Patents

Literature

73results about How to "Improve capture capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

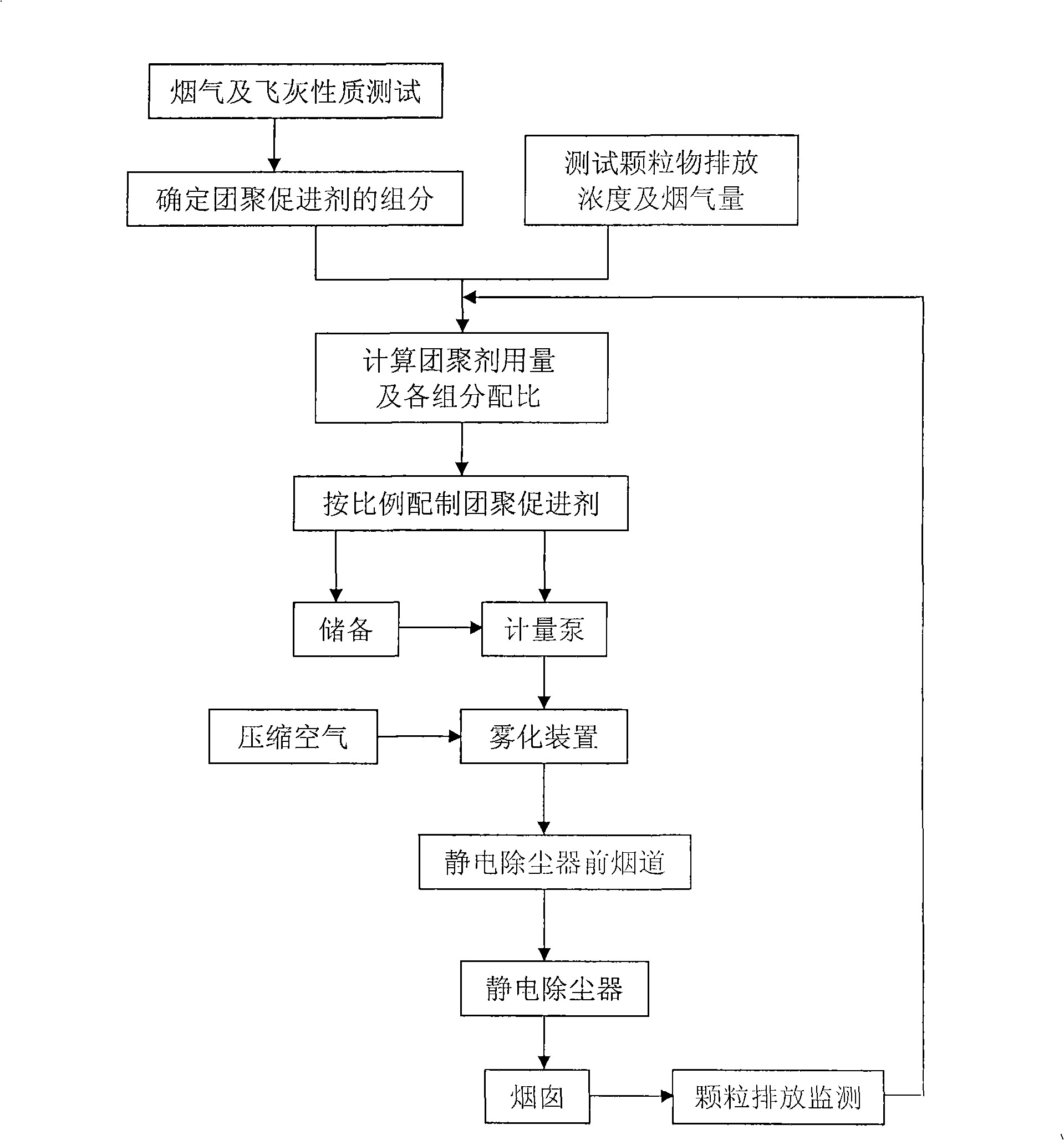

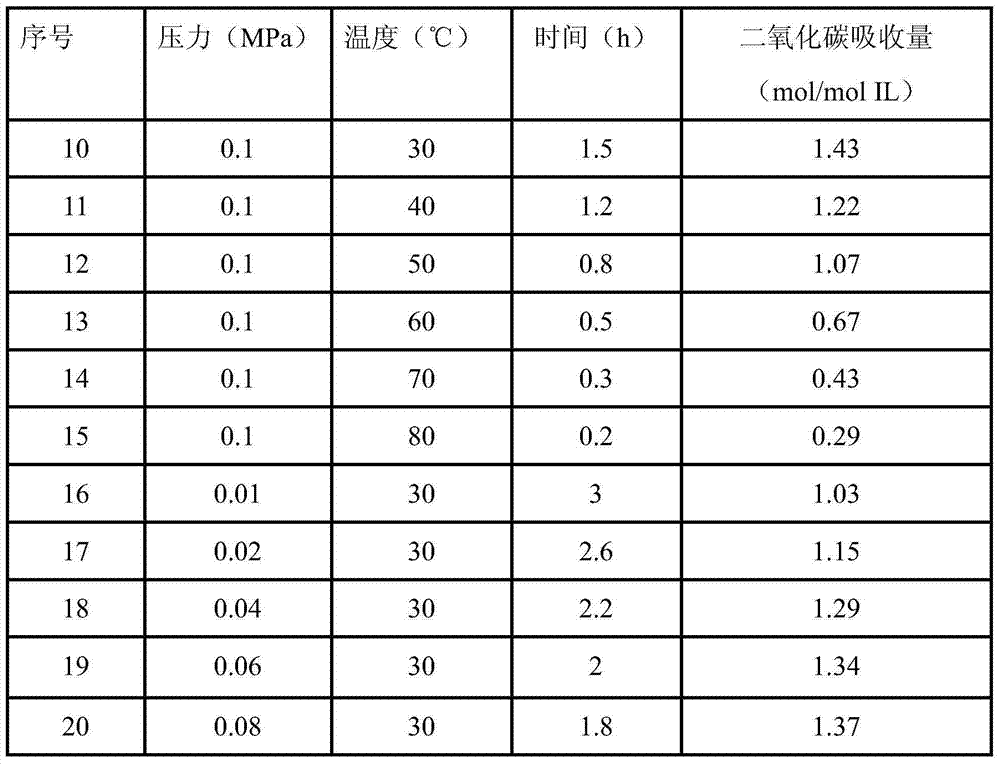

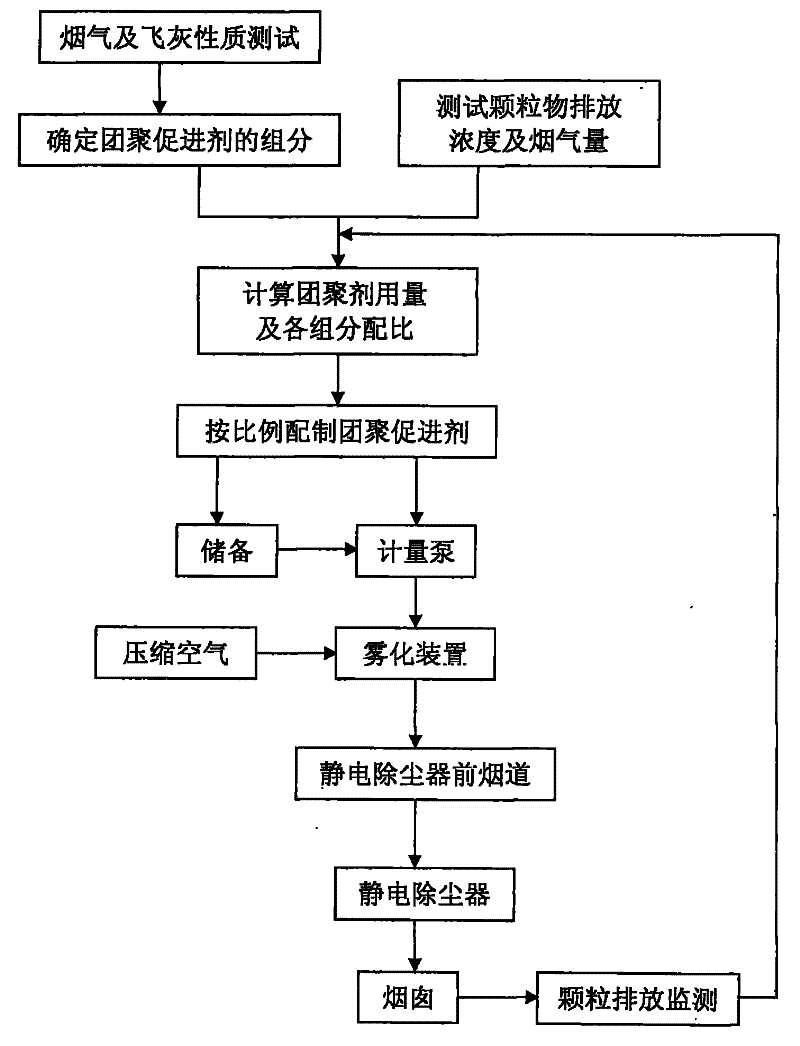

Coal-fired ultrafine grain chemical agglomeration promotor

ActiveCN101513583AWide variety of sourcesEasy to synthesizeAuxillary pretreatmentElectrostatic separationInorganic saltsWater soluble

The invention discloses a coal-fired ultrafine grain chemical agglomeration promotor which comprises the components based on mass percent: 0.001-0.2% of surface active agent, 0.0001-0.01% of water-soluble high molecular compound, 0.001-0.05% of inorganic salt additive and the rest of water. The invention can effectively promote ultrafine grains to agglomerate, improve the removal efficiency of a static precipitator for the ultrafine grains and high specific resistance flying ash, and reduce the soot emission and the charges for disposing pollutant of enterprises. The agglomeration promotor has the components with wide source, economical price, environmental protection, simple synthetic process, easy operation and no environmental pollution.

Owner:武汉天空蓝环保科技有限公司

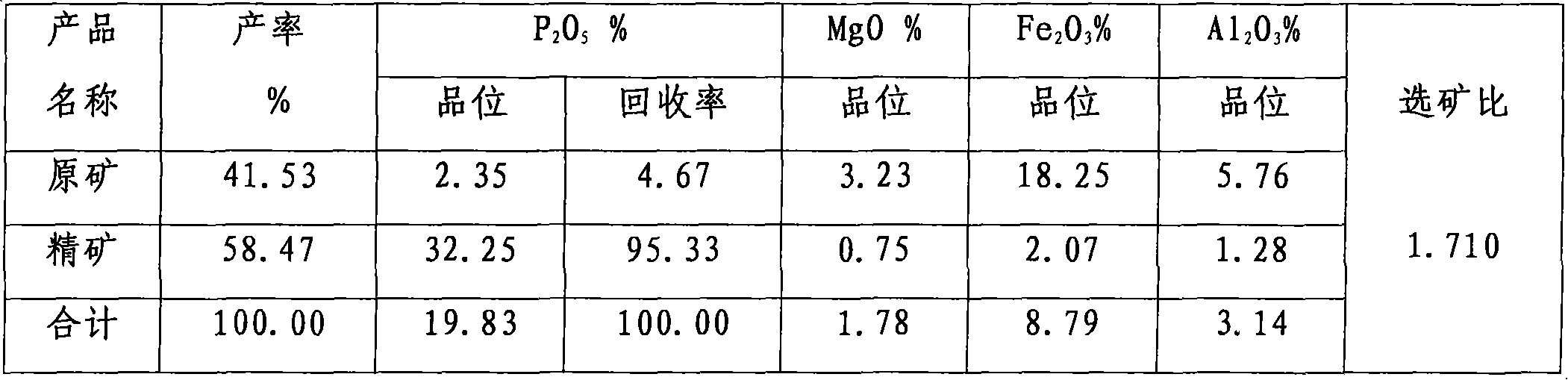

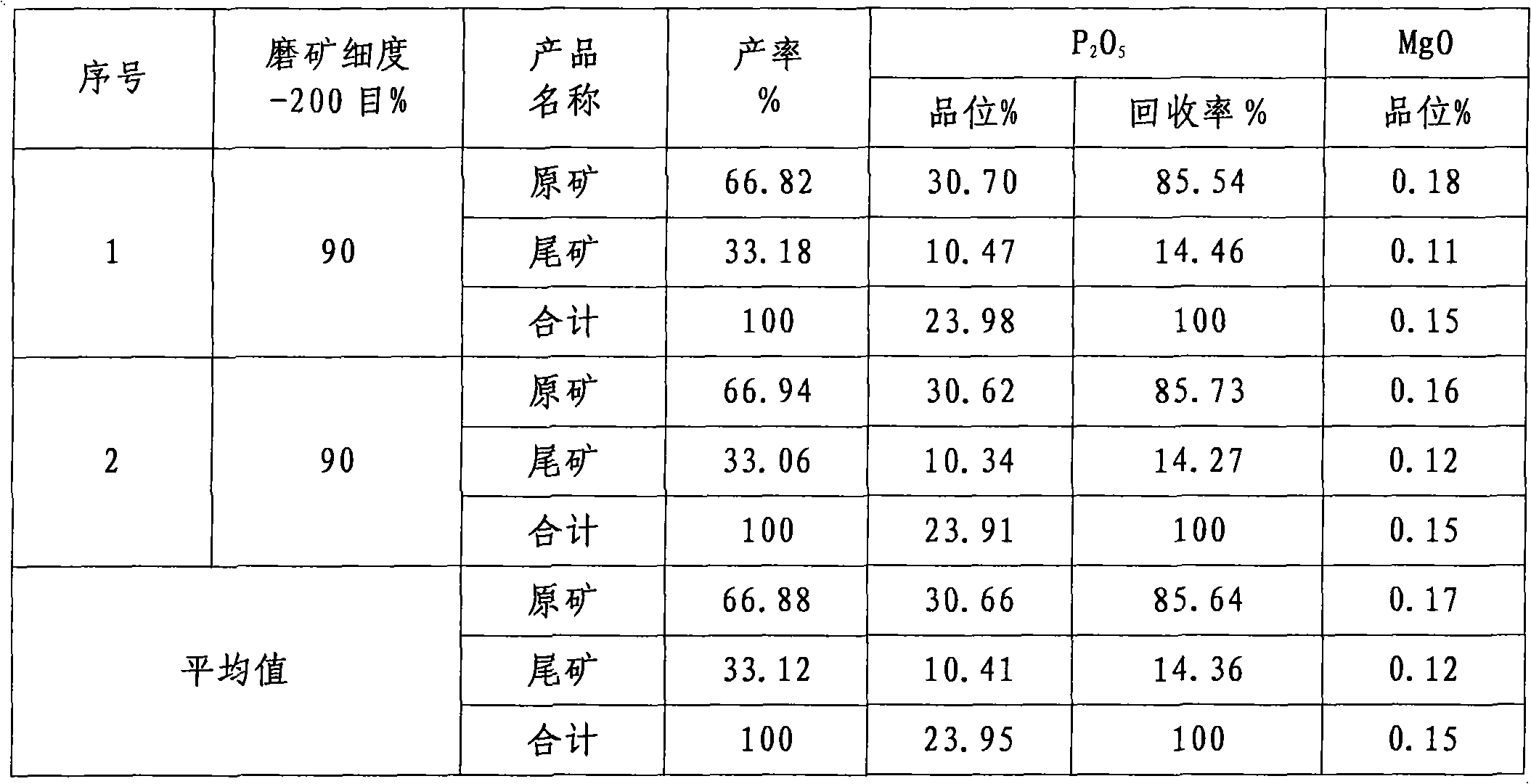

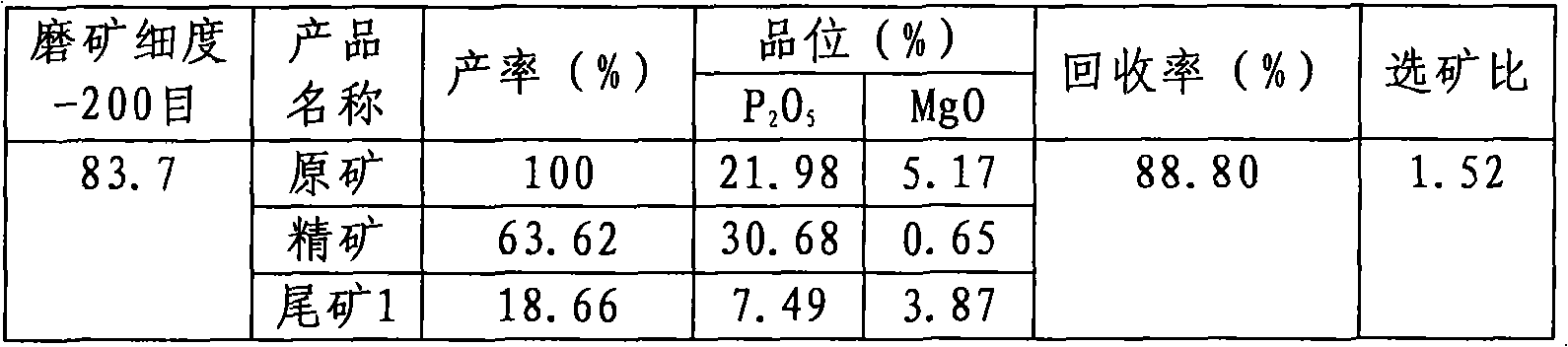

Collophanite flotation collector and method for preparing same

ActiveCN101797536AStable chemical propertiesGood water solubilityFatty acids production/refiningFlotationSolubilityFatty acid

The invention relates to a collophanite normal-temperature flotation collector, in particular to collophanite flotation collector prepared from natural rubber seed oil fatty acid, belonging to the collector. The invention also relates to a method for preparing the collophanite flotation collector. The collophanite flotation collector comprises natural rubber seed oil fatty acid, tall oil, tributyl phosphate, tween 80, dodecyl benzene sulfonic acid, inorganic base and water. The collophanite flotation collector has stable chemical performance, good water solubility, high flotation speed, suitable viscosity and strong selectivity and collection performance, is easy to diffuse in collophanite pulp, can be used for obverse floatation and reverse flotation and can generate uniform bubbles, obviously shorten the floatation time, improve the concentrate grade and reduce the content of impurities in the concentrate product.

