohmic contact at a first end of each leg to form a hot junction (30) for conversion of heat into an electrical signal. The thermocouple may be deposited on a surface of a thermal barrier coating or between a thermal barrier coating and an underlying metal substrate.

Owner:SIEMENS ENERGY INC

Film heat flux sensor and preparation method thereof

InactiveCN102928460AImprove consistencyRaise the level of reliabilityMaterial heat developmentDecorative surface effectsThin film thermocouplesHeat flow

The invention discloses a film heat flux sensor and a preparation method thereof. The film heat flux sensor is characterized in that a high temperature-resistant film thermocouple array (thermopile) is prepared on the surface of a substrate by a micromachining technology; a thick heat barrier layer and a thin heat barrier layer are arranged on the high temperature-resistant film thermocouple array; and through sensing the difference between temperatures under the thick heat barrier layer and the thin heat barrier layer, the film heat flux sensor can measure a heat flux according to the height difference of the thick heat barrier layer and the thin heat barrier layer. The film heat flux sensor can measure heat fluxes of middle and outer layer materials of a high-speed aircraft in flight and provides data reference for a heat protection design. The preparation method has simple processes and a reliable structure.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Thermocouple for gas turbine environments

InactiveUS8033722B2Thermometer detailsThermometers using electric/magnetic elementsThin film thermocouplesEngineering

A thin-film thermocouple (12) is disclosed for use with a gas turbine component. The thermocouple may be formed on a non-planar substrate (22) having formed thereon an electrically insulating layer (34) capable of maintaining its insulating properties at gas turbine operating temperatures. A first thermocouple leg (26) made of pure platinum is then deposited on the dielectric layer (34). A second thermocouple leg (28) made of another pure metal or a transparent ceramic oxide is also formed on the dielectric layer (34) wherein the first and second thermocouple legs make ohmic contact at a first end of each leg to form a hot junction (30) for conversion of heat into an electrical signal. The thermocouple may be deposited on a surface of a thermal barrier coating or between a thermal barrier coating and an underlying metal substrate.

Owner:SIEMENS ENERGY INC

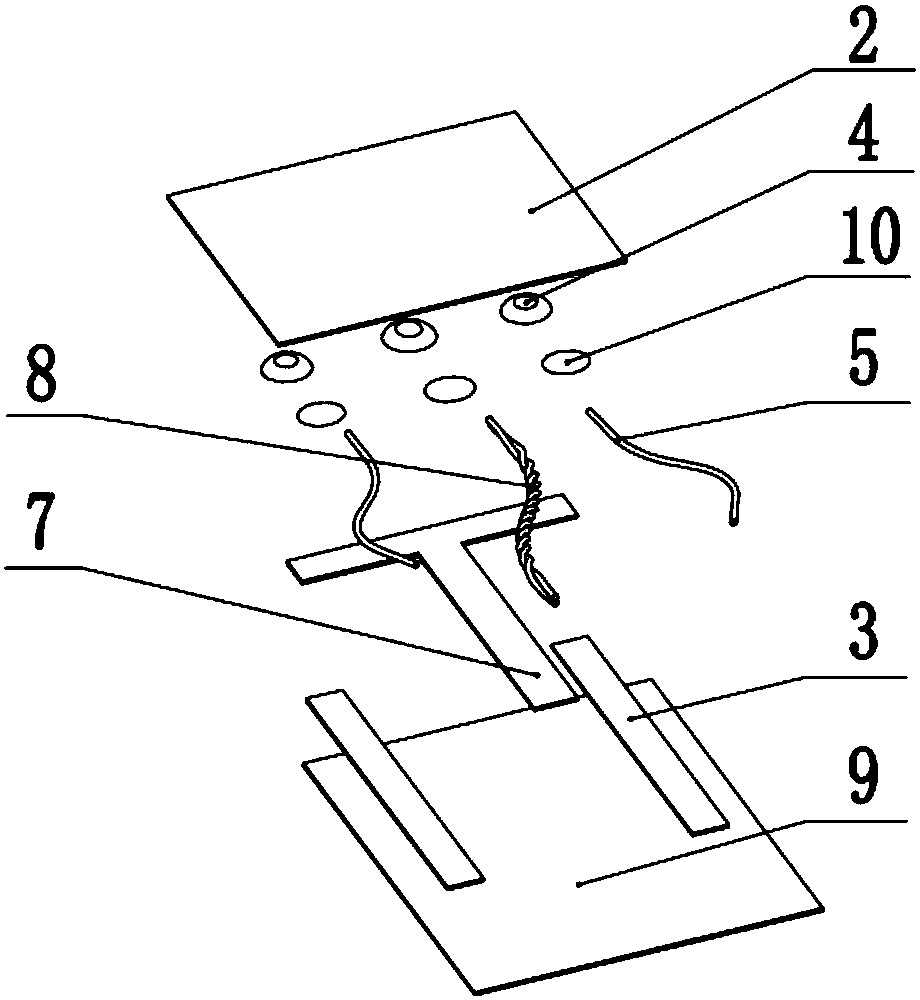

Transient temperature distribution sensor in fuel cell

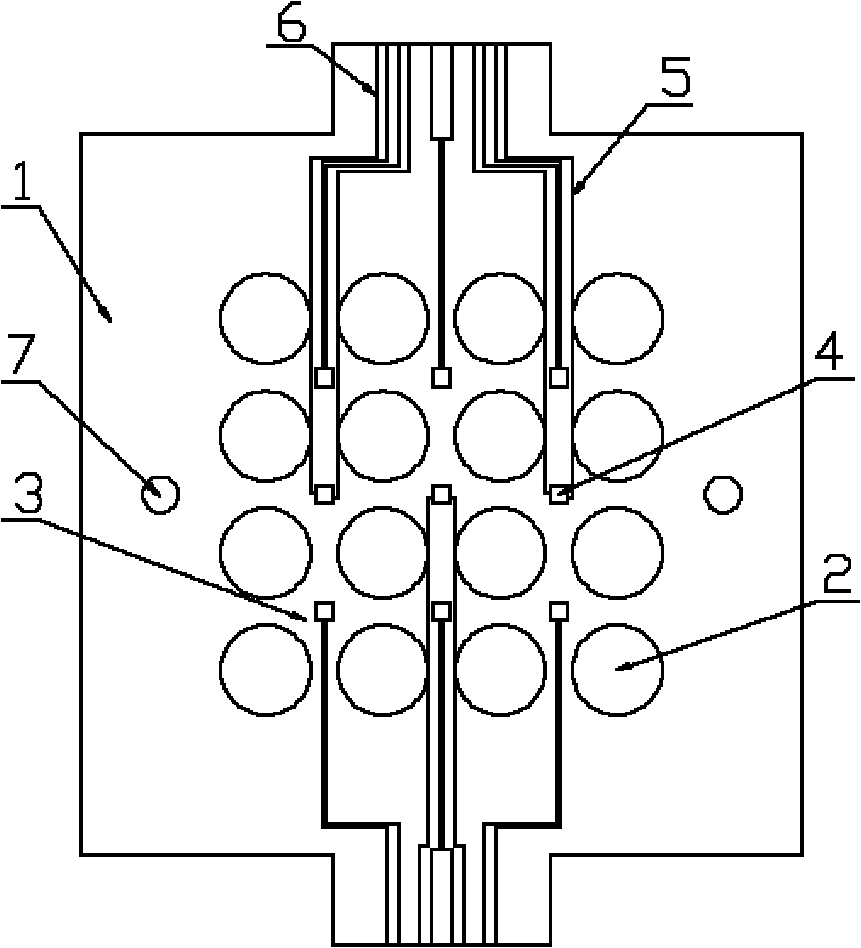

ActiveCN102157743AAvoid problems such as leakageReduce volumeFuel cell heat exchangeThermometers using electric/magnetic elementsThin film thermocouplesCopper plating

The invention discloses a transient temperature distribution sensor in a fuel cell, and thin film thermocouples are arranged on ribs between adjacent flow passages on a graphite flow field plate of the fuel cell for measuring transient temperature distribution in the fuel cell. The single thin film thermocouple is formed by adopting a vacuum evaporation coating technology for evaporation of four layers of thin films, a silicon dioxide insulating layer with the thickness of 0.1-0.15 mu m is plated at the first layer, copper is plated at the second layer, nickel is plated at the third layer, the thicknesses of the copper plated layer and the nickel plated layer are 0.08-0.1 mu m respectively, and a silicon dioxide thin layer with the thickness of 0.01-0.02 mu m is finally plated. Leading-out wires of the thin film thermocouples extend to the edge of the graphite flow field plate by utilizing the process of a printed circuit, a standard wiring port for connecting with an external circuitis further arranged, and a data acquisition system is used for exporting signals. A measuring device is simple and easy to operate, the real-time temperature distribution in the fuel cell is measured, the cell is easy to disassemble and assemble, and the impacts on the overall performances of the fuel cell are small.

Owner:BEIJING UNIV OF TECH

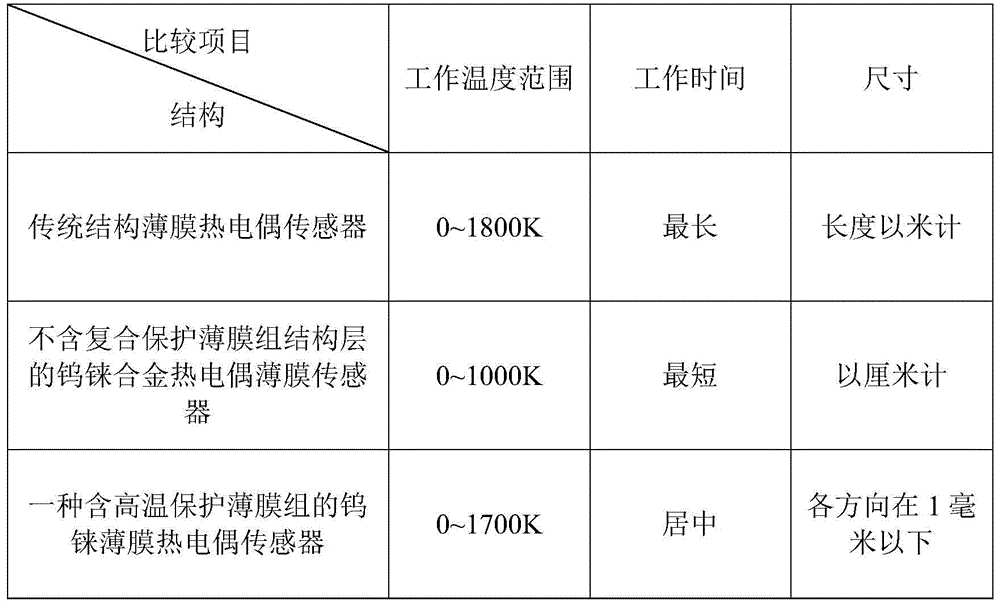

Tungsten-rhenium film thermocouple sensor containing high temperature protection film group and preparation method

ActiveCN105675160ASolve transpirationSolve sheddingThermometer detailsThermometers using electric/magnetic elementsThin film thermocouplesRhenium

The invention discloses a tungsten-rhenium film thermocouple sensor containing a high temperature protection film group and a preparation method. The high temperature protection film group and parallel tungsten-rhenium film thermocouple jointly form a sensor chip. A tungsten-rhenium film group, a high-temperature electrode and an aluminium oxide film protective layer are connected on a silicon carbide-based substrate, and cover an amorphous silicon carbide film protective layer. The tungsten-rhenium film thermocouple sensor can measure temperature signals for a long time under high temperature (1000 to 1700K), has the characteristics of high temperature resistance, oxidation prevention and high Seebeck coefficient, and solves the problems in existing technologies, such as the problems of thermal mismatch and oxidation under high temperature and failure around 1400K.

