Preparation method of metal compound nano-structure thin-film material

A technology of metal compounds and nanostructures, applied in nanotechnology, nanotechnology, structural parts, etc., can solve the problems of reducing the utilization efficiency of reactants, achieve the effect of improving utilization efficiency and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

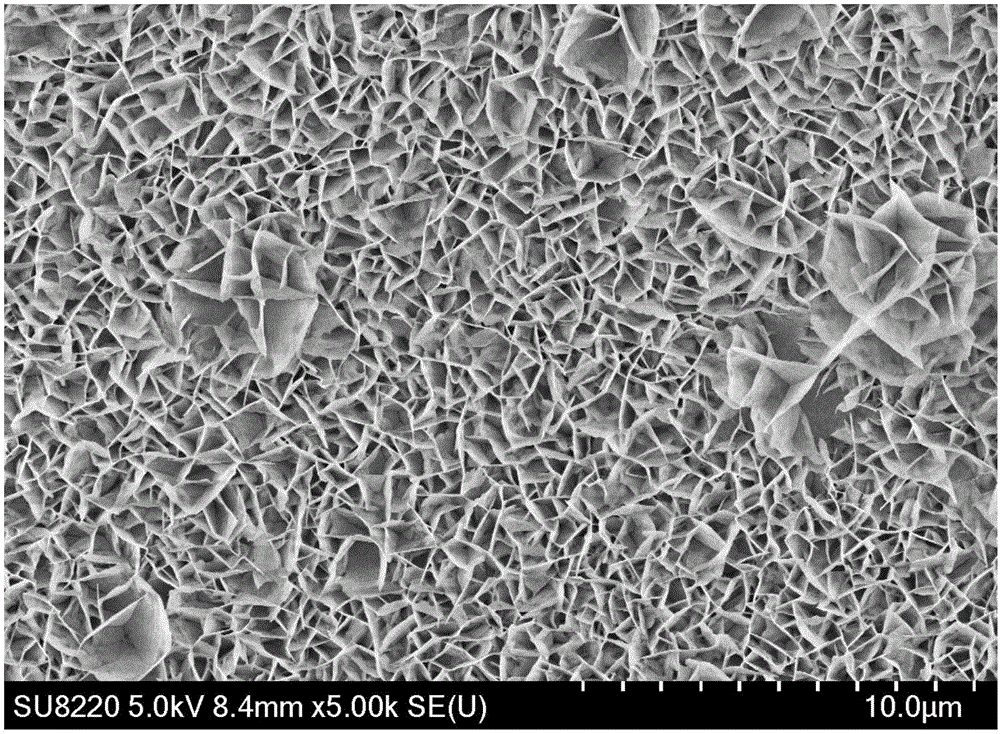

[0038] Preparation of β-Ni(OH) on the surface of nickel foam substrate 2 The method of nanosheet thin film is as follows:

[0039] Freshly prepared 20 ml Ni(NO 3 ) 2 Aqueous solution, Ni(NO 3 ) 2The concentration is 0.025mol / L, and transferred to a 50 ml stainless steel autoclave with polytetrafluoroethylene as the liner. Will pre-cleaned 10 x 10mm 2 The nickel foam base is placed horizontally on the bottom of the polytetrafluoroethylene liner. The autoclave was sealed and hydrothermally reacted at a temperature of 200°C for 24 hours. The product is cooled, separated, washed and dried from the reaction solution. Prepared β-Ni(OH) 2 The nanosheet thin film is used as the negative electrode material, together with the nickel foam substrate, it is directly applied to the sodium-ion battery.

