High-voltage side gate drive circuit capable of resisting noise interference

A gate drive circuit, high-voltage side technology, applied in the field of high-voltage power MOS gate drive and analog integrated circuits, can solve problems such as increasing the negative VS voltage, and achieve the effects of reducing power consumption, saving chip area, and facilitating integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

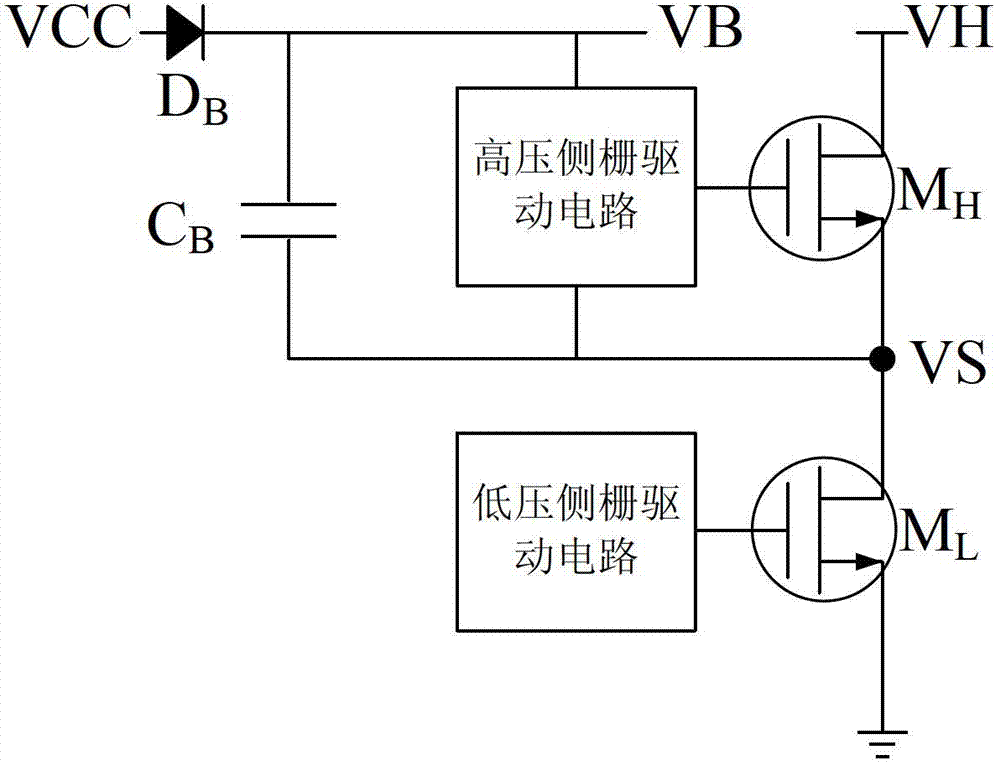

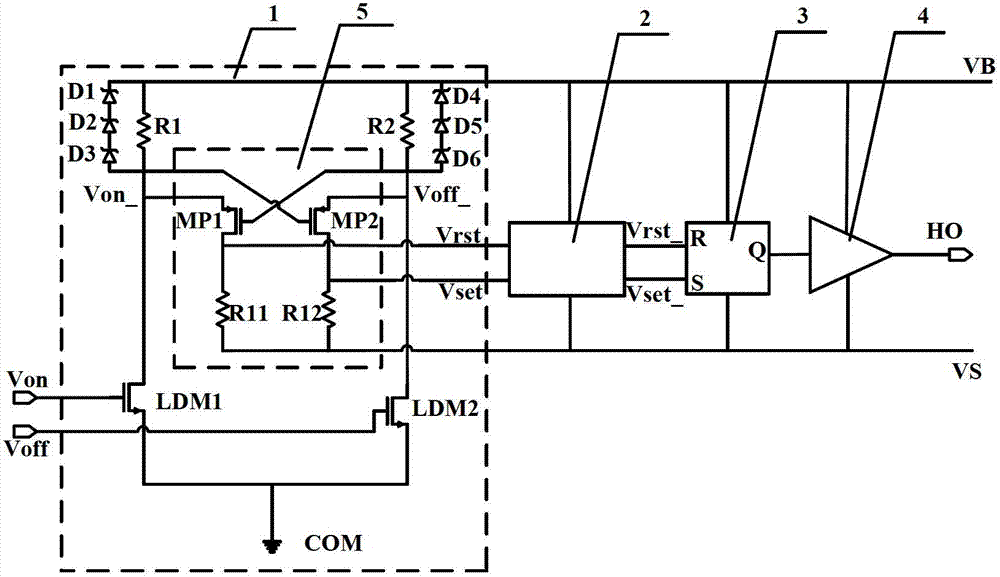

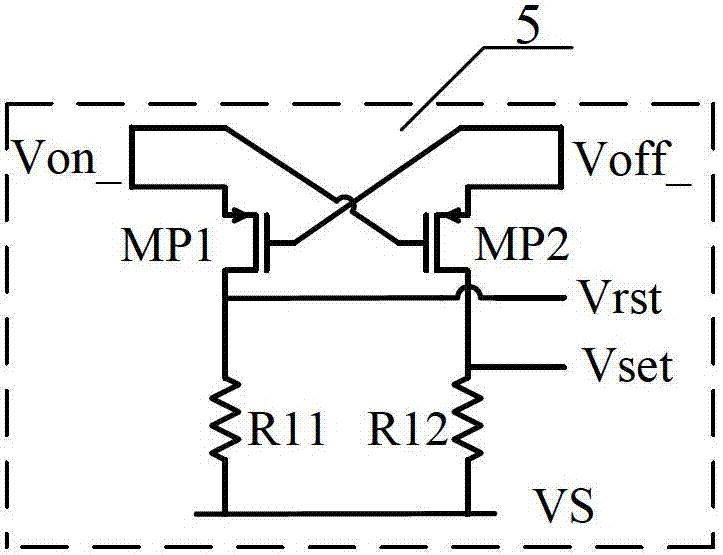

[0022]A high-voltage side gate drive circuit capable of resisting noise interference, comprising a high-voltage level shift circuit 1, a differential-mode noise elimination circuit 2, an RS flip-flop 3, an output driver stage circuit 4, a common-mode noise elimination circuit 5, and a high-voltage circuit The translation shift circuit 1 converts the input two-way low-voltage pulse signal into a high-voltage pulse signal output, and the high-voltage pulse signal enters the differential-mode noise elimination circuit 2 after passing through the common-mode noise elimination circuit 5, and the output signal of the differential-mode noise elimination circuit 2 passes through the RS The flip-flop 3 enters the output driver stage circuit 4, and the output driver stage circuit 4 outputs a drive signal to control the switch of the external power tube. It is characterized in that a common mode is provided between the high voltage level shift circuit 1 and the differential mode noise elim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com