Film thermocouple and manufacturing method thereof

A technology of thermocouple and thin film, which is applied in the direction of directly heat-sensitive electrical/magnetic element thermometers, measuring heat, and using electrical devices, etc., which can solve the problem of poor reliability and low measurement accuracy of non-metallic surface temperature measurement. problems, to avoid floating or falling off problems, high measurement accuracy and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

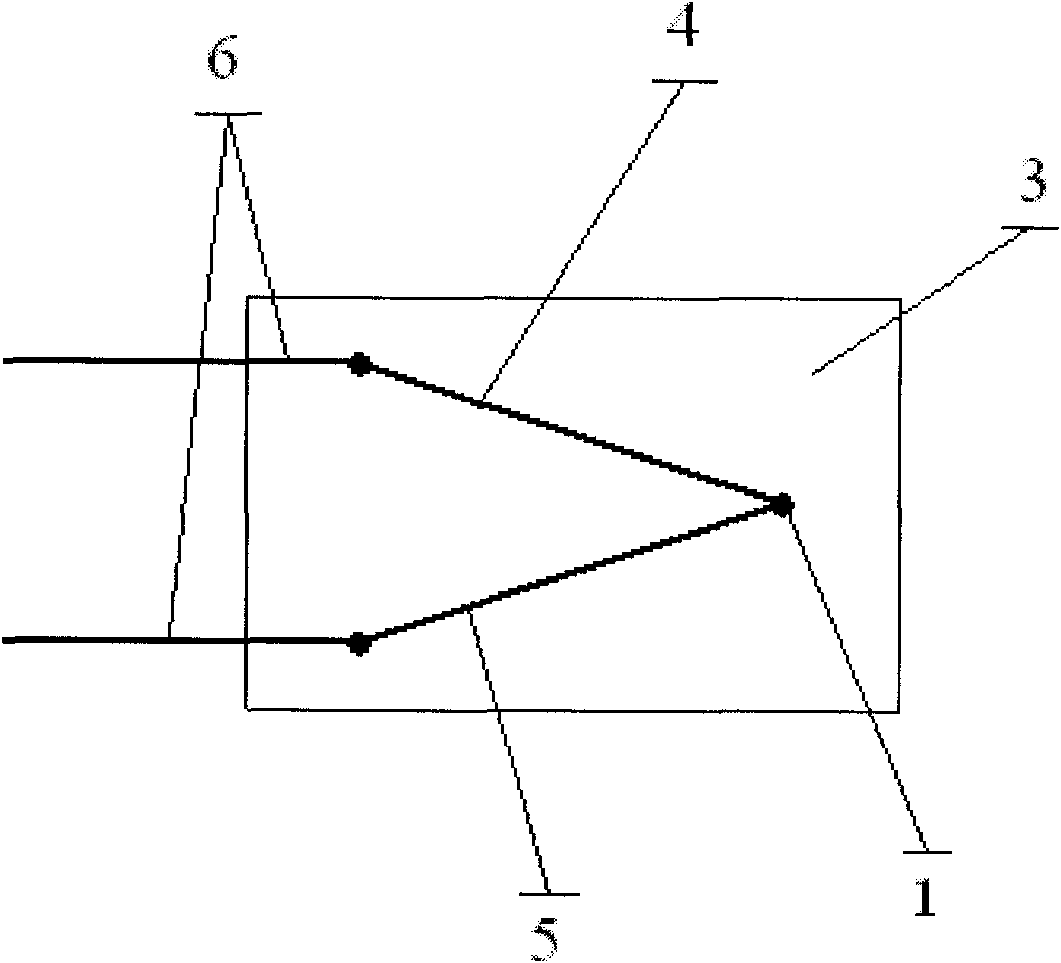

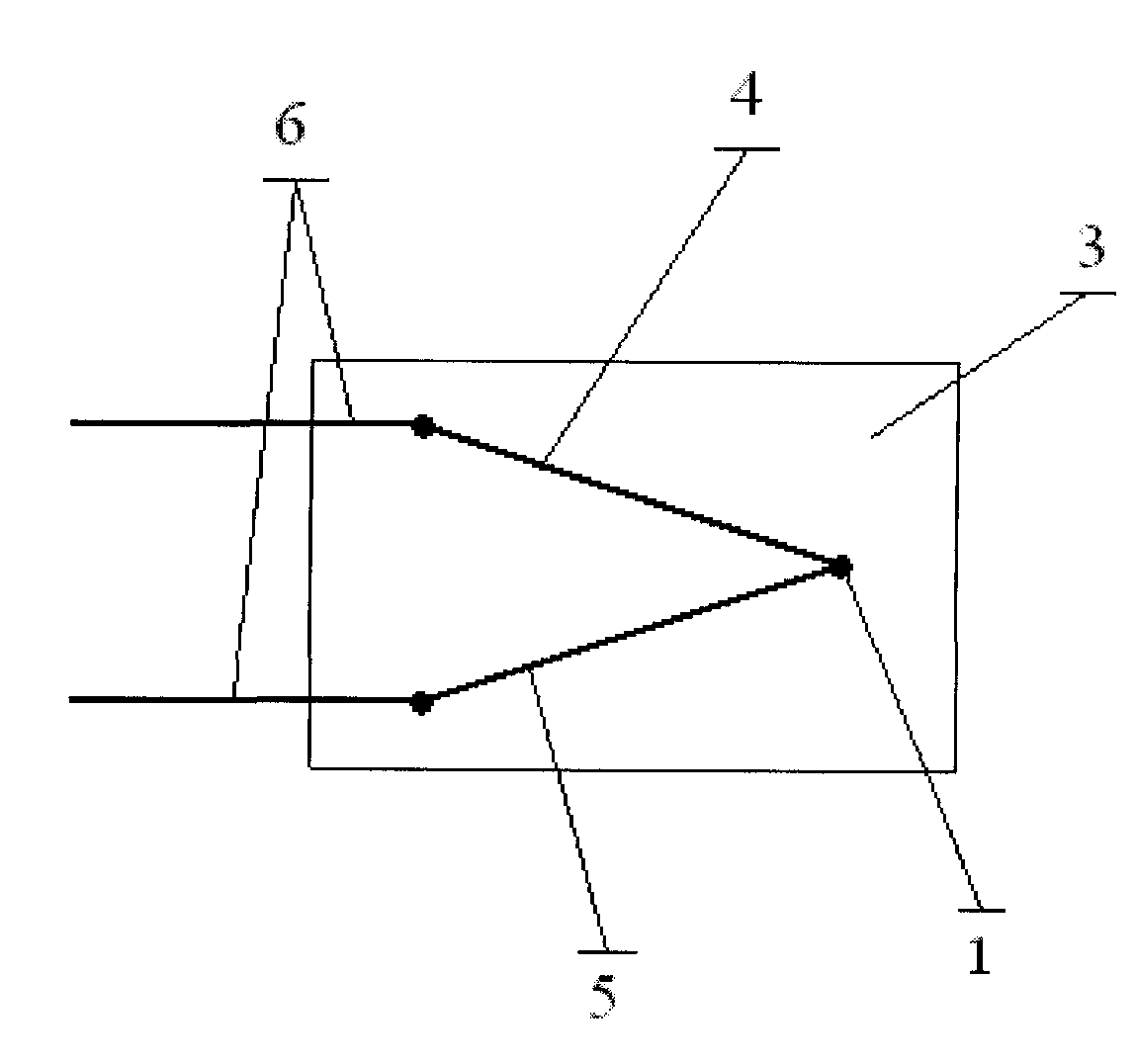

[0024] see figure 2 , which is a structural schematic diagram of the first embodiment of the thin film thermocouple of the present invention. The thin film thermocouple includes a thermal electrode A4, a thermal electrode B5 and a pair of lead wires 6. Wherein, the thermode A4 and the thermode B5 are two kinds of standard thermode materials, which are directly formed on the surface of the member 3 to be measured by means of vacuum ion sputtering. Moreover, the thermal electrode A4 and the thermal electrode B5 are connected to each other to form a thermocouple, and the junctions overlap and are in close contact, and the junction point of the two is the temperature measurement point 1 . At the same time, the lead wires 6 are led out from the thermal electrode A4 and the thermal electrode B5 respectively. In actual measurement, generally zero degrees is used as a referen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com