Owner:XI AN JIAOTONG UNIV

Integrated thin film temperature heat flow compound sensor and preparation method thereof

InactiveCN102928106ARealize temperature measurementImprove consistencyThermometers using electric/magnetic elementsUsing electrical meansThin film sensorThin film thermocouples

The invention discloses an integrated thin film temperature and heat flow compound sensor and a preparation method thereof. The sensor is a heat and heat flow measurement integrated thin film sensor. The integrated thin film temperature and heat flow compound sensor disclosed by the invention uses a micro-mechanical machining technology to manufacture a group of thin film thermoelectric couples on the surface of a substrate, and is used for temperature measurement. Meanwhile, a high-temperature-resistant film thin thermoelectric couple array (a thermoelectric pile) is prepared on the surface of the substrate, and a thick thermal barrier layer and a thin thermal barrier layer are arranged on the film thin thermoelectric couple array; and a heat flow can be measured by sensing temperature difference of the thick thermal barrier layer and the thin thermal barrier layer and combining height difference of the thick thermal barrier layer and the thin thermal barrier layer. The integrated thin film temperature and heat flow compound sensor disclosed by the invention has the beneficial effects that the integrated thin film temperature and heat flow compound sensor can simultaneously measure temperature variation and the heat flow of materials of a middle layer and an outer layer in a flying process of a high-speed aircraft, and provide data reference for thermal protection design. Furthermore, the thin film temperature and heat flow sensor with the adoption of the invention has the advantages of simple preparation technique and reliable structure.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Sheet-like thin film thermocouple for measuring surface transient temperature

InactiveCN107101735AVerify reliabilityThermometer detailsThermometers using electric/magnetic elementsThin film thermocouplesSputtering

The invention discloses a sheet-like thin film thermocouple for measuring the surface transient temperature, comprising a sheet-like high-temperature ceramic substrate, a thin film thermal electrode, a thin film insulating layer and a lead. Thin film thermodes are prepared on a ceramic substrate by plasma sputtering, and a hot junction is set between the thin film thermodes, namely, a measuring end. The thermodes are covered by the thin film insulating layer. The sheet-like thin film thermocouple can be used for the measurement of the surface temperature of a special configuration object in an environment of 1000 DEG C or higher.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Oxide film thermocouple and preparation method thereof

InactiveCN105300544AImprove high temperature service performanceReduce heat volatilizationThermoelectric device manufacture/treatmentThermometers using electric/magnetic elementsThin film thermocouplesProtection layer

The invention relates to an oxide film thermocouple and a preparation method thereof. A magnetron sputtering technology is adopted, the oxide film thermocouple used for high temperature measurement is prepared on a high temperature ceramic substrate in a deposition manner; and an oxide protection layer is coated to improved the heat volatility of the oxide film thermocouple and improve the usage performance of the thermocouple. The film thermocouple is directly pasted to the surface of the ceramic substrate, can be used in a vacuum condition and an oxidation atmosphere and can work stably for a long time under a high temperature from 1000 DEG C to 1250 DEG C.

Owner:XI AN JIAOTONG UNIV

Intelligent transient milling temperature-measuring tool based on film thermocouple

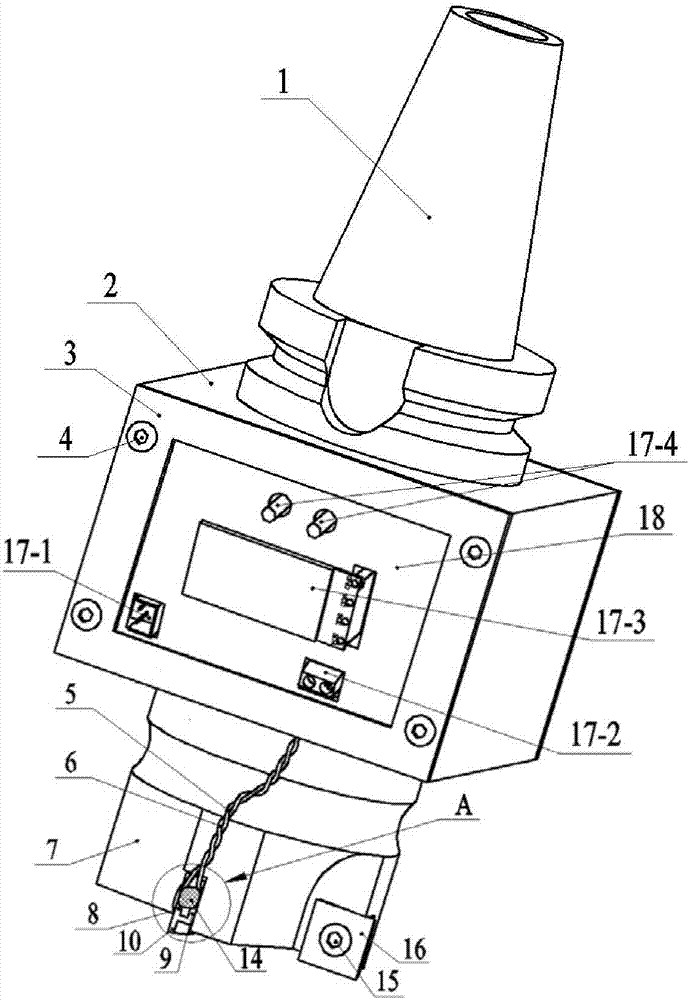

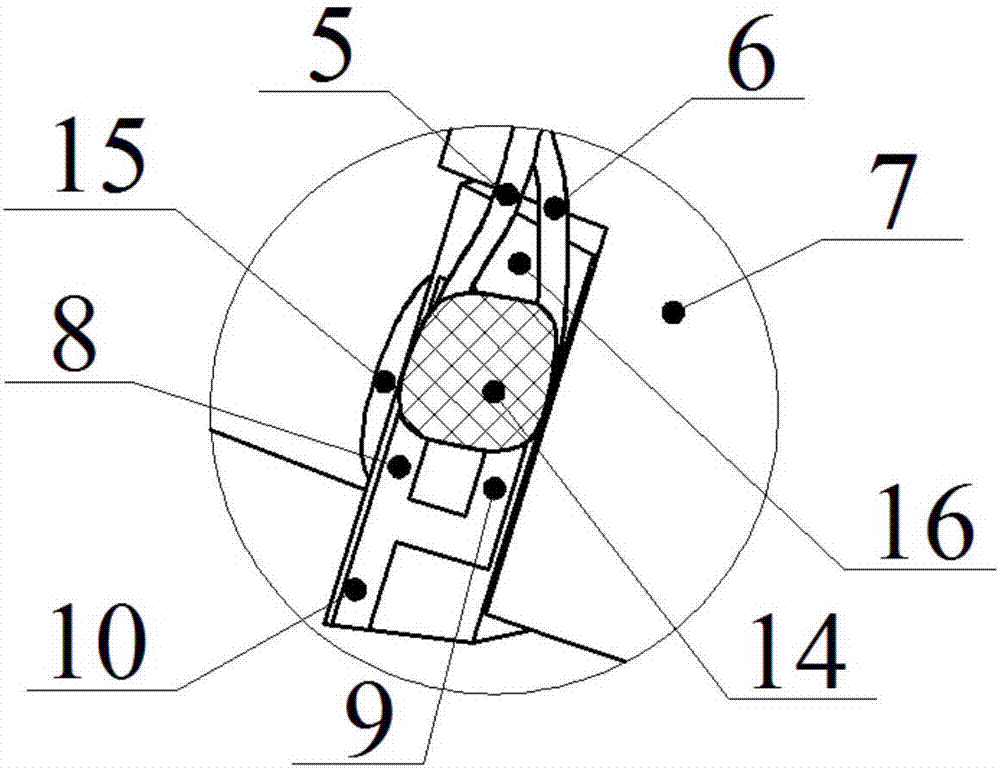

ActiveCN106975984ASmall heat capacityReduce volumeMeasurement/indication equipmentsThin film thermocouplesNumerical control

The invention discloses an intelligent transient milling temperature-measuring tool based on a film thermocouple. Automatic acquisition, processing and storage and wireless transmission of temperature data can be achieved by adoption of an advanced film thermocouple transient temperature measuring method and a self-designed temperature acquisition module. The tool specifically comprises a temperature acquisition terminal mounted in a temperature acquisition terminal fixing assembly, a numerical control tool handle and a facing milling tool disk connected with the numerical control tool handle in a matched mode, and film thermocouple temperature measuring blades are fixed to the facing milling tool disk. The intelligent transient milling temperature-measuring tool based on the film thermocouple can be applicable to high-speed cutting, thin-walled pieces and precision and ultra-precision machining, and has the advantages that the response speed and measuring precision are high, and the transient temperature of a cutting zone on a production site can be accurately measured in real time.

Owner:DALIAN JIAOTONG UNIVERSITY

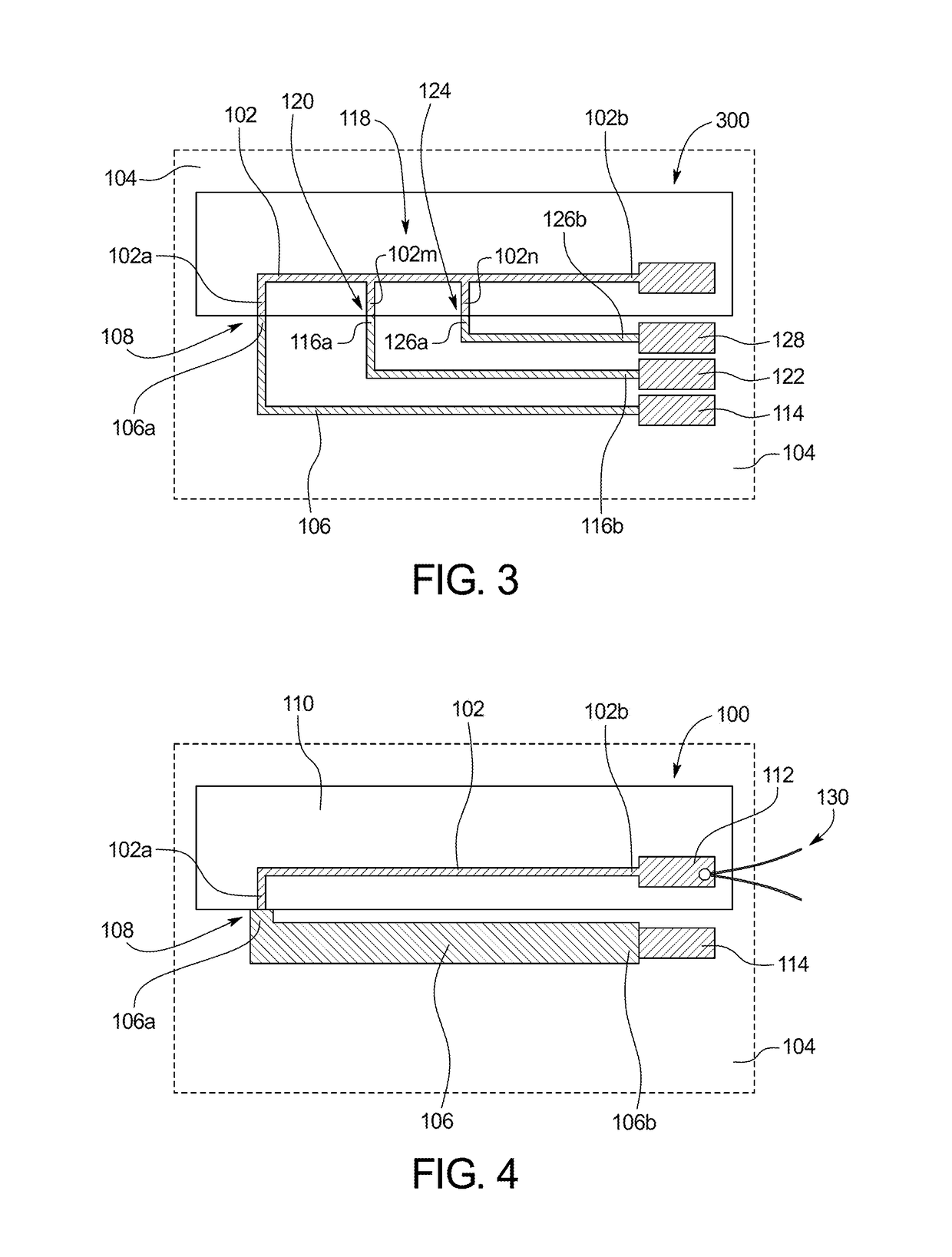

Thin-film Thermocouple for Measuring the Temperature of a Ceramic Matrix composite (CMC) Component

ActiveUS20180087973A1Thermometers using electric/magnetic elementsUsing electrical meansThin film thermocouplesMaterials science

A thin-film thermocouple for measuring the temperature of a ceramic matrix composite (CMC) component comprises a first thermocouple leg and a second thermocouple leg deposited on a surface of a CMC component, where each of the first and second thermocouple legs has a length extending from a reference end to a working end thereof. The working ends of the first and second thermocouple legs are joined at a junction region on the surface. At least one of the first thermocouple leg and the second thermocouple leg comprises silicon carbide.

