A follow-up rotary visual inspection device

A visual inspection device and rotary technology, which is applied in the direction of measuring devices, optical devices, and optical testing of flaws/defects, etc., can solve problems such as inability to realize continuous online inspection, failure to meet work requirements, slow speed, etc., and achieve dynamic measurement High speed, high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

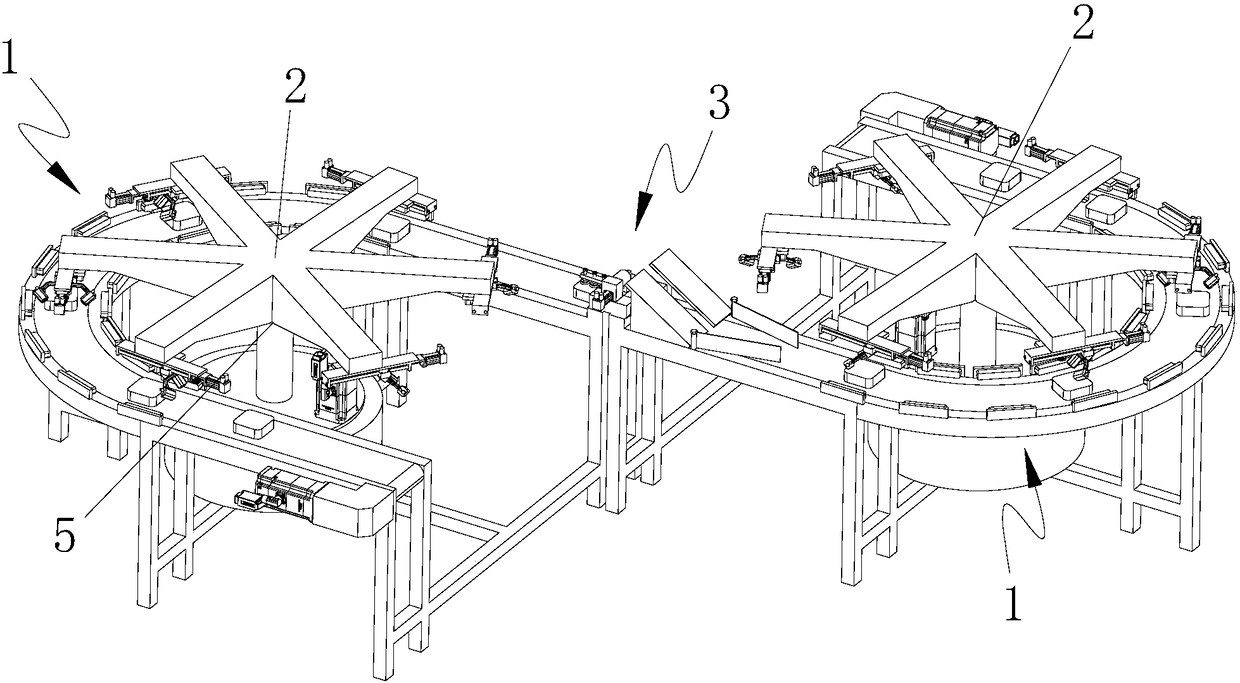

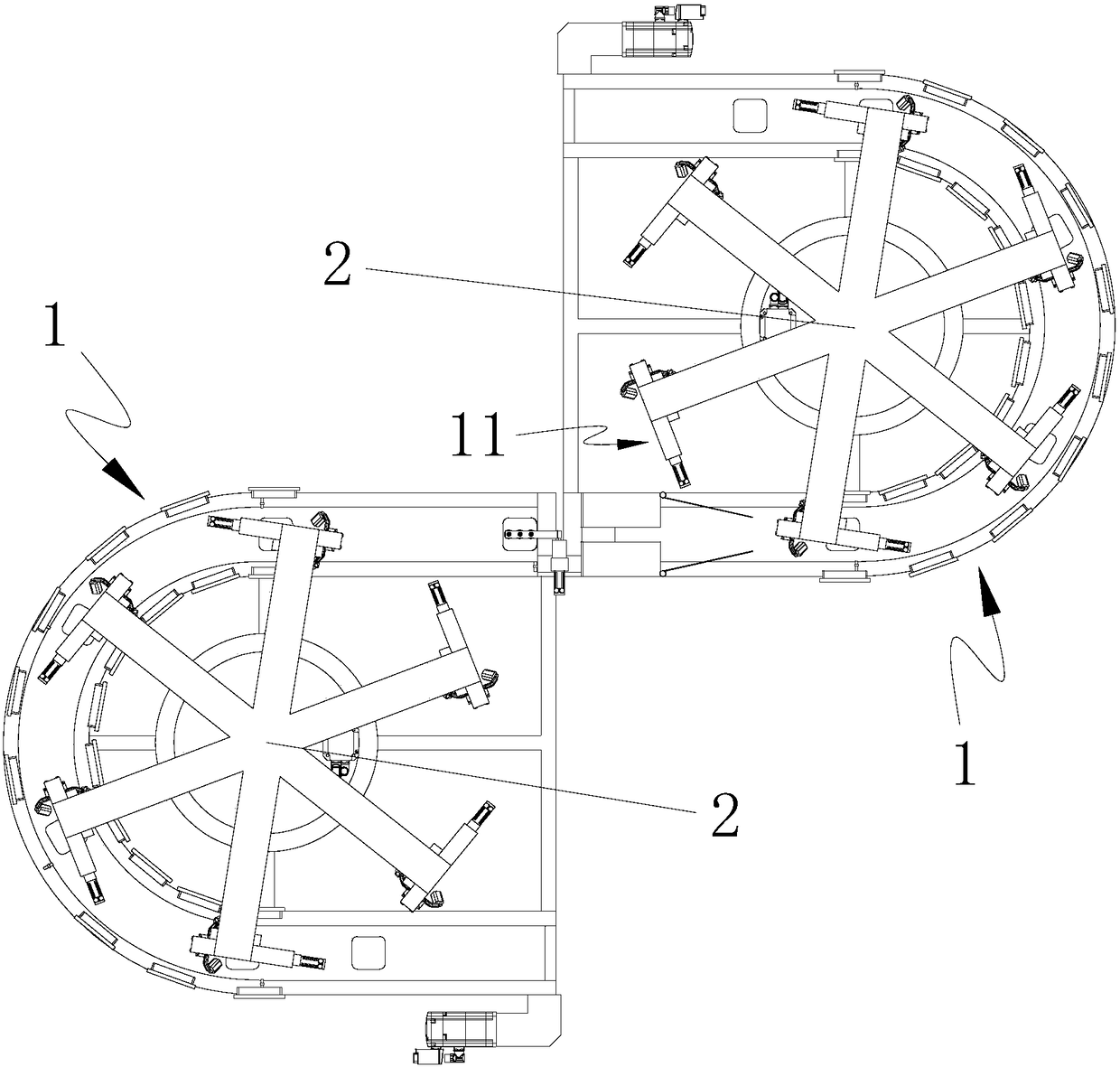

