Preparation method of g-C3N4/MXene composite material

A composite material, g-c3n4 technology, applied in the field of nano functional material preparation, to achieve the effects of easy control of process parameters, good photocatalytic performance, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

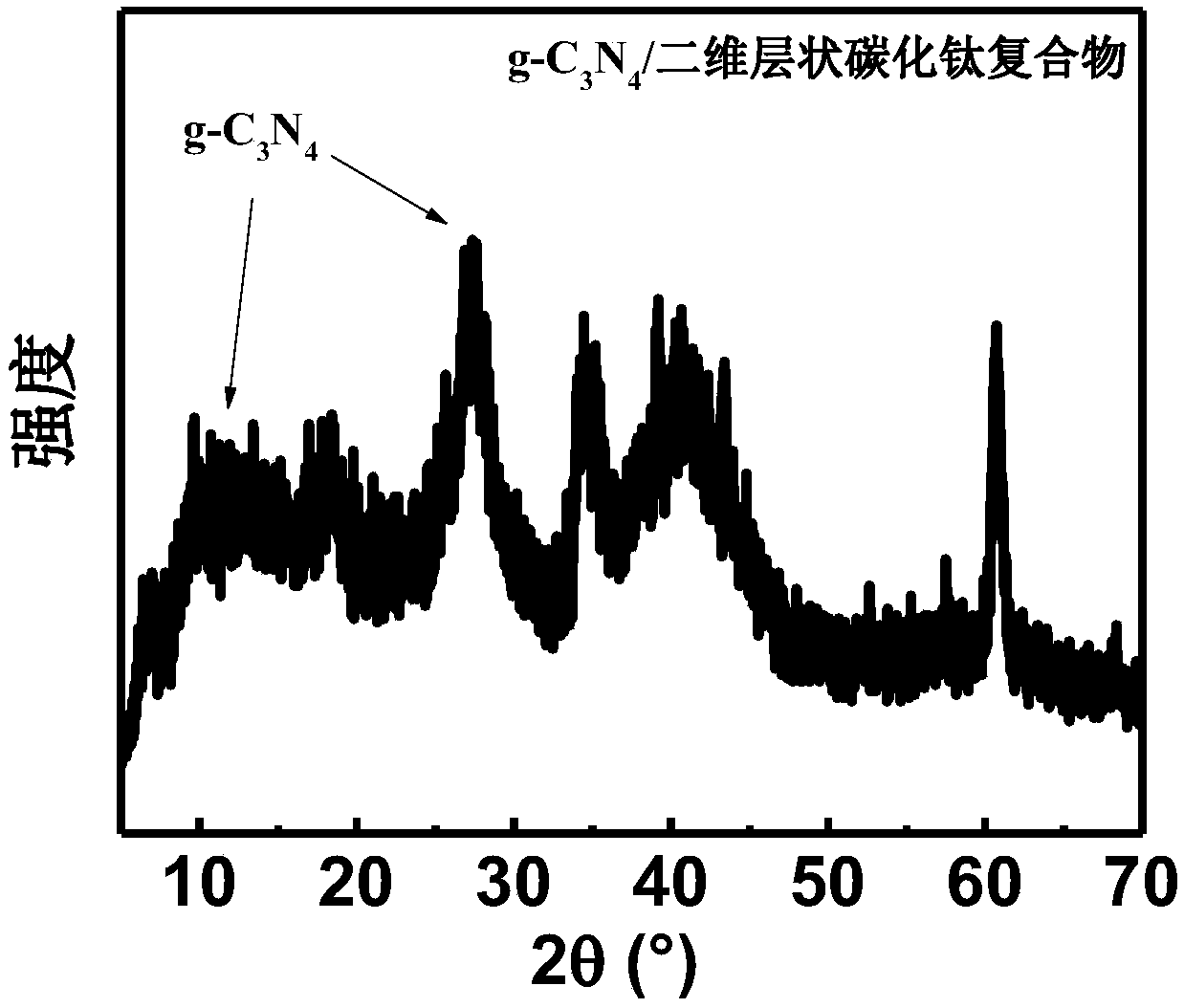

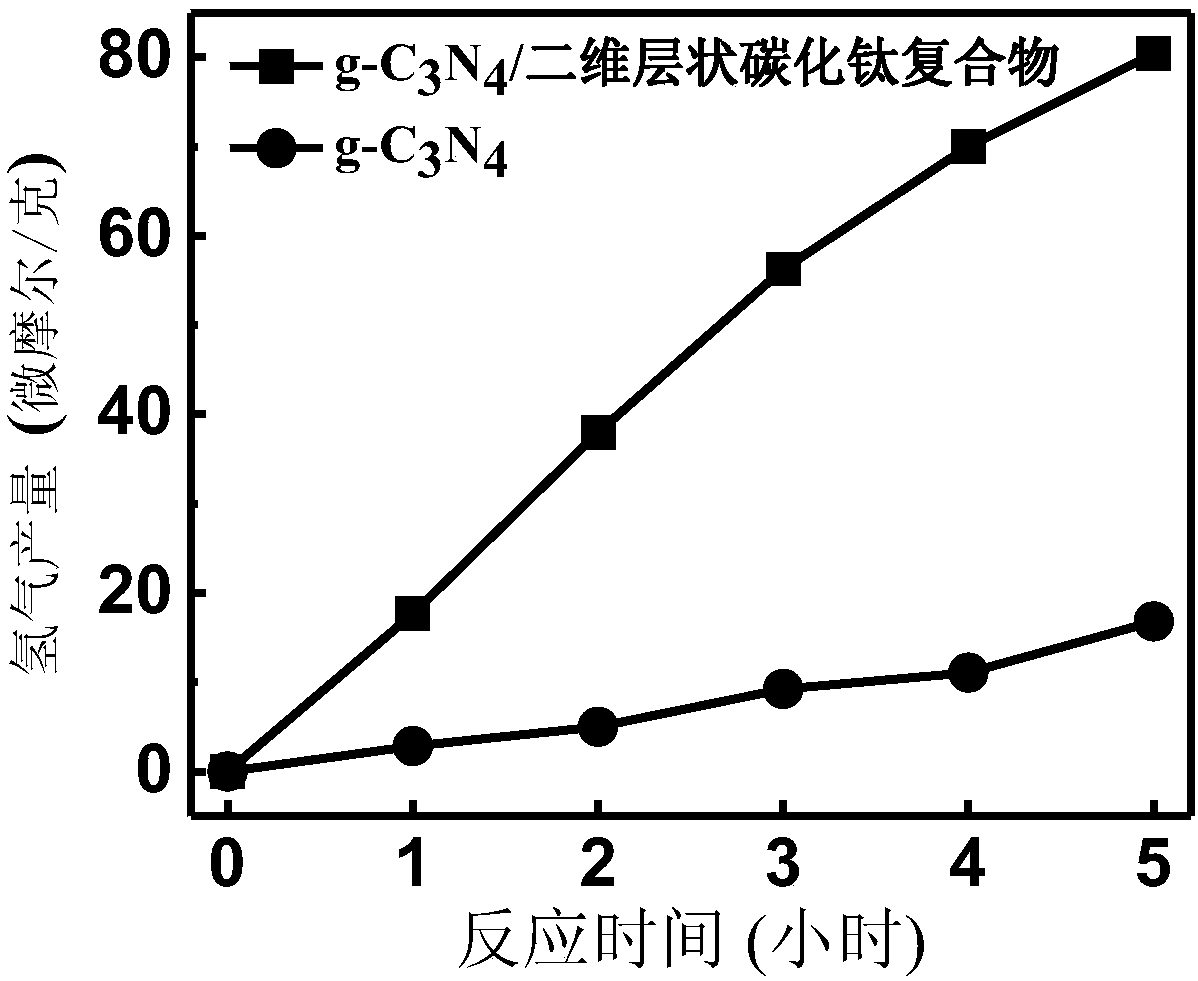

Embodiment 1

[0028] (1) Ti with a purity greater than 98% 3 AlC 2 The ceramic powder was added to 40% HF solution at a ratio of 0.06g / ml, stirred at 60°C for 24 hours; then washed with deionized water until the pH was 6-7, and the obtained solid sample was vacuum-dried at 60°C ; The dried powder is placed in 0.05g / ml urea aqueous solution (Ti 3 AlC 2 The mass ratio of urea to urea is 1:1), stirred at 60°C for 24h; then washed with deionized water for 2 to 3 times, and the obtained solid sample was vacuum-dried at 60°C to obtain a two-dimensional layered structure Ti 3 C 2 (MXene material).

[0029](2) Add 2g of thiourea to 20ml of water, stir at 60°C for 2h, then add 0.1g of the MXene material in step (1), and continue stirring for 10h; then dry it by freeze-drying to obtain MXene and g-C 3 N 4 The mixture of precursor substances is placed in a tube furnace for calcination treatment under an argon atmosphere. The calcination temperature is 600°C, the calcination time is 1h, and the ...

Embodiment 2

[0034] (1) Ti with a purity greater than 98% 2 AlC ceramic powder is added to 40% HF solution at a proportioning concentration of 0.01g / ml, stirred at 20°C for 30h; then washed with deionized water until the pH is 6-7, and the obtained solid sample is vacuumed at 20°C Drying; place the dried powder in 0.05g / ml aqueous urea (Ti 2 The mass ratio of AlC to urea is 1:1), stirred at 20°C for 24h; then washed with deionized water for 2 to 3 times, and the obtained solid sample was vacuum-dried at 20°C to obtain a two-dimensional layered structure Ti 2 C (MXene material).