Owner:YUNNAN CHEM RES INST

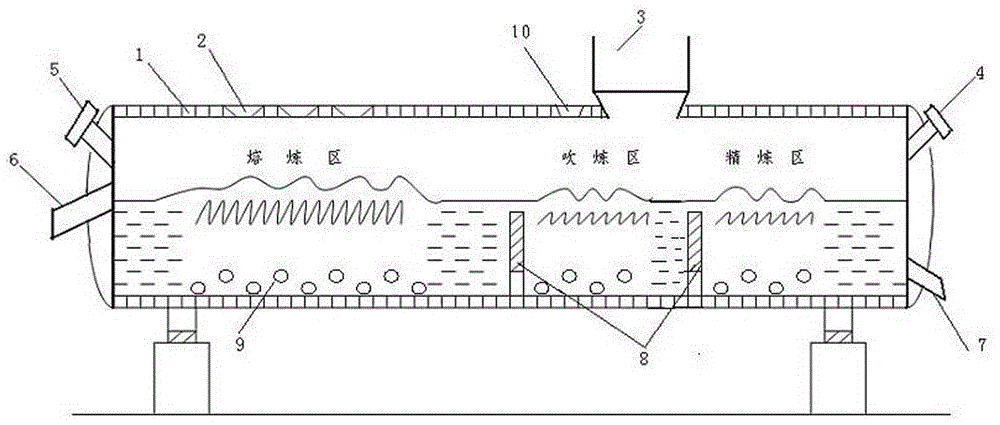

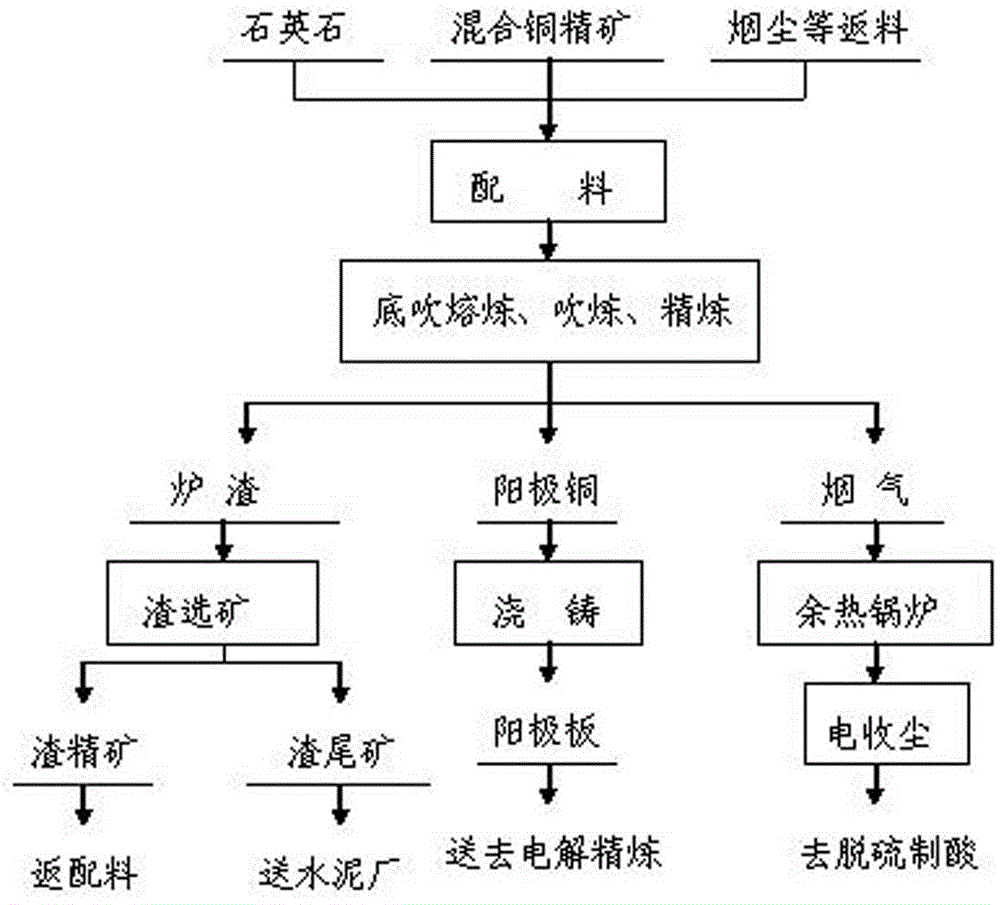

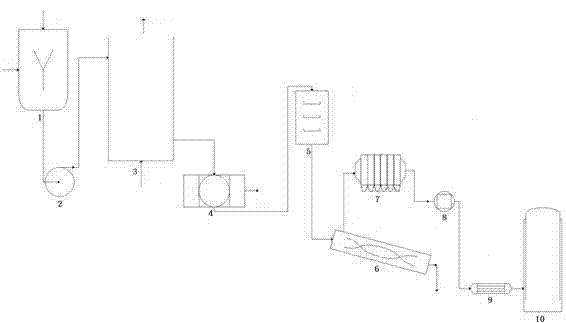

One-step copper smelting technology and device thereof

The invention relates to a one-step copper smelting technology and a device thereof. The interior of a furnace body is divided into three zones, namely a smelting zone, a blowing zone and a refining zone, by a retaining wall; and two rows of spray guns which are arranged in a staggered manner and have an included angle with a vertical line are arranged at the bottoms of the zones; return dust is mixed and then added into mixed copper concentrate and a solvent through a charging opening of the smelting zone, oxygen-enriched air is sprayed through the spray guns to carry out self-heating smelting, to generate copper matte; the spray guns in the blowing zone spray oxygen-enriched air so as to blow copper matte into crude copper and slag; the spray guns in the refining zone supply oxygen-enriched air for oxidization, and supply natural gas as a reductant for reduction, and the generated anode copper with high purity is interruptedly discharged form a copper discharging opening, so that the low-altitude pollution problem caused by SO2 can be solved, the operation environment can be greatly improved, the utilization rate of sulfur and heat can be obviously increased, and further the economic benefits can be increased further; in addition, the invention provides a one-step copper smelting technology which is more advanced, shorter in flow, lower in investment, lower in comprehensive energy consumption, higher in recovery rate, and better in comprehensive utilization in comparison with the existing continuous copper smelting technology.

