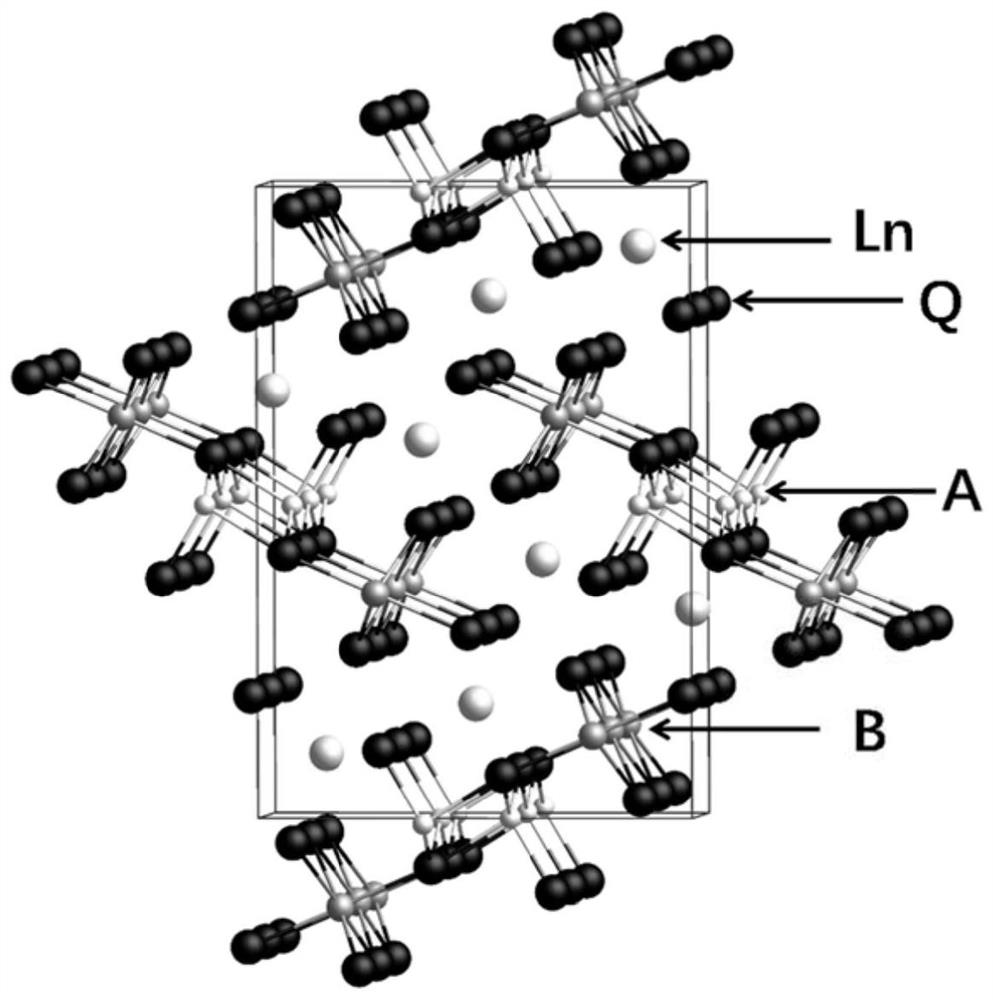

Compound capable of being used for thermoelectric material and preparation method of compound

A technology of thermoelectric materials and compounds, applied in thermoelectric device node lead-out materials, chemical instruments and methods, polycrystalline material growth, etc., can solve the problems of expensive raw materials, low thermoelectric conversion efficiency, simple preparation process, etc., and achieve environmental friendliness , low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] According to the second aspect of the present invention, a method for preparing a compound that can be used in thermoelectric materials is used to prepare the compound that can be used in thermoelectric materials in the first aspect, the compound is polycrystalline, including:

[0034] (1) Press Ln 2 ABQ 5 The chemical composition ratio selects the corresponding elemental substance or chalcogen compound as the raw material, weighs and mixes it under an inert atmosphere;

[0035] (2) Put the raw material into a sealed container such as a quartz glass tube that is isolated from water and oxygen, and then seal it after vacuuming; the sealed container such as a quartz glass tube after packaging is carried out at 500 ° C to 700 ° C for the first solid phase reaction, The reaction time is 12h-48h; after opening the closed container such as quartz glass tube, grinding and repackaging, the second solid phase reaction is carried out at 500°C-700°C, the reaction time is 48h-96h,...