Owner:ROLLS ROYCE CORP

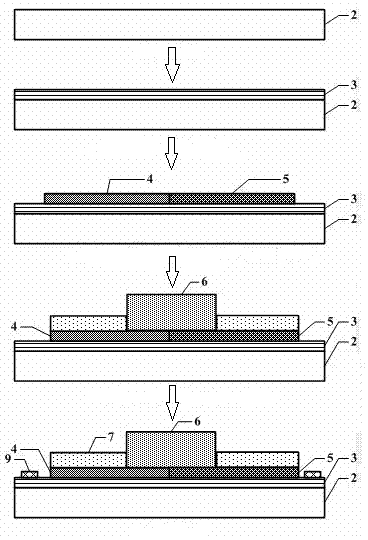

High-temperature thin-film thermocouple temperature sensor

InactiveCN104748876AReduce volumeReduce weightThermometers using electric/magnetic elementsUsing electrical meansThin film thermocouplesHot Temperature

The invention relates to a high-temperature thin-film thermocouple temperature sensor manufactured by the vacuum film technology. The high-temperature thin-film thermocouple temperature sensor is that the part of which the temperature is to be detected is selected from a high-temperature detecting material; the specific shape of a Pt thermocouple electrode and a PtRh thermocouple electrode; then the processes of processing a metal mask, preparing an Al2O3 insulating layer, preparing a Pt thermocouple film, preparing a PtRh thermocouple and preparing an Al2O3 insulating protecting layer are sequentially carried out to prepare the micron or submicron thin-film thermocouple temperature sensors employing the Pt material and the PtRh material. Compared with the prior art, the high-temperature thin-film thermocouple temperature sensor has the advantages of being reasonable in structure, convenient to operate, long in service life, fast to respond in temperature detection, and high in temperature detection accuracy, and the upper limit of temperature detection is up to 1200 DEG C.

