PEDOT: PSS self-supporting thermoelectric film and preparation method thereof

A thermoelectric thin-film, self-supporting technology, applied in the manufacture/processing of thermoelectric devices, and lead-out materials for thermoelectric device junctions. performance, improved conductivity, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

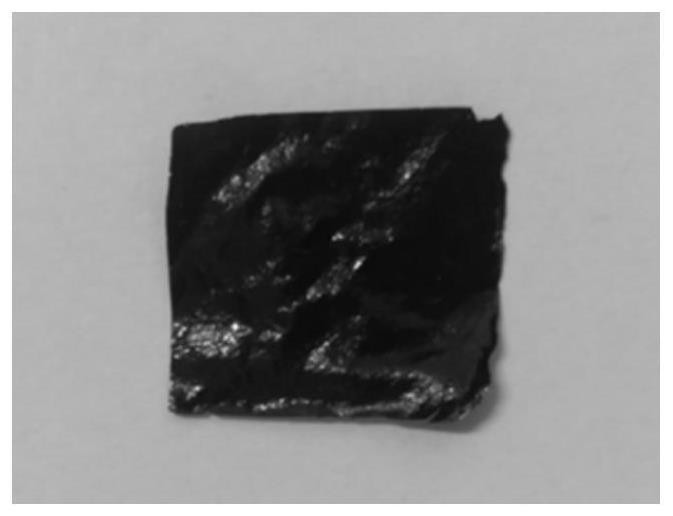

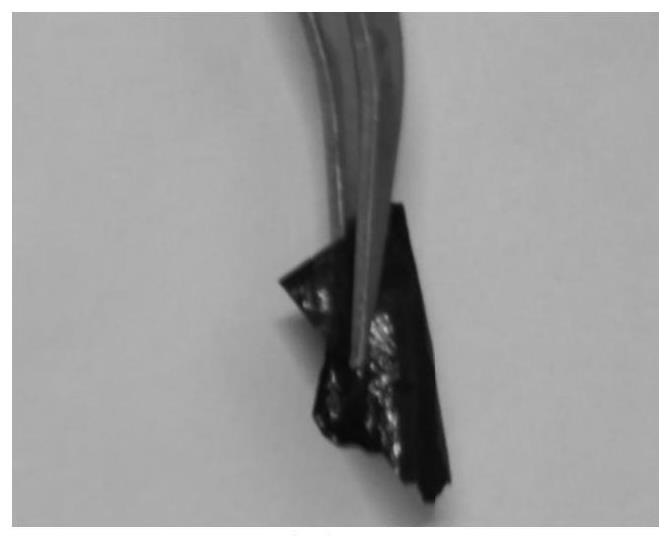

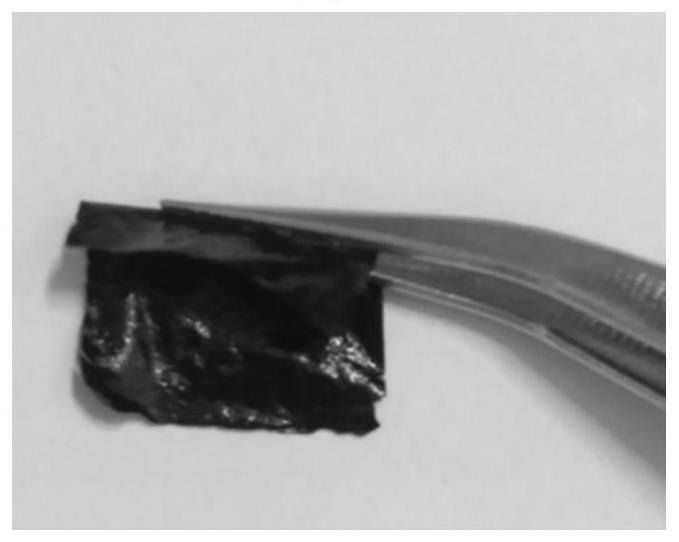

Image

Examples

preparation example Construction

[0030] A kind of high-performance PEDOT of the present invention: The preparation method of PSS self-supporting thermoelectric thin film comprises the following steps:

[0031] Step 1: Clean the glass substrate with deionized water, acetone, and isopropanol in sequence, and then dry it;

[0032] Step 2: Drop-coat 100-300 μL of PEDOT:PSS aqueous solution (Clevious PH1000) onto the glass substrate obtained in Step 1, place in a vacuum drying oven, and dry at 50-100°C for 8-12 hours to obtain film A;

[0033] PEDOT:PSS aqueous solution is a commercial product, the specification is Clevious PH1000, the specific information is as follows:

[0034]

[0035] Step 3: soak the film A obtained in step 2 in an organic polar solvent for 5-20 minutes, then take it out, rinse it with deionized water for 2-3 times, and dry it at 60-80°C for 10-20 minutes to obtain film B;

[0036] The organic polar solvent is ethylene glycol, formamide, N,N-dimethylformamide, sorbitol, dimethyl sulfoxide...

Embodiment 1

[0039] Step 1: Clean the glass substrate with deionized water, acetone, and isopropanol in sequence, and then dry it;

[0040] Step 2: Drop-coat 100 μL of PEDOT:PSS aqueous solution (Clevious PH1000) onto the glass substrate obtained in Step 1, place it in a vacuum drying oven, and dry at 50°C for 8 hours to obtain Film A;

[0041] Step 3: soak the film A obtained in step 2 in ethylene glycol for 5 minutes, then take it out, rinse it twice with deionized water, and dry it at 60°C for 20 minutes to obtain film B;

[0042] Step 4: Drop the L-ascorbic acid solution with a concentration of 0.5 mol / L and a volume of 200 μL on the surface of the film B obtained in Step 3 until it is completely covered, rinse it with deionized water after staying for 20 minutes, and dry it at 60°C to obtain PEDOT:PSS self- The thermoelectric thin film C is supported.

Embodiment 2

[0044] Step 1: Clean the glass substrate with deionized water, acetone, and isopropanol in sequence, and then dry it;

[0045] Step 2: Drop-coat 200 μL of PEDOT:PSS aqueous solution (Clevious PH1000) onto the glass substrate obtained in Step 1, place it in a vacuum drying oven, and dry at 60°C for 12 hours to obtain film A;

[0046]Step 3: soak the film A obtained in step 2 in formamide (analytical pure) for 15 minutes, then take it out, rinse it with deionized water for 3 times, and dry it at 80°C for 15 minutes to obtain film B;

[0047] Step 4: Drop the L-ascorbic acid solution with a concentration of 1mol / L and a volume of 200 μL on the surface of the film B obtained in Step 3 until it is completely covered, rinse it with deionized water after staying for 5 minutes, and dry at 80°C to obtain PEDOT:PSS self- The thermoelectric thin film C is supported.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com