[0035] (2) Add 2 g of melamine to 20 ml of water, stir at 20°C for 2 h, then add 20 mg of the MXene material in step (1), and continue stirring for 24 h; then dry it by freeze-drying to obtain MXene and g-C 3 N 4 The mixture of precursor substances is placed in a tube furnace for calcination under an argon atmosphere. The calcination temperature is 500°C, the calcination time is 10h, and the heating rate is 10...

Embodiment 3

[0038] (1) Ti with a purity greater than 98% 2 AlC ceramic powder is added to 40% HF solution at a proportioning concentration of 0.01g / ml, stirred at 20°C for 30h; then washed with deionized water until the pH is 6-7, and the obtained solid sample is vacuumed at 20°C Drying; place the dried powder in 0.05g / ml aqueous urea (Ti 2 The mass ratio of AlC to urea is 1:1), stirred at 20°C for 24h; then washed with deionized water for 2 to 3 times, and the obtained solid sample was vacuum-dried at 20°C to obtain a two-dimensional layered structure Ti 2 C (MXene material).

[0039] (2) Add 10g of melamine into 20ml of water, stir at 50°C for 1.5h, then add 3g of the MXene material in step (1), and continue stirring for 10h; then dry it by freeze-drying to obtain MXene and g-C 3 N 4 The mixture of precursor substances is placed in a tube furnace for calcination in an air atmosphere. The calcination temperature is 550°C, the calcination time is 2h, and the heating rate is 10°C / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com