Owner:SHAANXI ELECTRICAL APPLIANCE RES INST

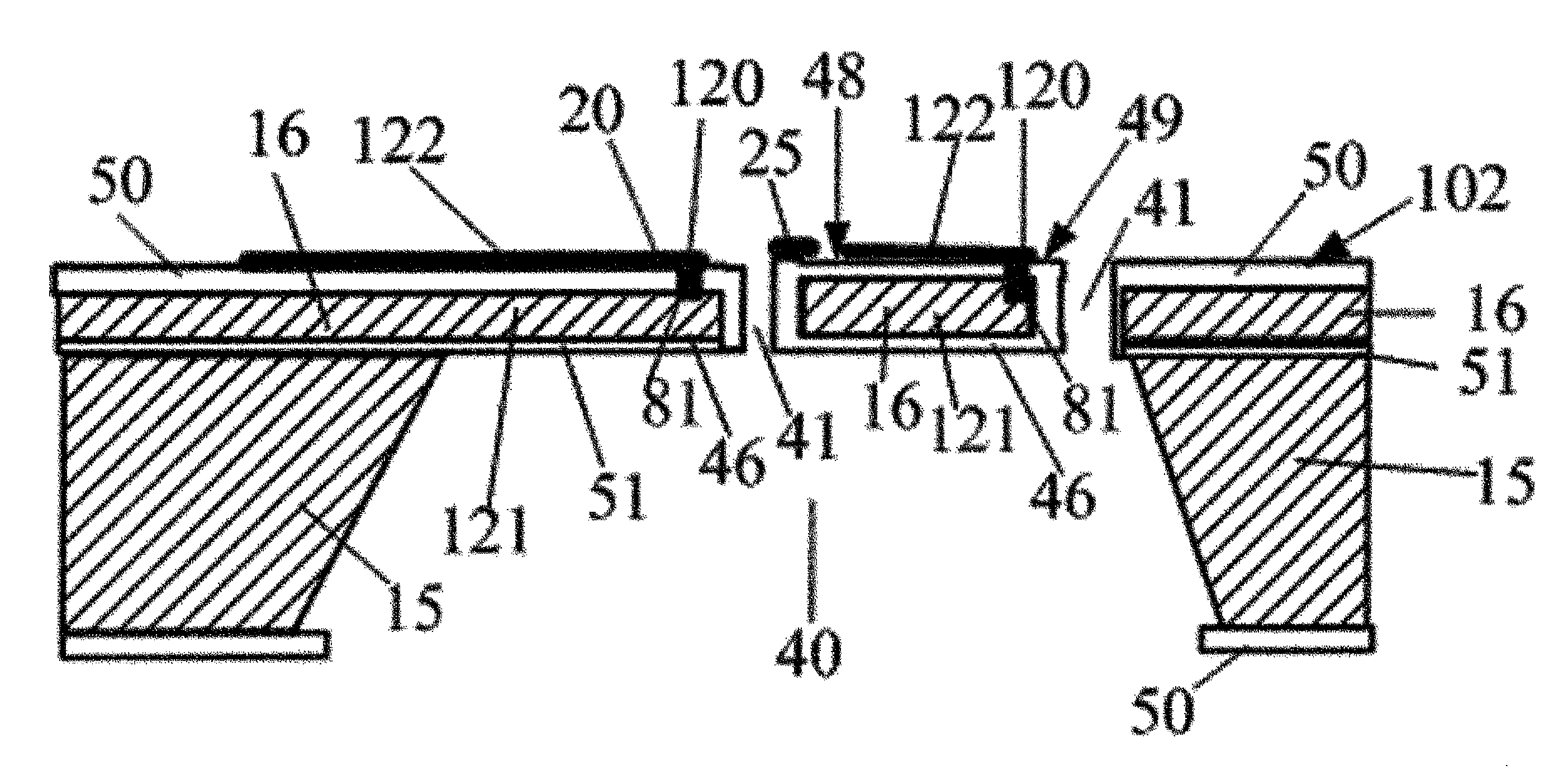

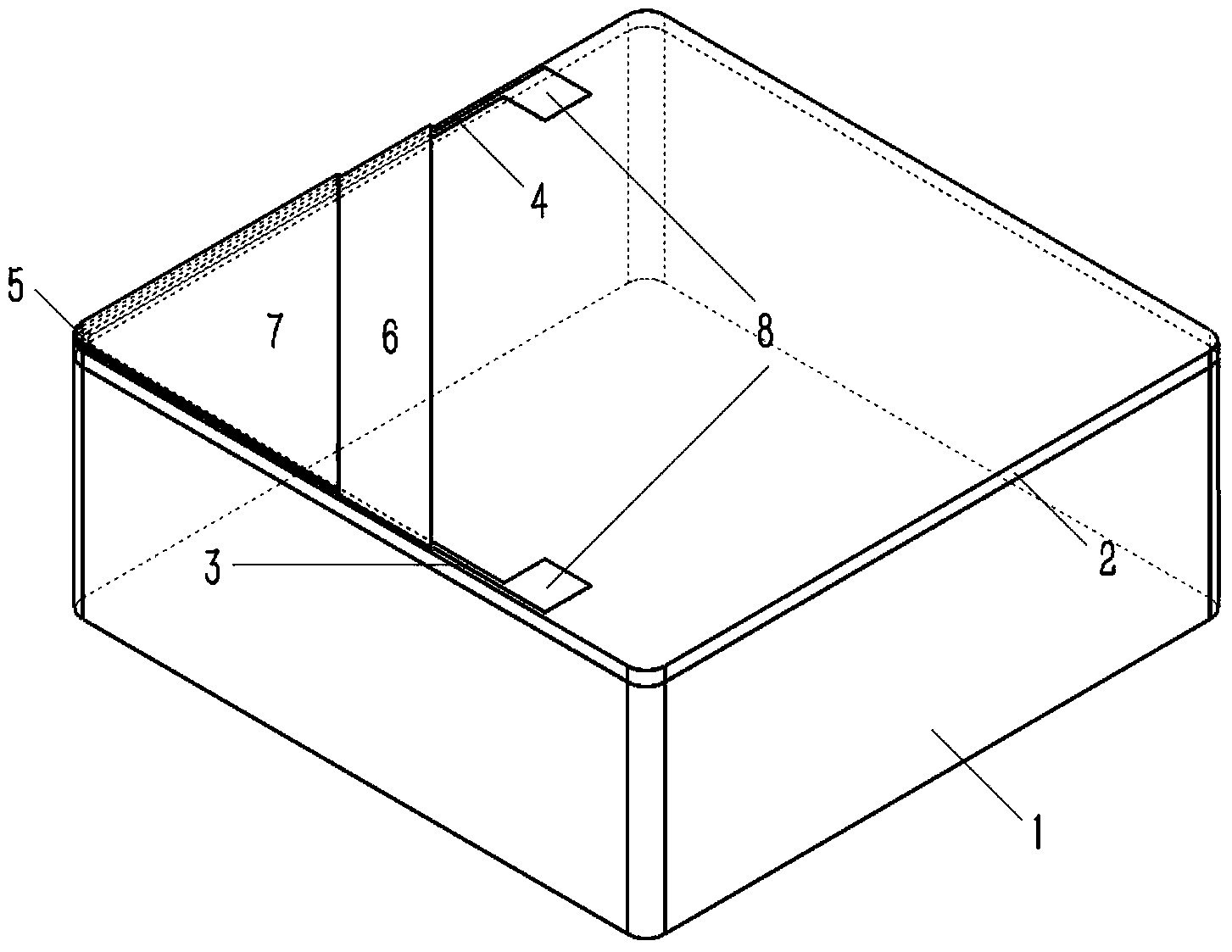

Micro-nano fluid system and preparation method thereof

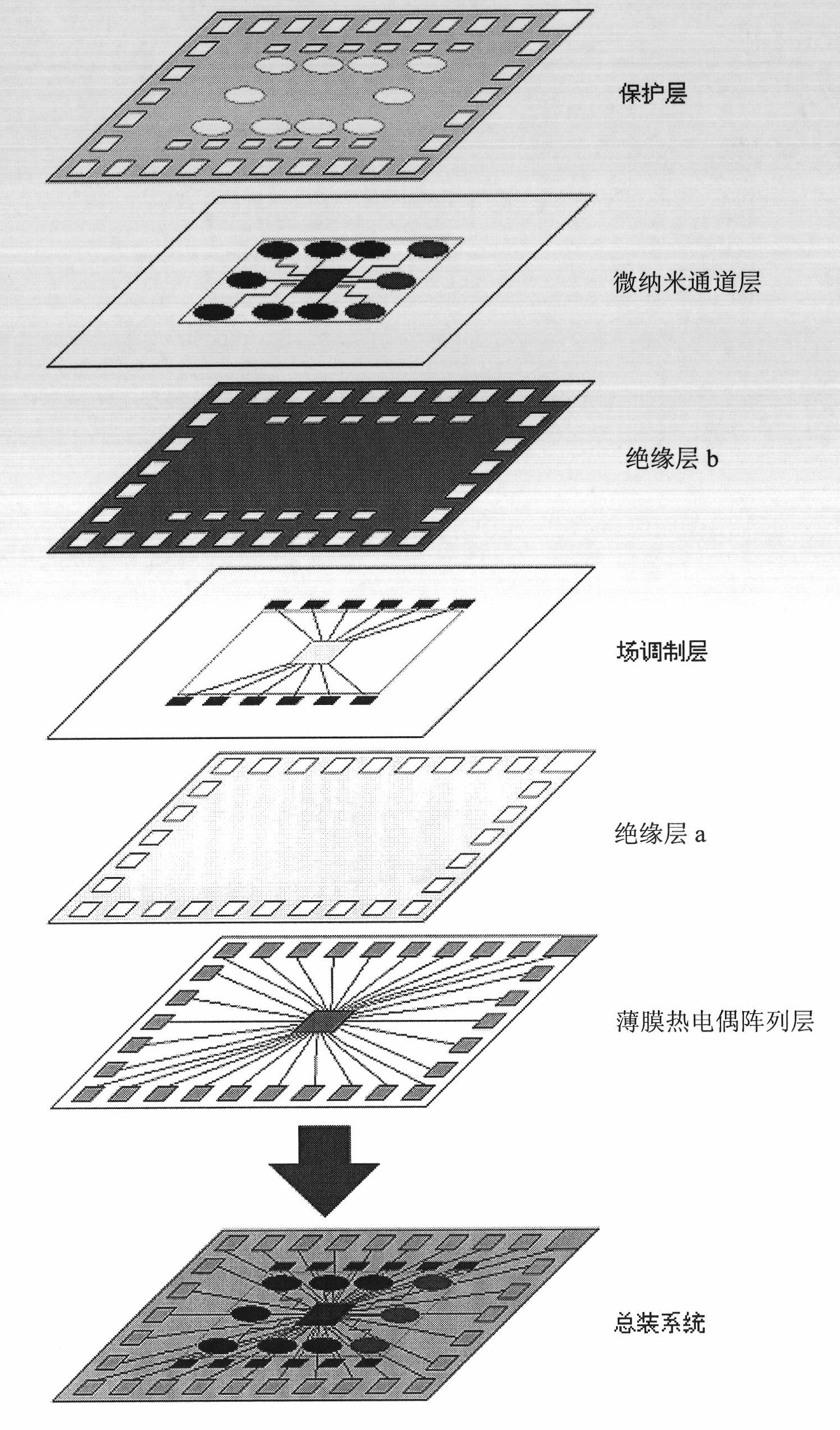

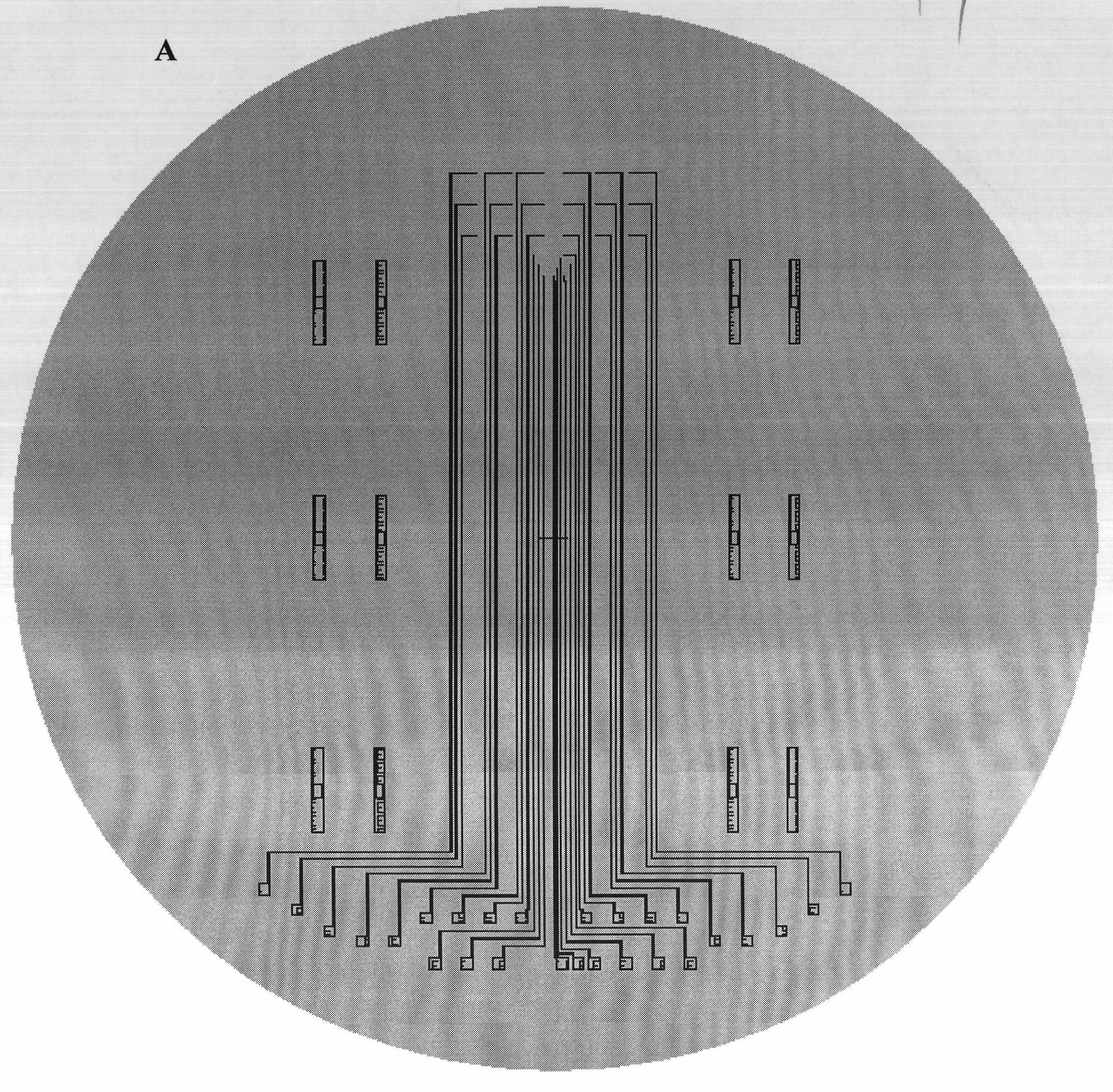

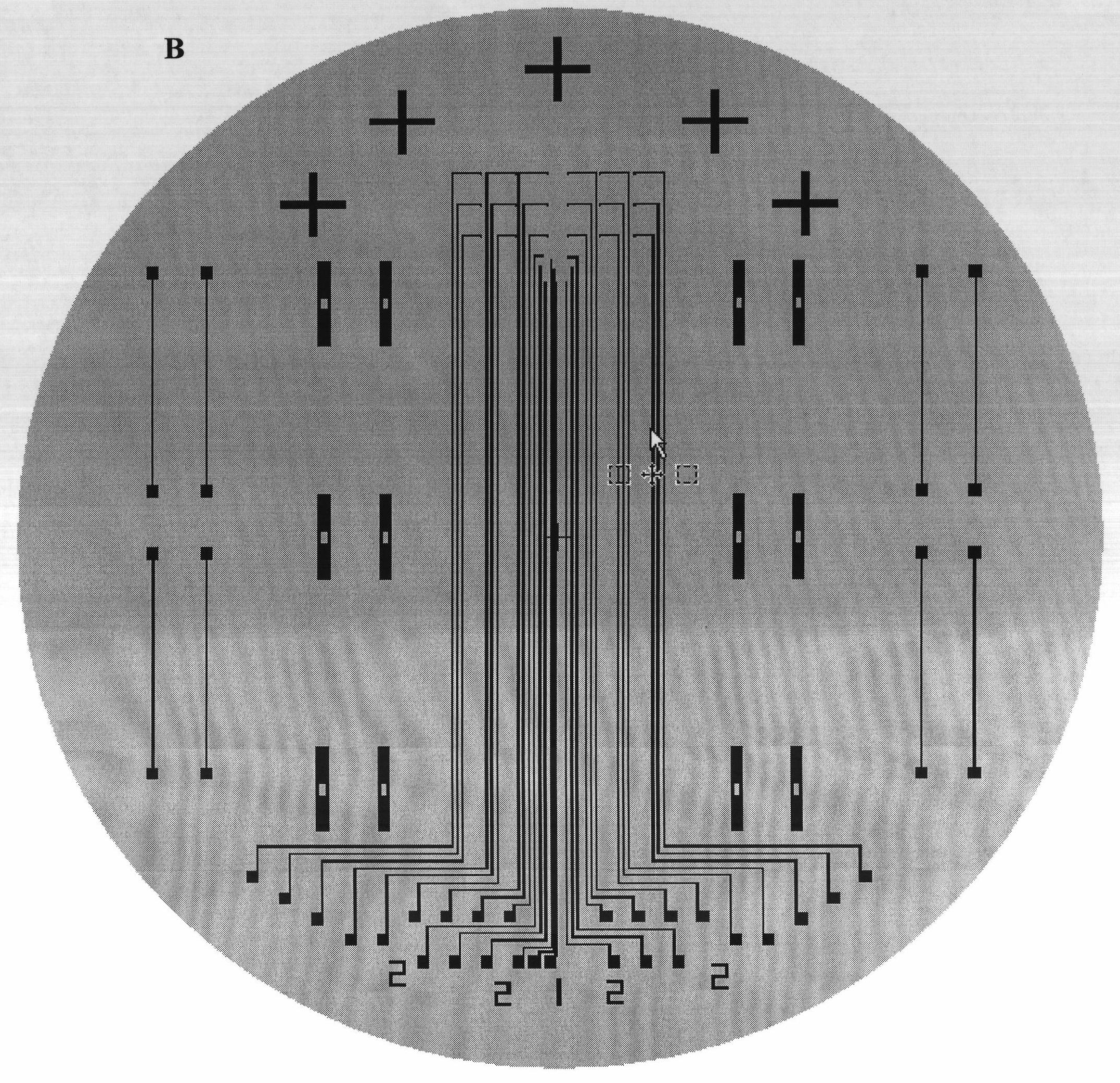

InactiveCN102009941AFunction increaseCompact structureMaterial nanotechnologyFixed microstructural devicesThin film thermocouplesMicro nano

The invention discloses a method for preparing a micro-nano fluid system. The method comprises the following steps of: (1) preparing a film thermocouple array on a substrate to obtain a film thermocouple array layer; (2) preparing an insulating layer a on the prepared film thermocouple array layer prepared in the step 1), and preparing a field modulation layer on the insulating layer a; and 3) preparing an insulating layer b on the field modulation layer prepared in the step 2), preparing a micro-nano channel layer on the insulating layer b, and packaging to prepare the micro-nano fluid system. The prepared micro-nano fluid testing system has local temperature measurement and control function and can perform direct current and high-frequency electromagnetic measurement. The system is diversified in function, compact in structure and high in testing accuracy, and has good application prospects in the research fields of physics, chemistry, biology and the like.

Owner:PEKING UNIV

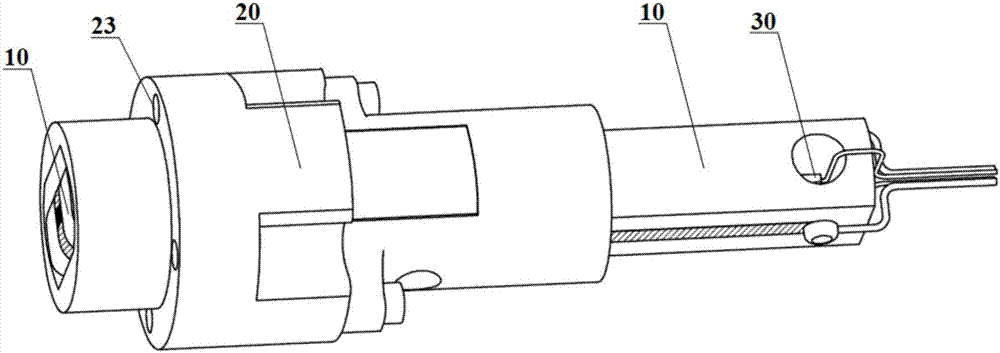

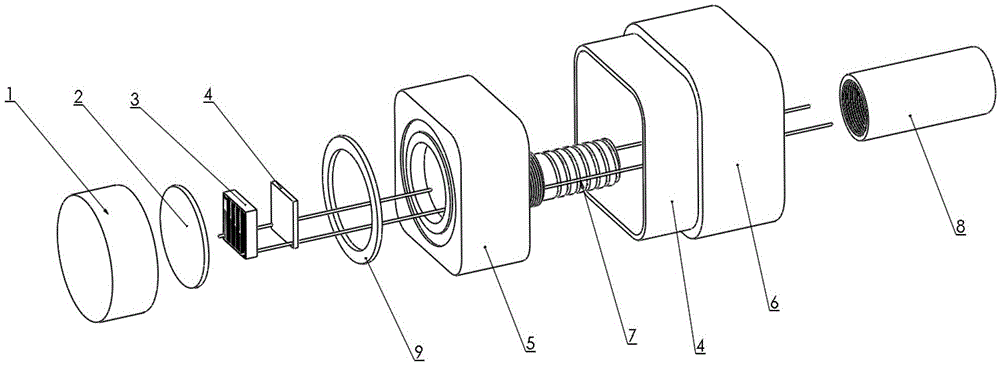

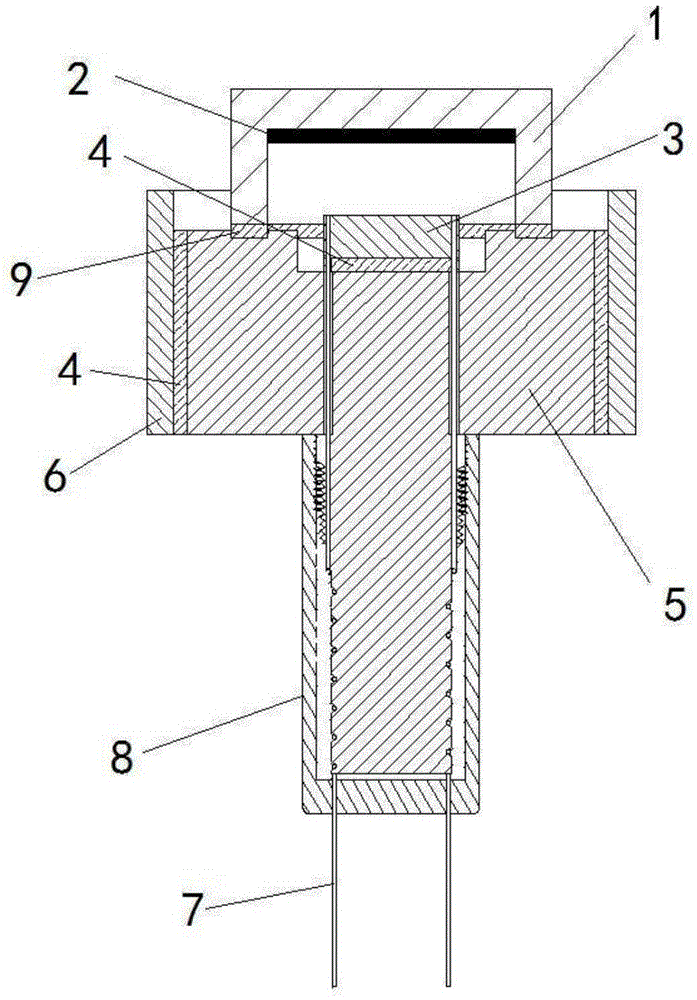

Probe-type thin film thermocouple temperature sensor and manufacturing method thereof

