Artificial multi-layer structure strontium titanate thermoelectric material and preparation method thereof

A multi-layer structure, thermoelectric material technology, applied in the field of functional composite materials and thermoelectric materials, can solve the problem that the thermoelectric figure of merit cannot be improved, and achieve the effect of decreasing thermal conductivity, reducing thermal conductivity, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] The preparation of artificial multilayer structure strontium titanate thermoelectric material includes the following steps:

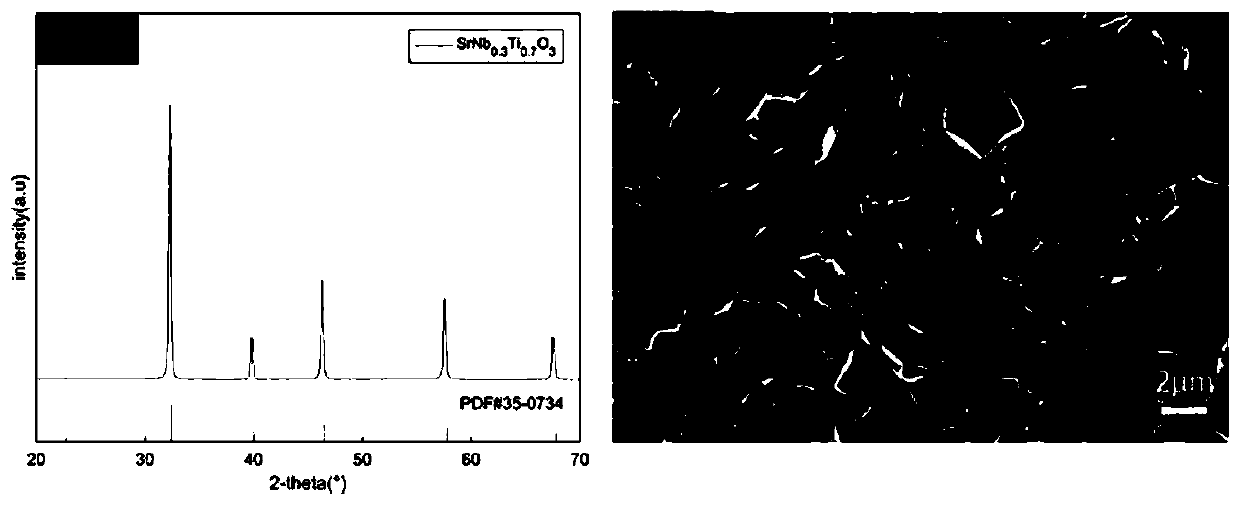

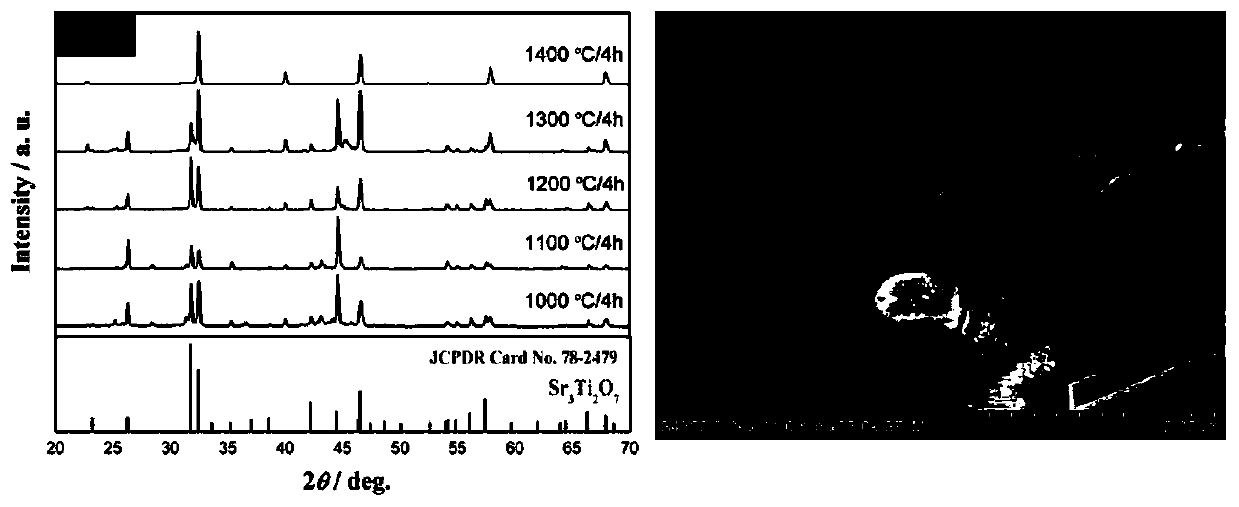

