Insertion sheet for measuring internal temperature distribution of fuel cell

A fuel cell and internal temperature technology, which is applied to fuel cells, fuel cell additives, thermometers, etc., can solve the problems of not being universally applicable to fuel cells, uneven temperature distribution, and difficulty in disassembling and assembling batteries, and achieves convenient and rapid disassembly and assembly. The effect of convenient measurement of battery, transient temperature distribution, and simplified measurement steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Accompanying drawing is the specific embodiment of the present invention;

[0045] Below in conjunction with accompanying drawing, content of the present invention is described in further detail:

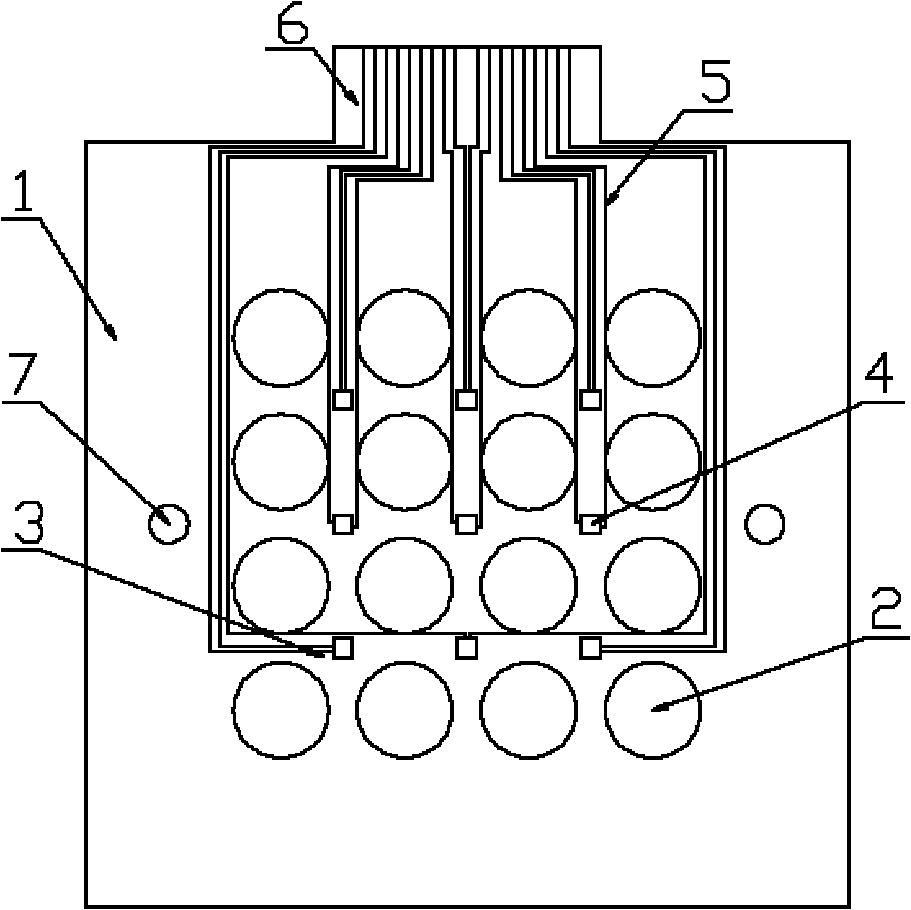

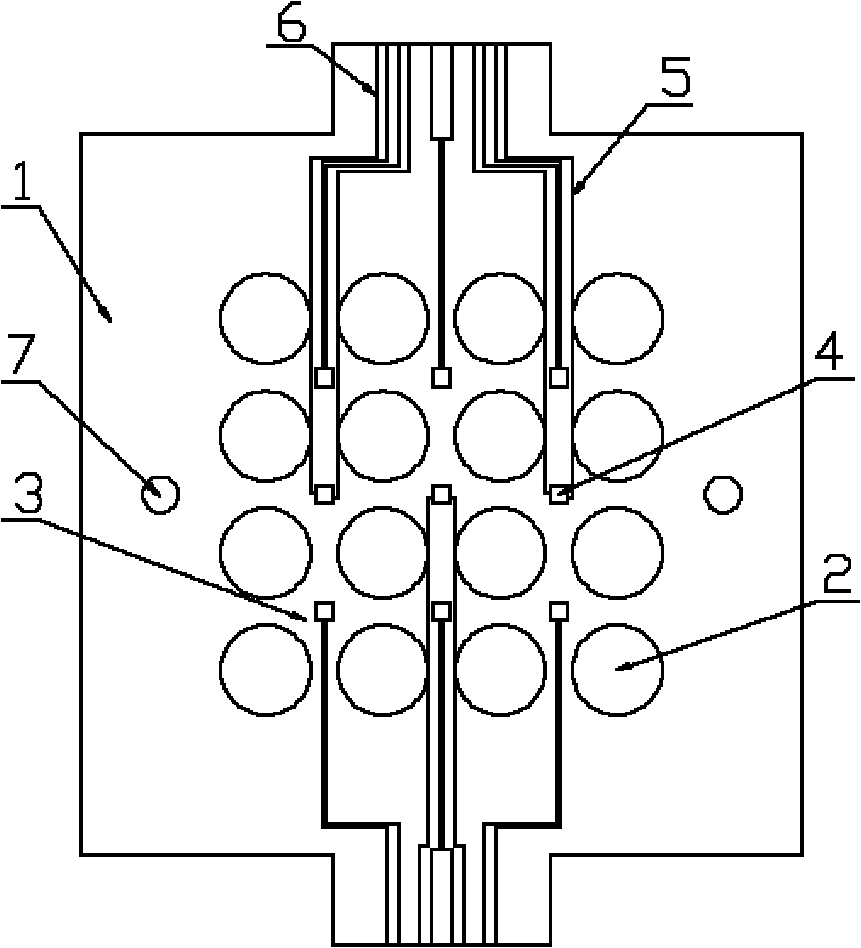