ActiveCN108007595ARealize instantaneous dynamic measurementFast dynamic measurementThermometer detailsThermometers using electric/magnetic elementsThin film thermocouplesThin film sensor

The invention discloses a probe-type thin film thermocouple temperature sensor and a manufacturing method thereof, and belongs to the technical field of thin film sensors. In the invention, a thin film thermocouple is deposited on a ceramic cylinder, a platinum resistor temperature sensor is packaged on the tail portion of the ceramic cylinder to measure the temperature of a cold end of the thin film thermocouple, and temperature compensation is performed on the thin film thermocouple. The ceramic cylinder with the thin-film thermocouple deposited is packaged and fixed in a metal tube shell using a high-temperature ceramic insulating bonding agent, and a temperature measurement junction of the thin film thermocouple is flush with the end surface of the tube shell and is directly exposed tothe temperature measurement environment. The characteristics of small physical size and fast response of the thin film thermocouple can be used to solve the need for instantaneous temperature measurement of a high-temperature and high-speed flow field in the aerospace field. At the same time, the probe-type tube shell package structure solves the technical problems of application and installationof the thin film thermocouple in practical engineering measurement environments.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

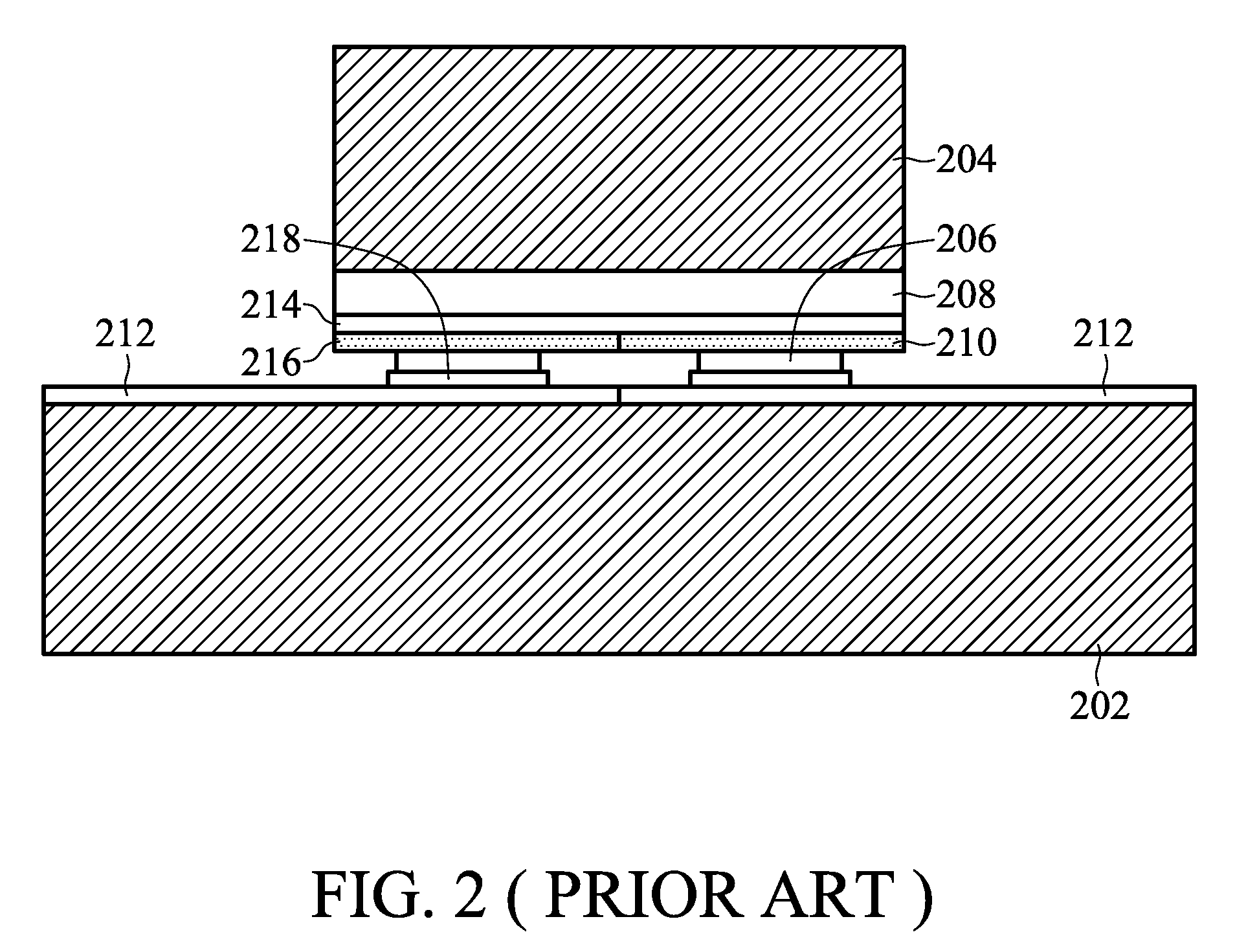

Thermoelectric module device with thin film elements and fabrication thereof

ActiveUS8269098B2Thermoelectric device with peltier/seeback effectThermoelectric device detailsThin film thermocouples

Owner:IND TECH RES INST

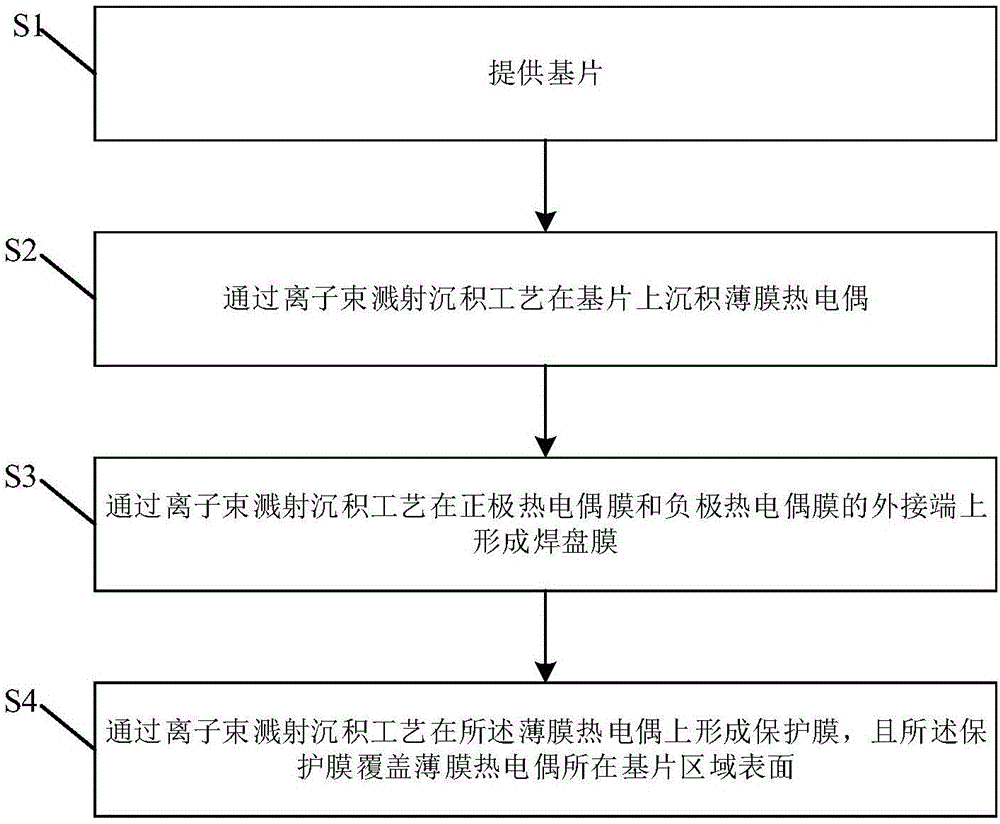

Thin film temperature sensor and manufacturing method

ActiveCN106197718AHigh measurement accuracyReduce thicknessThermometers using electric/magnetic elementsVacuum evaporation coatingThin film thermocouplesTemperature response

The invention relates to a thin film temperature sensor and a manufacturing method. The thin film temperature sensor at least comprises a substrate, a thin film thermocouple, bonding pad films and a protective film, wherein the thin film thermocouple is formed on the substrate through the ion beam sputtering deposition technology; the thin film thermocouple comprises a positive pole thermocouple film and a negative pole thermocouple film, and the inner end of the positive pole thermocouple film and the inner end of the negative pole thermocouple film are in butt joint to form a thermocouple connection point; the bonding pad films are formed at the outer end of the positive pole thermocouple film and the outer end of the negative pole thermocouple film through the ion beam sputtering deposition technology and are used for being connected with an external lead; the protective film covers the thin film thermocouple through the ion beam sputtering deposition technology and covers the surface of the area, where the thin film thermocouple is located, of the substrate. The thin film temperature sensor is manufactured through the ion beam sputtering deposition technology, multiple layers of the manufactured thin films are high in density and high in adhesive force, the plated thin film thermocouple is small in thickness and quick in temperature response, and after being packaged, the thermocouple is small in size and high in measurement precision.

