Dynamic test device and method for thread sealing performance of oil pipe adapter

A thread sealing and dynamic testing technology, applied in the field of oil pipes, can solve the problems of taking into account, and achieve the effect of ensuring the overall sealing performance, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

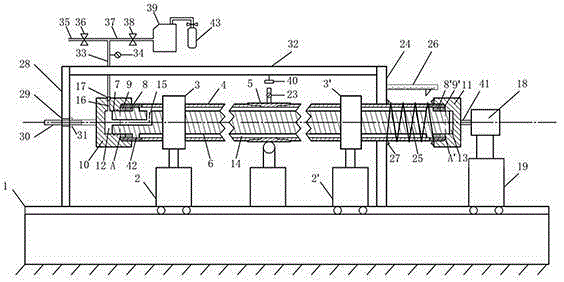

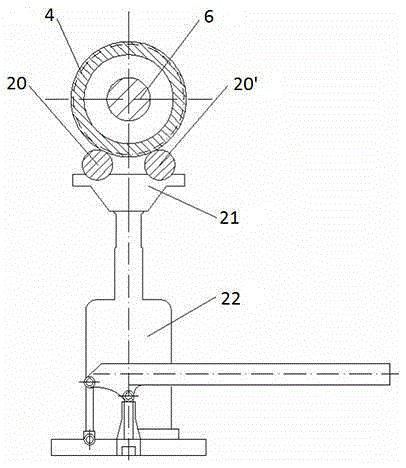

[0033] like figure 1As shown, a dynamic testing device for thread sealing performance of oil pipe joints includes a slide rail 1, a pad 2, an oil pipe holder 3, an oil pipe test piece 4, a collar 5, a core rod 6, a sealing assembly, a vibration exciter 18, Bending moment loading module, static load tensioning module, booster module, top plate 32, leak detector 38 and other components. The oil pipe test piece 4 is connected with a collar 5, and the core rod 6 is placed in the middle, and an annular cavity 14 is formed between the core rod 6 and the oil pipe test piece 4, and the oil pipe test piece 4 is clamped in the oil pipe holder 3, Both ends are sealed by sealing components, and the oil pipe holder 3 is symmetrically installed on the pad 2, and the pad 2 is placed on the slide rail 1 and can be translated and fixed on the slide rail 1; 18 contacts for applying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com