Owner:DONGYING LUFANG METAL MATERIAL

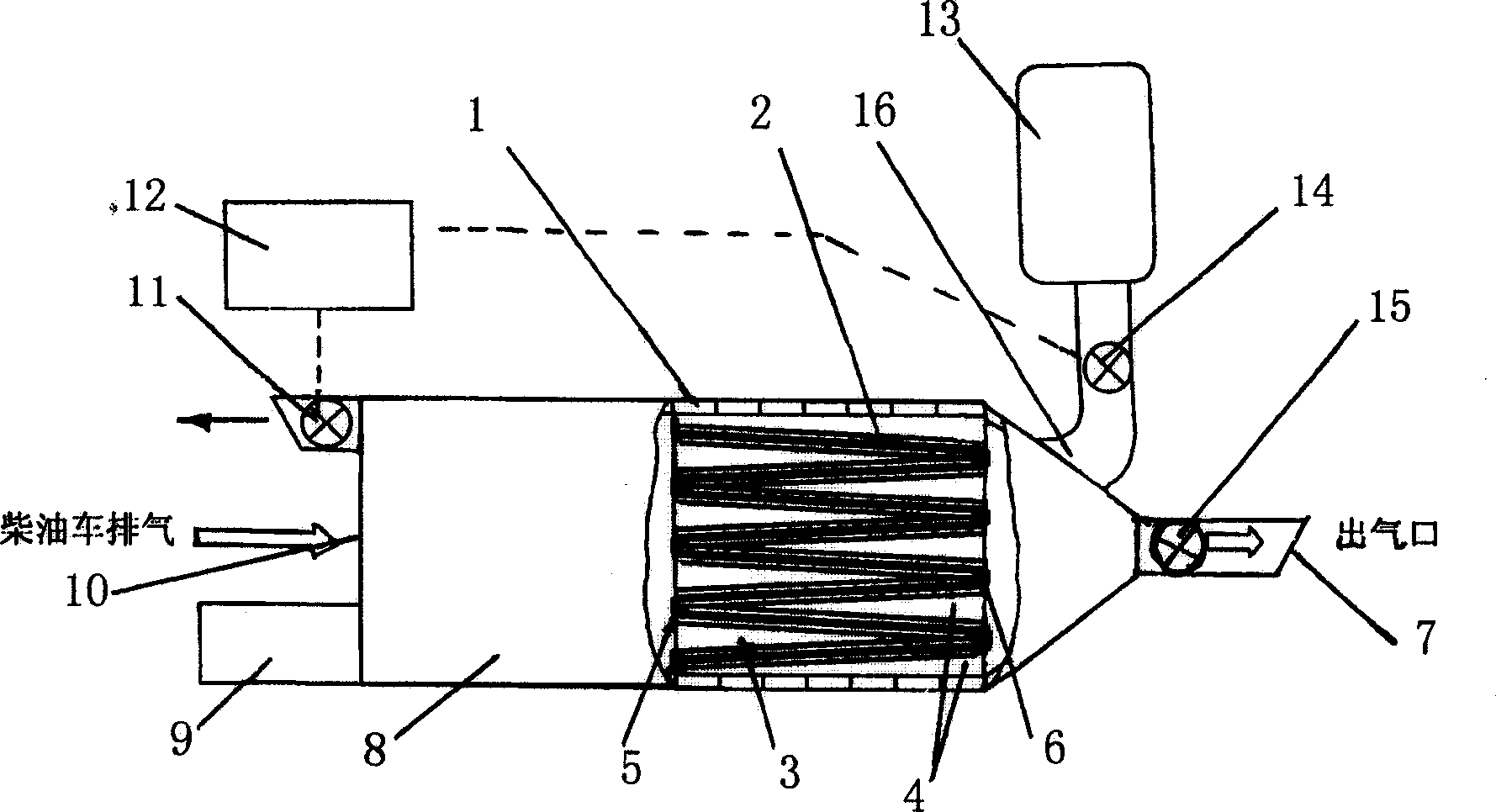

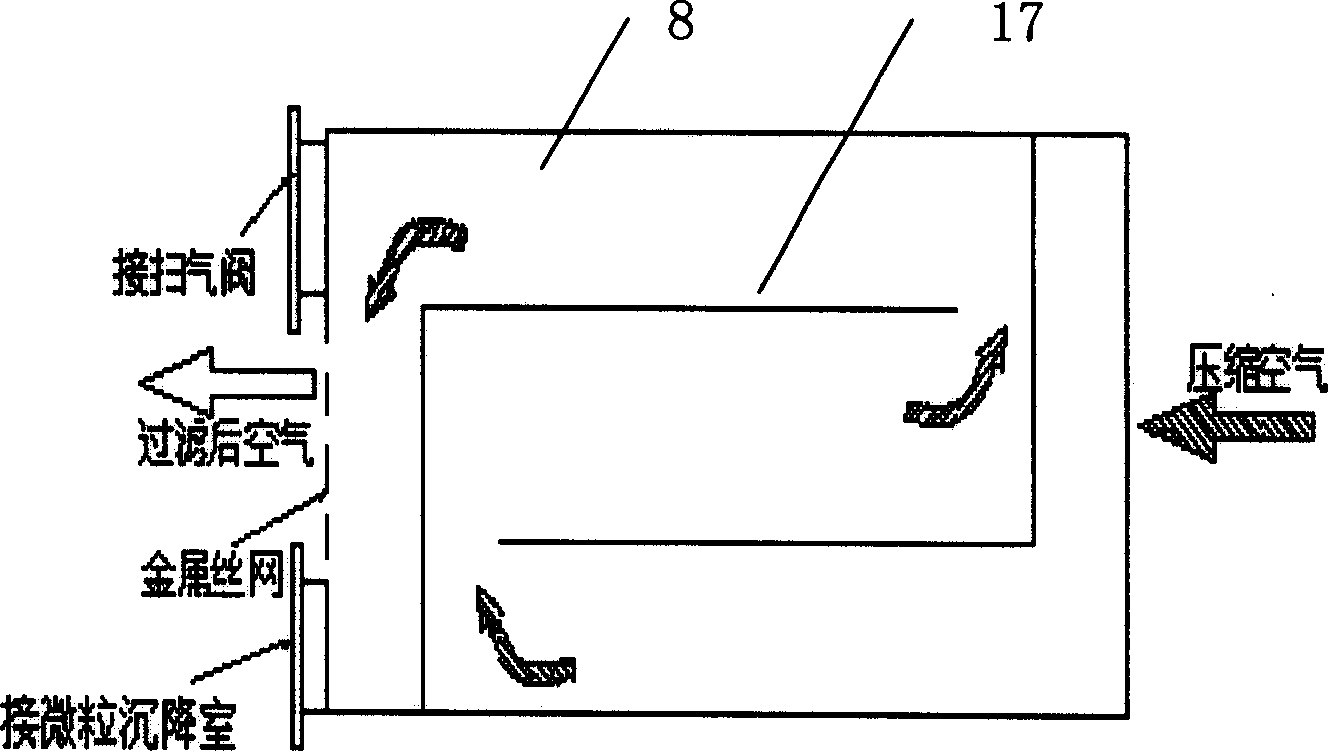

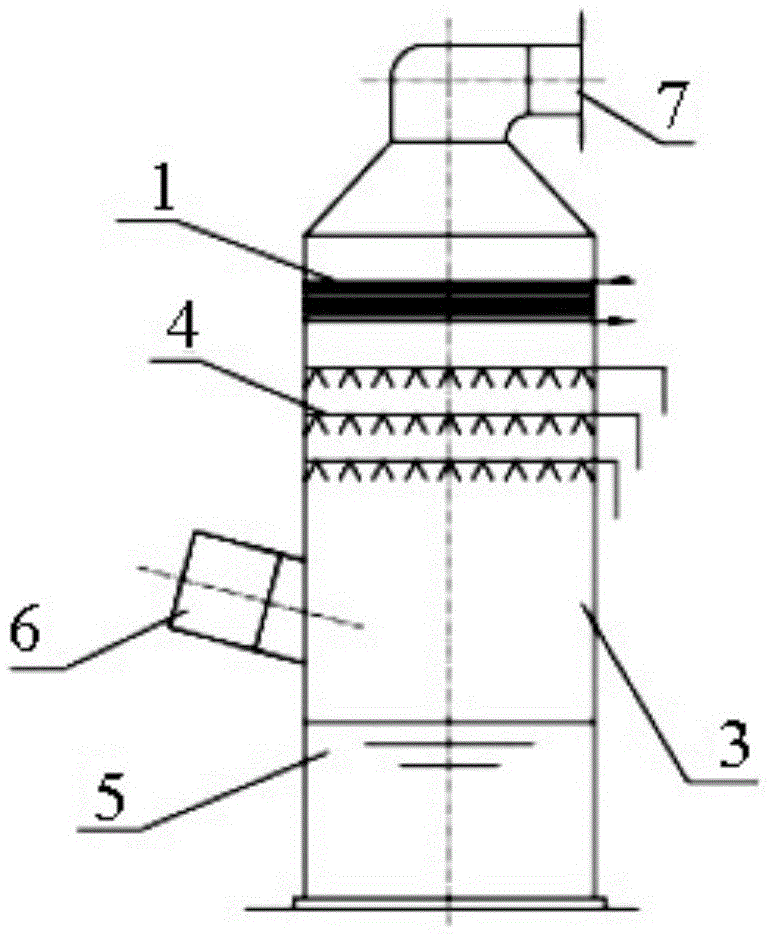

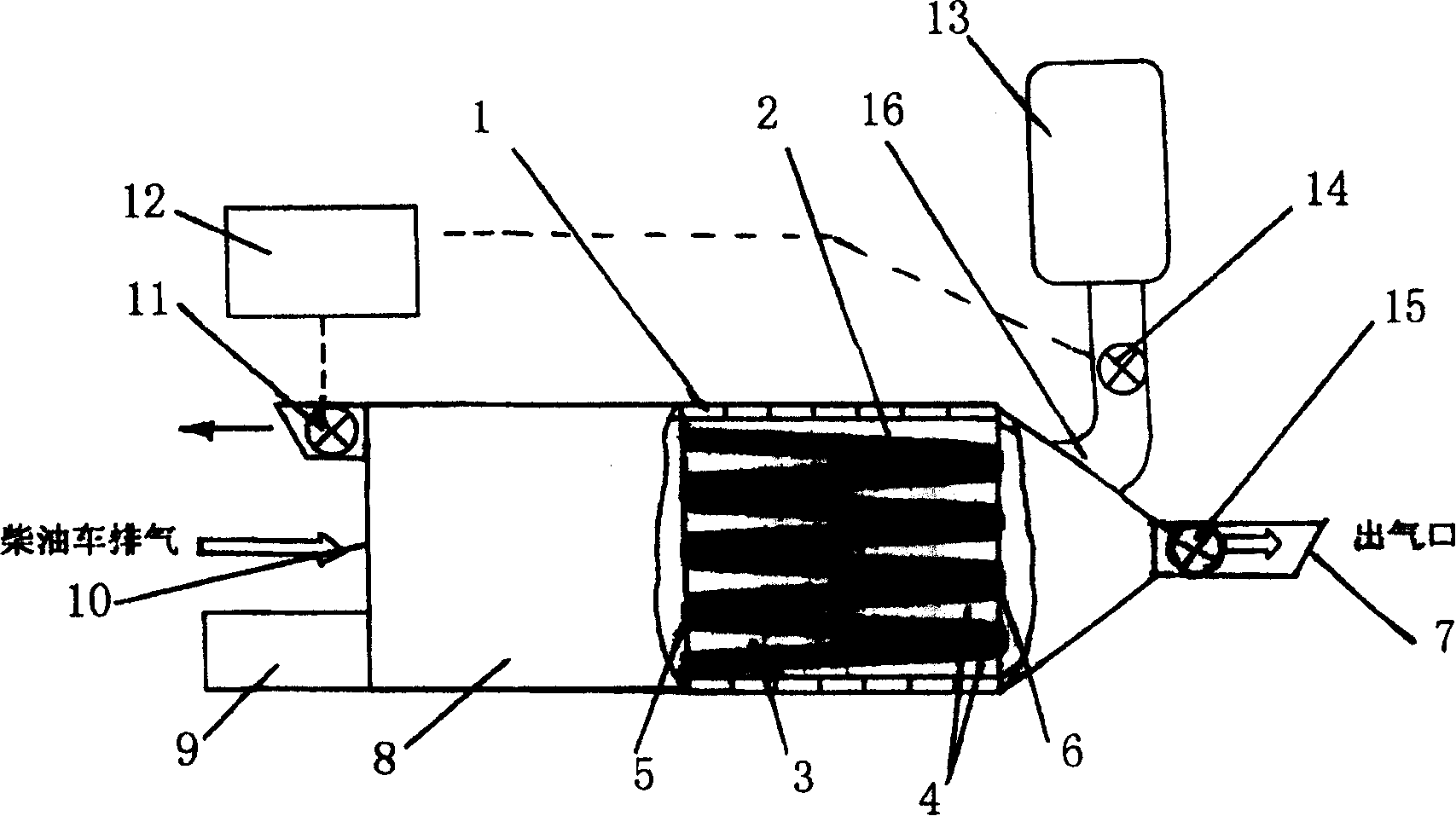

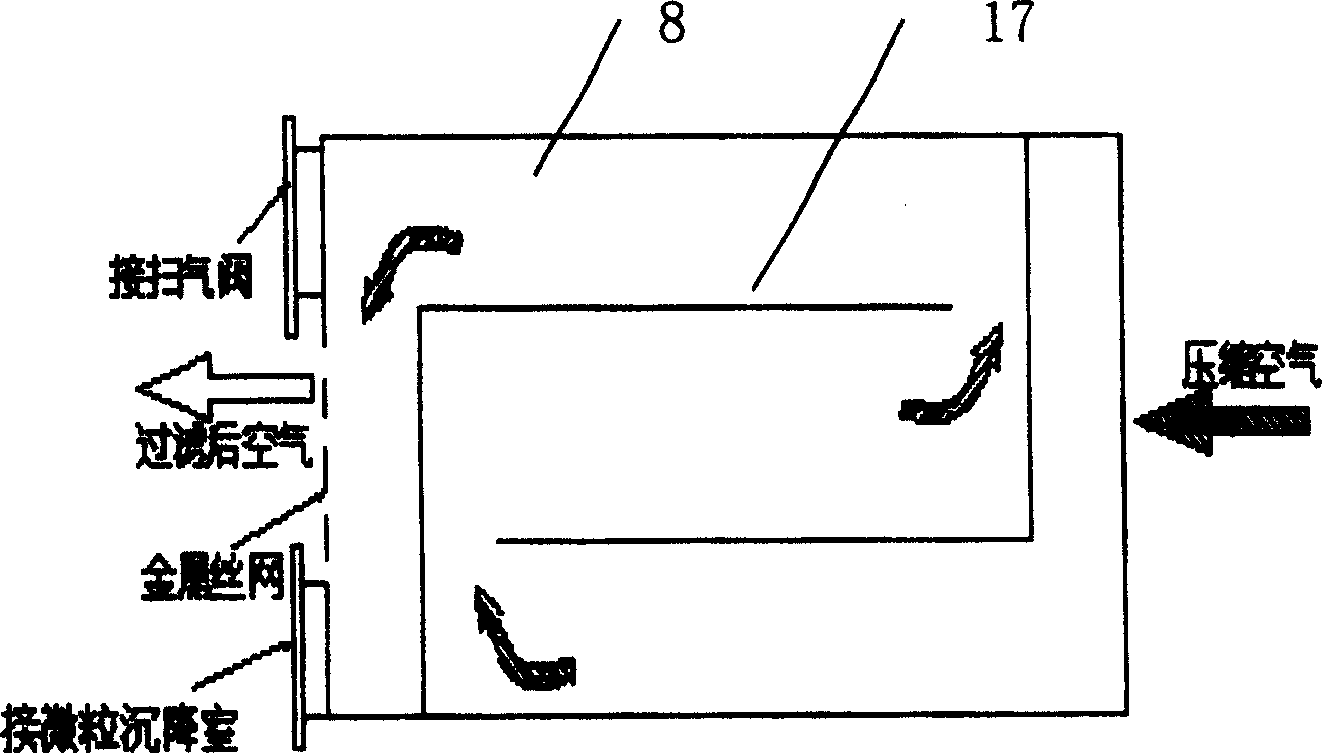

Wall flow type net plate apparatus with reverse jet regenerating unit for collecting microparicle discharged by diesel vehicle

InactiveCN1693682AReduce exhaust pollutionReduce manufacturing costExhaust apparatusSilencing apparatusParticulatesMicroparticle

This invention discloses a converse regenerating wall flow type metal net plate apparatus for collecting microparticle discharged by diesel vehicle. The composite metal plate masking filter layer inclined certain angles in outer shell, 'WW' type is formed through baffle. Extension room is set between air intake and the filter layer, the room is connected to scavenging valve and carbon smoke second collecting device. Pneumatic disc valve, blowback cavity and air compress air tank at one side of the gas outlet are connected to the shell. Waste gas discharged by the engine enters from collector intake, and particles in the waste gas are entrapped when it flows through 'WW' type composite metal shadow masking. Discharging back pressure ascends when the particles deposit to certain quantity, and the regenerating equipment starts to blow out the accumulative particles from filter, and the particles are second collected and burned in collector. The structure is simple, cost is low, purification effect and regeneration effect is good, life is long and a good product for generalization.

Owner:TSINGHUA UNIV +1

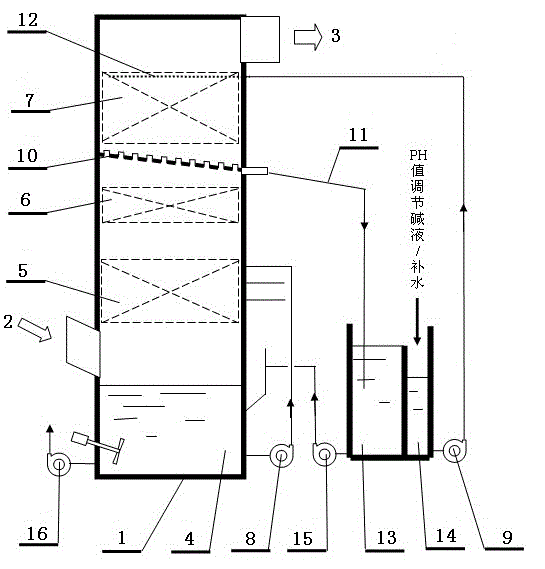

High-efficiency wet-type electric dust removal and desulfuration system and process

ActiveCN102716639AGuaranteed desulfurization efficiencyImprove dust removal system efficiencyCombination devicesGypsumWater balance

The invention discloses a high-efficiency wet-type electric dust removal and desulfuration system and a process. A wet-type electric dust remover is arranged above a demister in a desulfuration tower. First of all, the demister is used for pre-removing mist drops and dust from clean smoke; the wet-type electric dust remover is used for performing fine treatment on the clean smoke; therefore, an extremely high environment-friendly discharging requirement is met; and the desulfuration efficiency is guaranteed, the efficiency of a dust removal system of the desulfuration tower is improved, and the dust discharge concentration at the outlet of the desulfuration tower is reduced, so that the latest discharge standard required in China is met. According to the wet-type electric dust remover, the problem of gypsum rain can be solved; various pollutants can be removed at the same time; furthermore, a water accumulation plate is arranged between the demister and the wet-type electric dust remover and used for collecting and recycling washing water of the wet-type electric dust remover, so that the washing water of the wet-type electric dust remover cannot directly enter into a neutralization oxidation pond of the desulfuration tower; and therefore, the water balance of the whole system is guaranteed.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

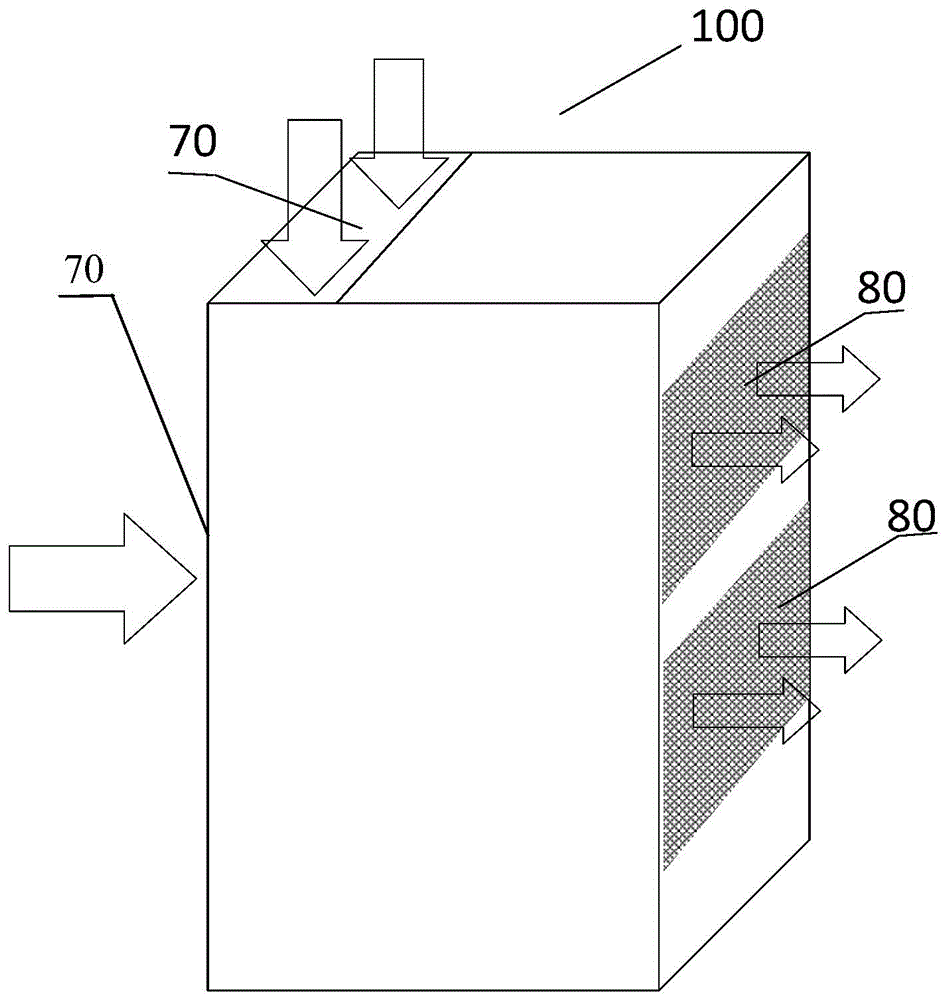

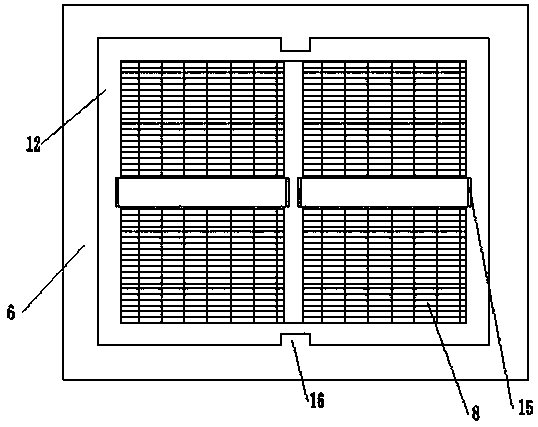

Double face side absorption type spray system

ActiveCN104858095AIncrease the air intake areaImprove the capture effectLiquid surface applicatorsCoatingsTrappingDynamic pressure

The invention relates to a double face side absorption type spray system. The double face side absorption type spray system comprises an air inlet, a dynamic pressure chamber, a static pressure chamber, a paint spray chamber and a paint mist separation chamber, which are sequentially arranged from the top down, wherein two rows of paint mist trapping devices are symmetrically arranged in the paint mist separation chamber, air inlets of the two rows of the paint mist trapping devices are oppositely arranged, and stream guidance spaces for leading air to flow are left between the two rows of the paint mist trapping devices and on the upper portions of the paint mist trapping devices. Compared with the prior art, the paint mist trapping devices respectively arranged on two sides of the paint mist separation chamber can increase the draught area and the separating area of the air in multiples, the quantity of paint mist trapping units and paint mist trapping absorption ability can be greatly improved, replacement frequency of the paint mist trapping units is reduced, and the stream guidance space left between the two rows of the paint mist trapping devices, located on the two sides of the paint mist separation chamber, can homogenize loads of all the paint mist trapping units, and can improve the trapping absorption ability of the paint mist trapping units for paint mist and stability of the double face side absorption type spray system.