Owner:北京埃德万斯离子束技术研究所股份有限公司

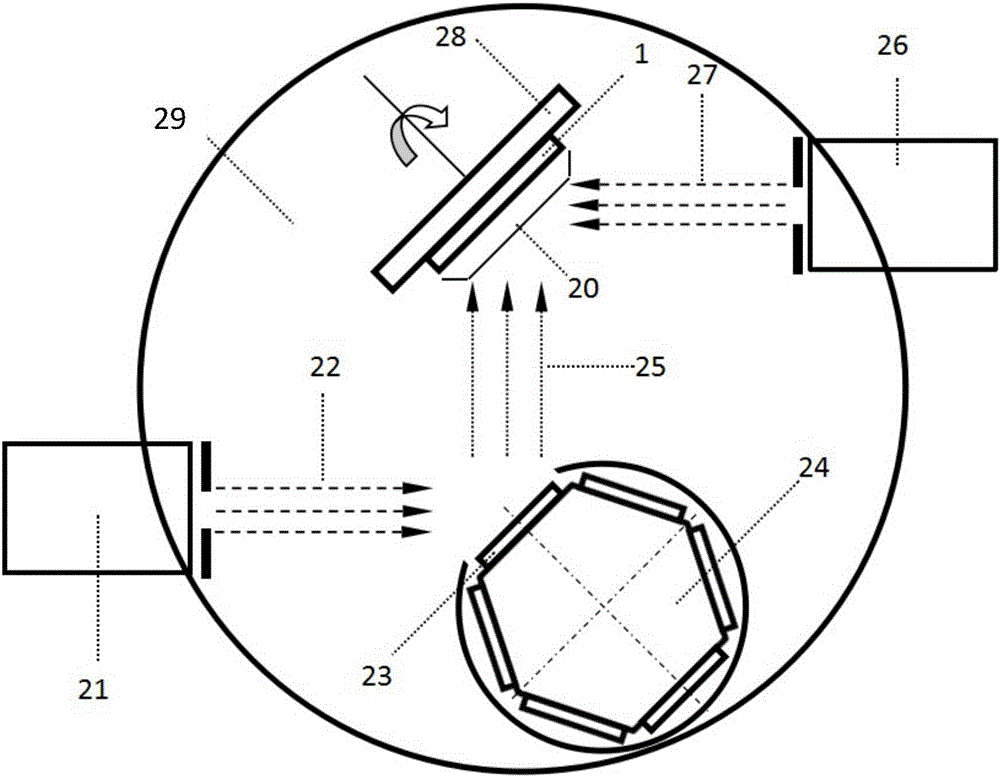

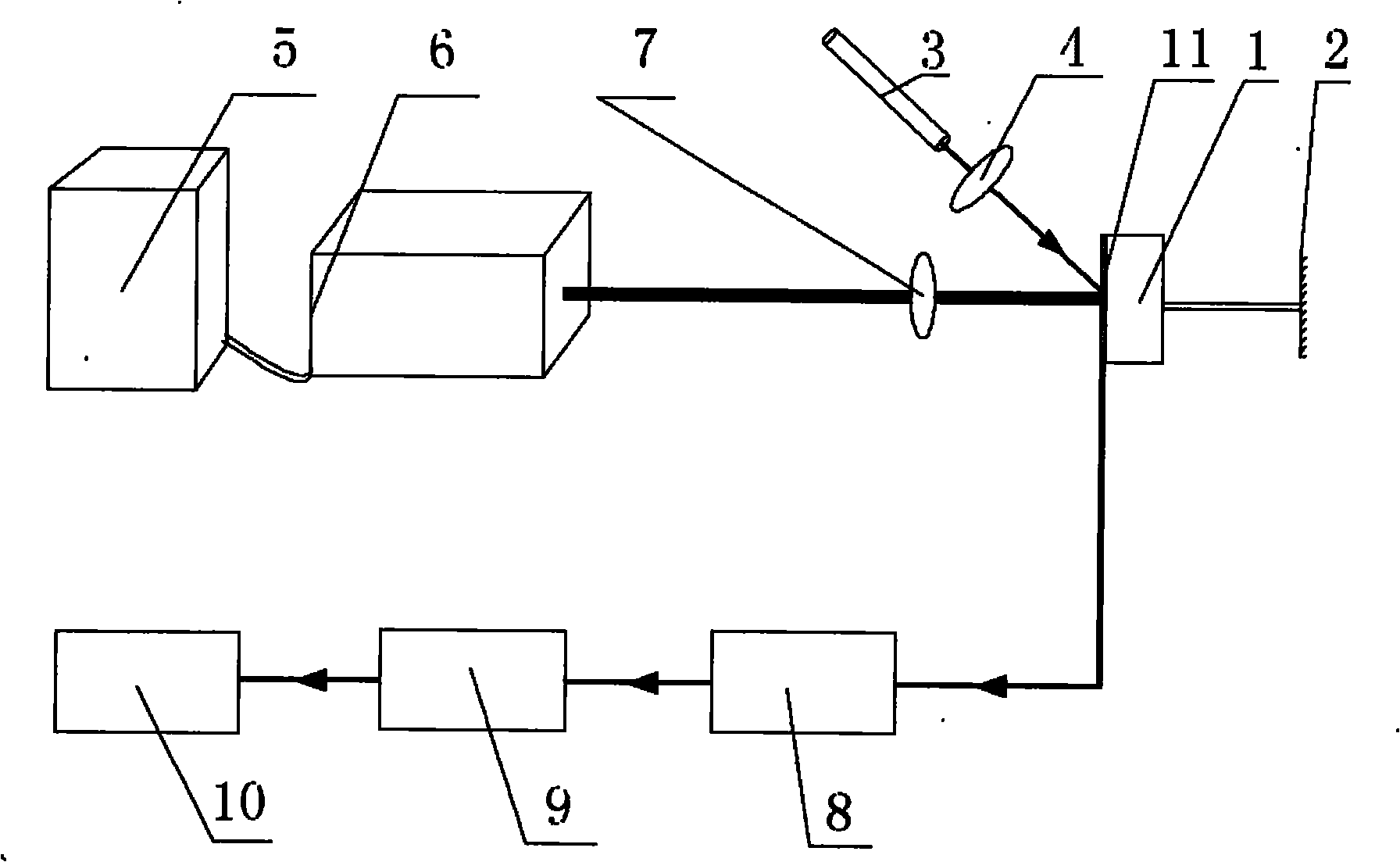

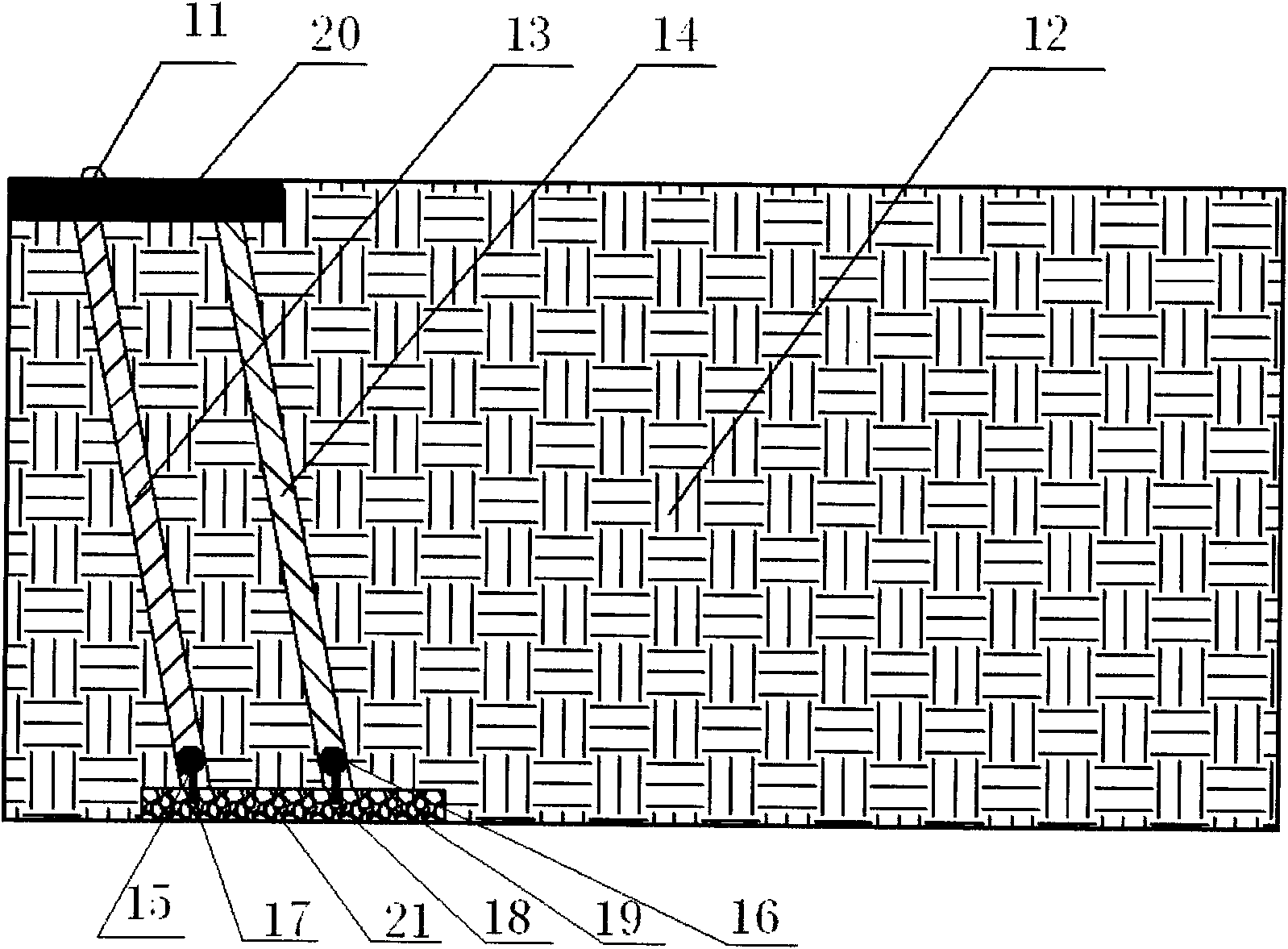

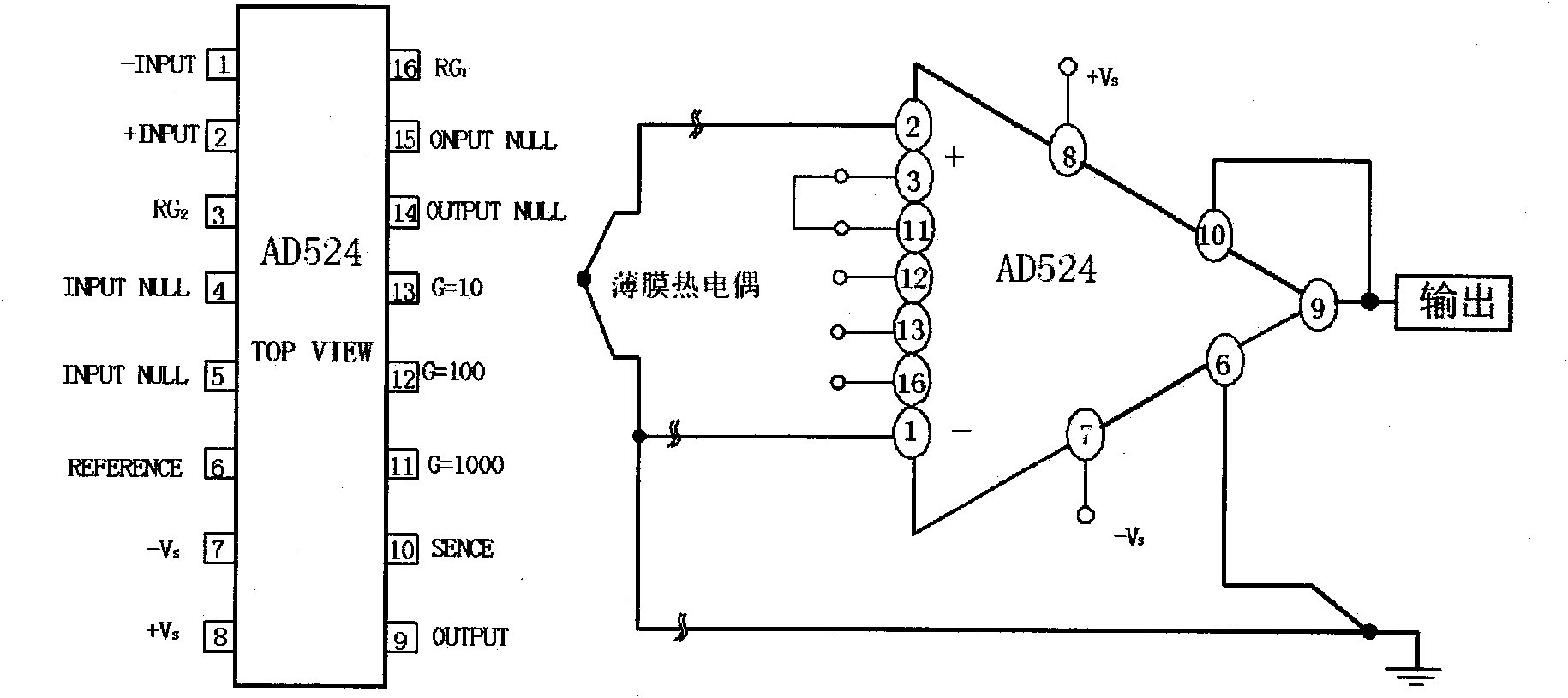

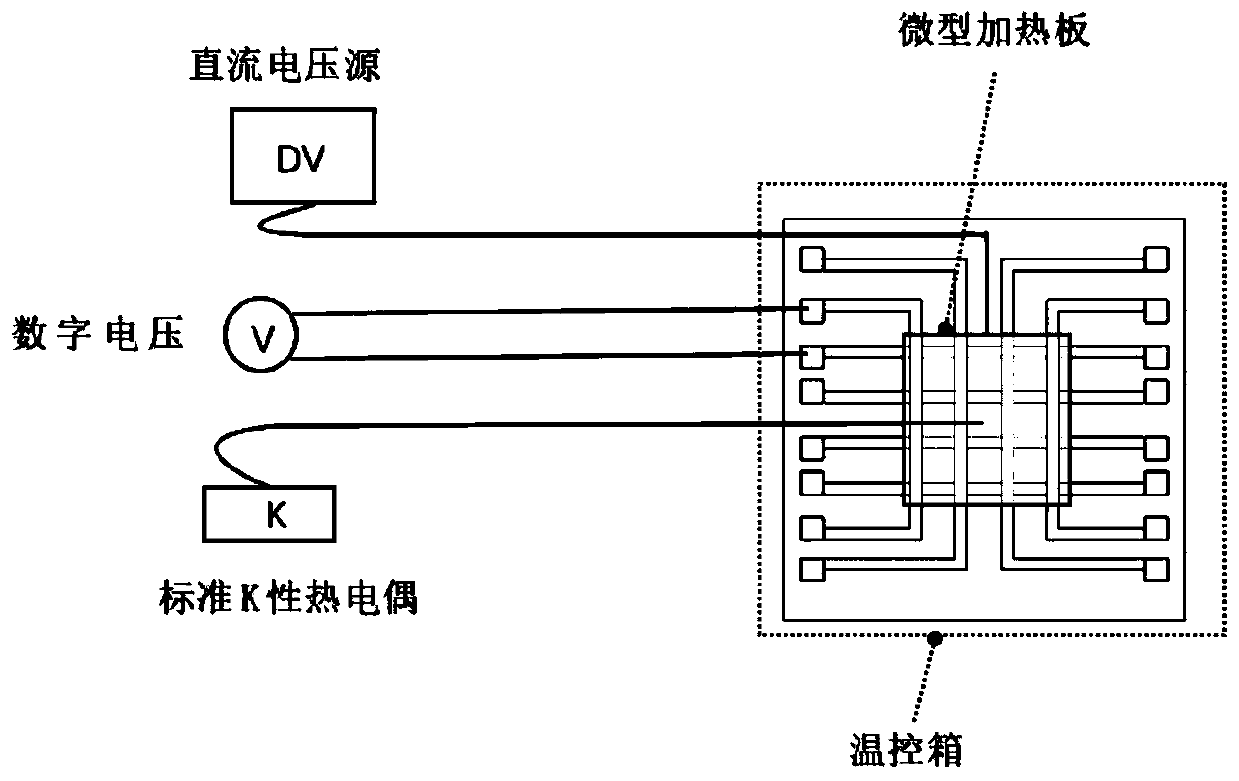

System and method for dynamically demarcating film thermocouple by adopting laser

ActiveCN101858797ARealize dynamic calibrationSimple and fast operationThermometer testing/calibrationThin film thermocouplesAudio power amplifier

The invention discloses a system and a method for dynamically demarcating a film thermocouple by adopting a laser. The system comprises a laser test-bed frame, a continuous He-Ne laser, a lens group, a precise amplifier, a dynamic signal acquisition instrument, a computer, testing software, a laser control power supply, an Ultra-CFR short-pulse laser and a frequency doubling crystal. The laser control power supply is connected with the Ultra-CFR short-pulse laser through an electric power cable, and laser emitted by the Ultra-CFR short-pulse laser irradiates the film thermocouple on the laser test-bed frame through the frequency doubling crystal. In the invention, the Ultra-CRF short-pulse laser with the pulse width of 8ns is adopted as an excitation heat source to carry out the dynamic demarcation of the film thermocouple, and the experiment result shows that the least response time of the film thermocouple can reach 0.042 ms, thereby the dynamic demarcation of the film thermocouple with microsecond response time can be realized.