Embodiment 2

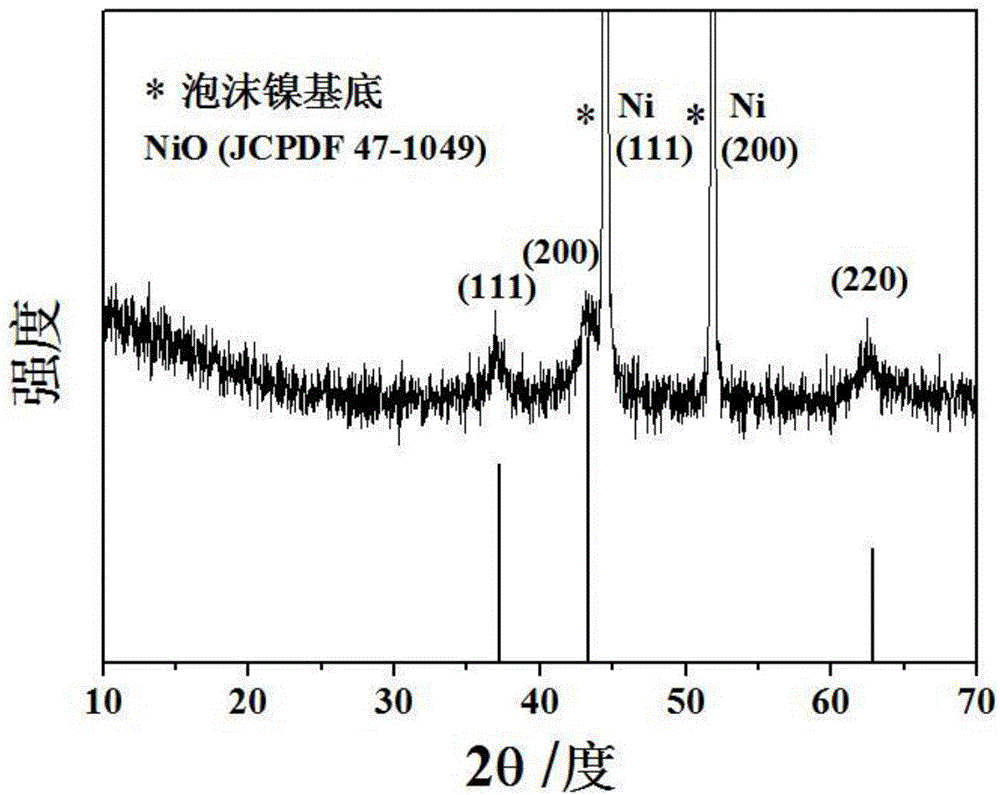

[0041] The method for preparing NiO nanosheet film on the surface of nickel foam substrate is as follows:

[0042] Freshly prepared 20 ml Ni(NO 3 ) 2 Aqueous solution, Ni(NO 3 ) 2 The concentration is 0.025mol / L, and transferred to a 50 ml stainless steel autoclave with polytetrafluoroethylene as the liner. Will pre-cleaned 10 x 10mm 2 The nickel foam base is placed horizontally on the bottom of the polytetrafluoroethylene liner. The autoclave was sealed and hydrothermally reacted at a temperature of 200°C for 24 hours. The product is cooled, separated, washed and dried from the reaction solution to obtain β-Ni(OH) 2 film precursors. The prepared β-Ni(OH) 2 The thin film precursor was placed in a burning boat, and then put into the quartz tube of the tubular resistance furnace, and the temperature was raised at 1°C / min in a nitrogen-protected atmosphere. When the temperature rose to the set temperature of 300°C, it was kept for 6 hours, and then naturally cooled to ro...

Embodiment 3

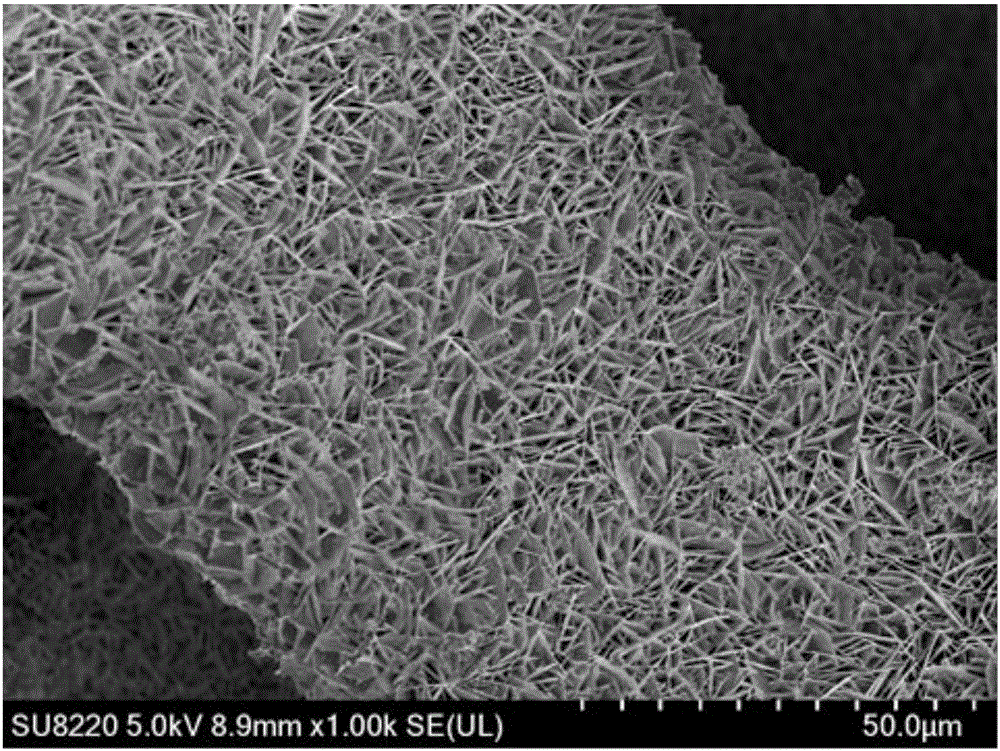

[0044] Preparation of Co on the surface of nickel foam substrate 3 o 4 The nanoparticle film method is as follows:

[0045] Freshly prepared 20 ml of Co(NO 3 ) 2 Aqueous solution, Co(NO 3 ) 2 The concentration is 0.025mol / L, and transferred to a 50 ml stainless steel autoclave with polytetrafluoroethylene as the liner. Will pre-cleaned 10 x 10mm 2 The nickel foam base is placed horizontally on the bottom of the polytetrafluoroethylene liner. The autoclave was sealed and hydrothermally reacted at a temperature of 160° C. for 24 hours. The product is cooled, separated, washed and dried from the reaction liquid. Co produced 3 o 4 Nanoparticle thin films are used as anode materials, together with nickel foam substrates, for direct application in Na-ion batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com