High-temperature ceramic base film thermocouple and manufacturing method thereof

A technology of high-temperature ceramics and thermocouples, which is applied in the manufacture/processing of thermoelectric devices, thermometers, and heat measurement. It can solve the problems of increased internal stress of the film, influence of sensor performance, and poor insulation, so as to improve thermal conductivity. Good dynamic response, the effect of preventing oxygen from entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

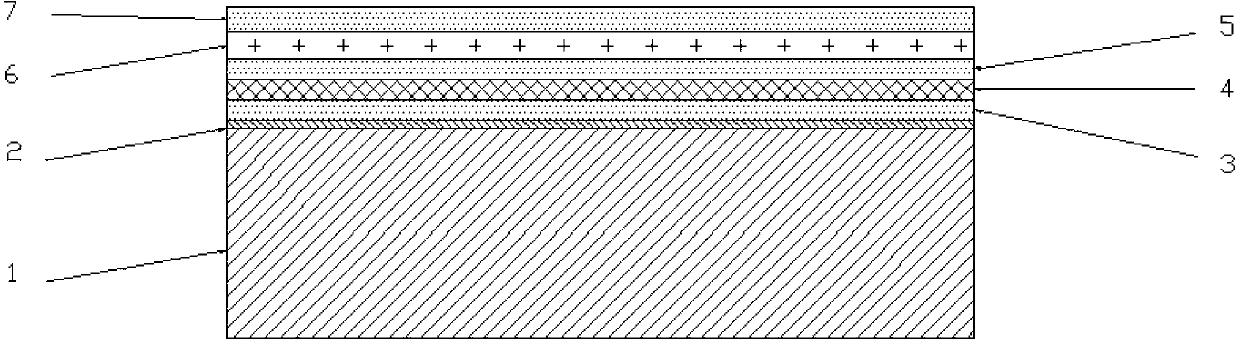

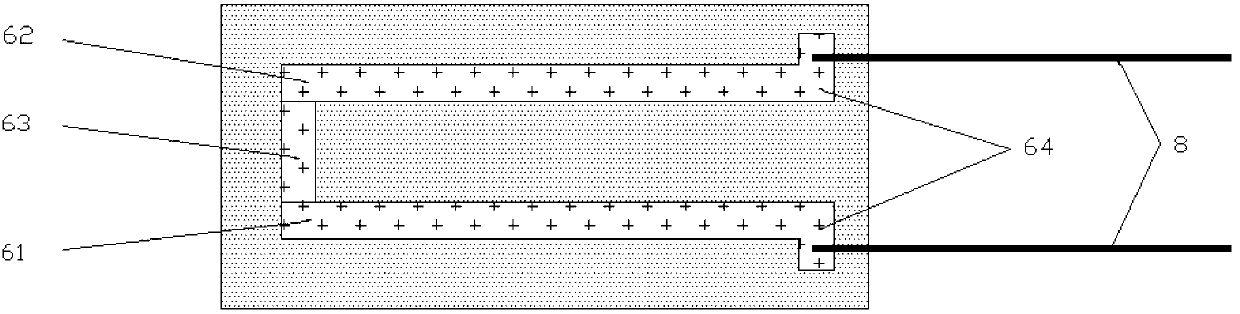

[0024] High-temperature ceramic-based thin-film thermocouples, which in turn include ceramic substrate 1, SiO 2 Layer 2, first Al 2 o 3 Layer 3, middle layer 4, second Al 2 o 3layer 5, thermocouple layer 6 and the third Al 2 o 3 layer 7; the thermocouple layer 6 includes thermocouple electrodes A61 and thermocouple electrodes B62 arranged in parallel, and the two are communicated through the thermocouple hot junction region 63; the thermocouple electrodes A61 and the thermocouple electrodes B62 pass through two The connection area 64 of two thermocouple films and wires communicates with two sections of compensation wires 8; the compensation wires 8 are made of the same material as the thermocouple electrodes. In this embodiment, the thermocouple electrode materials are S-type thermocouple electrodes specified by the national standard.

[0025] In this embodiment, the ceramic substrate 1 is a fiber-reinforced SiC ceramic composite material, and the first Al 2 o 3 layer 3...

Embodiment 2

[0035] High-temperature ceramic-based thin-film thermocouples, which in turn include ceramic substrate 1, SiO 2 Layer 2, first Al 2 o 3 Layer 3, middle layer 4, second Al 2 o 3 layer 5, thermocouple layer 6 and the third Al 2 o 3 layer 7; the thermocouple layer 6 includes thermocouple electrodes A61 and thermocouple electrodes B62 arranged in parallel, and the two are communicated through the thermocouple hot junction region 63; the thermocouple electrodes A61 and the thermocouple electrodes B62 pass through two The connection area 64 of the first thermocouple film and the wire communicates with two sections of compensation wire 8; the material of the compensation wire 8 is the same as that of the thermocouple electrode. In this embodiment, the material of the thermocouple electrode is the K-type thermocouple electrode specified by the national standard.

[0036] In this embodiment, the ceramic substrate 1 is a fiber-reinforced SiC ceramic composite material, and the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com