Owner:嘉兴启净涂装科技有限公司

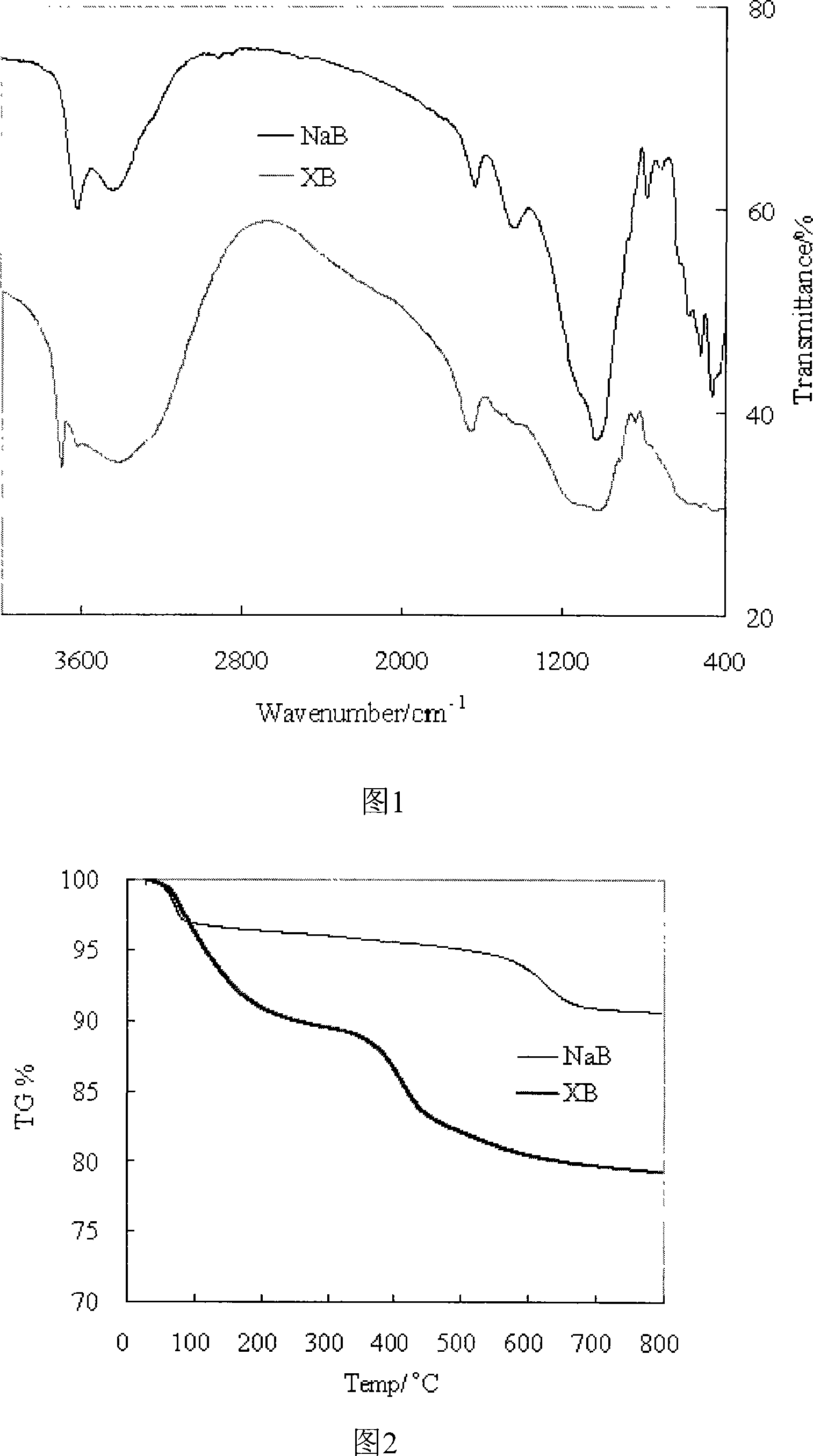

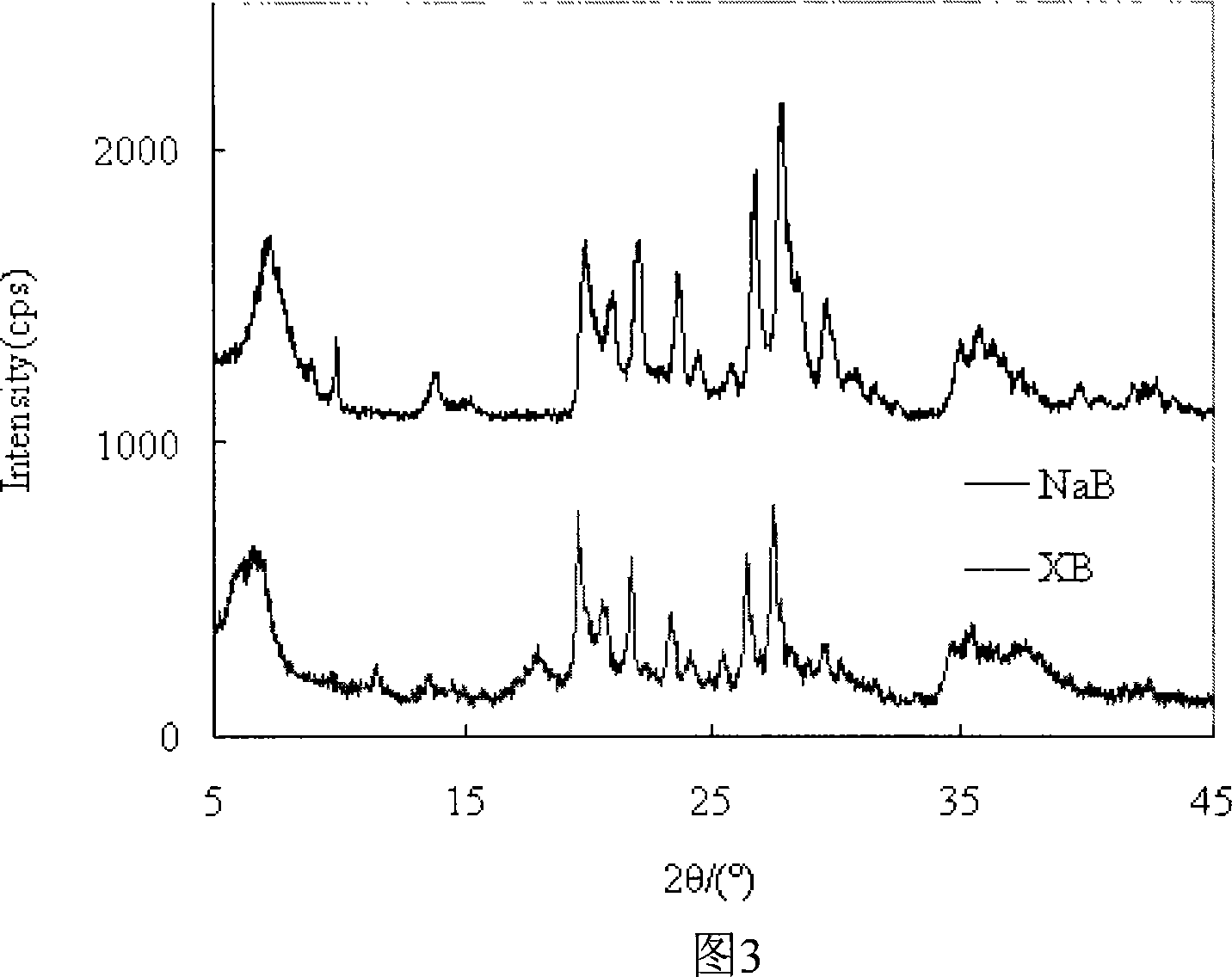

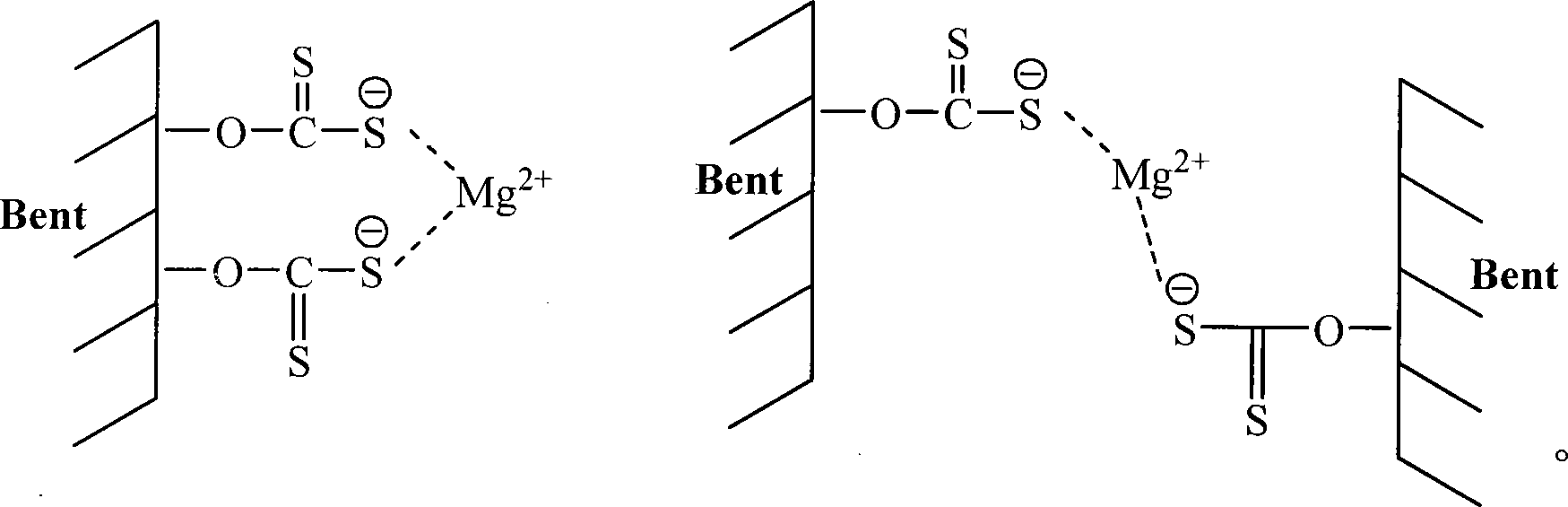

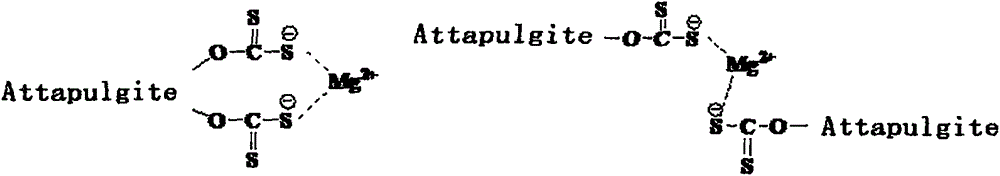

Xanthation bentonite absorbingsubstance and method for preparing the same

InactiveCN101081359AImprove stabilityHigh ion exchange capacityOther chemical processesWater/sewage treatmentSodium BentoniteSorbent

The present invention is xanthated bentonite as one kind of metal ion adsorbent with high adsorption capacity and its preparation process. The metal ion adsorbent with high adsorption capacity is prepared with bentonite sodium as material, and through dispersing, alkalization, reacting with SO2, and treating with magnesium salt to form stable magnesium salt of xanthated bentonite. The xanthated bentonite has powerful adsorption on heavy metal ion, and may be used in treating waste water containing heavy metal ion. Treating waste water containing heavy metal ion with the xanthated bentonite has the features of simple operation, high speed, high metal ion eliminating rate, easy solid-liquid separation, etc.

Owner:NORTHWEST NORMAL UNIVERSITY

Paint mist treatment method and spraying tank

ActiveCN105498400AAvoid decompositionPromote degradationCombination devicesGas treatmentWater curtainDecomposer

The invention relates to the technical field of spraying waste gas treatment, in particular relates to a paint mist treatment method and a spraying tank. The paint mist treatment method comprises the following steps: (1) carrying out spraying adsorption on spraying waste gas by a water curtain formed by circulating water on a water screen baffle plate; (2) enabling the spraying waste gas to enter a rotary washing drum, carrying out rotary washing on the spraying waste gas, and carrying out spraying absorption on the spraying waste gas by a spraying device arranged at the top part of the rotary washing drum; (3) exhausting the spraying waste gas after treating the spraying waste gas through a demisting layer, wherein a paint mist decomposer and a paint mist catcher are added in the circulating water which is used for treating the spraying waste gas. According to the paint mist treatment method disclosed by the invention, the technologies of water screen spraying, rotary washing and spraying adsorption are combined, and a good paint mist removing effect is obtained; the paint mist decomposer and the paint mist catcher are matched with each other to be added in the circulating water, so that paint mist can be effectively prevented from sticking on the inner wall of the spraying tank; the paint mist in the circulating water is enabled to be flocculated and floats up, so that cleaning of floating paint mist scum is facilitated, the service cycle of the circulating water is prolonged, and the damage to equipment is reduced.

Owner:吴永光 +1

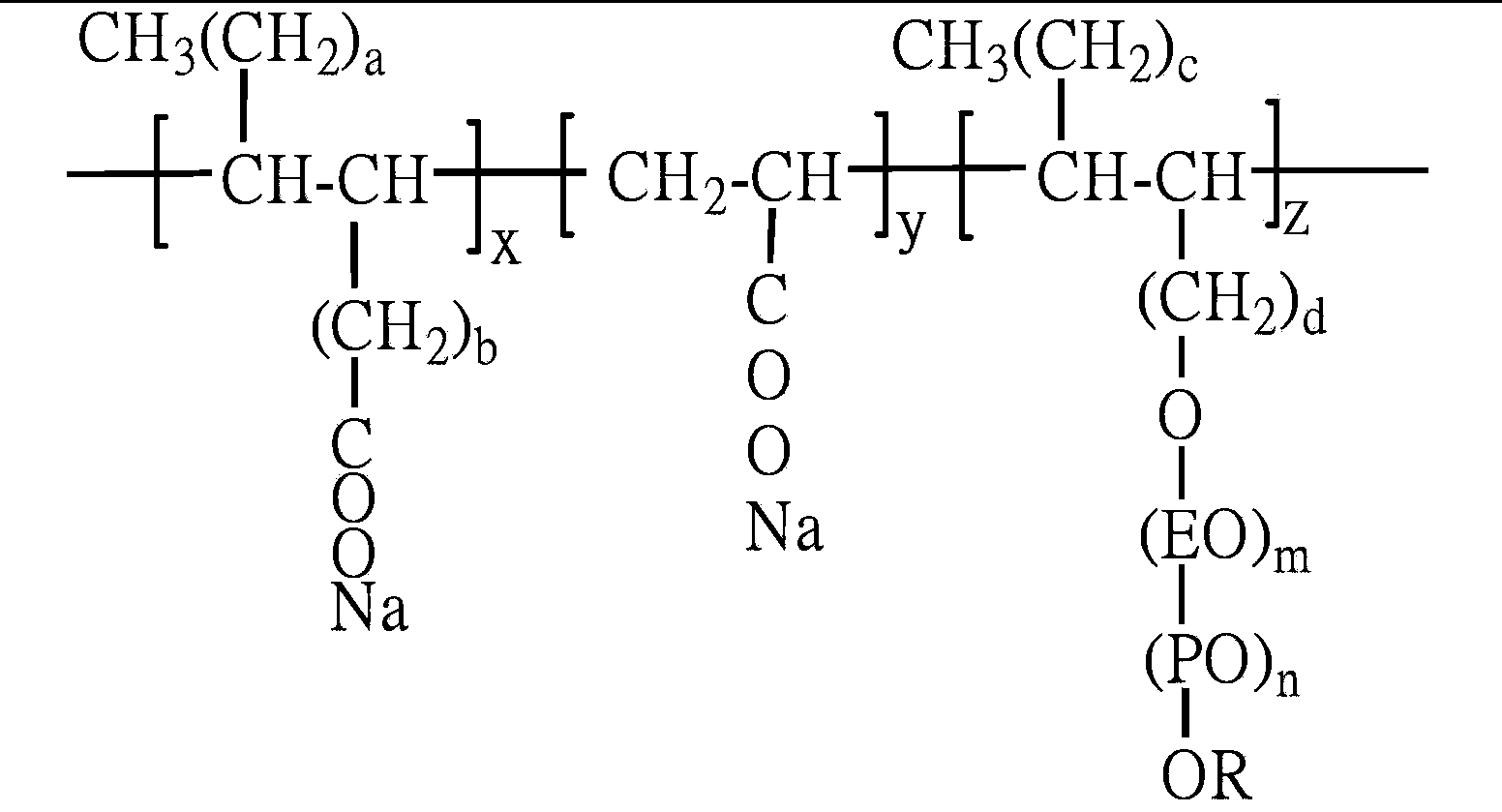

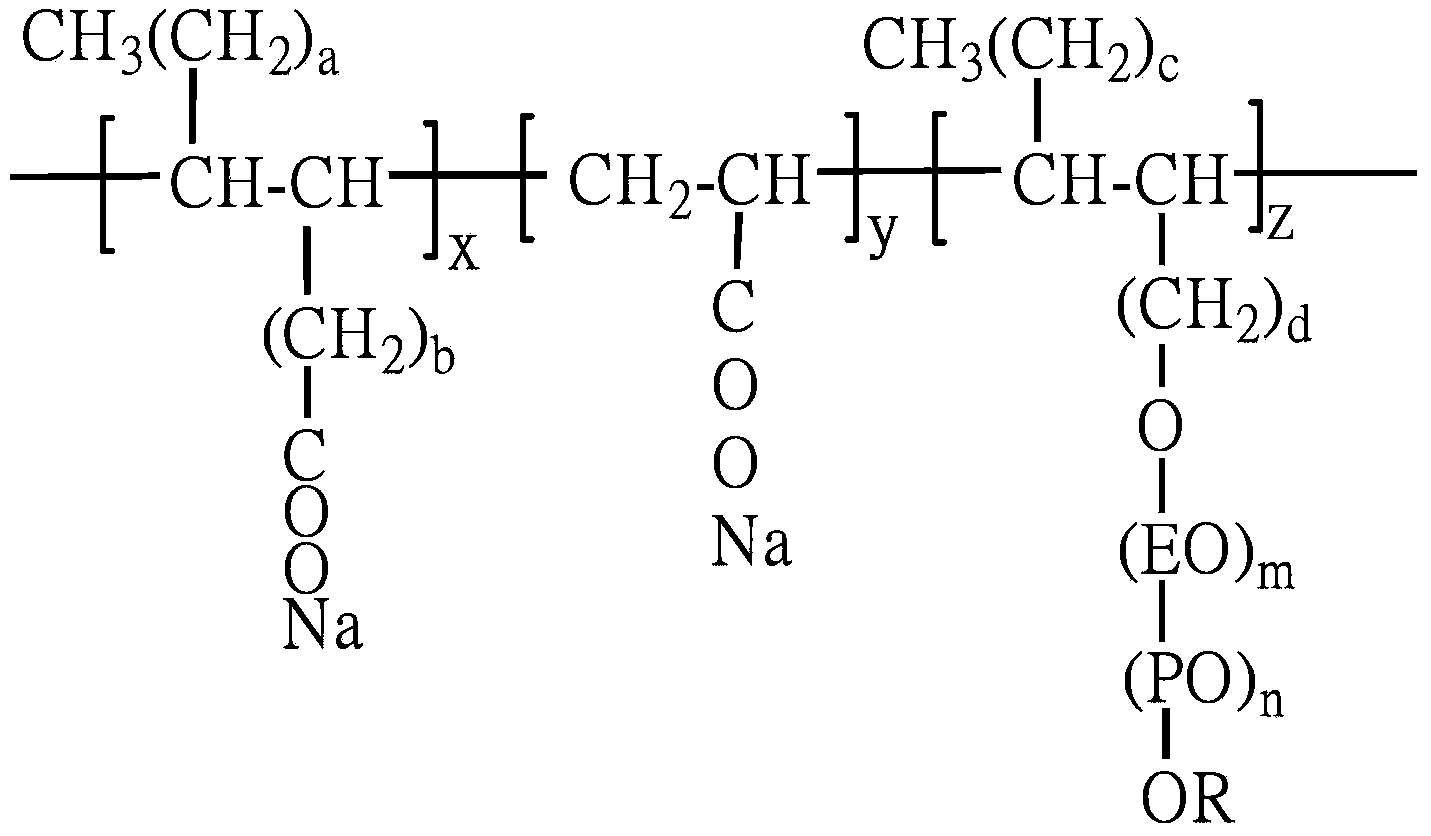

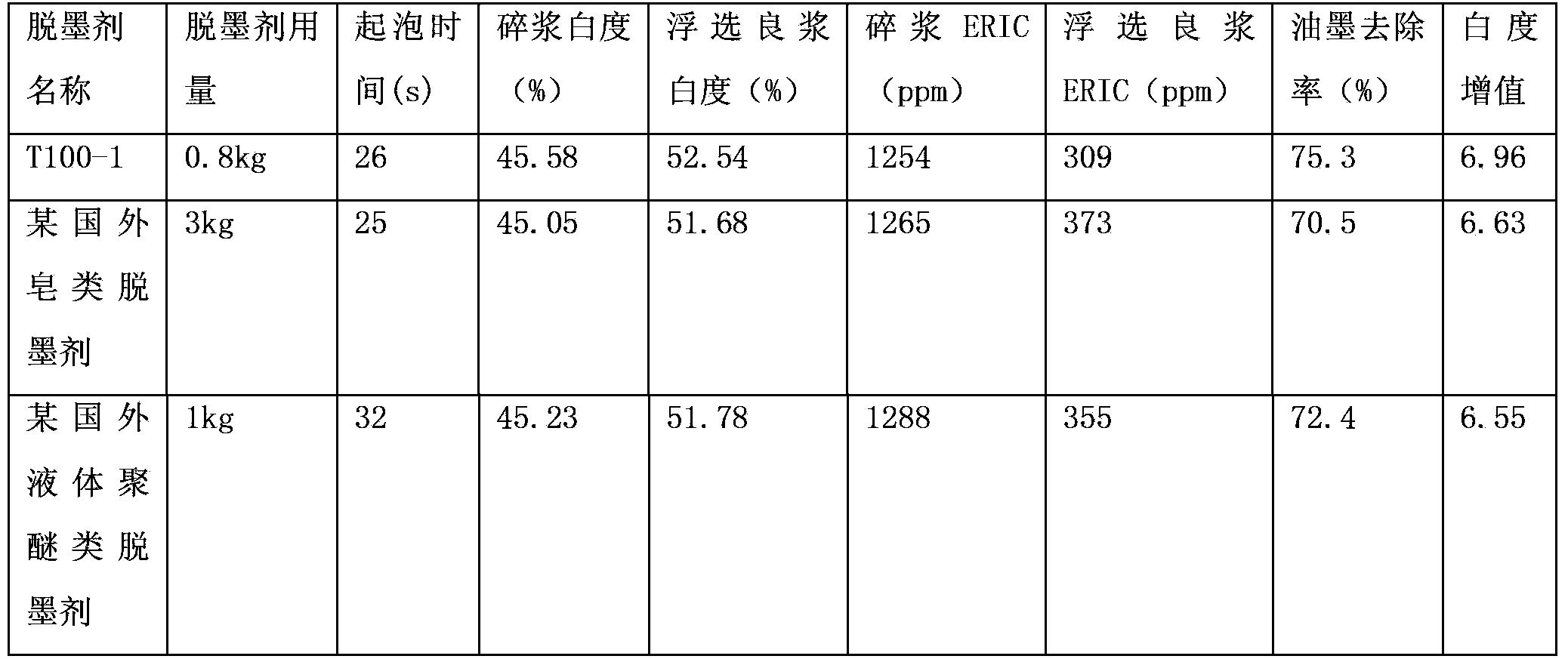

Low-foaming liquid polyether waste paper deinking agent and synthetic method thereof

ActiveCN103396697AImprove permeabilityThe size is easy to controlPaper recyclingChemical paints/ink removersPotassium hydroxideSolvent

The invention relates to a papermaking auxiliary agent, and more specifically relates to a low-foaming liquid polyether waste paper deinking agent and a synthetic method thereof. The low-foaming liquid polyether waste paper deinking agent is capable of completely replacing sodium soaps, and a main compound of the low-foaming liquid polyether waste paper deinking agent is a special polyether. The synthetic method comprises following steps: (1) adding an unsaturated fatty alcohol which is used as an initiator into a reaction vessel, adding potassium hydroxide which is used as a catalyst for reaction, removing water until weight ratio of water is less than 0.3%, and adding oxirane and epoxypropane separately so as to obtain unsaturated enol-polyether; (2) adding an unsaturated long-chain fatty acid, toluene solvent and a catalyst into the reaction vessel, heating to 60 to 80 DEG C, at the same time dropwise adding a mixed solution of the product obtained in step (1), acrylic acid and toluene, then heating the mixture to 70 to 85 DEG C, and keeping the temperature for 1.5 to 4h so as to obtain a product; and (3) mixing and reacting the product obtained in step (2), propylene glycol block polyether, fatty alcohol-polyoxyethylene ether-7 or fatty alcohol-polyoxyethylene ether-9, and water so as to obtain the special polyether.

