A high-voltage gate drive circuit with anti-noise

A driving circuit and high-voltage gate technology, applied in logic circuit interface devices, eliminating voltage/current interference, logic circuit connection/interface layout, etc., to reduce conduction time, reduce power consumption, and reduce narrow pulse width required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

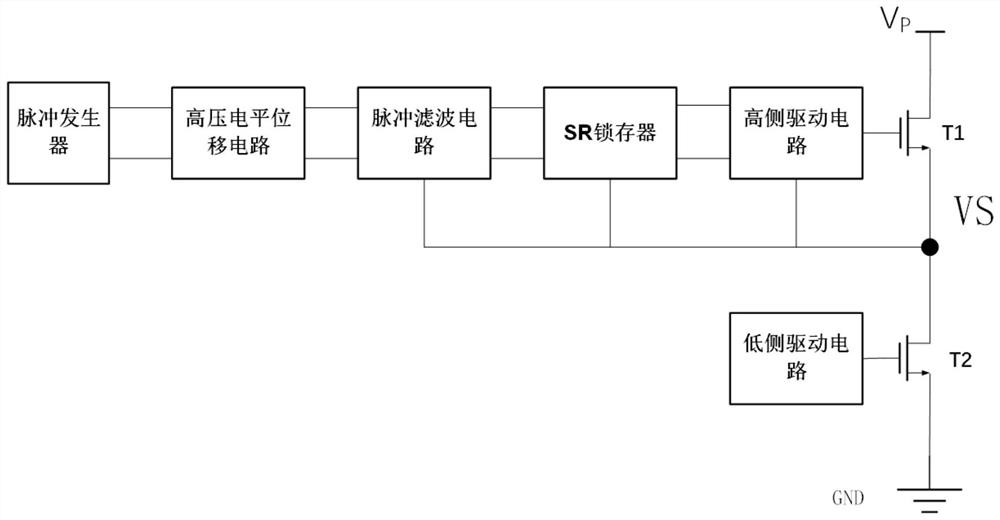

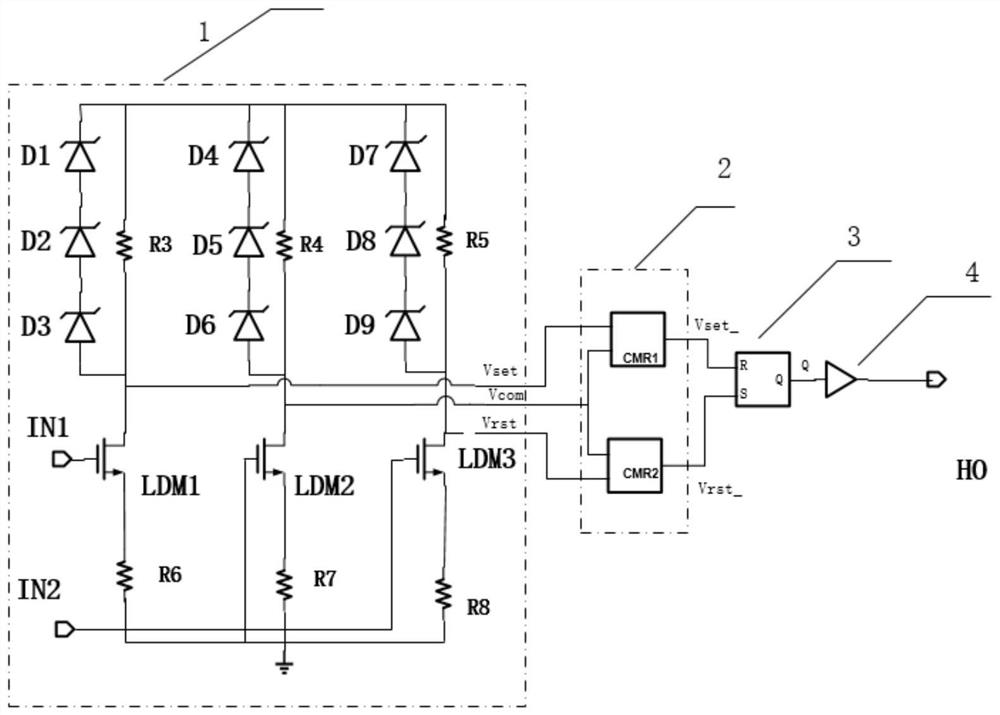

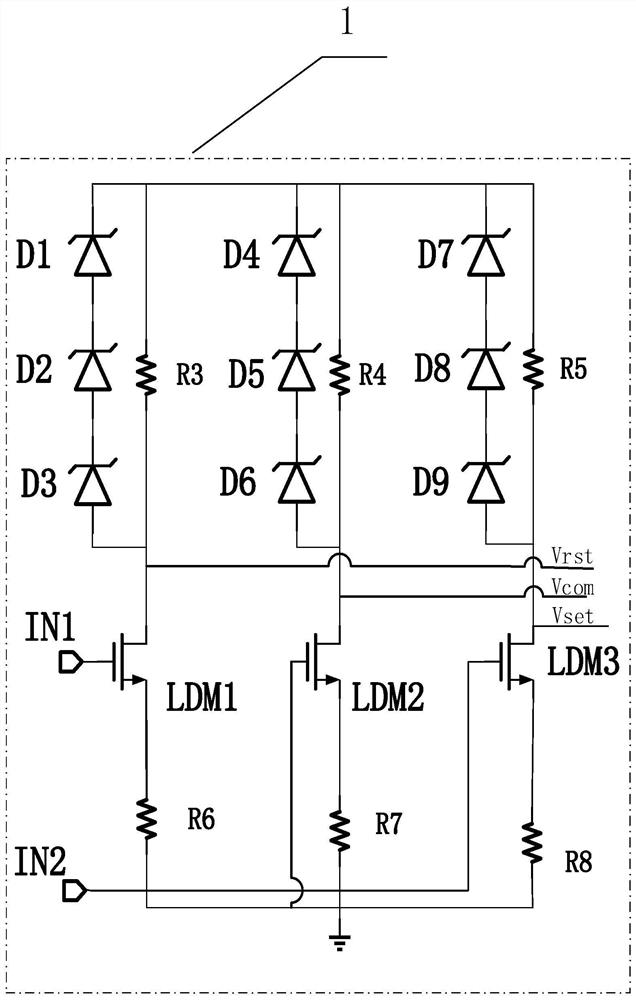

[0035] like figure 2 Shown is an anti-noise high-voltage gate drive circuit proposed by the present invention, including a high-voltage level shift module 1, a common-mode noise elimination composed of a first common-mode noise elimination module CMR1 and a second common-mode noise elimination module CMR2 Circuit 2, SR latch 3 and drive module 4. The high-voltage grid drive circuit proposed by the present invention mainly uses narrow pulses to reduce the power consumption of the circuit. The high-voltage level shift module 1 includes two input terminals and three output terminals, which are used to transfer the input two-way low-voltage pulse control signals Converted into a high-voltage pulse signal, together with the output of the high-voltage common-mode signal, the signal level is improved through the LDMOS tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com