Method for synthesizing pyrite type iron disulfide through high-temperature and high-pressure secondary reaction and application

A secondary reaction, pyrite-type technology, used in iron sulfide, chemical instruments and methods, applications, etc., can solve the problems of restricted development and utilization, harsh synthesis conditions, and low synthesis efficiency, achieving fast synthesis speed and synthesis. High efficiency and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

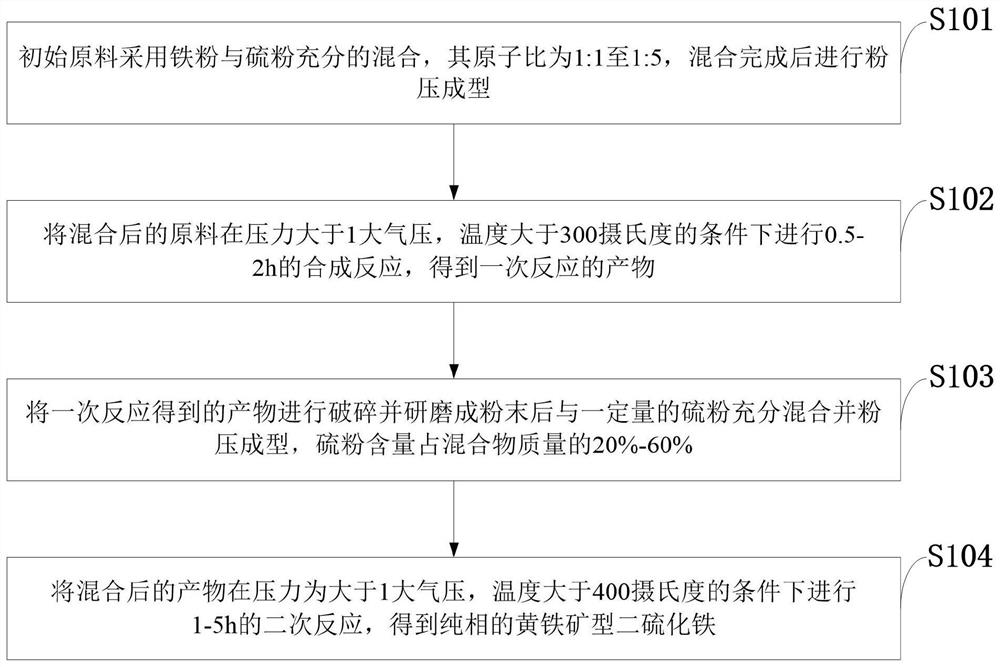

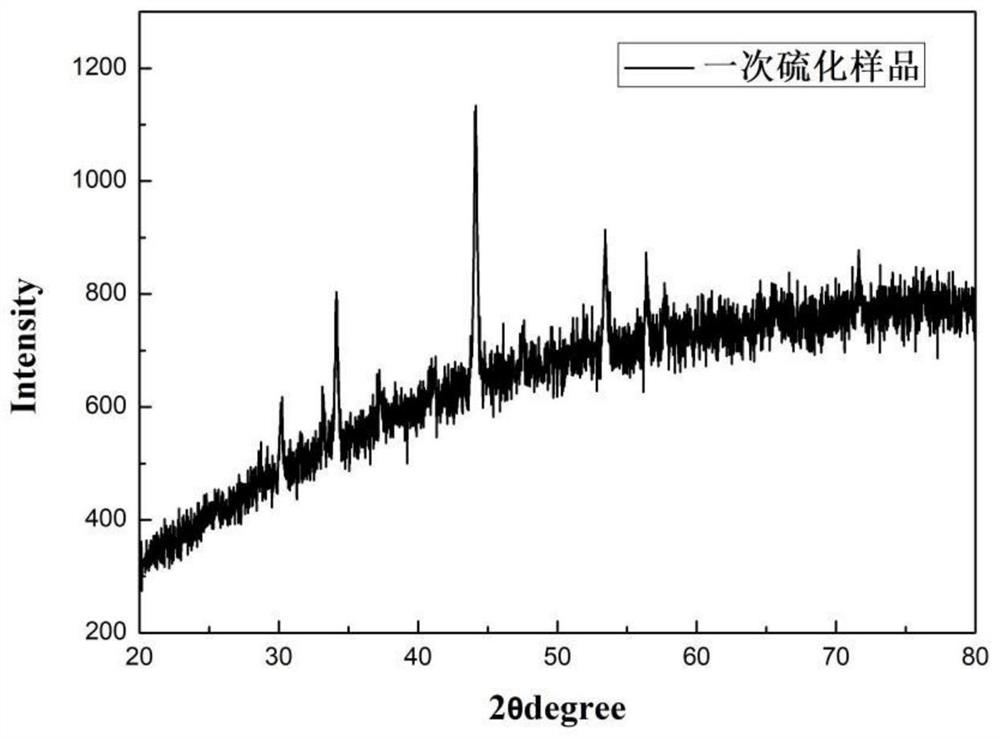

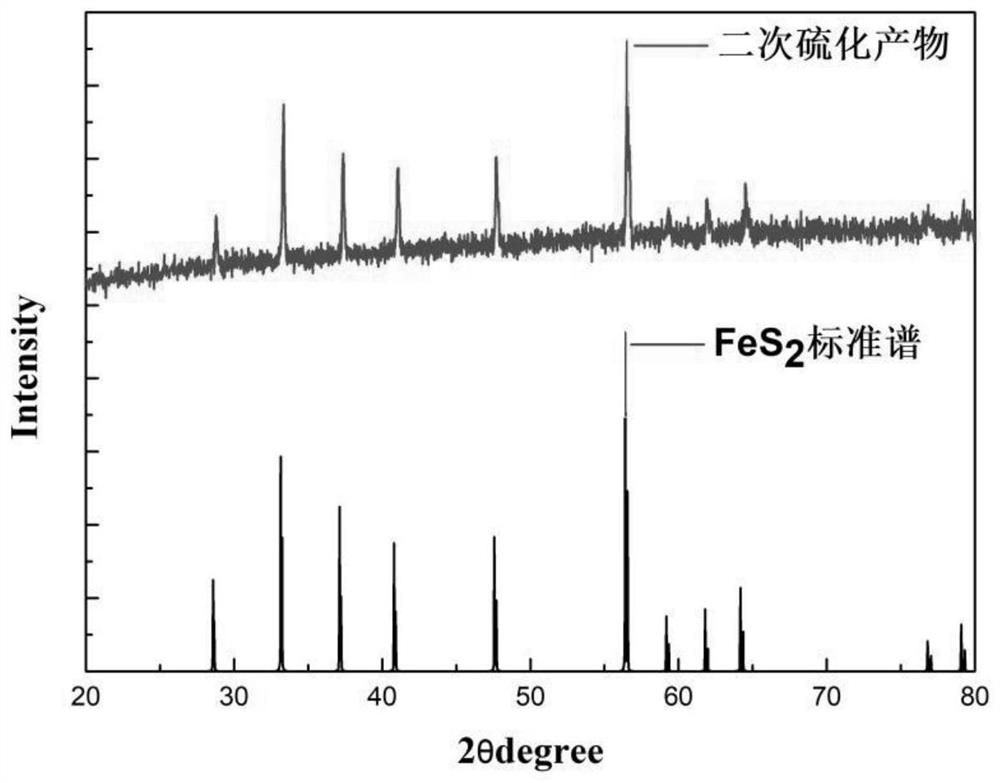

[0036] The synthesis method of the pyrite-type iron disulfide provided in the embodiment of the present invention includes: fully mixing iron powder and sulfur powder at an atomic ratio of 1:2.5 to obtain initial raw materials. The initial raw material powder was pressed into shape, placed under a high pressure of 1 GPa, and heated at a temperature of 600° C. for 1 hour to obtain a primary reaction product. Fully mix the primary reaction product with 50% by mass of sulfur powder, and carry out a secondary reaction for three hours at a pressure of 1GPa and a temperature of 600°C. The product of the secondary reaction was analyzed by xrd means to be a pure phase of pyrite-type iron disulfide.

Embodiment 2