[0044] Step 1, first prepare cubic phase niobium-doped strontium titanate (SrTiO) 0.7 Nb 0.3 o 3 ) as the matrix phase. Raw materials are SrTiO 3 ,TiO 2 , Nb 2 o 5 . The sintering temperature is 1300-1400°C, the heating rate is 3°C-7°C, the holding time is 3h-5h, and the furnace is cooled. Then flake Sr was prepared by the molten salt method 3 Ti 1.7 Nb 0.3 o 7 As the embedded phonon scattering center phase, the raw materials are SrTiO 3 ,TiO 2 , Nb 2 o 5 . The type of molten salt is NaCl, the molar ratio of salt material is about (100:1), the sintering temperature is 1000℃~1400℃, the heating rate is 2℃ / min~6℃ / min, and the holding time is 3h~5h. cool down. The specific process parameters are shown in Table 1.

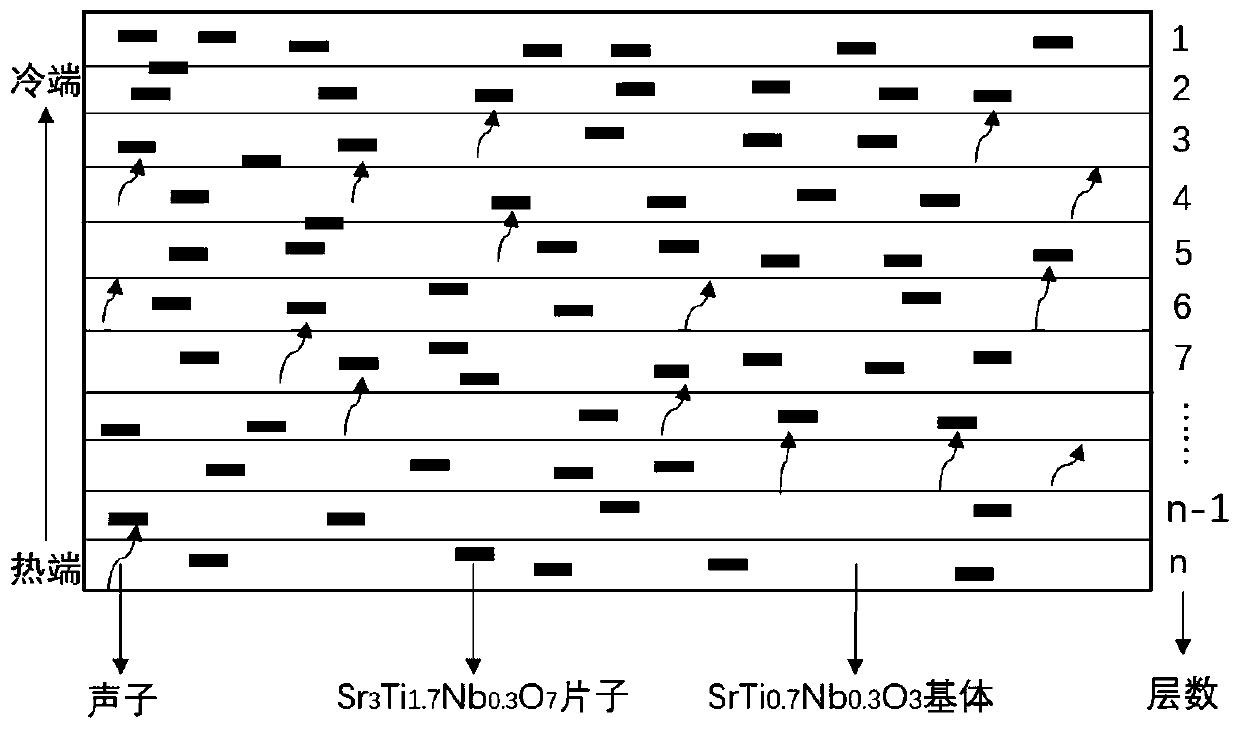

[0045] Step 2, the prepared SrTi 0.7 Nb 0.3 o 3 and Sr 3 Ti 1.7 Nb 0.3 o 7 The powders are mixed according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com