Probe-type thin film thermocouple temperature sensor and manufacturing method thereof

A technology of temperature sensor and thermocouple, applied in the direction of thermometers, thermometers, and parts of thermometers that are directly sensitive to heat/magnetic elements, can solve the problem of not being able to achieve real-time measurement of the temperature of the flow field on the inner wall of the engine, without considering the cold Problems such as terminal temperature compensation, difficulty in realizing flat substrate installation, etc., achieve the effect of overcoming insulation problems, overcoming online compensation, and facilitating installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

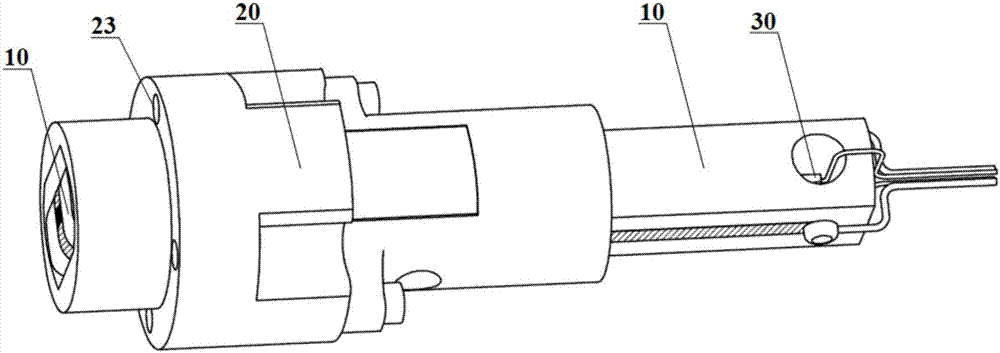

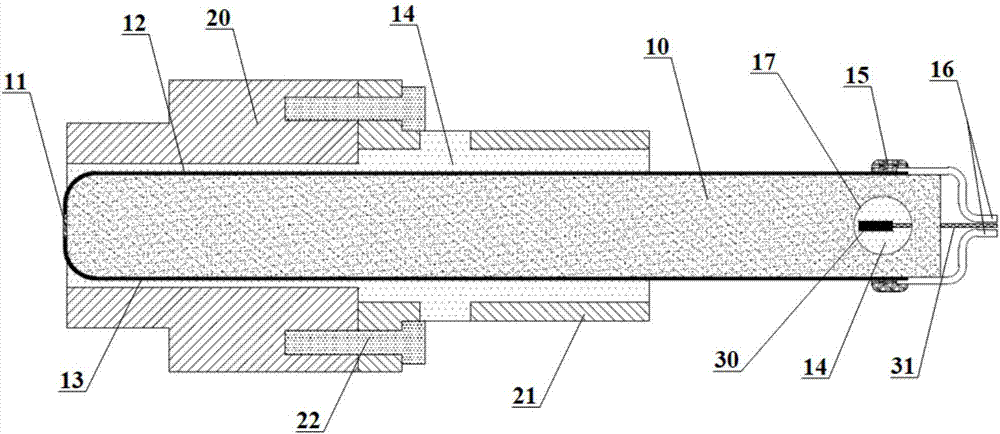

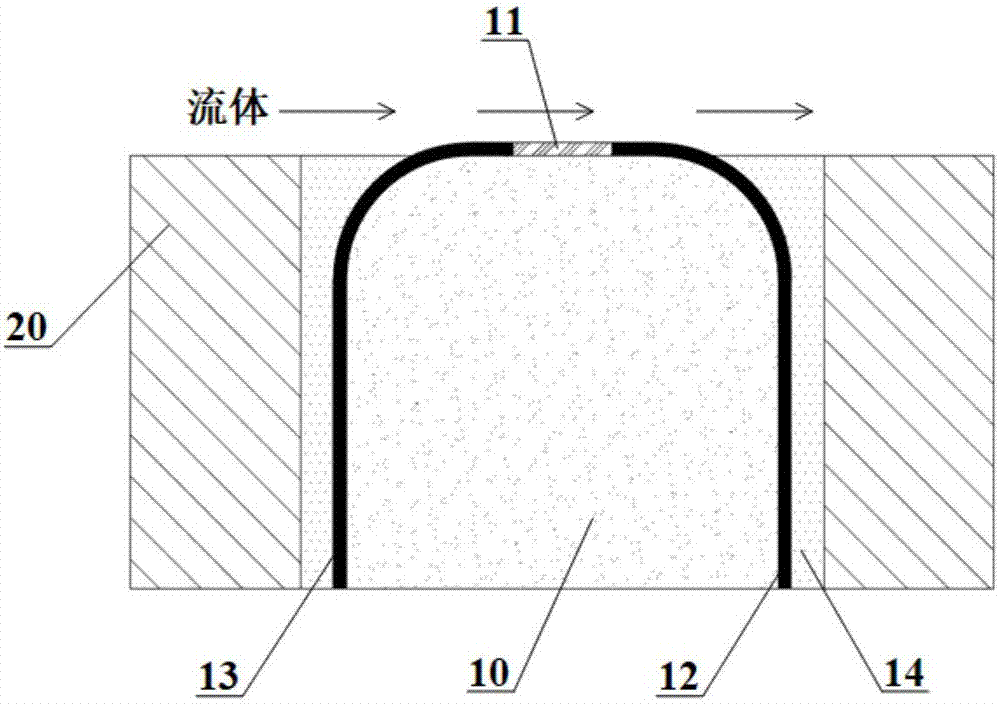

[0025] The probe-type thin-film thermocouple temperature sensor in this embodiment mainly includes a ceramic cylinder 10, a temperature measuring point 11, a first thin-film thermocouple arm 12, a second thin-film thermocouple arm 13, a ceramic insulating bonding agent 14, and a conductive silver paste. 15. Thin-film thermocouple leads 16, platinum resistor mounting holes 17; packaging shell 20, metal fixing sleeve 21, sleeve fixing screws 22, sensor fixing mounting holes 23; platinum resistor 30, platinum resistor lead wire 31. The temperature measuring point 11, the first thin-film thermocouple arm 12 and the second thin-film thermocouple arm 13 are prepared on the ceramic cylinder by thin-film deposition technology, and the performance of the thin-film thermocouple is stabilized by a heat treatment process; the ceramic cylinder 10 is passed through The ceramic insulating bonding agent 14 is packaged and fixed in the metal casing 20 and the metal fixing sleeve 21, and the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com