Owner:威尔(福建)生物有限公司

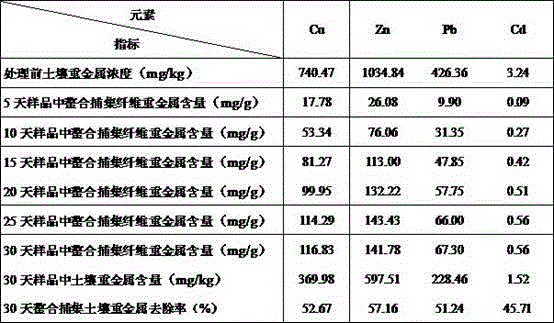

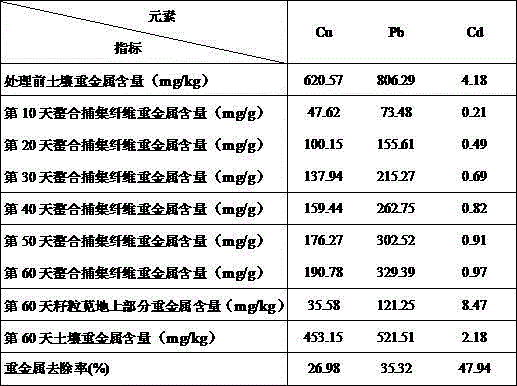

In-situ capturing treatment method for soil heavy metal pollution

ActiveCN105689371AImprove capture capacityProcessing speedContaminated soil reclamationHigh concentrationHeavy metal chelation

The invention discloses an in-situ capturing treatment method for soil heavy metal pollution. The method comprises the steps of 1 deep ploughing and cleaning-up of soil, 2 burying of chelating capturing materials, 3 dry and wet adjustment, 4 soil heavy metal activation, 5 removing of the chelating capturing materials, 6 activating and recycling of the chelating capturing materials, 7 soil microelement supplementing and the like. According to the method, the chelating capturing materials are used for effectively removing water-soluble heavy metal, exchangeable heavy metal and part of carbonate-exchangeable heavy metal in soil, and the main route of soil heavy metal environmental risk transfer is effectively interdicted. The heavy metal chelating capturing materials adopted in the method can effectively treat trace metal pollution, high-concentration heavy metal pollution and multi-metal combined pollution, and the chelating capturing materials obtained after treatment can be activated and recycled. In addition, the method has the beneficial effects of being easy to operate, capable of being used in combination with other restoring methods easily, good in treatment effect, low in cost, free of secondary environmental risks and the like.

Owner:SHENZHEN DUOYUAN TUOZHAN ENVIRONMENTAL PROTECTION TECH CO LTD

Method for implementing trapping and separation of CO2 in flue gas by adopting magnesium-based absorbent

InactiveCN102580468AStrong capture capacityImprove capture capacityProductsCarbon compoundsChemistryMagnesium

The invention discloses a method for implementing trapping and separation of CO2 in flue gas by adopting a magnesium-based absorbent and relates to a CO2 trapping and separation technology. According to the invention, Mg(OH)2 suspension is used as the absorbent for CO2 in the flue gas; compared with the existing CO2 trapping capacity, the CO2 trapping capacity of the method is finally greatly improved by controlling conditions of a suitable solid-to-liquid ratio of the suspension, a ratio of the absorbent to the flue gas and the like; and a food-grade CO2 product with high purity is also obtained. The method disclosed by the invention has strong CO2 trapping capacity, simple process, low trapping agent regeneration cost and strong technical applicability.

Owner:HENAN UNIV OF SCI & TECH

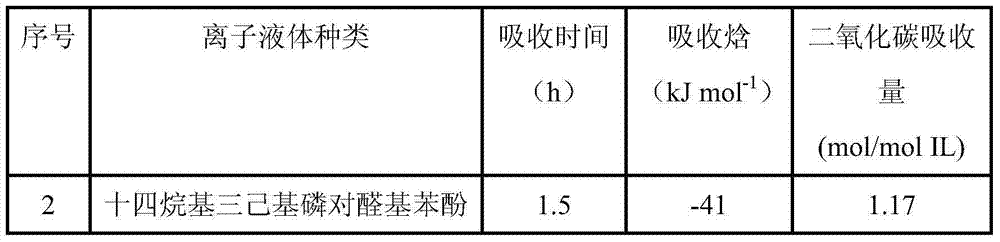

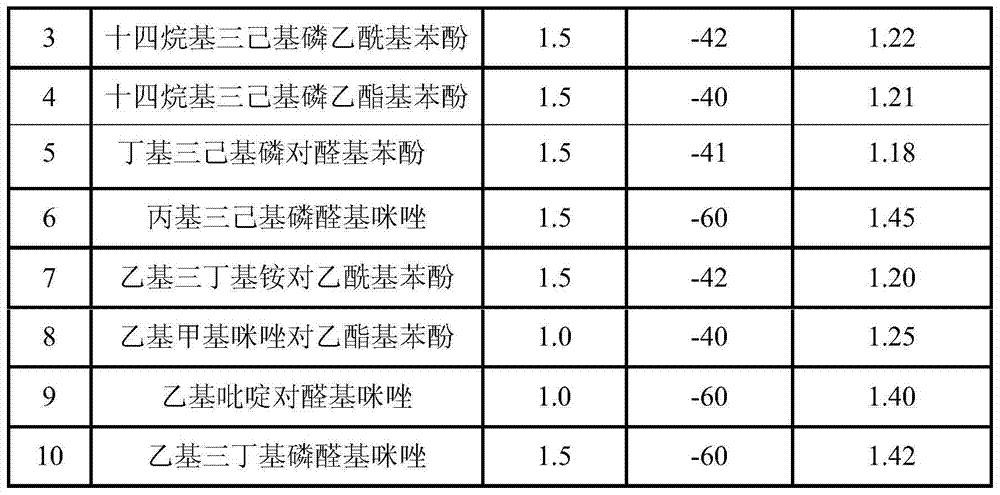

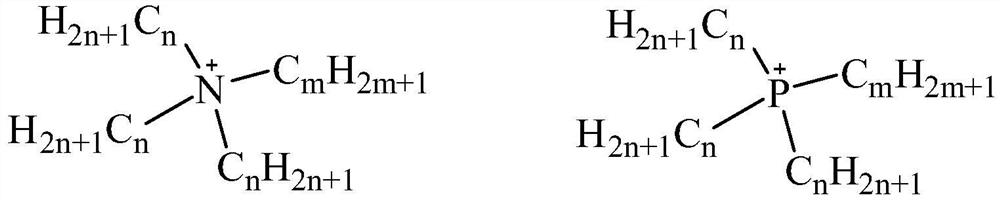

Efficient and energy-saving method for trapping carbon by ionic liquid

InactiveCN103752134AImprove capture capacityReduced effectProductsCarbon compoundsTrappingSpatial structure

The invention discloses an efficient and energy-saving method for trapping carbon by ionic liquid, which is applied to chemical trapping of carbon dioxide. A high-capacity, low-energy consumption and recyclable trapping of carbon dioxide is realized by using a synergistic effect of Lewis acids and bases and C-H...O, and thus a potential method is provided for industrial trapping of carbon dioxide. Compared with a conventional method, the method adopted by the invention is very novel, and has the following characteristics and beneficial effects: 1, through designing anion functionalized ionic liquid with different space structures and using the synergistic effect of Lewis acids and bases and C-H...O between carbonyl and carbon dioxide, the trapping amount of the ionic liquid to the carbon dioxide is greatly increased, which is up to 1.4mol / mole ionic liquid; and 2, due to the introduction of an electron-withdrawing function of the carbonyl, the acting enthalpy of the ionic liquid and the carbon dioxide is reduced, and the carbon dioxide is more easily desorbed.

Owner:ZHEJIANG UNIV

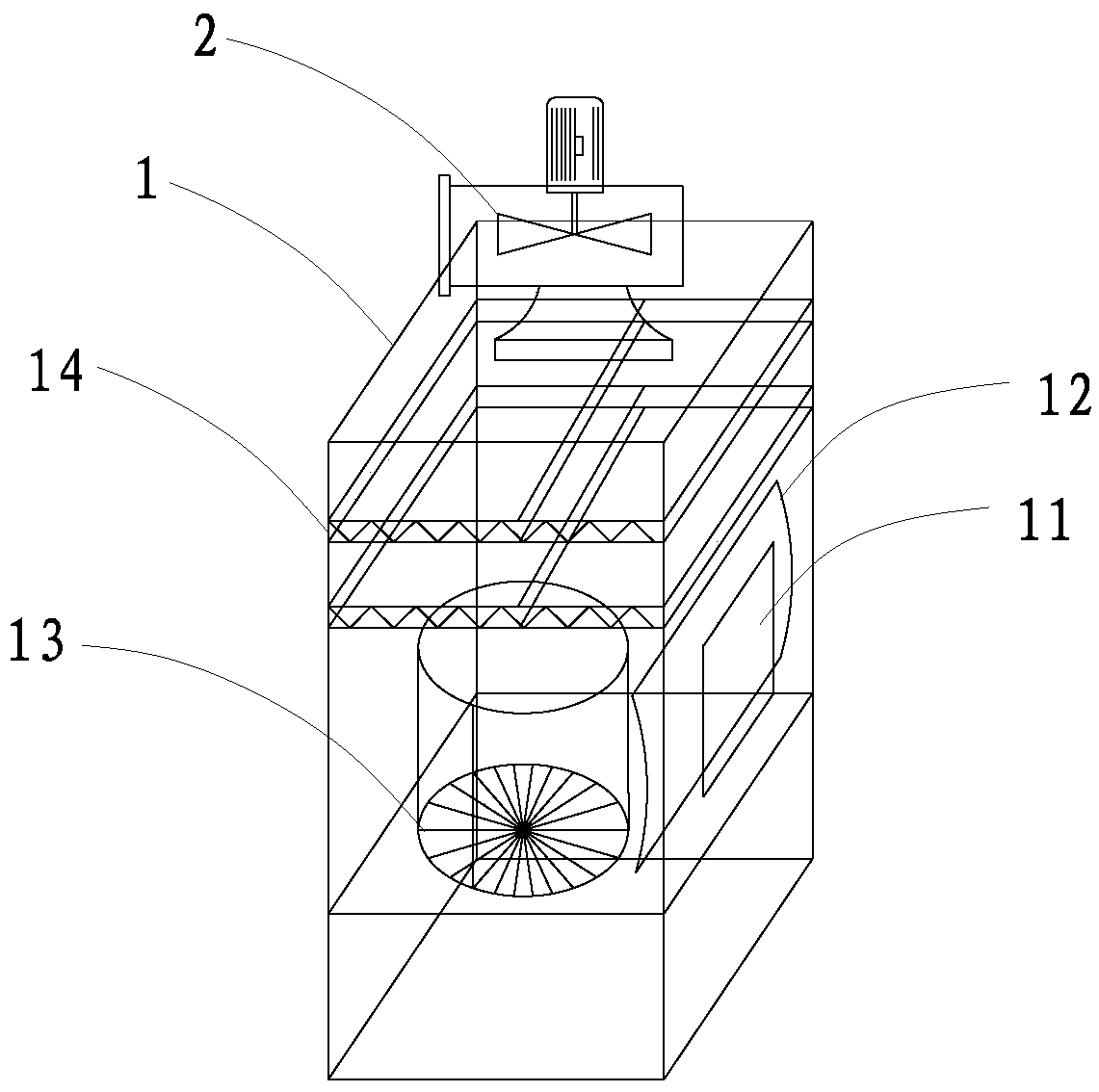

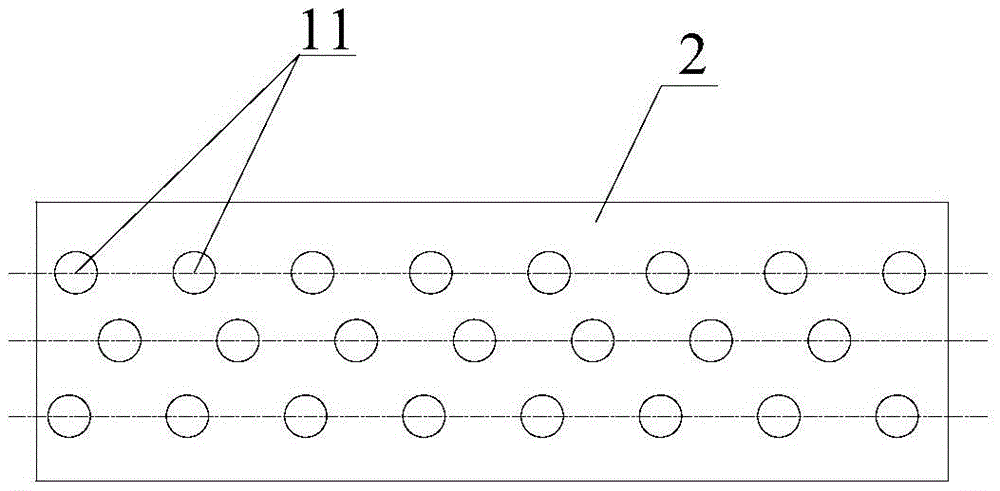

Apparatus for collecting by-product in semiconductor process

ActiveCN109979849AImprove capture capacityIncrease volumeGas treatmentFinal product manufactureProduction rateSemiconductor package

Disclosed is an apparatus for collecting a by-product in a semiconductor process, the apparatus including: a housing; a heater plate; a heater power supply unit; first and second upper horizontal brackets collecting a by-product; a by-product collecting tower allowing the exhaust gas to pass through an exhaust gas passing space and collecting the by-product; the lower horizontal bracket guiding the exhaust gas toward the window and collecting the by-product contained in the exhaust gas; the window blocking the powder form by-product from introducing to a gas collecting and discharging port andguiding the exhaust gas thereto; and the gas collecting and discharging port. Accordingly, the apparatus can increase capacity of collecting a by-product with a simple structure, thereby extending areplacement period of the apparatus. In addition, the apparatus can collect a large amount of by-products quickly and efficiently over a long period of time.

Owner:MILAEBO

Coal-fired ultrafine grain chemical agglomeration promotor

ActiveCN101513583BLower specific resistanceImprove conductivityAuxillary pretreatmentElectrostatic separationInorganic saltsWater soluble

The invention discloses a coal-fired ultrafine grain chemical agglomeration promotor which comprises the components based on mass percent: 0.001-0.2% of surface active agent, 0.0001-0.01% of water-soluble high molecular compound, 0.001-0.05% of inorganic salt additive and the rest of water. The invention can effectively promote ultrafine grains to agglomerate, improve the removal efficiency of a static precipitator for the ultrafine grains and high specific resistance flying ash, and reduce the soot emission and the charges for disposing pollutant of enterprises. The agglomeration promotor has the components with wide source, economical price, environmental protection, simple synthetic process, easy operation and no environmental pollution.