Embodiment 1

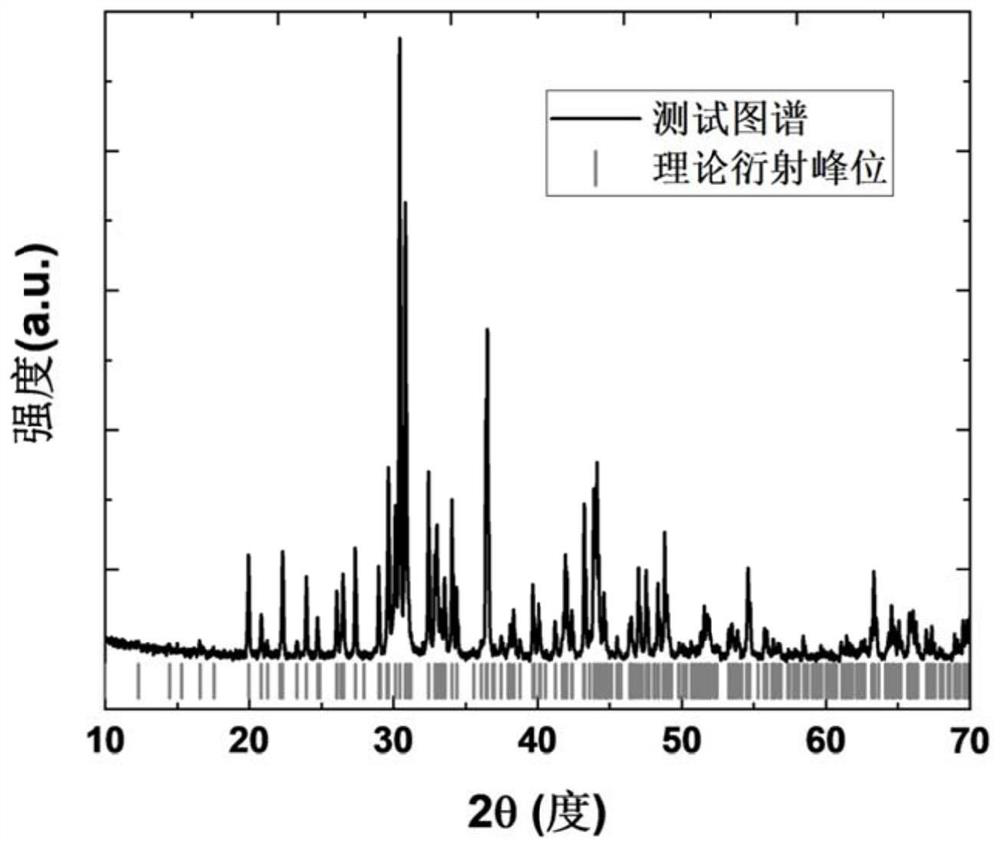

[0048] La block, Cu powder, Sb powder and Se powder (mass percentage purity is respectively 99.9%, 99.99%, 99.99% and 99.999% the same below) in the glove box that is full of Ar gas according to La 2 CuSbSe 5 The stoichiometric ratio was weighed, mixed and vacuum-packed in a quartz glass tube, and then placed in a muffle furnace and slowly heated to 700°C for 24 hours. After the tube is opened, the powder is ground and repackaged, then placed in a muffle furnace and slowly raised to 700°C, reacted for 96 hours, and cooled with the furnace. The obtained pure phase powder is subjected to SPS sintering at a temperature of 500°C and 50Mpa, and finally a bulk thermoelectric material is made.

