Micro-nano fluid system and preparation method thereof

A fluid system, micro-nano technology, applied in the field of micro-nano fluid system and its preparation, can solve the problems of weak control performance, limited characterization means, single function, etc., and achieve the effect of compact structure, effective thermal conductivity, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

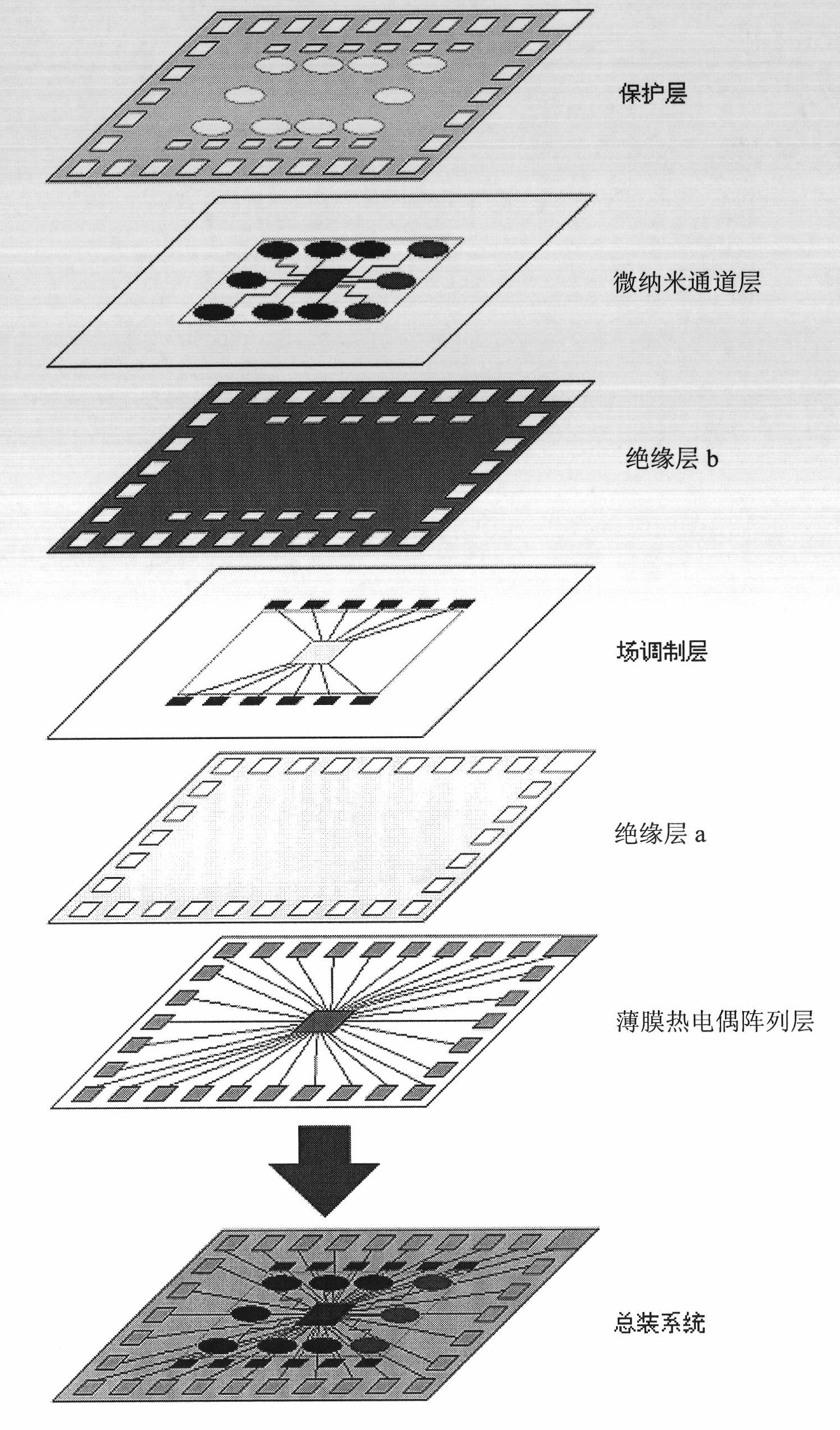

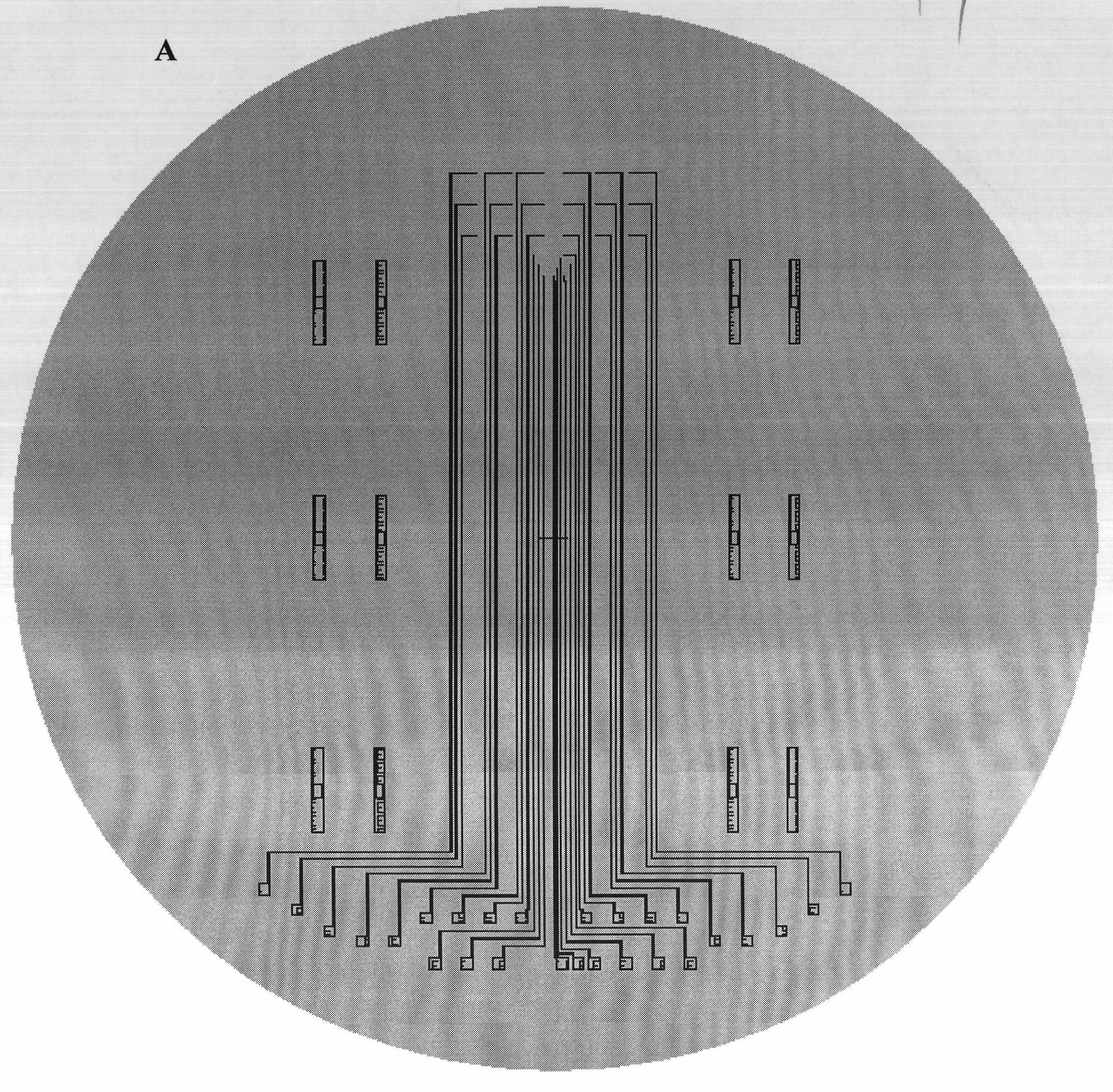

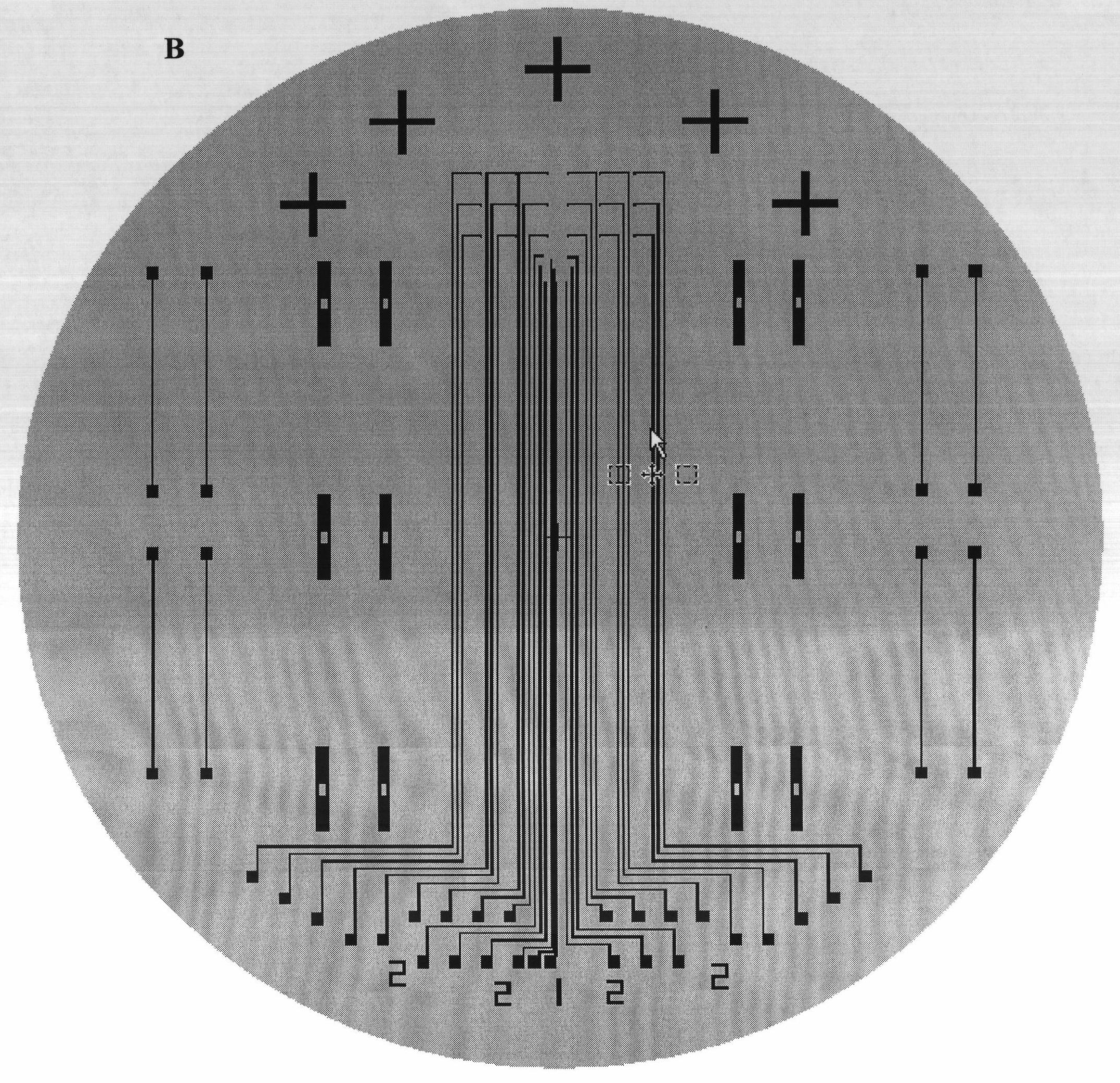

[0046] 1) Design and prepare mask plates A and B and use mask plates A and B to prepare thin-film thermocouple array layers:

[0047] Design masks A and B according to the following requirements of the thin-film thermocouple array layer: the thermocouple array layer is composed of a thin-film thermocouple array, and the array is