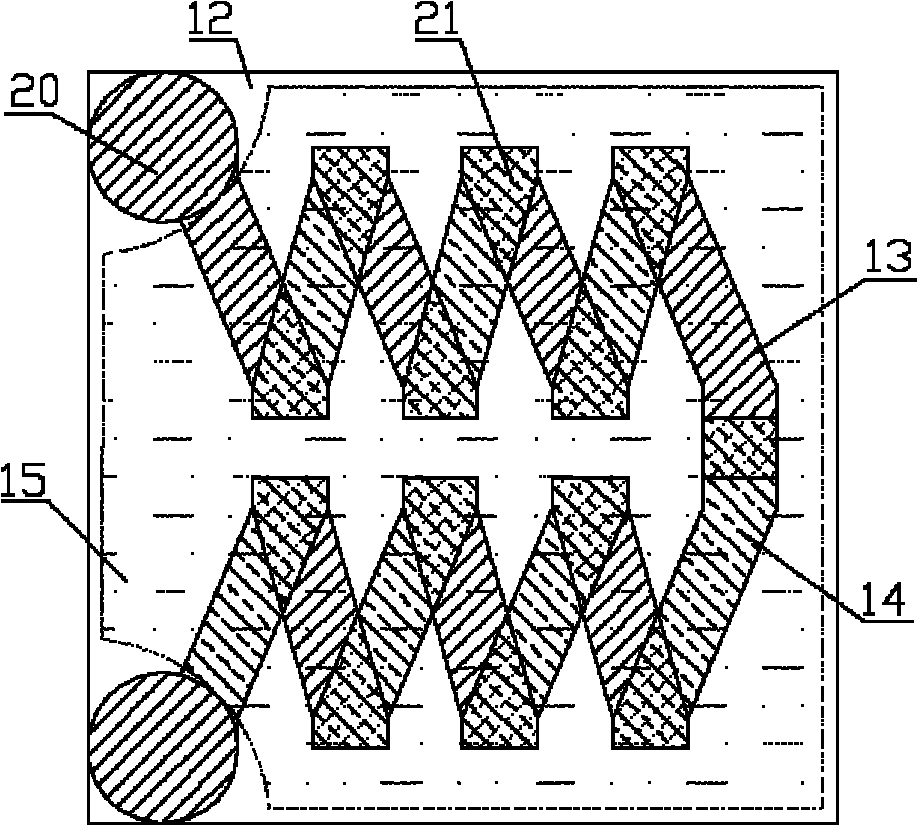

[0046] refer to figure 1 , figure 2 As shown, the position and quantity of the standard connection ports of the transient film thermocouple inserts can be set according to the requirements. The substrate 1 is a thin sheet with good conductivity, which is made of double-sided gold plating on a stainless steel plate. like figure 1 , figure 2 , image 3 As shown, the present invention includes a gold-plated stainless steel substrate 1, the thickness of the gold-plated layer is 0.08-0.1 μm, and the substrate 1 is provided with grooves and ridges of the fuel cell flow channel, which have the same geometric size and shape and corresponding geometric positions. The leaky seam 2 and the rib 3 are coated with a thin film thermocouple 4 on the entire surface of the rib 3, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com