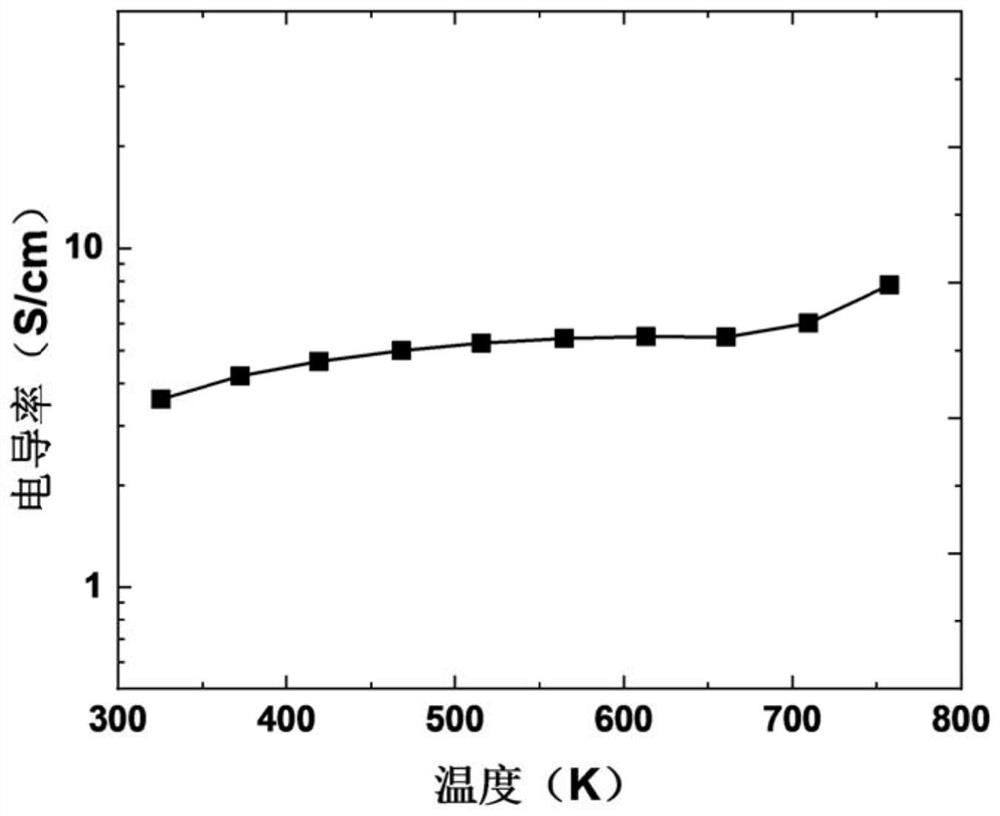

[0049] XRD diffraction patterns of bulk thermoelectric materials ( figure 2 ) indicates that a pure-phase polycrystalline sample was prepared by the above process. The material has good electrical conductivity, and the conductivity at room temperature is as high as 3.5S / cm ( image 3 ), ...

Embodiment 2

[0051] La block, Cu powder, Sb powder and Se powder were placed in a glove box filled with Ar gas according to La 2 CuSbSe 5 The stoichiometric ratio was weighed, mixed and vacuum-packed in a quartz glass tube, and then placed in a muffle furnace and slowly heated to 700°C for 24 hours. After the tube was opened, the powder was ground and repackaged, and then placed in a muffle furnace and slowly raised to 950°C for melting reaction. The reaction time was 12 hours, and then slowly lowered to room temperature. The obtained pure phase powder is subjected to SPS sintering at a temperature of 500°C and 50Mpa, and finally a bulk thermoelectric material is made.

[0052] The XRD diffraction pattern of the bulk thermoelectric material is similar to that of Example 1, indicating that a pure-phase polycrystalline sample is prepared by the above process. The electrical conductivity, Seebeck, thermal conductivity at room temperature, and thermoelectric figure of merit at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com