A photoinitiator mixed solution standard material and a preparing method thereof

A photoinitiator and standard substance technology, which is applied in the field of photoinitiator mixed solution standard substance and its preparation, can solve problems such as differences in delivery, difficult data comparison, and difficult arbitration of disputed data, so as to improve the consistency of comparison, The effect of reducing uncertainty and filling up blanks in research and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

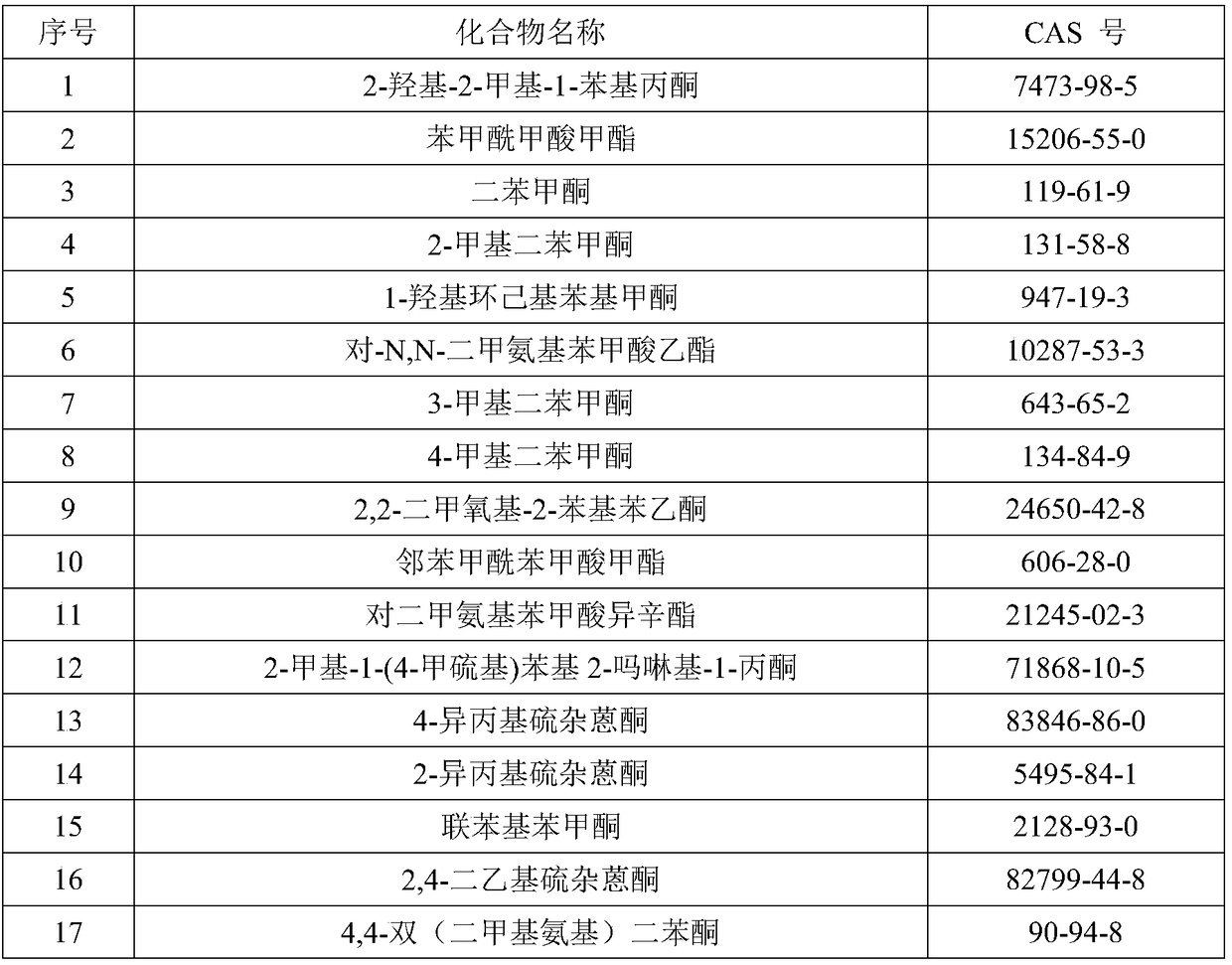

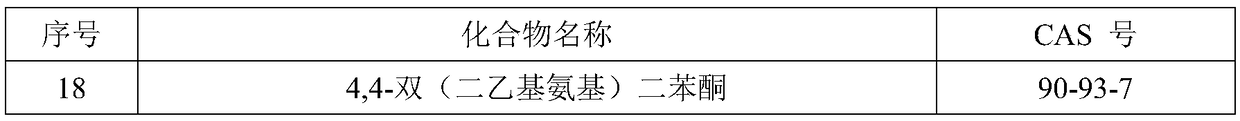

[0027] (1) Purchase 18 kinds of photoinitiator crude products from the market, use acetonitrile to make a nearly saturated solution, and prepare sample crystals by freezing and crystallization. Cool down to -18°C for 48 hours. Select the single crystal particles generated therein to prepare about 1 g of pure products of each initiator; use acetonitrile to dissolve each pure product, remove the solvent by rotary evaporation to obtain pure products with uniform content, and transfer them to brown storage samples .

[0028] (2) Determination and uncertainty evaluation of 18 kinds of photoinitiator pure products; according to GB / T 9740-2008 "General Method for Determination of Evaporation Residue of Chemical Reagents" to determine the evaporation residue a of each pure product; according to GB / T 6283 " Determination of moisture content in chemical products Karl Fischer method "Determination of horizontal content b in samples; use headspace-gas chromatography to determine residual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com