Owner:武汉天空蓝环保科技有限公司

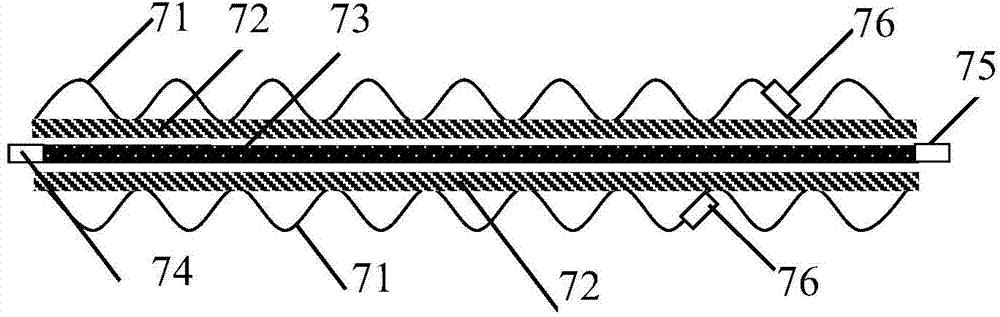

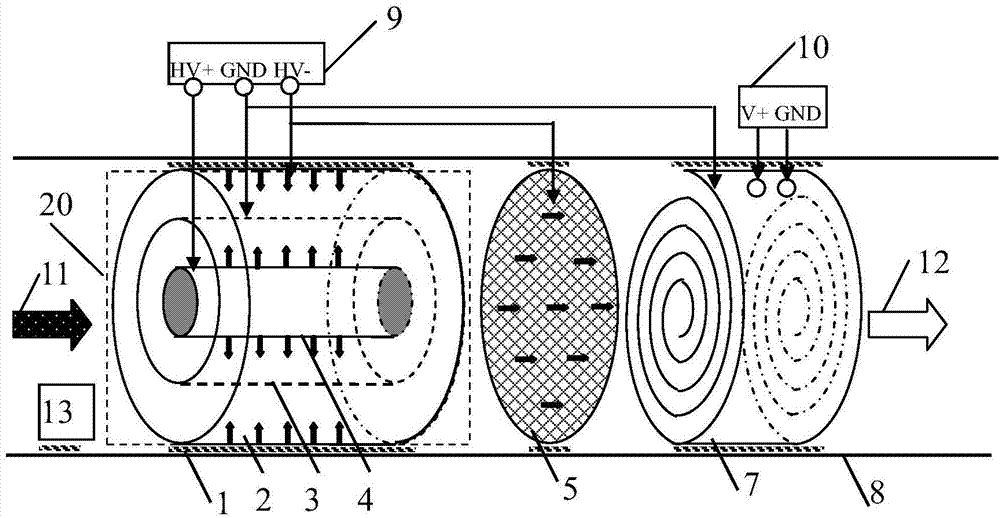

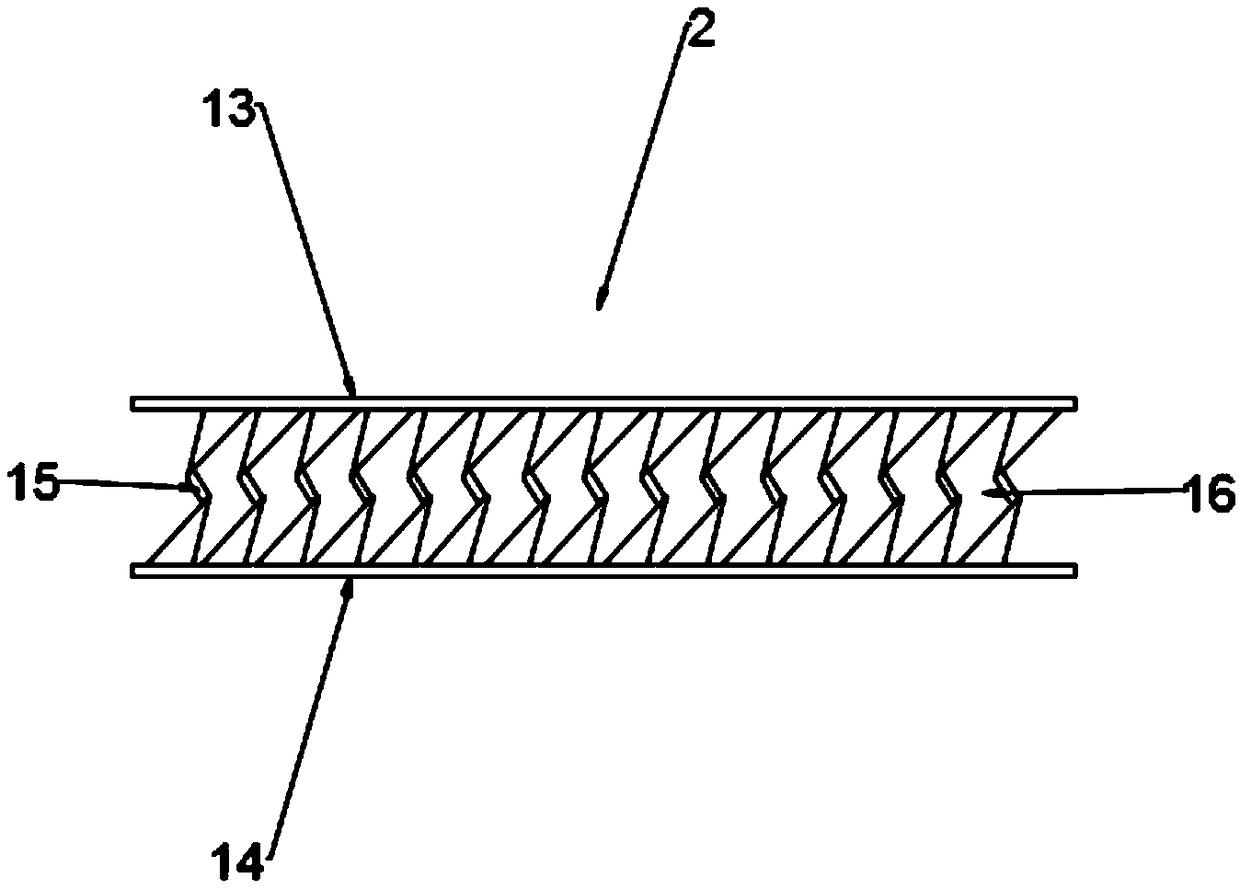

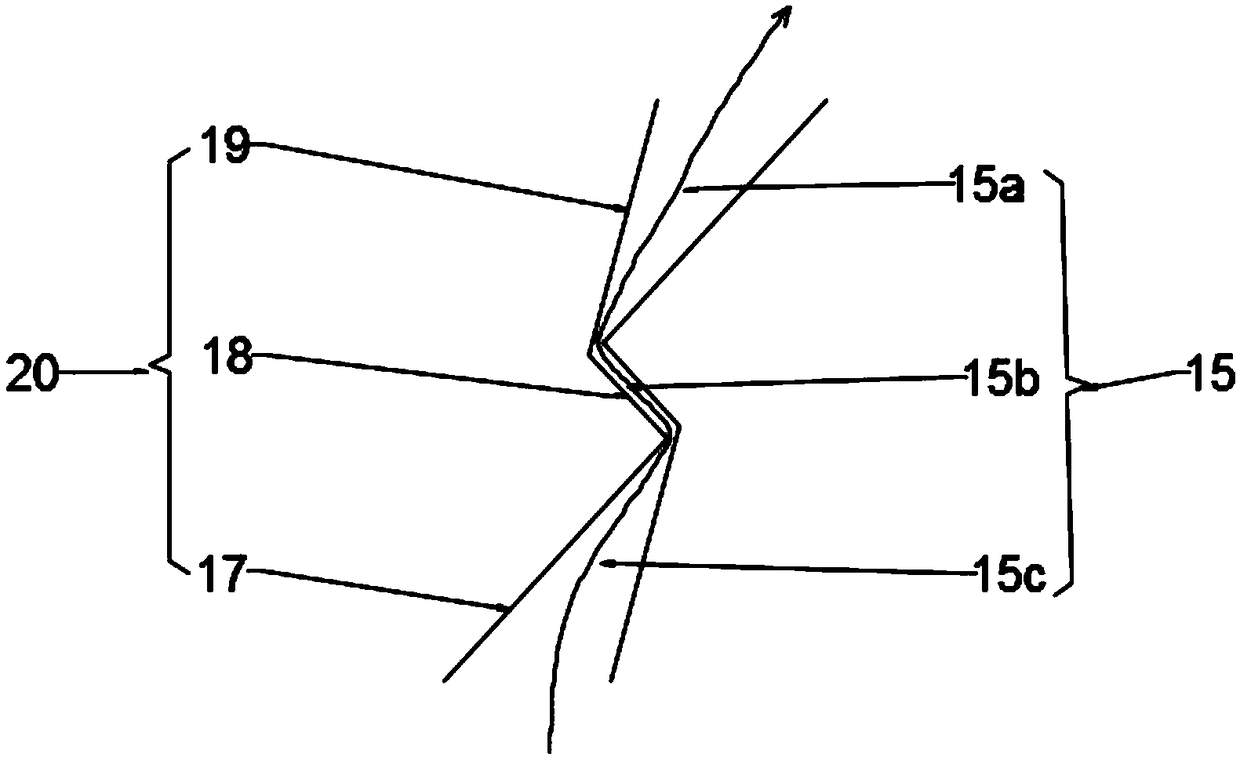

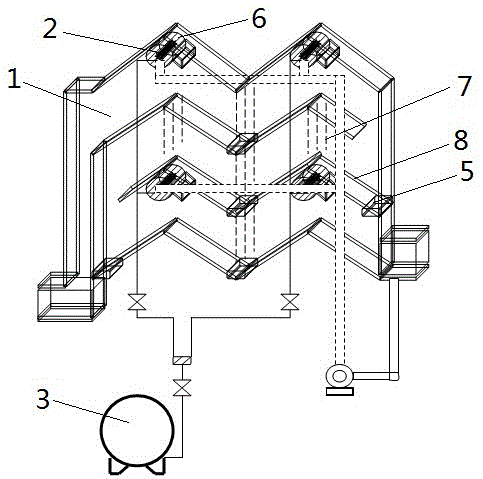

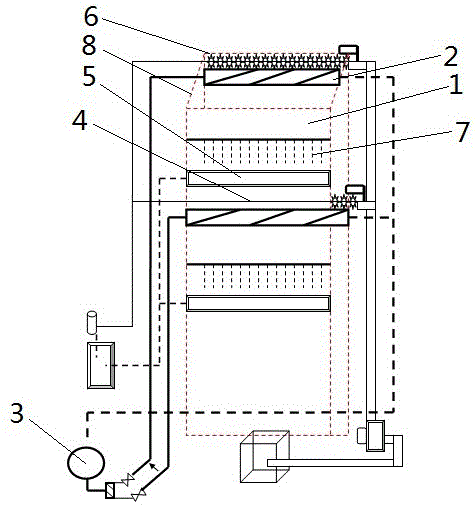

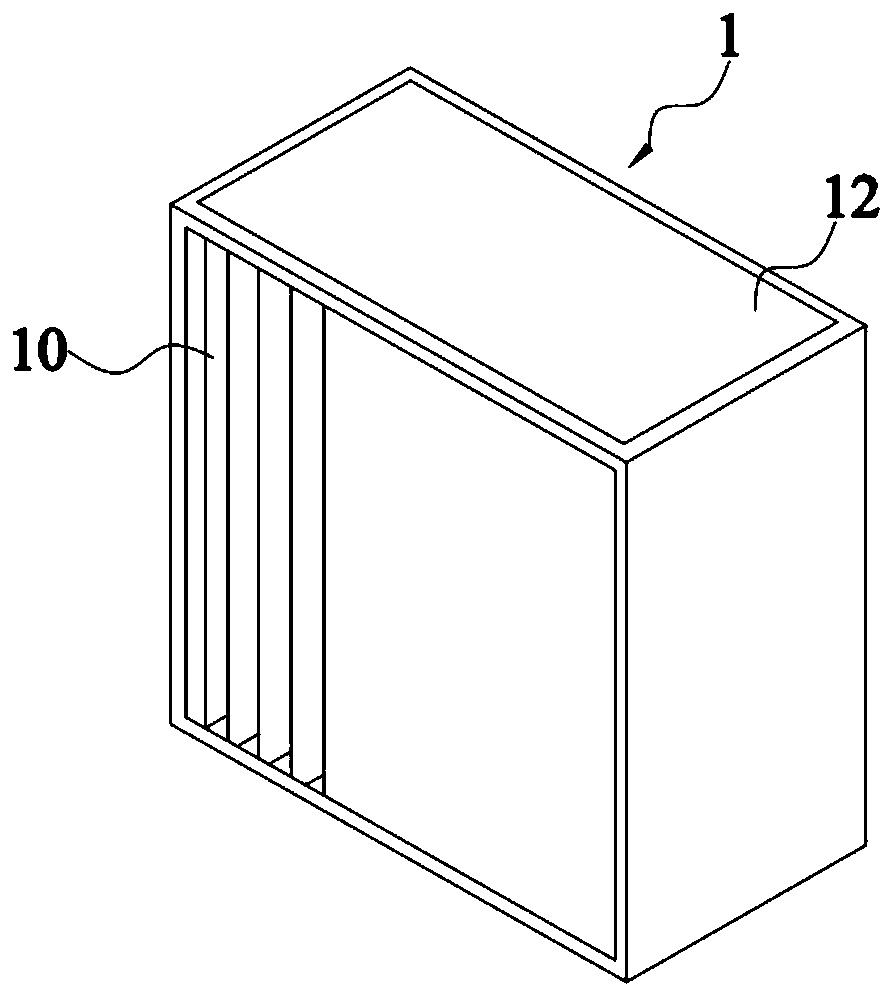

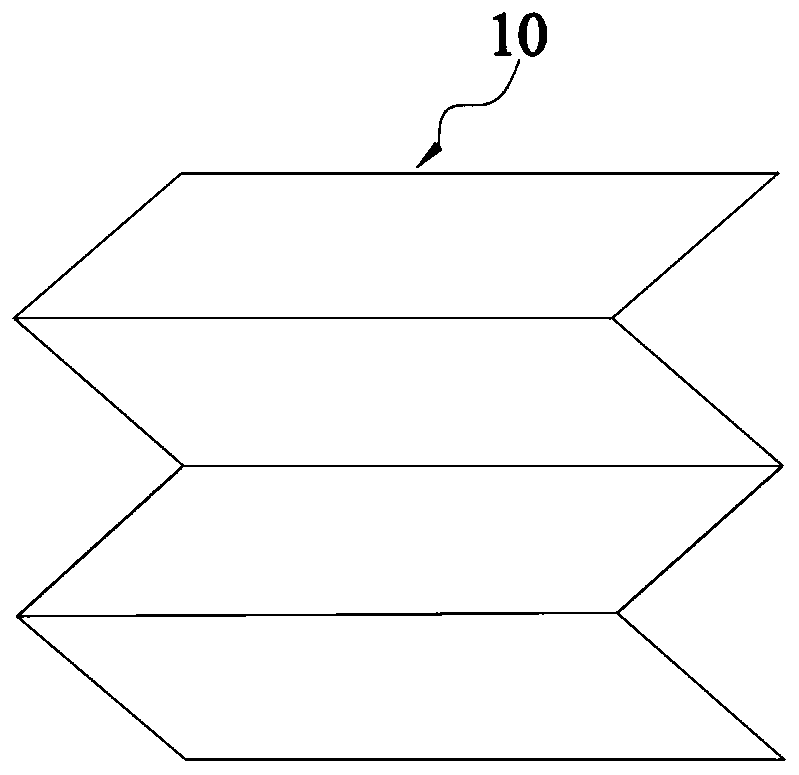

Automobile tail gas particulate matter trap and filter element

ActiveCN104763493ASmall exhaust pressure lossImprove capture capacityExhaust apparatusSilencing apparatusParticulatesInsulation layer

The invention discloses an automobile tail gas particulate matter trap and a filter element. A particulate matter coagulation unit (20), a charging unit (5) and the filter element (7) are arranged in a shell (8) in sequence in a direction from air inlet to air outlet, and the filter element (7) is wound into a cylindrical shape through a metal fiber plate (70). The metal fiber plate (70) comprises two metal fiber filtration and adsorption outer surface layers (71) and an electric heating film layer (73) clamped between the two metal fiber filtration and adsorption outer surface layers; heat conduction insulation layers (72) are arranged between the metal fiber filtration and adsorption outer surface layers (71) and the electric heating film layer (73); and the cross sections of the metal fiber filtration and adsorption outer surface layers (71) are corrugated, and the metal fiber filtration and adsorption outer surface layers (71) guide tail gas in the longitudinal direction. The automobile tail gas particulate matter trap is integrated with multiple functions of electrostatic adsorption and dust removal, filter element diffusion, intercepting, collision mechanism dust removing and the like, and the particulate matter trap effect is improved; the exhaust pressure loss of an engine is small, and the particulate matter trap effect is good; and the filter element is convenient to regenerate and reliable, and has the advantages of being low in use and maintenance cost and is suitable for popularization.