Owner:DALIAN JIAOTONG UNIVERSITY

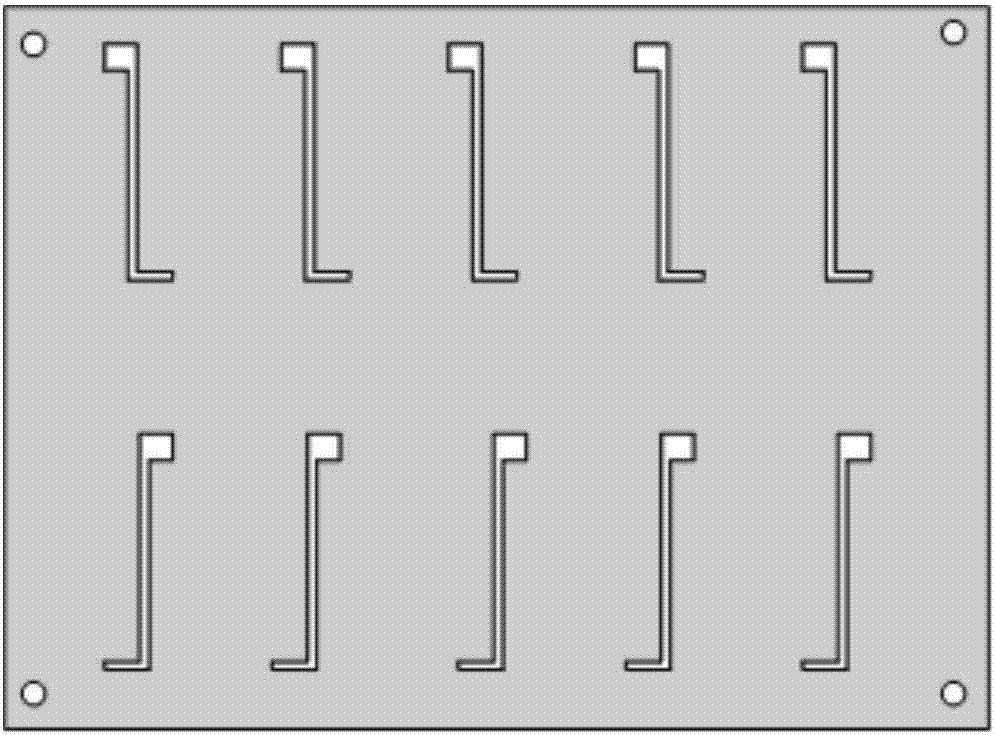

Thin film thermocouple for metal cutting temperature measurement and manufacturing method thereof

InactiveCN103560204AGuaranteed to workAchieve electrical isolationThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThin film thermocouplesEvaporation

The invention discloses a thin film thermocouple for metal cutting temperature measurement and a manufacturing method thereof, and belongs to the technical field of thin films and machining measurement. According to the thin film thermocouple for metal cutting temperature measurement, a plurality of layers of functional thin films are deposited on a ceramic turning tool blade base through the utilization of a hollow mechanical mask plate and the electron beam evaporation technology. Firstly, a buffering layer is plated on the base in advance for solving the problem that the surface of the ceramic turning tool blade is rough. Then, the Ni electrode and the NiCr electrode of the thin film thermocouple are respectively manufactured on the buffering layer by using the mask plate, and a temperature measuring node is formed at the tip of a turning tool. To protect the thin film thermocouple and enable the thin film thermocouple to play a stable role in metal cutting temperature measurement, and an insulating layer and a hardening protecting layer are respectively deposited on a thermal node area through an electron beam evaporation method. The thin film thermocouple for metal cutting temperature measurement has the advantages of being high in flexibility, high in response speed and the like, can be applied to an industrial production environment, and solves the problem that a traditional method cannot be used for measuring the transient temperature which changes rapidly in metal cutting machining.

Owner:TSINGHUA UNIV

Film thermocouple temperature sensor inlaid into multi-layer PCBs, and transient temperature monitoring system and method

ActiveCN108489627AHigh measurement accuracyAccurate measurementThermometers using electric/magnetic elementsUsing electrical meansThin film thermocouplesMonitoring system

The present invention discloses a film thermocouple temperature sensor inlaid into a multi-layer PCBs, and a transient temperature monitoring system and method. The system comprises: a film thermocouple temperature sensor located between any two PCB requiring monitoring transient temperatures, wherein the film thermocouple temperature sensor is formed by laminating each prepreg and multiple PCBs into one body through adoption of a PCB lamination process and parameters; the plurality of prepreg; the PCBs with different layers; a cold-end compensator connected with the film thermocouple temperature sensor; a signal amplification module connected with the cold-end compensator; a data collection module connected with the signal amplification module; a computer; and upper computer software. Thefilm thermocouple temperature sensor inlaid into the multi-layer PCBs, and the transient temperature monitoring system and method achieve real-time and accurate measurement of temperatures between the PCB layers, and are rapid in response, accurate and convenient to locate and high in measurement precision.

Owner:DALIAN JIAOTONG UNIVERSITY

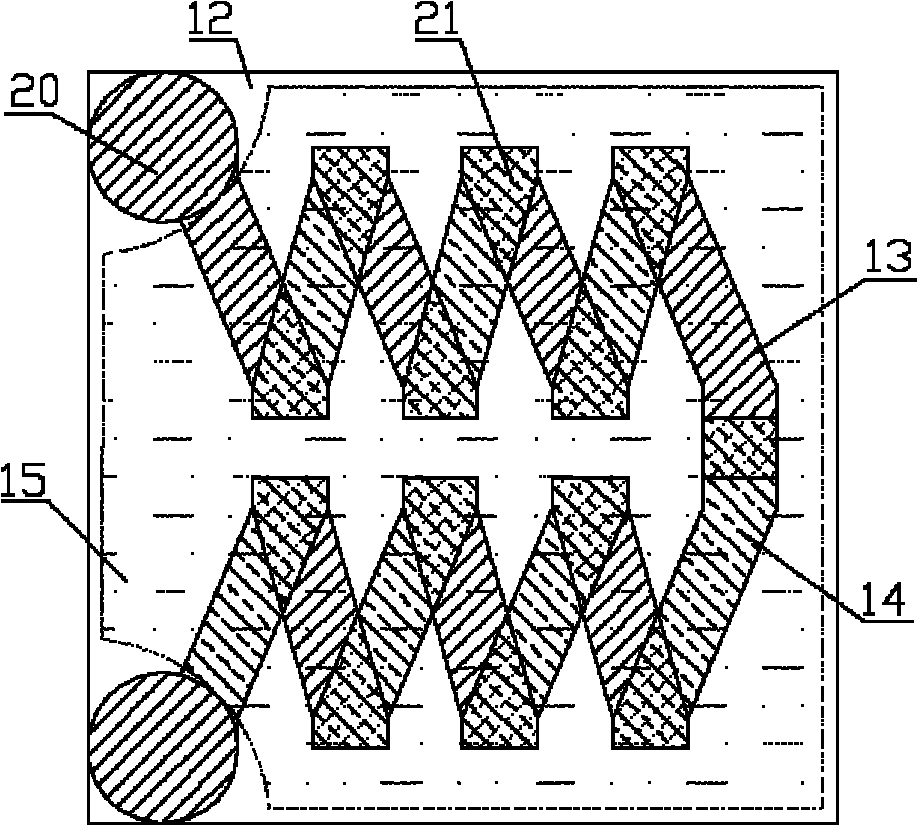

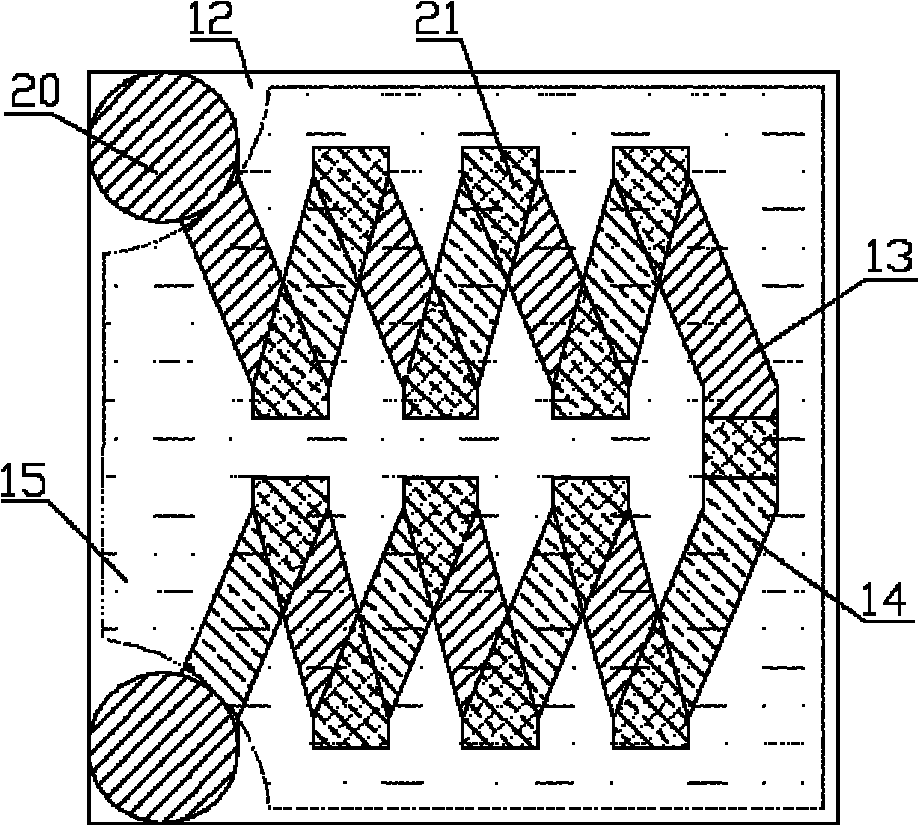

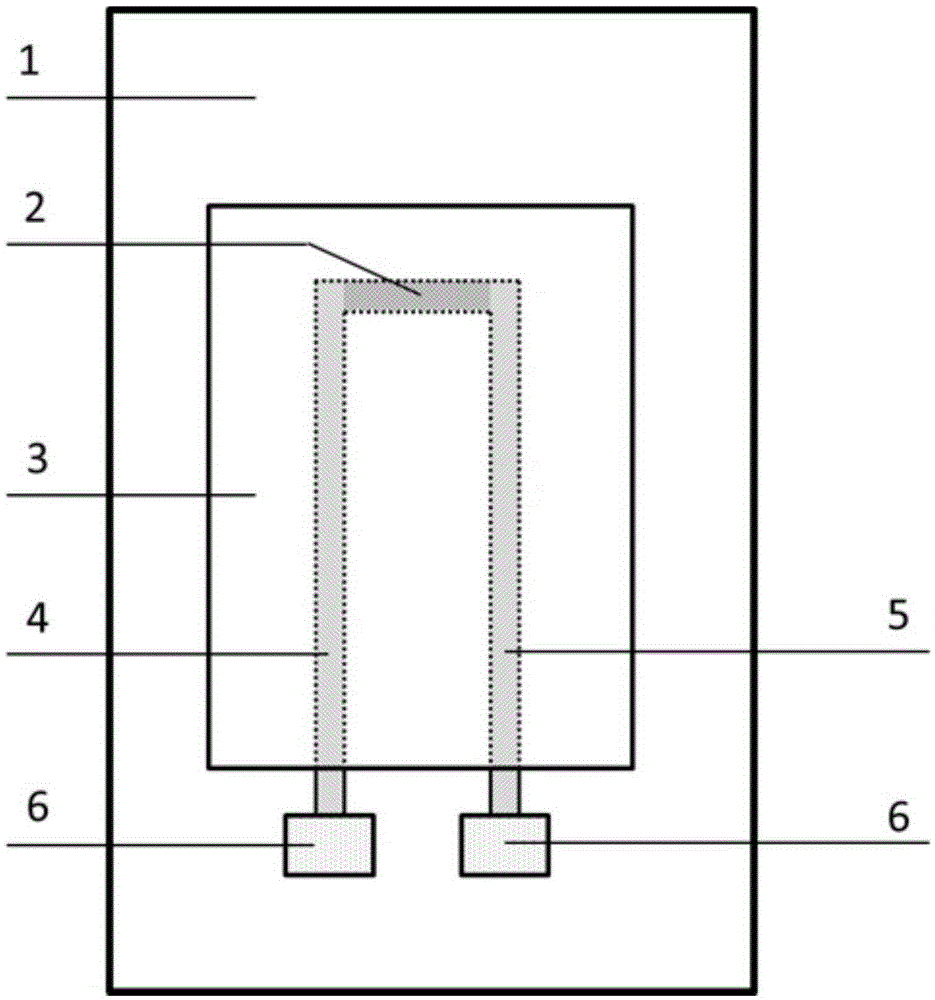

High-spatial resolution flexible film thermocouple temperature sensor

InactiveCN109781287AMeet all flexible requirementsEasy to measureThermometers using electric/magnetic elementsUsing electrical meansThin film thermocouplesImage resolution

