Film radiant heat flow sensor and manufacturing method thereof

A heat flow sensor and thin film technology, applied in the field of thin film special sensors, can solve the problems of complex structure, large volume, slow response speed, etc., and achieve the effects of improving processing efficiency, reducing manufacturing cost and improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

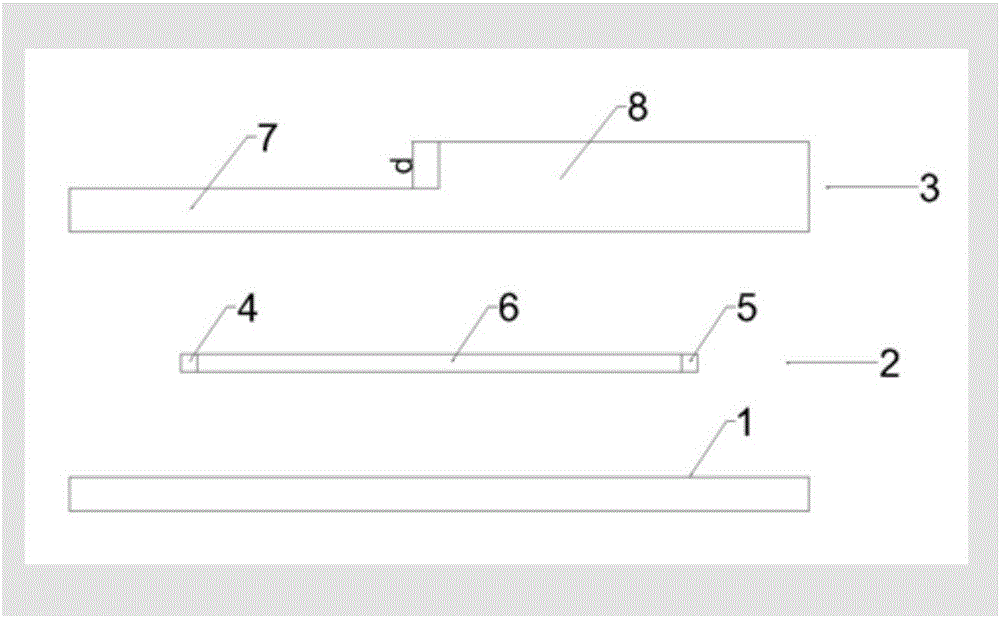

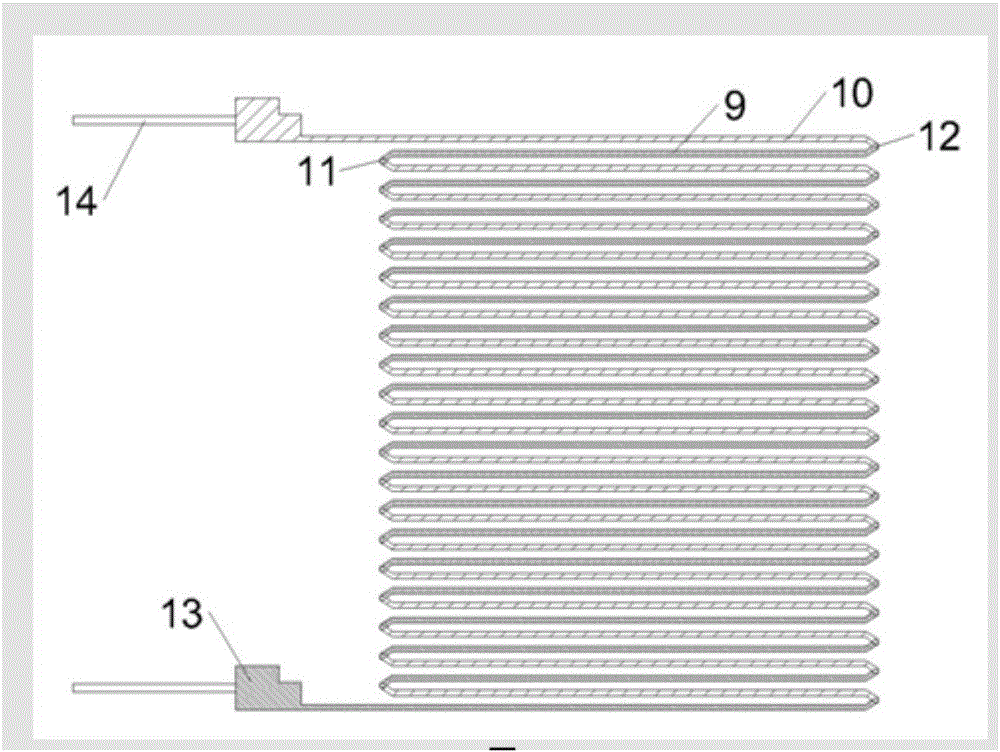

[0021] The preparation method of the above-mentioned thin film radiation heat flow sensor comprises the following steps:

[0022] (1) Ultrasonic cleaning of the substrate with acetone for 10 minutes, ultrasonic cleaning of the substrate with absolute ethanol for 10 minutes, and ultrasonic cleaning of the substrate with deionized water for 10 minutes to remove surface oil and impurities;

[0023] (2) Put the substrate on the vacuum chuck of the glue leveling machine, evenly coat the photoresist, and bake the photoresist with a heating platform to evaporate a certain amount of solution;

[0024] (3) Put the substrate and the glass mask plate on the planet carrier of the photolithography machine for photolithography, prepare the photolithographic pattern of the A electrode 9, put it into the heating platform again and bake to make the photoresist further evaporate a certain amount of solution;

[0025] (4) Put the substrate into the sample platform of the coating machine, deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com