Application of indium tin oxide with (400) crystal plane preference on transparent thin film thermocouple

An indium tin oxide and transparent film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem of high cost, long time consumption, anti-oxidation failure, etc. of indium tin oxide transparent film thermocouples problem, to achieve the effect of convenient large-scale industrial production, high Seebeck coefficient, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

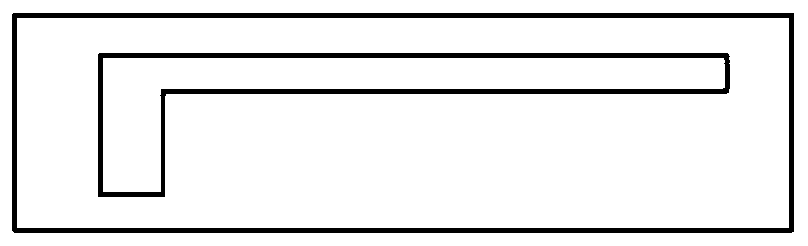

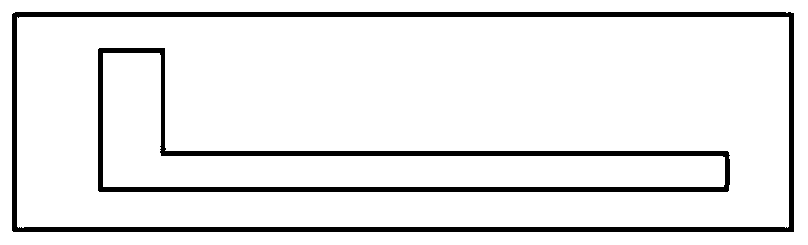

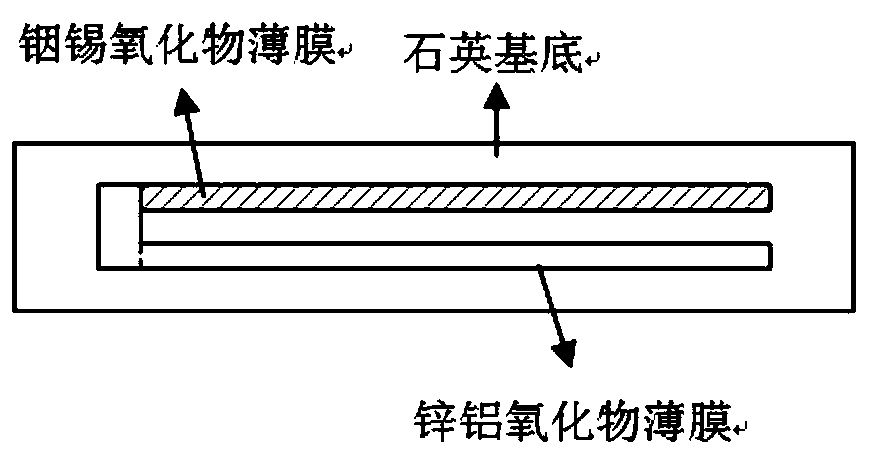

[0021] An application of indium tin oxide with (400) crystal face preference on a transparent thin film thermocouple, using a DC pulse magnetron sputtering method at natural room temperature with a quartz plate as the base material, such as figure 1 The mask plate shown is placed on the base material, and the zinc-aluminum oxide is used as the sputtering target. The purity of the zinc-aluminum oxide is 99.99%, wherein: the mass percentage of zinc oxide is 98wt.%. The mass percentage is 2wt.%, with argon as the sputtering gas, the purity of argon is 99.99%, and the zinc-aluminum oxide film electrode in the transparent film thermocouple is prepared by magnetron sputtering, and the thickness of the zinc-aluminum oxide film pole is 1500nm; Then, using the method of DC pulse magnetron sputtering at natural room temperature with the above-mentioned quartz plate deposited with zinc-aluminum oxide as the base material, the figure 2 The mask plate shown is placed on the base material...

Embodiment 2

[0026] An application of indium tin oxide with (400) crystal face preference on a transparent thin film thermocouple, using a DC pulse magnetron sputtering method at natural room temperature with a quartz plate as the base material, such as figure 1 The mask plate shown is placed on the base material, and the zinc-aluminum oxide is used as the sputtering target. The purity of the zinc-aluminum oxide is 99.99%, wherein: the mass percentage of zinc oxide is 98wt.%. The mass percentage is 2wt.%, with argon as the sputtering gas, the purity of argon is 99.99%, and the zinc-aluminum oxide film electrode in the transparent film thermocouple is prepared by magnetron sputtering, and the thickness of the zinc-aluminum oxide film pole is 1500nm; Then, use the method of radio frequency magnetron sputtering to use the above-mentioned quartz sheet deposited with zinc-aluminum oxide as the base material at natural room temperature, such as figure 2 The mask plate shown is placed on the ba...

Embodiment 3

[0031] An application of indium tin oxide with (400) crystal face preference on a transparent thin film thermocouple, using a DC pulse magnetron sputtering method at natural room temperature with a quartz plate as the base material, such as figure 1The mask plate shown is placed on the base material, and the zinc-aluminum oxide is used as the sputtering target. The purity of the zinc-aluminum oxide is 99.99%, wherein: the mass percentage of zinc oxide is 98wt.%. The mass percentage is 2wt.%, with argon as the sputtering gas, the purity of argon is 99.99%, and the zinc-aluminum oxide film electrode in the transparent film thermocouple is prepared by magnetron sputtering, and the thickness of the zinc-aluminum oxide film pole is 600nm; Then, using the method of DC pulse magnetron sputtering at natural room temperature with the above-mentioned quartz plate deposited with zinc-aluminum oxide as the base material, the figure 2 The mask plate shown is placed on the base material, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com