Owner:REED XINXIANG ROAD INC

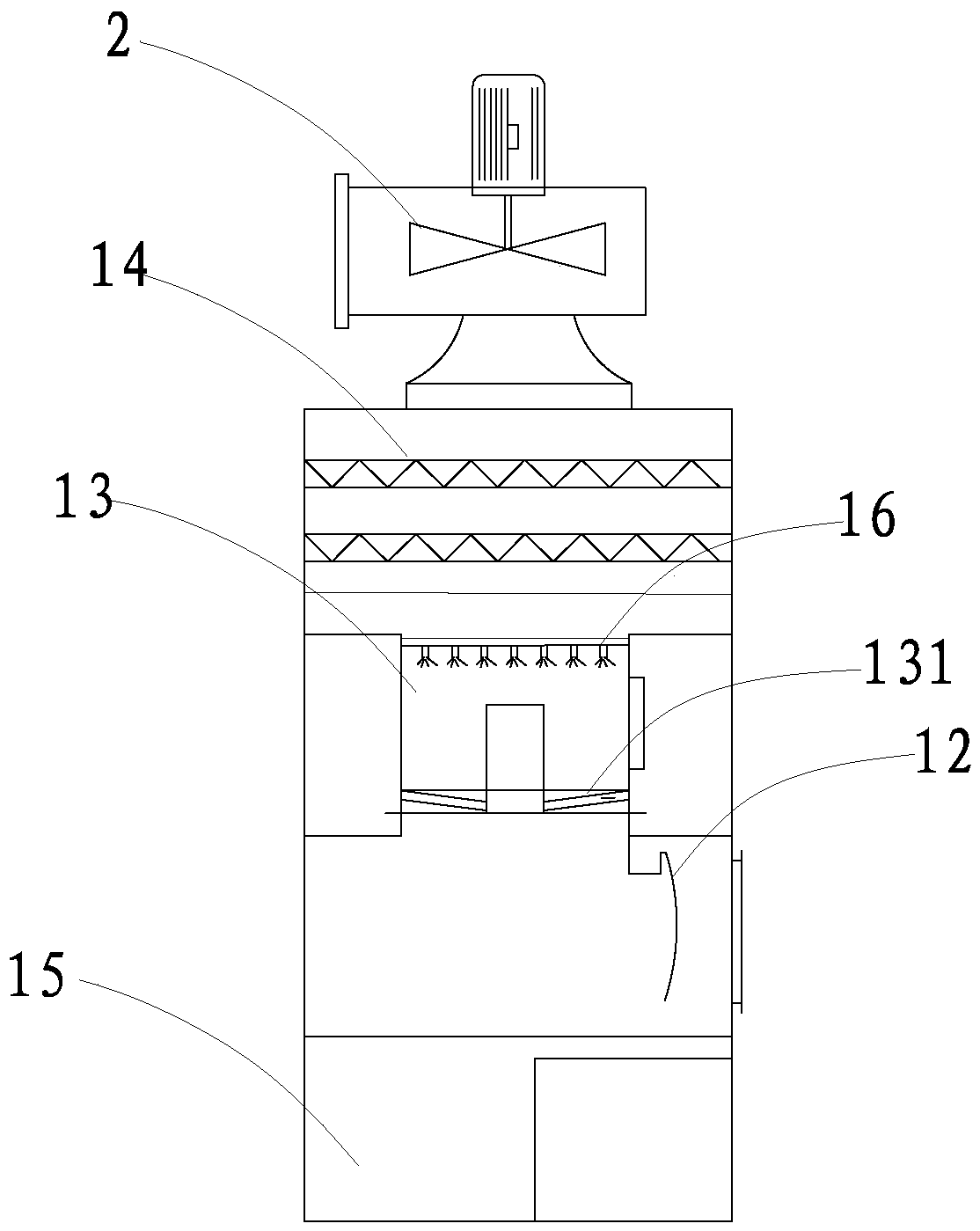

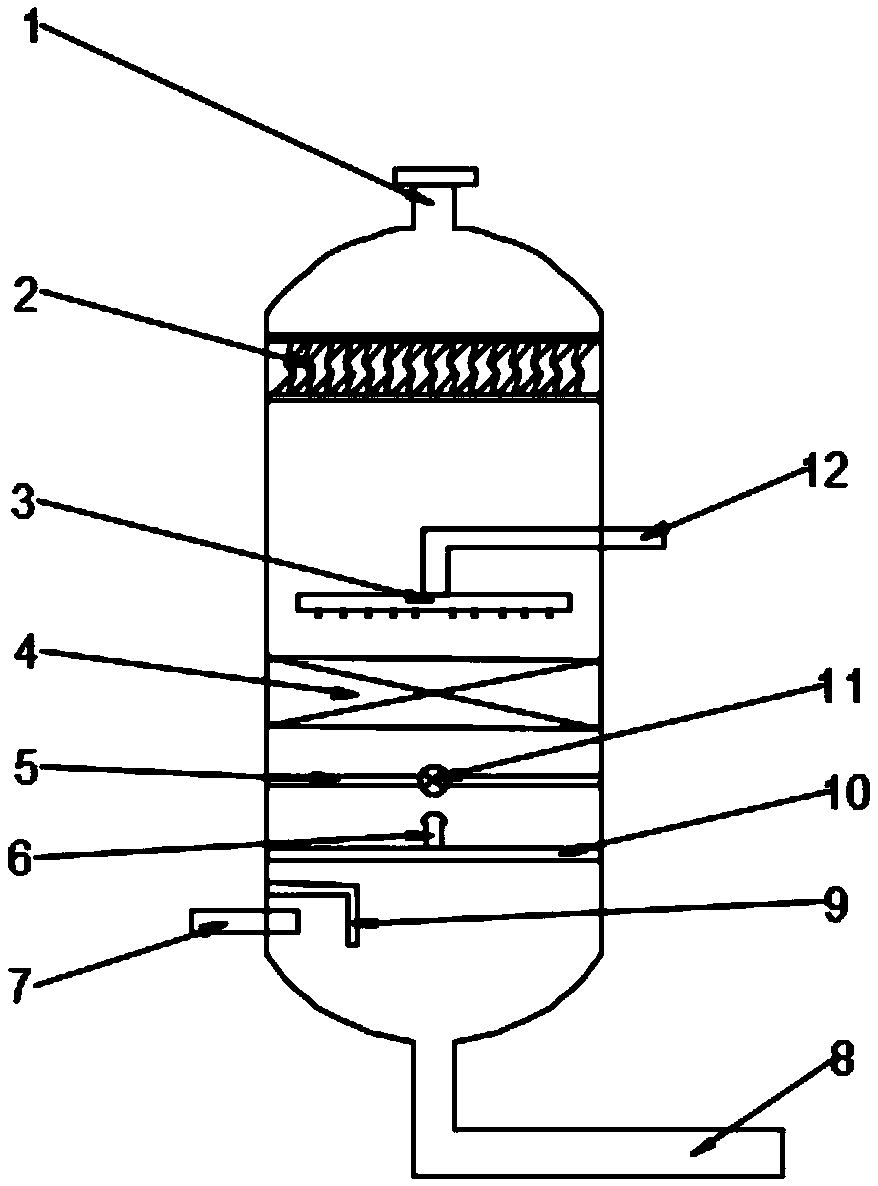

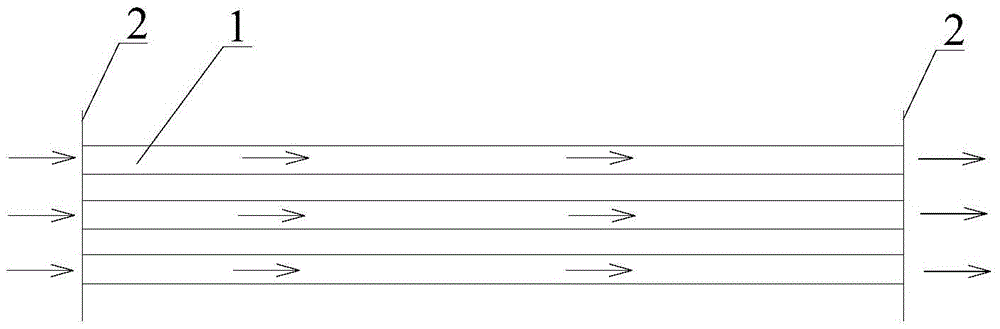

Waste gas absorption and purification equipment

InactiveCN109157951AStrong capture capacityIncrease the gas-liquid contact areaCombination devicesExhaust gasEngineering

The invention relates to the technical field of purification machinery equipment, in particular to waste gas absorption and purification equipment and solves the problem that liquid is carried in exhaust gas. The invention has the technical key points that the waste gas absorption and purification equipment comprises a gas outlet, a gas inlet, a liquid outlet and a liquid inlet; the liquid inlet is connected with a liquid distributor, and a gas-liquid separation device is arranged above the liquid distributor and is positioned between the gas outlet and the liquid inlet; the gas-liquid separation device comprises a first supporting piece and a second supporting piece, and first baffles, second baffles and third baffles are arranged between the first supporting piece and the second supporting piece; one first baffle, one second baffle and one third baffle form a baffle; the gas-liquid separation device comprises a plurality of baffles arranged in parallel, and a first overflow passage and a second overflow passage which are arranged in a staggered manner are formed between the adjacent baffles. As the waste gas absorption and purification equipment is provided with the gas-liquid separation device, the gas-liquid separation device can more thoroughly separate the gas from the liquid carried in the gas.

Owner:霸州市辉月网络技术有限公司

Wet process desulphurization demisting device and wet process desulphurization device

InactiveCN105477896AImprove capture capacityAvoid plaster rainDispersed particle separationVapor condensationGypsumEngineering

The invention discloses a wet process desulphurization demisting device and a wet process desulphurization device, and belongs to the technical field of wet process desulphurization. The wet process desulphurization demisting device provided by the invention comprises at least two layers of parallel pipe rows; the two adjacent layers of pipe rows are in staggered arrangement; each layer of pipe row respectively comprises a plurality of mutually parallel hollow thin pipes and also comprises a cooling medium source; at least partial hollow thin pipes are communicated with the cooling medium source; the cooling medium source is used for providing cooling media for the hollow thin pipes. According to the wet process desulphurization demisting device and the wet process desulphurization device provided by the invention, the cooling media are communicated inside the pipe rows for cooling smoke gas; water vapor in the smoke gas can be condensed by using fine particulate matters and liquid drops as the core, so that the mass of the fine particulate matters and the liquid drops can be increased; the inertia is increased; the catching capability of the demisting device on the fine particulate matters and the liquid drops is improved; the generation of gypsum rain is avoided; the demisting effect is improved. The wet process desulphurization device provided by the invention is provided with the wet process desulphurization demisting device, and has the advantages that the scale formation blockage cannot easily occur; the demisting effect is good.

Owner:YANTAI LONGYUAN POWER TECH

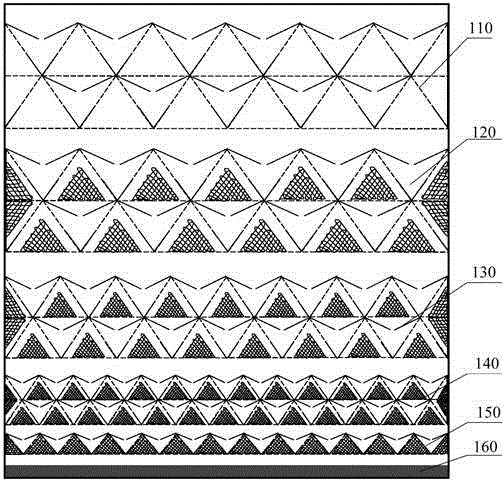

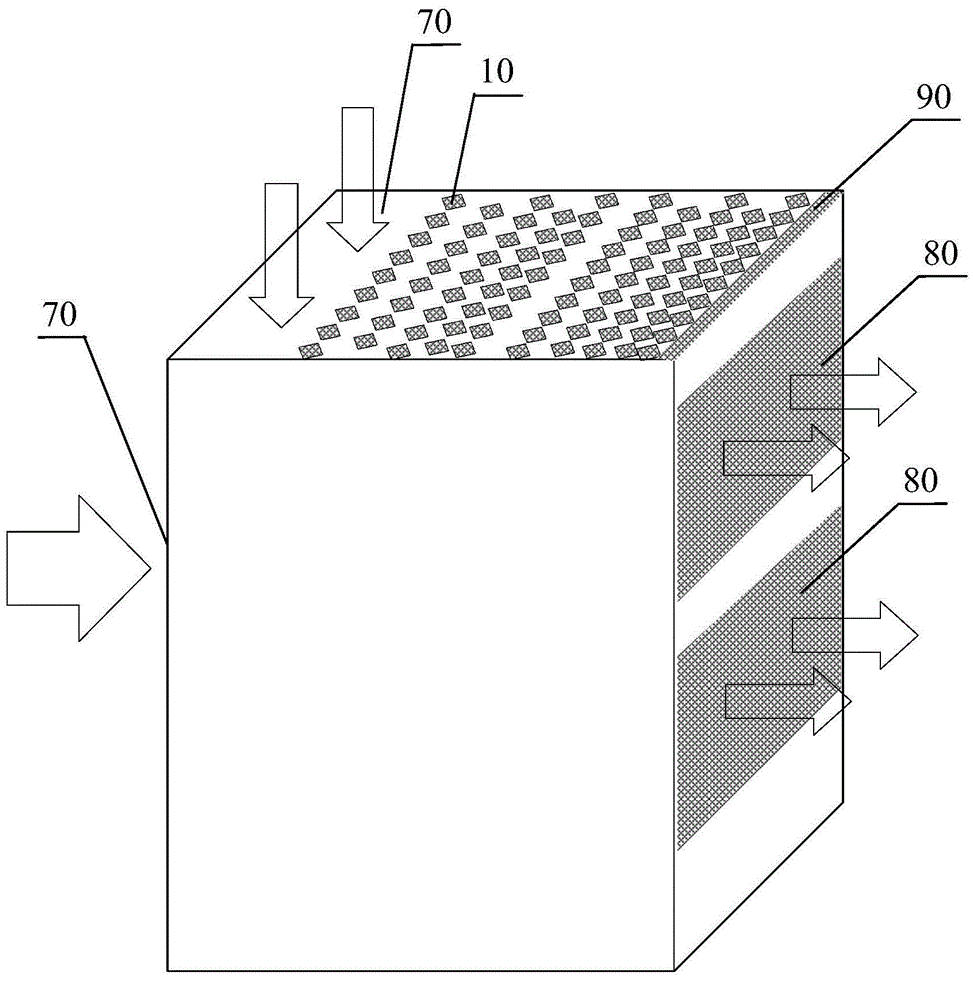

Dry type venturi paint mist trapping device and application thereof

ActiveCN104971558AAvoid cloggingImprove capture capacityCombination devicesDispersed particle filtrationLacquerFiltration

The invention relates to a dry type venturi paint mist trapping device. The device comprises a shell, wherein multiple rows of paint mist filtration and interception units arrayed in a cross manner are arranged in the shell, a gap is left between each two adjacent paint mist filtration and interception units in the same row, and the gap and the surfaces of the paint mist filtration and interception units at two sides form an air flowing channel of a venturi structure. The paint mist trapping device filters and intercepts paint particles in a filtration manner at the early stage and in a filtration and impact force co-existing manner at the late stage. By virtue of the venturi structure, the amount of paint particles intercepted and captured through the impact force can be greatly increased. Besides, the invention further relates to a dry type paint spraying system with the dry type venturi paint mist trapping device. The paint mist trapping device is arranged at the exhaust opening of the paint spraying system, so as to separate paint mist in the air. Compared with the prior art, the dry type venturi paint mist trapping device has a strong capture and absorption capability for paint mist, and the environment pollution and energy consumption can be greatly reduced.

Owner:周小参

Application of carboxylate compound as absorbent for capturing carbon dioxide

ActiveCN114558549ASolve corrosiveSolve volatileOther chemical processesWater contaminantsPhosphoniumQuaternary ammonium ions

The invention discloses application of a carboxylate compound as an absorbent for capturing carbon dioxide. The carboxylate compound provided by the invention is used as an absorbent for capturing carbon dioxide and / or is applied to preparation of the absorbent for capturing carbon dioxide; carboxylic acid anions in the carboxylate compound are carboxylate radicals with carbon chains with more than 3 carbon atoms, and cations are substituted quaternary ammonium ions and / or quaternary phosphonium ions. The method for efficiently trapping carbon dioxide in an energy-saving manner by adopting a carboxylate compound stable to water comprises the following steps: placing an aqueous solution of the carboxylate compound in a carbon dioxide atmosphere to absorb carbon dioxide, so as to obtain a conjugate of carboxylate and carbon dioxide separated out from water. The invention is used for solving the problems of corrosivity, volatility and high energy consumption of the existing system, and can obtain higher carbon dioxide capture capacity at high temperature, low pressure of carbon dioxide pressure and high pressure; the conjugate of carboxylate and carbon dioxide is stable to water; the carboxylate can be regenerated.

Owner:BEIJING YUTAN TECH CO LTD

Xanthic acid-based attapulgite adsorbent as well as preparation method and application thereof

InactiveCN106111072AImprove stabilityHigh ion exchange capacityOther chemical processesWater contaminantsMagnesium saltWastewater

The invention discloses a xanthic acid-based attapulgite adsorbent. The adsorbent is prepared from attapulgite, sodium hydroxide, carbon disulfide, soluble magnesium salt and deionized water. The invention also discloses a preparation method of the xanthic acid-based attapulgite adsorbent. The preparation method comprises the following steps: dispersing and alkalifying attapulgite, then subjecting attapulgite to reaction with carbon disulfide, then carrying out transformation by utilizing magnesium salt to generate a magnesium salt solution of xanthic acid-based attapulgite and finally carrying out washing and drying, thus obtaining the xanthic acid-based attapulgite adsorbent. The xanthic acid-based attapulgite adsorbent is used for removing dyes in wastewater. The xanthic acid-based attapulgite adsorbent provided by the invention has strong dye adsorption capacity, short adsorption time and high adsorption capacity. The preparation method is simple and practicable to operate and rapid and convenient to operate and has the advantages of high dye decolorization rate and easiness in solid-liquid separation after adsorption.

Owner:定西师范高等专科学校

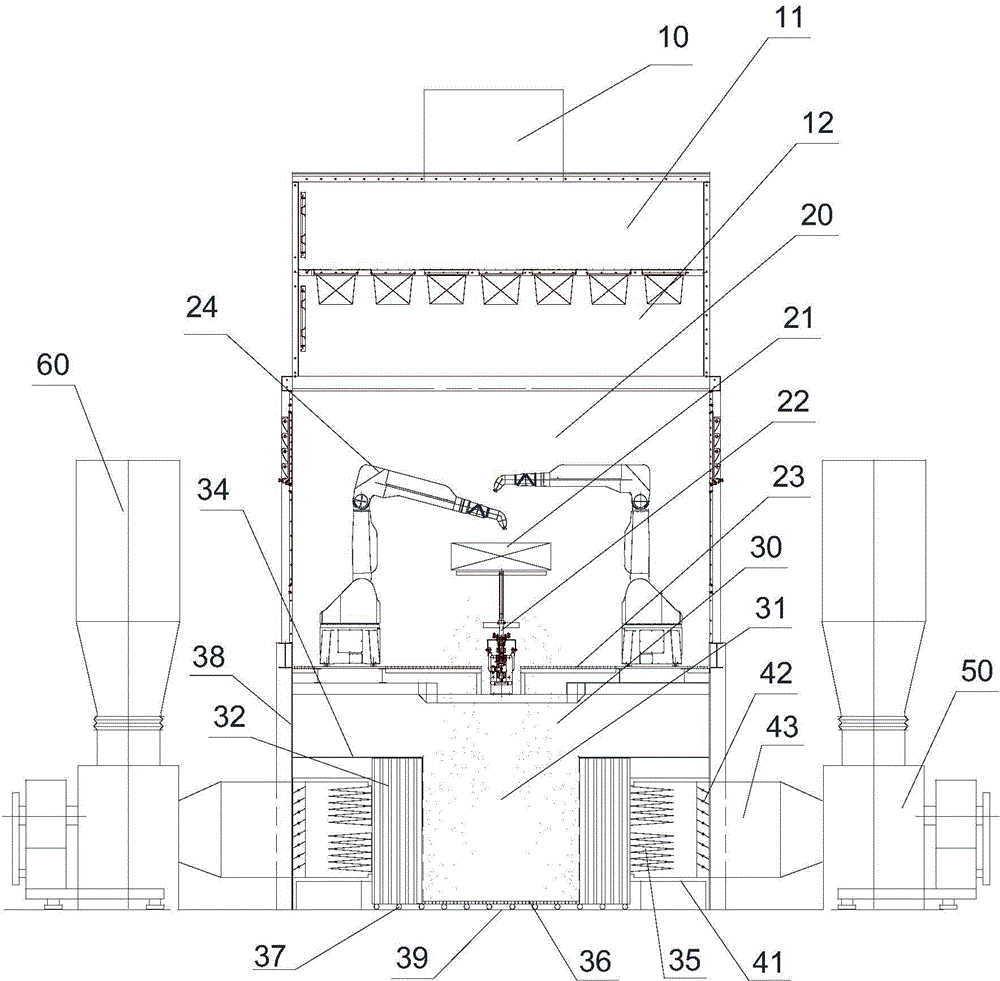

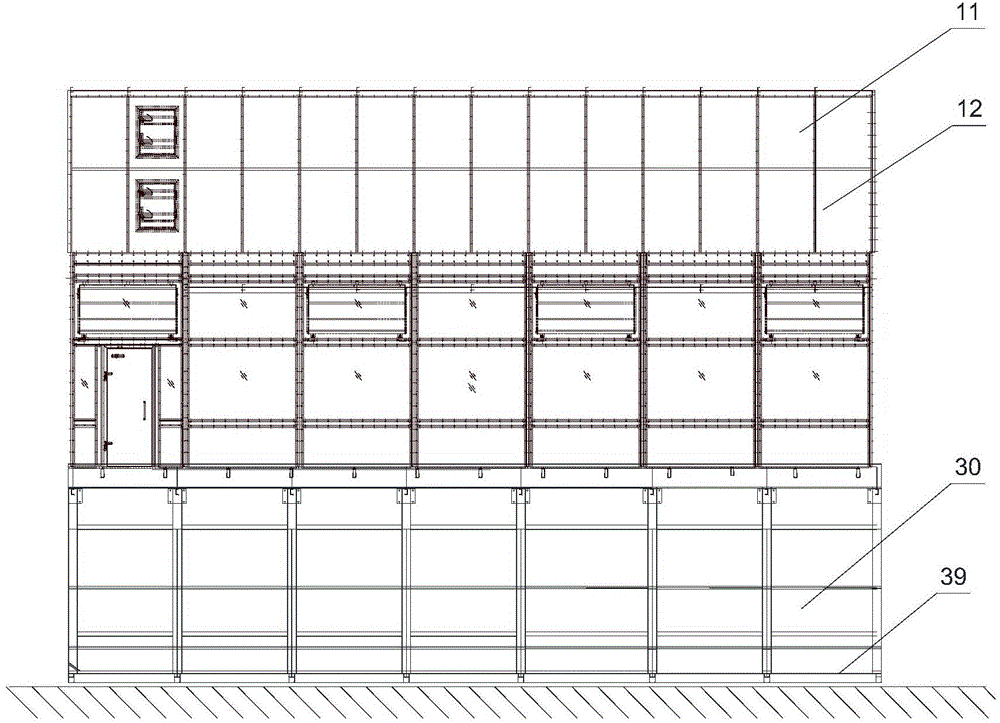

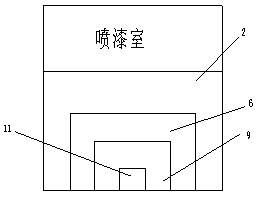

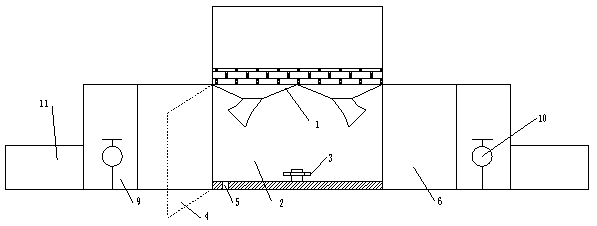

Novel dry type paint mist separated vehicle coating equipment

PendingCN108160386AImprove capture capacityPrevent disengagementGas treatmentDispersed particle filtrationOzone generatorLacquer

