A multi-active area light-emitting diode with p-i-n tunnel junction

A p-i-n, light-emitting diode technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems affecting the performance of LEDs, affecting the quality of material crystals, etc., to achieve the effect of improving internal quantum efficiency, improving crystal quality, and increasing the probability of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

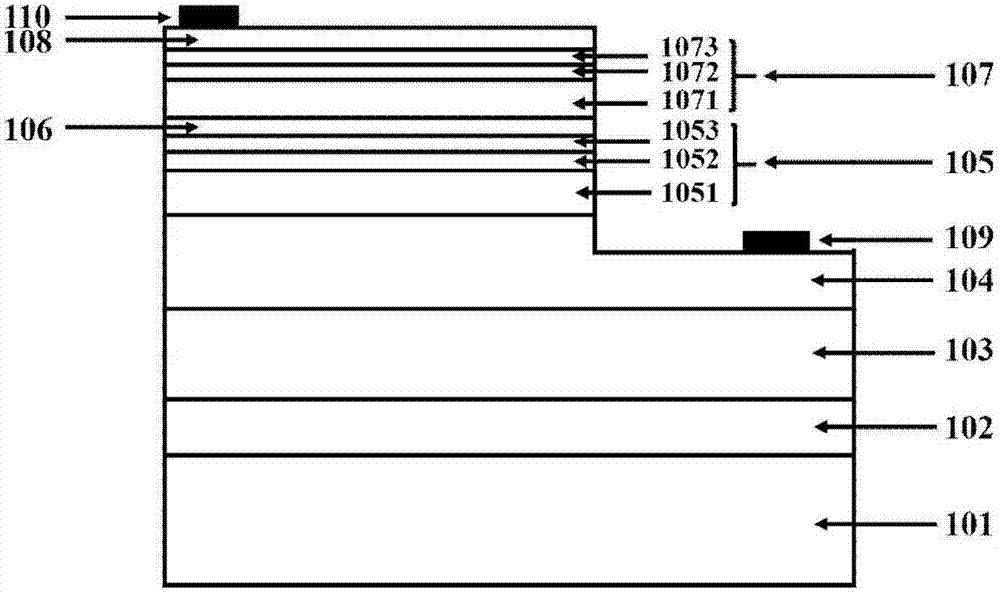

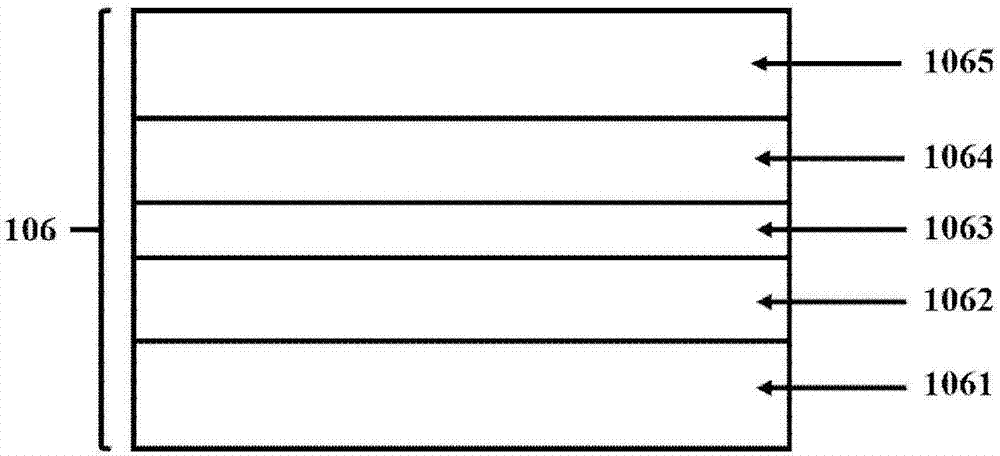

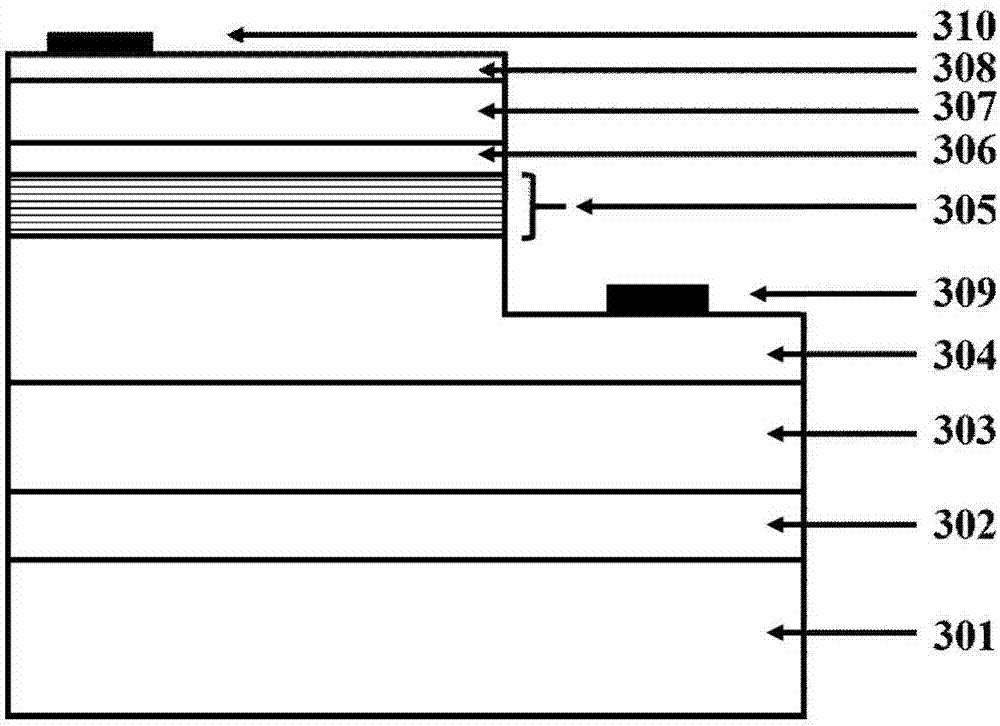

[0030] Such as figure 1 As shown, it is a multi-active-region LED with p-i-n tunnel junction provided by the present invention, which is characterized in that: from bottom to top, it includes a polar c-plane sapphire substrate 101, an AlN nucleation layer 102, an AlGaN buffer layer 103, and an n-type AlGaN layer 104, a first light emitting region 105, a p-i-n tunnel junction 106, a second light emitting region 107, and an indium tin oxide (ITO) conductive layer 108, wherein the light emitting region is made of Al x1 Ga 1-x1 N / Al x2 Ga 1-x2 N multiple quantum well active regions 1051 and 1071, p-type Al x3 Ga 1-x3 N electron blocking layers 1052 and 1072 and p-type AlGaN hole injection layers 1053 and 1073, where x 1 2 3 , lead out the n-electrode 109 and the p-electrode 110 on the n-region and the ITO conductive layer respectively. figure 2 A schematic diagram of the p-i-n tunnel junction layer structure of the multi-active area LED with p-i-n tunnel junction provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com