[0038] The synthesis method of the pyrite-type iron disulfide provided in the embodiment of the present invention includes: fully mixing iron powder and sulfur powder at an atomic ratio of 1:5 to obtain initial raw materials. The initial raw material powder was pressed into shape, placed under a high pressure of 1 GPa, and heated at a temperature of 500° C. for 1 hour to obtain a primary reaction product. Fully mix the primary reaction product with 50% by mass of sulfur powder, and carry out a secondary reaction for 1 hour at a pressure of 2GPa and a temperature of 650°C. The product of the secondary reaction was analyzed by xrd means to be a pure phase of pyrite-type iron disulfide.

Embodiment 3

[0040]The synthesis method of the pyrite-type iron disulfide provided in the embodiment of the present invention includes: fully mixing iron powder and sulfur powder at an atomic ratio of 1:3 to obtain initial raw materials. The initial raw material powder was pressed into shape, placed under a high pressure of 1 GPa, and heated at a temperature of 500° C. for 1 hour to obtain a primary reaction product. Fully mix the primary reaction product with 50% by mass of sulfur powder, and carry out a secondary reaction for 3 hours at a pressure of 5GPa and a temperature of 500°C. The product of the secondary reaction was analyzed by xrd means to be a pure phase of pyrite-type iron disulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com