Tungsten-rhenium film thermocouple sensor containing high temperature protection film group and preparation method

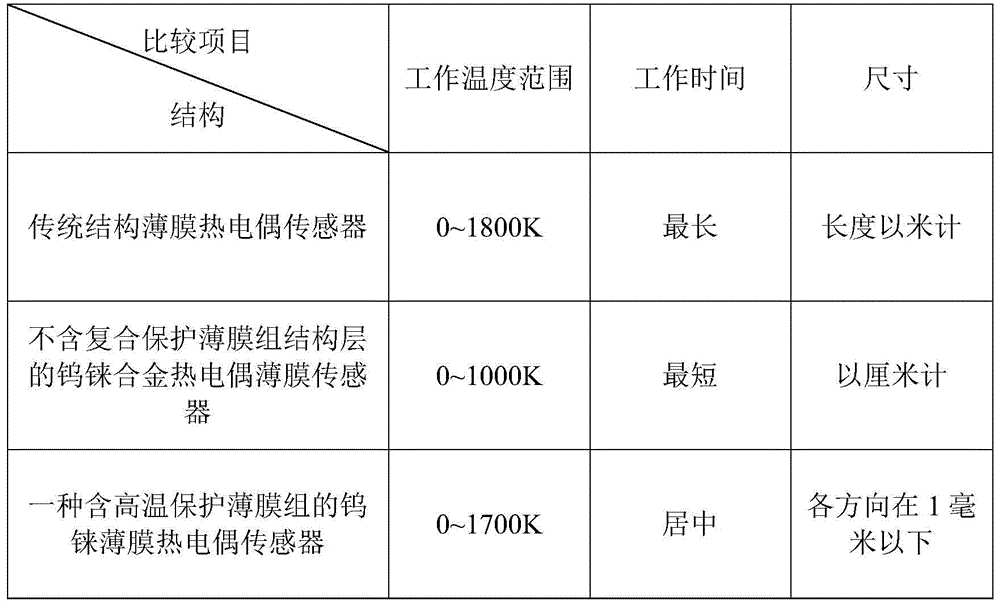

A thermocouple sensor, high temperature protection technology, applied in thermometer parts, instruments, thermometers and other directions, can solve problems such as thermal mismatch, failure, oxidation, etc., to strengthen anti-oxidation, strengthen the effect, and solve the problem of material evaporation and shedding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

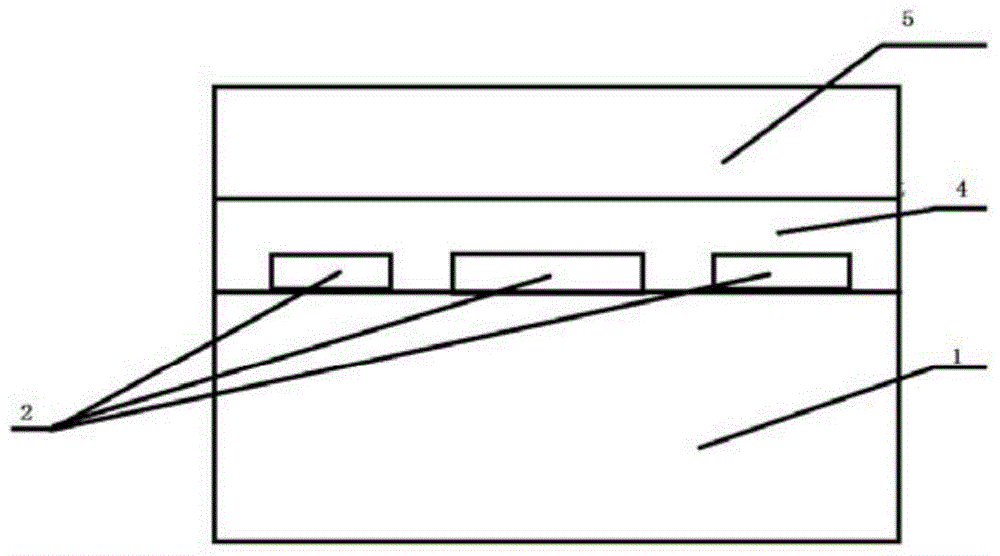

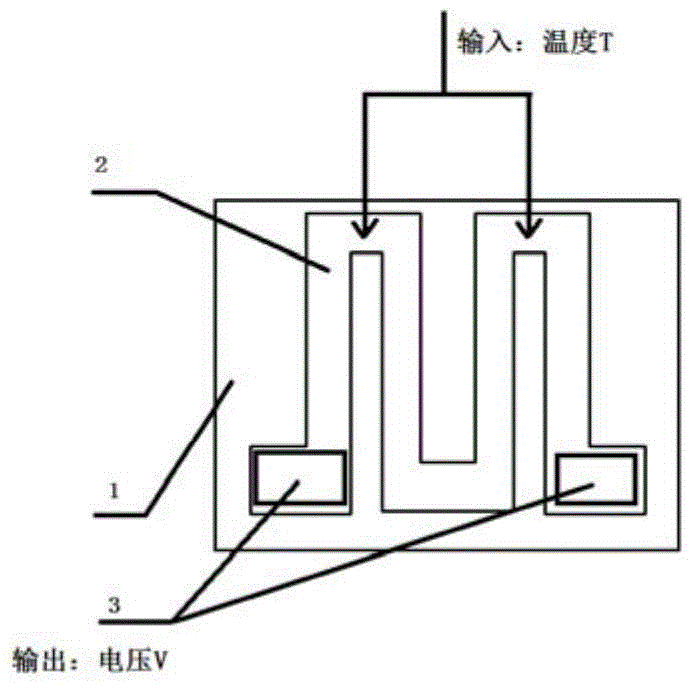

[0028] see figure 1 and figure 2 , the tungsten-rhenium thin-film thermocouple sensor containing the high-temperature protective thin-film group of the present invention includes a silicon carbide substrate 1, the front of the silicon carbide substrate 1 is connected to a parallel tungsten-rhenium alloy thin-film group 2, and the parallel-connected tungsten-rhenium alloy thin-film group 2 consists of multiple groups Tungsten-rhenium galvanic couple thin film positive electrode and tungsten-rhenium galvanic couple thin-film negative electrode, two metal films with different compositions, form the whole thin-film galvanic couple. The tungsten-rhenium alloy positive electrode film and the tungsten-rhenium alloy negative electrode film in the parallel tungsten-rhenium alloy film group 2 are connected to each other, and the thickness is guaranteed to be consistent. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com