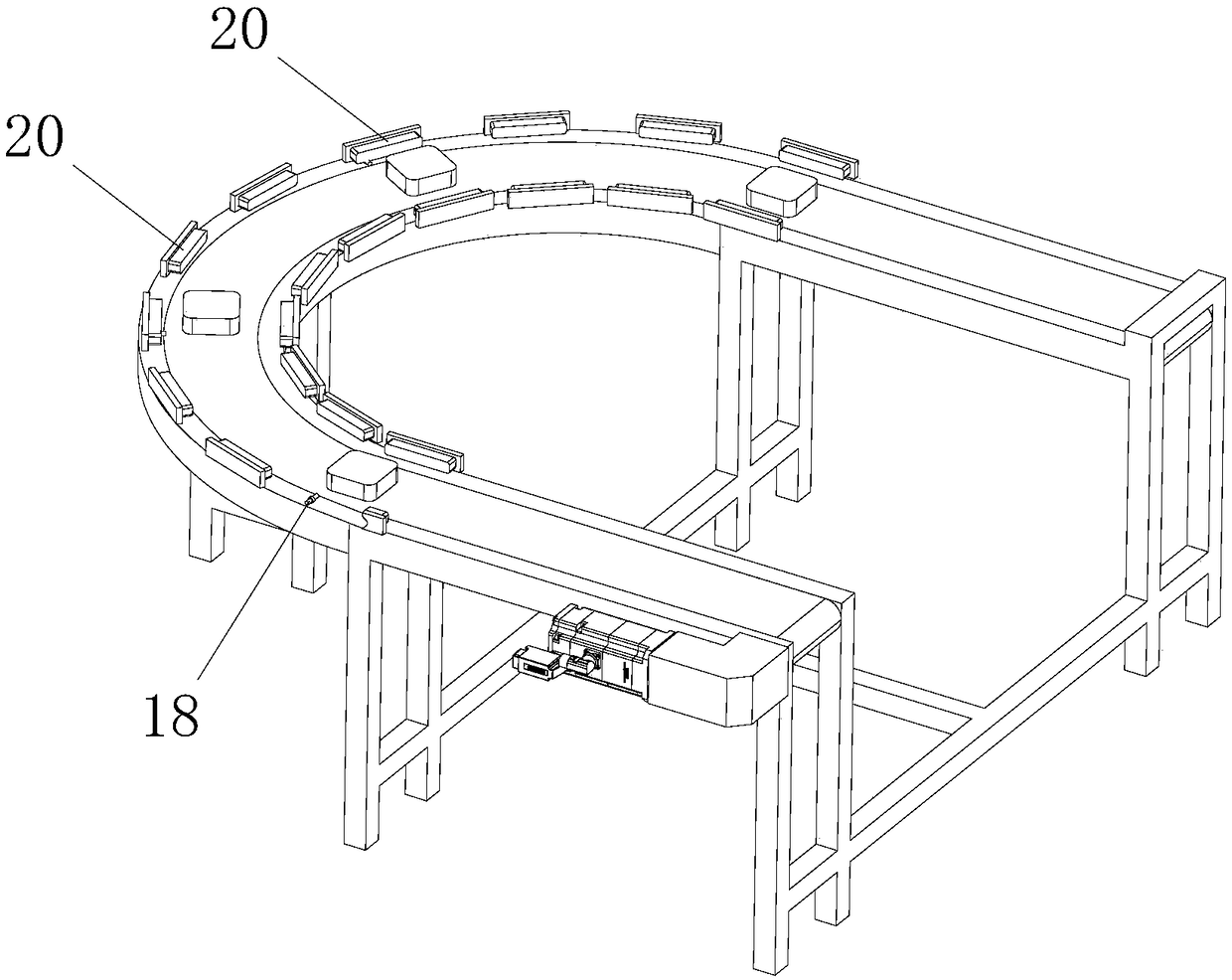

[0036] A follow-up rotary visual inspection device, comprising two U-shaped transmission platforms 1, two follow-up detection systems 2, and a workpiece turning mechanism 3, the two U-shaped transmission platforms are connected to form an S-shaped delivery platform , the follow-up detection system includes an image acquisition device 4 and a rotating platform 5 for driving the image acquisition device to rotate along the arc portion of the U-shaped transmission platform. The workpiece turnover mechanism is arranged at the joint of the two transmission platforms. The workpiece turnover mechanism It includes an overturning motor 6, an overturning arm 7, a suction cup 8, and a workpiece receiving inclined platform for receiving the overturned workpiece and sending the workpiece to another transmission platform. The overturning motor is connected with the overturning arm, and the suction cup is arranged on the overturning arm.

[0037] Preferably, the workpiece receiving ramp inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com