Application of preferred indium tin oxide with (400) crystal plane on transparent thin-film thermocouple

A technology of indium tin oxide and transparent thin film, which is applied in the direction of directly heat-sensitive electrical/magnetic element thermometers, heat measurement, and electrical devices, etc., which can solve the high cost and power consumption of indium tin oxide transparent thin film thermocouples Time length, anti-oxidation failure and other issues, to achieve the effect of facilitating large-scale industrial production, high Seebeck coefficient, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

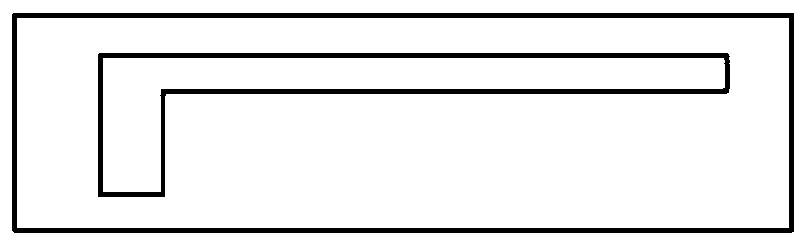

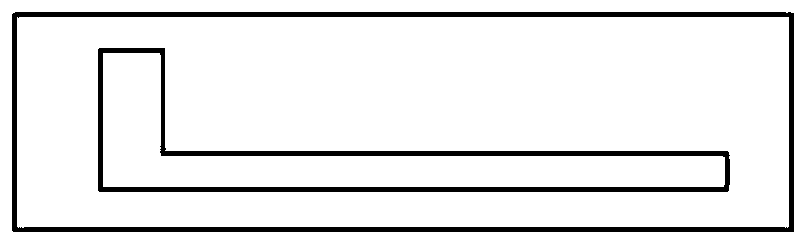

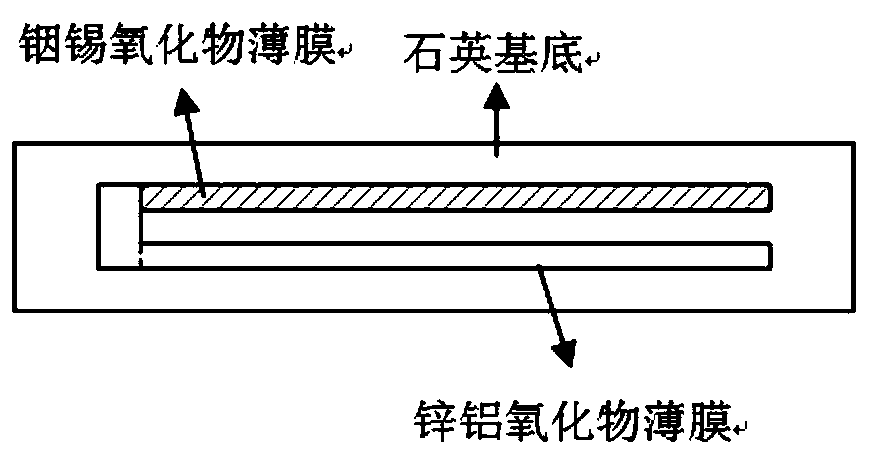

[0020] An application of indium tin oxide with (400) crystal face preference on a transparent thin film thermocouple, using a DC pulse magnetron sputtering method at natural room temperature with a quartz plate as the base material, such as figure 1 The mask plate shown is placed on the base material, and the zinc-aluminum oxide is used as the sputtering target. The purity of the zinc-aluminum oxide is 99.99%, wherein: the mass percentage of zinc oxide is 98wt.%. The mass percentage is 2wt.%, with argon as the sputtering gas, the purity of argon is 99.99%, and the zinc-aluminum oxide film electrode in the transparent film thermocouple is prepared by magnetron sputtering, and the thickness of the zinc-aluminum oxide film pole is 1500nm; Then, using the method of DC pulse magnetron sputtering at natural room temperature with the above-mentioned quartz plate deposited with zinc-aluminum oxide as the base material, the figure 2 The mask plate shown is placed on the base material...

Embodiment 2

[0025] An application of indium tin oxide with (400) crystal face preference on a transparent thin film thermocouple, using a DC pulse magnetron sputtering method at natural room temperature with a quartz plate as the base material, such as figure 1 The mask plate shown is placed on the base material, and the zinc-aluminum oxide is used as the sputtering target. The purity of the zinc-aluminum oxide is 99.99%, wherein: the mass percentage of zinc oxide is 98wt.%. The mass percentage is 2wt.%, with argon as the sputtering gas, the purity of argon is 99.99%, and the zinc-aluminum oxide film electrode in the transparent film thermocouple is prepared by magnetron sputtering, and the thickness of the zinc-aluminum oxide film pole is 1500nm; Then, use the method of radio frequency magnetron sputtering to use the above-mentioned quartz sheet deposited with zinc-aluminum oxide as the base material at natural room temperature, such as figure 2 The mask plate shown is placed on the ba...

Embodiment 3

[0030] An application of indium tin oxide with (400) crystal face preference on a transparent thin film thermocouple, using a DC pulse magnetron sputtering method at natural room temperature with a quartz plate as the base material, such as figure 1 The mask plate shown is placed on the base material, and the zinc-aluminum oxide is used as the sputtering target. The purity of the zinc-aluminum oxide is 99.99%, wherein: the mass percentage of zinc oxide is 98wt.%. The mass percentage is 2wt.%, with argon as the sputtering gas, the purity of argon is 99.99%, and the zinc-aluminum oxide film electrode in the transparent film thermocouple is prepared by magnetron sputtering, and the thickness of the zinc-aluminum oxide film pole is 600nm; Then, using the method of DC pulse magnetron sputtering at natural room temperature with the above-mentioned quartz plate deposited with zinc-aluminum oxide as the base material, the figure 2 The mask plate shown is placed on the base material,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com