a 3*3 (3 thin-film thermocouples in each column, 3 columns in total) array; Each thermocouple has two arms, the width of the main part of each arm is 50 μm, and the distance between the two arms of each thermocouple is 60 μm, and the distance between two adjacent thermocouples is 3mm; each The overlapping area of the two arms of each thermocouple is used as the hot end, which is a square of 20 μm×20 μm, and the width of the thermocouple arms near the hot end is changed from 50 μm to 20 μm; the other end of the thermocouple is used as the cold end, and each thermocouple’s The two arms are respectively led out to two lead-out electrodes with a size of ...

Embodiment 2

[0064] Carry out step 1)-step 4) according to step 1)-step 4) in embodiment 1 identical step;

[0065] 5) After placing a new molybdate nanowire (100 μm in length and 150 nm in diameter) on the insulating layer b obtained in step 4), prepare the micro-nano channel layer according to the following steps a-step e:

[0066] a, select the negative glue SU-8 that the model that MicroChem company sells is 3010, prepare the SU-8 glue layer with the spin coating method, the uniform glue parameter is the rotating speed 3000rpm, and the spin coating time is 30s, placed molybdate nanowire Spin coating on the insulating layer b to obtain a SU-8 adhesive layer with a thickness of 10 μm;

[0067] b. Dry the SU-8 adhesive layer obtained in step a at 95°C for 3 minutes, then dry it for 2 minutes after exposure for 15 seconds, and develop it with SU-8 developer for 3 minutes. Since the nanowires are water-soluble, after the above development steps , and dry to obtain a micro-nano channel laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com