A kind of gan epitaxy process method

An epitaxial process and process technology, applied in chemical instruments and methods, sustainable manufacturing/processing, crystal growth, etc., can solve the problems of large differences in lattice constants, affecting the quality of GaN epitaxy, and large adaptability, and achieve relief Effects of lattice mismatch, improvement of epitaxial quality, and reduction of lattice defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0020] Such as Figure 2-Figure 5 As shown, a GaN epitaxial process method of the present invention specifically includes the following steps:

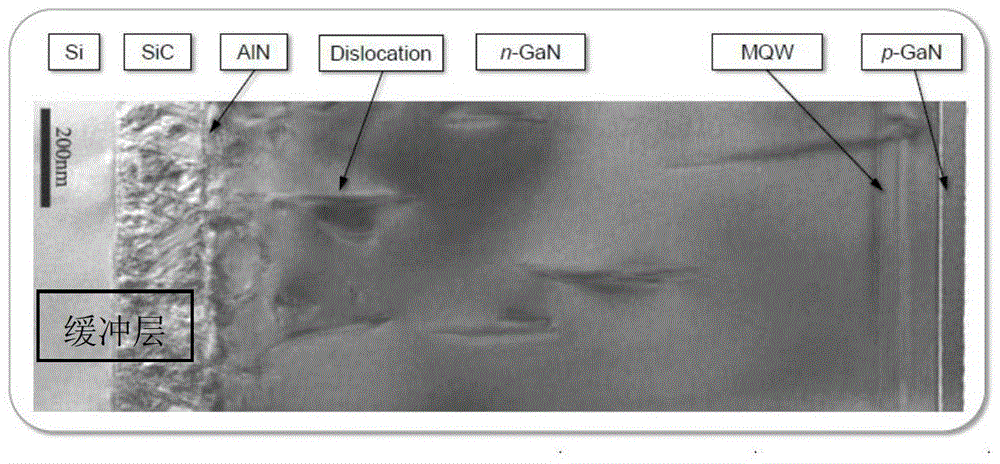

[0021] 1) if figure 2 As shown, Si is grown on a silicon substrate 10 with a crystal orientation of (111) (1-x-y) GexCy buffer layer 11; the surface crystal orientation of silicon substrate 10 is (111), Si (1-x-y) The GexCy buffer layer 11 satisfies: 8.2%≤x / y≤10.7%, and the thickness of the buffer layer 11 is 1-100nm. It is grown by vapor phase epitaxy or ultra-high vacuum chemical vapor deposition, the growth temperature is 500-1000 degrees Celsius, and the reaction gas source is SiH 4 or DCS (dichlorodihydrosilane), GeH 4 , SiH 3 CH 3 and H 2 .

[0022] 2) if image 3 As shown, gradually reduce the Si (1-x-y) The content of Ge in the GexCy buffer layer 11 is until it is 0, thereby growin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com