The invention discloses a high-spatial resolution flexible film thermocouple temperature sensor. The sensor comprises a flexible insulating substrate as well as a positive electrode thermocouple filmarray and a negative electrode thermocouple film array sequentially deposited on the surface of the flexible insulating substrate; the positive electrode thermocouple film array and the negative electrode thermocouple film array have a plurality of overlapping regions; the overlapping regions of the positive electrode thermocouple film array and the negative electrode thermocouple film array constitute thermal nodes; the surface of the flexible insulating substrate is divided into a sensitive region and a non-sensitive region; the thermal nodes are located in the sensitive region; the end portions of each positive electrode thermocouple film in the positive electrode thermocouple film array and the end portions of each negative electrode thermocouple film in the negative electrode thermocouple film array are connected with cold ends respectively; and the cold ends are located in a non-sensitive region. The sensor can accurately measure the temperature of a plurality of points to be measured under a condition that the number of sensors is not increased. The sensor has the advantages of simple structure, high reliability, high durability and low cost.

Owner:XI AN JIAOTONG UNIV

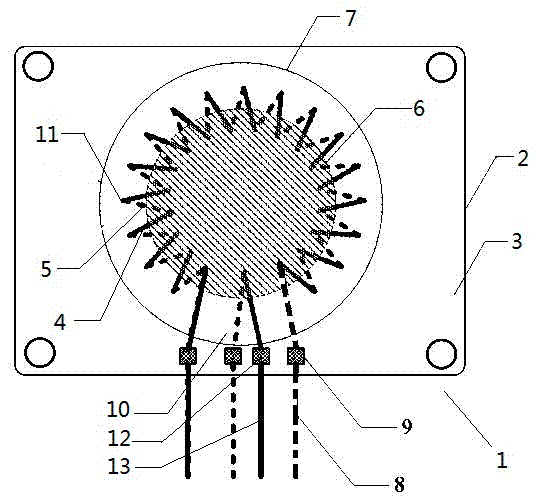

Encapsulation structure of tungsten-rhenium film thermocouple sensor chip and production method thereof

ActiveCN105651406AImprove easy failureImprove the problem of easy erosion under high-speed flow fieldSemiconductor/solid-state device detailsThermometers using electric/magnetic elementsThin film thermocouplesRhenium

The invention discloses an encapsulation structure of a tungsten-rhenium film thermocouple sensor chip and a production method thereof. A round recess equivalent to a sensor chip in size is formed in the upper surface of a substrate of the encapsulation structure, and the two are tightly bonded through refractory glass; a getter is sputtered on the upper surface inside a sealing cap, and the sealing cap is tightly bonded with the upper surface of the substrate through a bonding ring; a high-temperature compensating wire is connected with a thermocouple electrode of the sensor chip; the protruding high-temperature compensating wire is fixedly wound on a stud at the lower part of the substrate; and the sealing cap, the sensor chip, the refractory glass, the substrate and the high-temperature compensating wire are together assembled with a tube shell face to face and bonded through refractory glass. Through the invention, the problems of small measurement range and short life of the existing temperature sensor chip caused by easy failure of tungsten and rhenium at high temperature and erosion drop of a thermocouple film and the like can be solved, and an output function of collecting stable signals is realized.

Owner:XI AN JIAOTONG UNIV

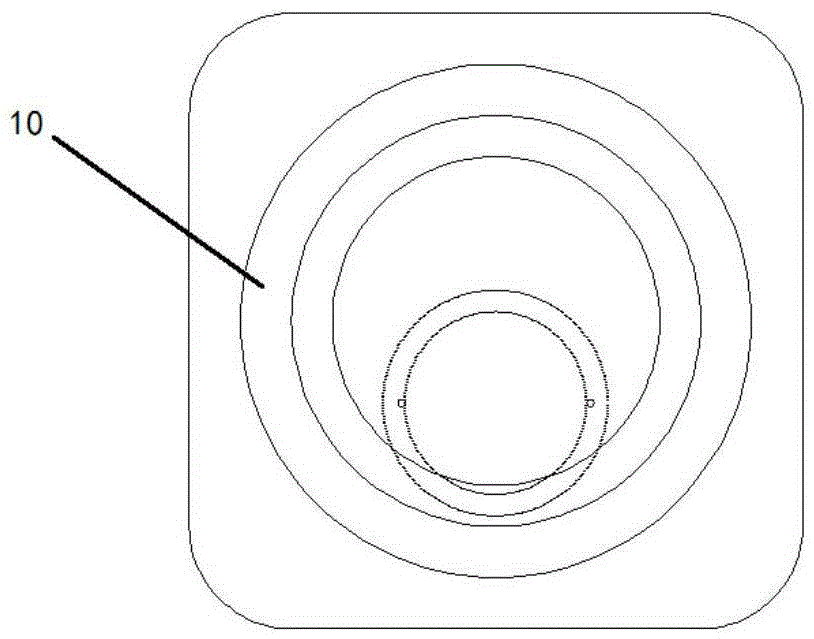

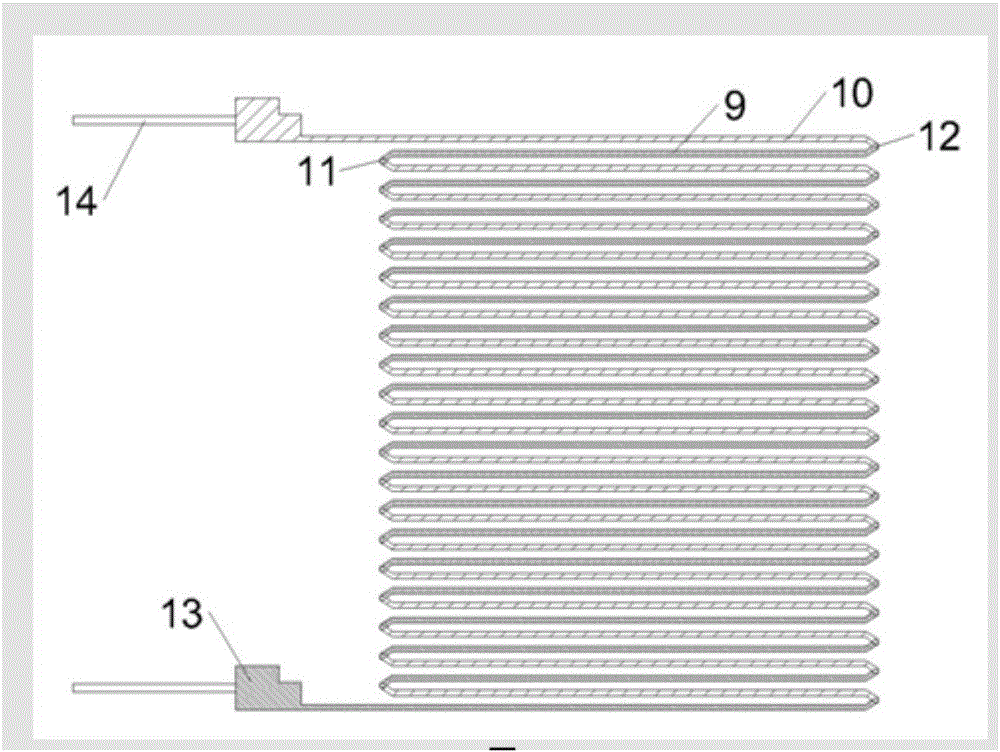

Film radiant heat flow sensor and manufacturing method thereof

InactiveCN106124064AReduce the temperatureRaise the level of reliabilityPyrometry using electric radation detectorsThin film thermocouplesEngineering

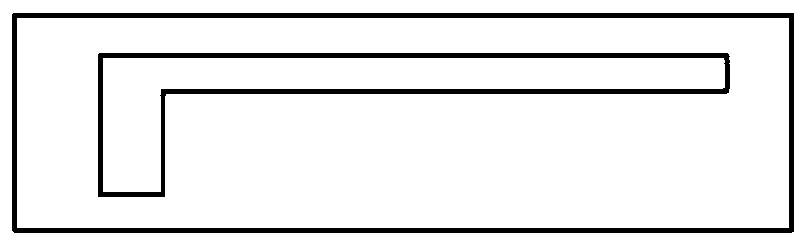

The invention discloses a film radiant heat flow sensor and a manufacturing method thereof. The film radiant heat flow sensor comprises a foundation 1, a film thermocouple array 2 arranged on the foundation 1 and thermal resistance layers 3 arranged on the film thermocouple array 2, wherein the film thermocouple array 2 comprises more than two film thermocouples which are connected in series through outer connection points 11, the film thermocouple comprises an A electrode 9 and a B electrode 10 which are connected, two adjacent outer connection points 11 are provided with the thermal resistance layers 3, and two external connection ends of the film thermocouple array 2 are respectively connected with compensation leads 14 corresponding to respective electrodes through a bonding pad 13. The film radiant heat flow sensor employs the mature process and materials in the prior art, the production process is simple, cost is low, and the film radiant heat flow sensor further has property of excellent measurement precision.

Owner:NANJING UNIV OF SCI & TECH

Film thermocouple and manufacturing method thereof

InactiveCN101819071ARealize measurementImprove reliabilityThermometers using electric/magnetic elementsVacuum evaporation coatingThin film thermocouplesThermocouple device

The invention belongs to the technical field of temperature measurement and in particular relates to a film thermocouple and a manufacturing method thereof. The film thermocouple comprises a thermode A, a thermode B and a connecting lead, wherein a junction of the thermode A and the thermode B is a temperature measuring point; the connecting lead is led out of the thermode A and the thermode B respectively; and the thermode A and the thermode B are molded on a surface of a member to be measured in a mode of vacuum ion sputtering. In addition, the invention also provides the manufacturing method for the film thermocouple. The thermode A and the thermode B which form the thermocouple are generated by directly sputtering on the surface of the member to be measured in the mode of vacuum ion sputtering, so the thermocouple is fixedly and reliably connected with the member to be measured, and is difficult to float and fall, and measurement accuracy is high.

Owner:CHINA AIRPLANT STRENGTH RES INST

Application of preferred indium tin oxide with (400) crystal plane on transparent thin-film thermocouple

InactiveCN110004410AHigh Seebeck coefficientEasy to makeThermometers using electric/magnetic elementsVacuum evaporation coatingThin film thermocouplesSputtering

The invention relates to the application of a preferred indium tin oxide with a (400) crystal plane on a transparent thin-film thermocouple, and belongs to the technical field of thin-film thermocouples. A preferred body-centered cubic ferromanganese ore phase polycrystalline indium tin oxide with the (400) crystal plane is made into a pole of the transparent thin-film thermocouple by magnetron sputtering; and the power density of magnetron sputtering is 4.8-8.0W / cm<2>. The indium tin oxide transparent thin-film thermocouple has a relatively high Seebeck coefficient by controlling the preferred orientation of the indium tin oxide thin-film obtained by magnetron sputtering.

Owner:DALIAN JIAOTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com