The invention discloses novel dry type paint mist separated vehicle coating equipment. The equipment comprises a spraying chamber, a diversion chamber, a paint mist filtering separation device and anozone generator; a grille is arranged on the lower portion of the spraying chamber, a diversion device is arranged on the lower portion of the grille and on the upper portion in the diversion chamber,at least one inspection door is arranged on the left side and the right side of the diversion chamber, at least one paint mist collecting chamber is arranged on the front side and the rear side of the diversion chamber, a paint mist separation device is arranged in each paint mist collecting chamber, each paint mist separation device is composed of a frame and a filter screen in the frame, the paint mist collection chamber is connected with an air purification chamber which is internally provided with the ozone generator, an outlet of the air purification chamber is connected with an exhaustpipe, and the exhaust pipe is connected with a draught fan. Accordingly, overspray paint mist generated by the spraying chamber is obtained, the effect of adsorbing and separating the overpsray paintmist from exhausted exhaust gas is good, and the emission standard is achieved.

Owner:NANTONG BEST MACHINE CO LTD

Wall flow type net plate apparatus with reverse jet regenerating unit for collecting microparicle discharged by diesel vehicle

InactiveCN100395435CReduce exhaust pollutionReduce manufacturing costExhaust apparatusSilencing apparatusParticulatesMicroparticle

This invention discloses a converse regenerating wall flow type metal net plate apparatus for collecting microparticle discharged by diesel vehicle. The composite metal plate masking filter layer inclined certain angles in outer shell, 'WW' type is formed through baffle. Extension room is set between air intake and the filter layer, the room is connected to scavenging valve and carbon smoke second collecting device. Pneumatic disc valve, blowback cavity and air compress air tank at one side of the gas outlet are connected to the shell. Waste gas discharged by the engine enters from collector intake, and particles in the waste gas are entrapped when it flows through 'WW' type composite metal shadow masking. Discharging back pressure ascends when the particles deposit to certain quantity, and the regenerating equipment starts to blow out the accumulative particles from filter, and the particles are second collected and burned in collector. The structure is simple, cost is low, purification effect and regeneration effect is good, life is long and a good product for generalization.

Owner:TSINGHUA UNIV +1

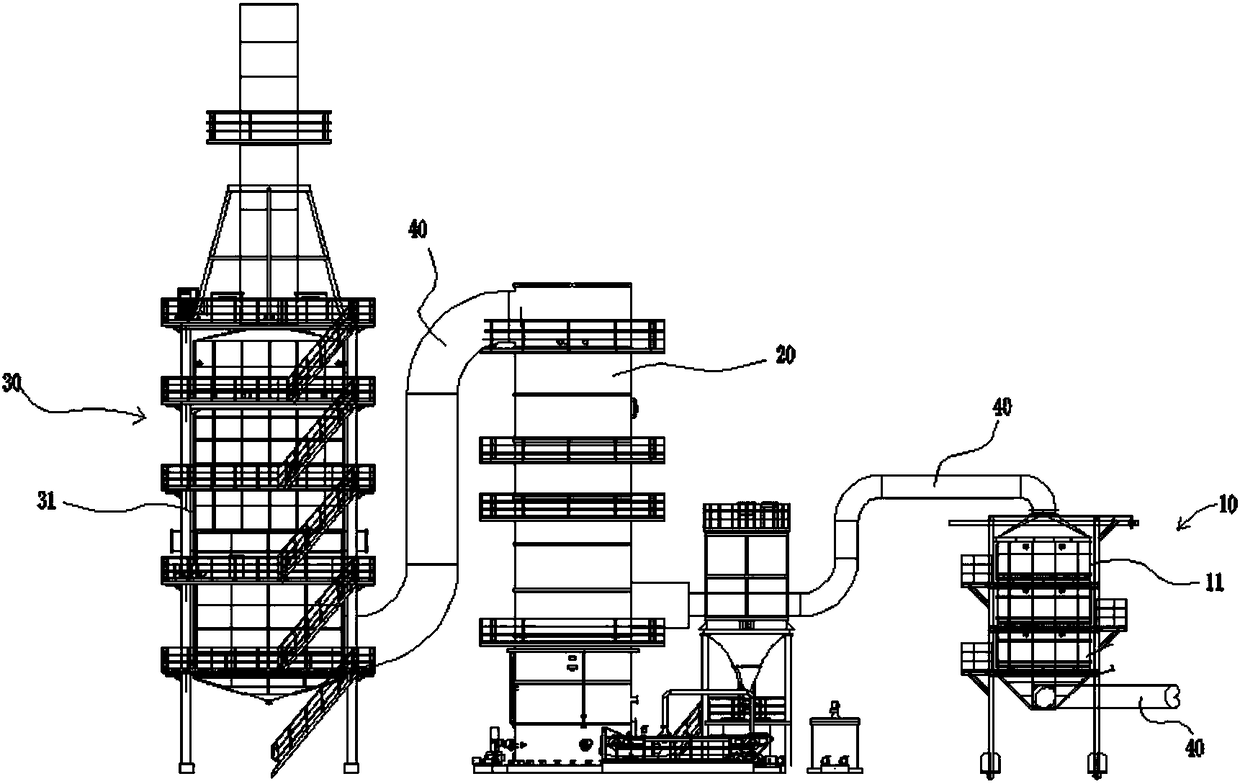

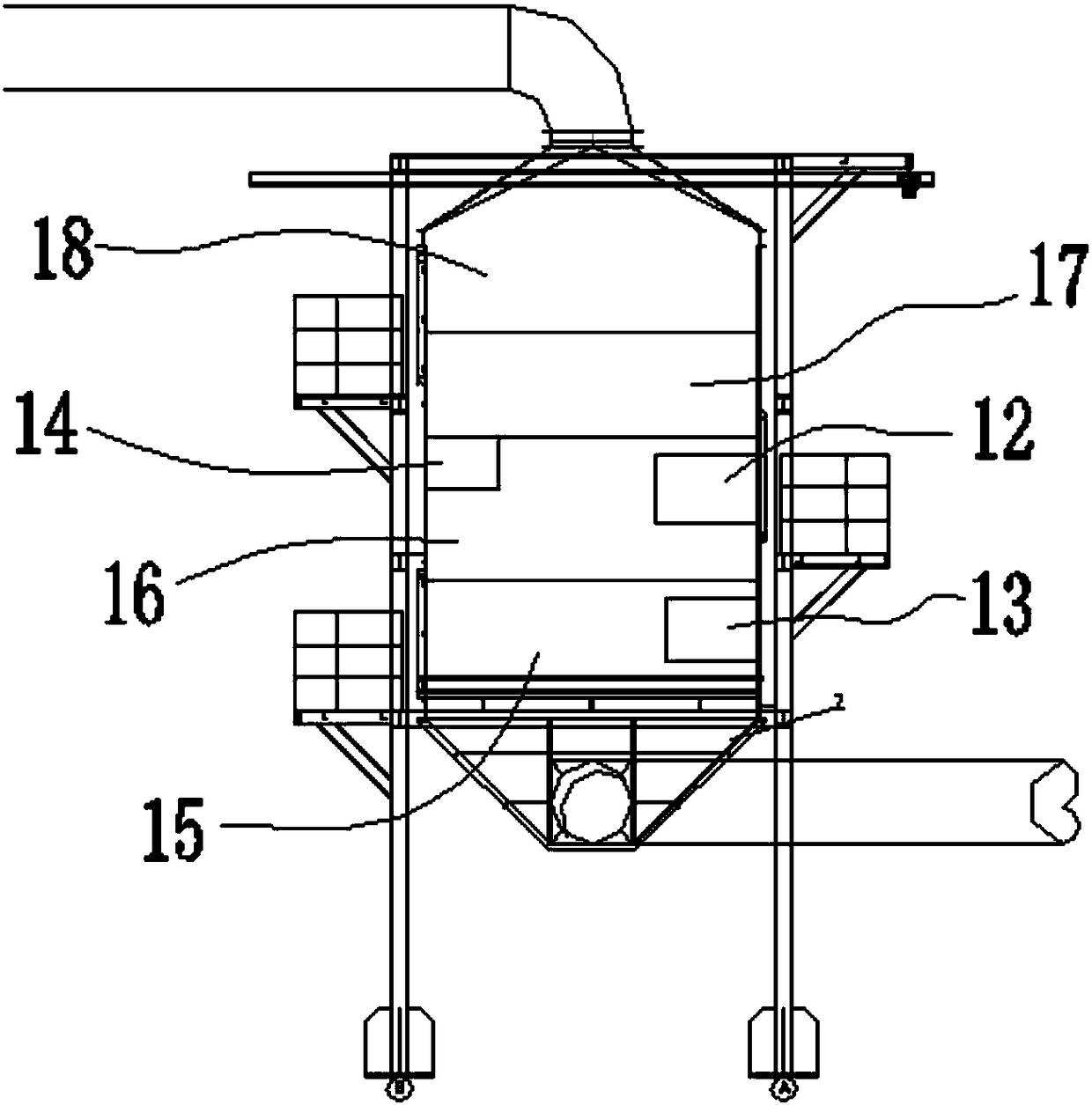

Industrial flue gas treatment device

ActiveCN104707420BAvoid emissionsEfficient captureHuman health protectionCombination devicesCold airFlue gas

The invention discloses an industrial smoke treatment device, and belongs to the field of industrial waste gas treatment. A smoke channel is arranged in a machine body; the industrial smoke treatment device is characterized in that a cold exchanger, a spraying pipe, a water collection tank and an air blower are arranged in the smoke channel. Smoke can be subjected to cold air flow disturbance and cold spraying, so that dust, fog dust and water are mutually fused to form large water drops, and fog drops and tiny dust particles can be effectively captured; the industrial smoke treatment device is particularly extremely high in capturing performance to the dust particles, the mist drops, aerosol, metal particles and acid fog, can effectively stop fog dust discharging, is high in fog and dust collection efficiency and can alleviate environmental pollution.

Owner:刘鹏飞

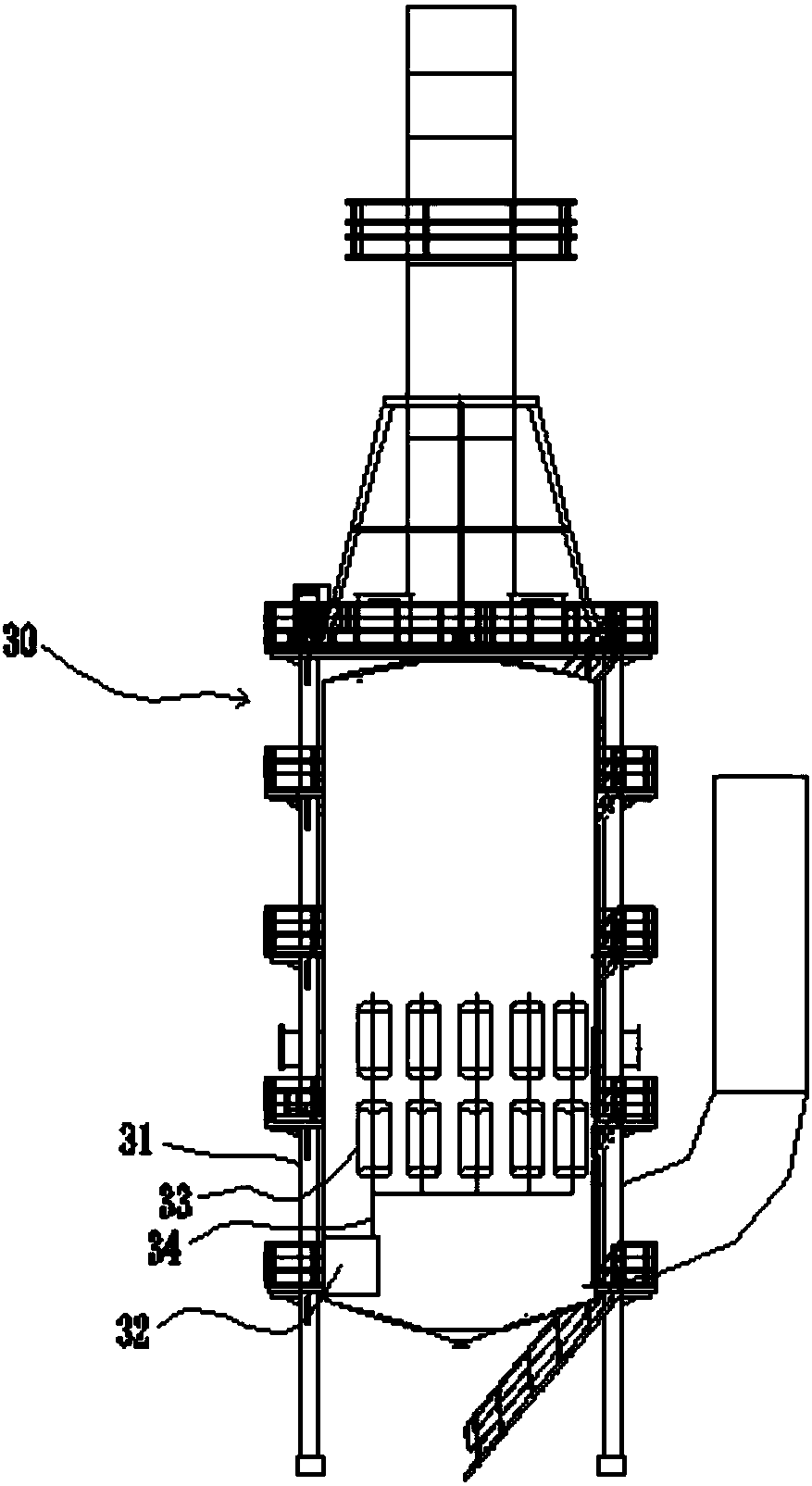

Flue gas purifying equipment of kiln

InactiveCN108211709ALow depreciation expenseHigh efficiency and activityGas treatmentElectrostatic separationFlue gasEmission standard

The invention relates to purifying equipment, in particular to flue gas purifying equipment of a kiln. The flue gas purifying equipment comprises low-temperature denitrifying equipment, desulfurizingequipment and wet type electrostatic demisting and dedusting equipment which are sequentially connected by a flue gas pipeline, wherein the low-temperature denitrifying equipment comprises a reactor body; the reactor body is divided into an ammonia spraying section, a mixing section, a flow equalizing section and a reaction section from bottom to top; an ammonia gas spraying device is arranged atthe ammonia spraying section; a reductant preparation system and a catalyst spraying device are arranged at the mixing section; the wet type electrostatic demisting and dedusting equipment comprises an electric demister body and a high-voltage electrostatic device in the electric demister body; the high-voltage electrostatic device is connected with a plurality of corona wires, and the plurality of corona wires are respectively inserted into hollow deposition electrode pipes and are not in contact with the inner walls of the deposition electrode pipes. The flue gas purifying equipment has theadvantages that the purifying efficiency is high, and the purifying effect is obvious; the 5mg-below superlow emission standard can be reached.

Owner:佛山市莫森环境工程有限公司

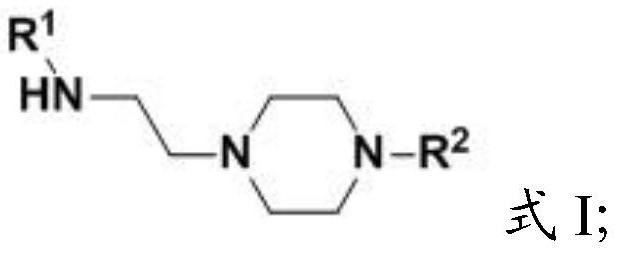

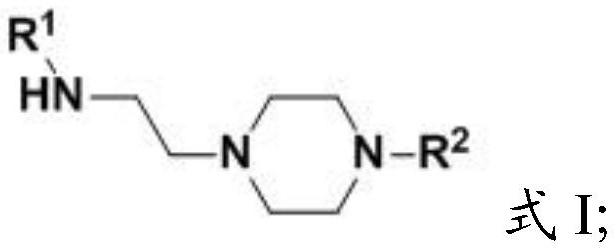

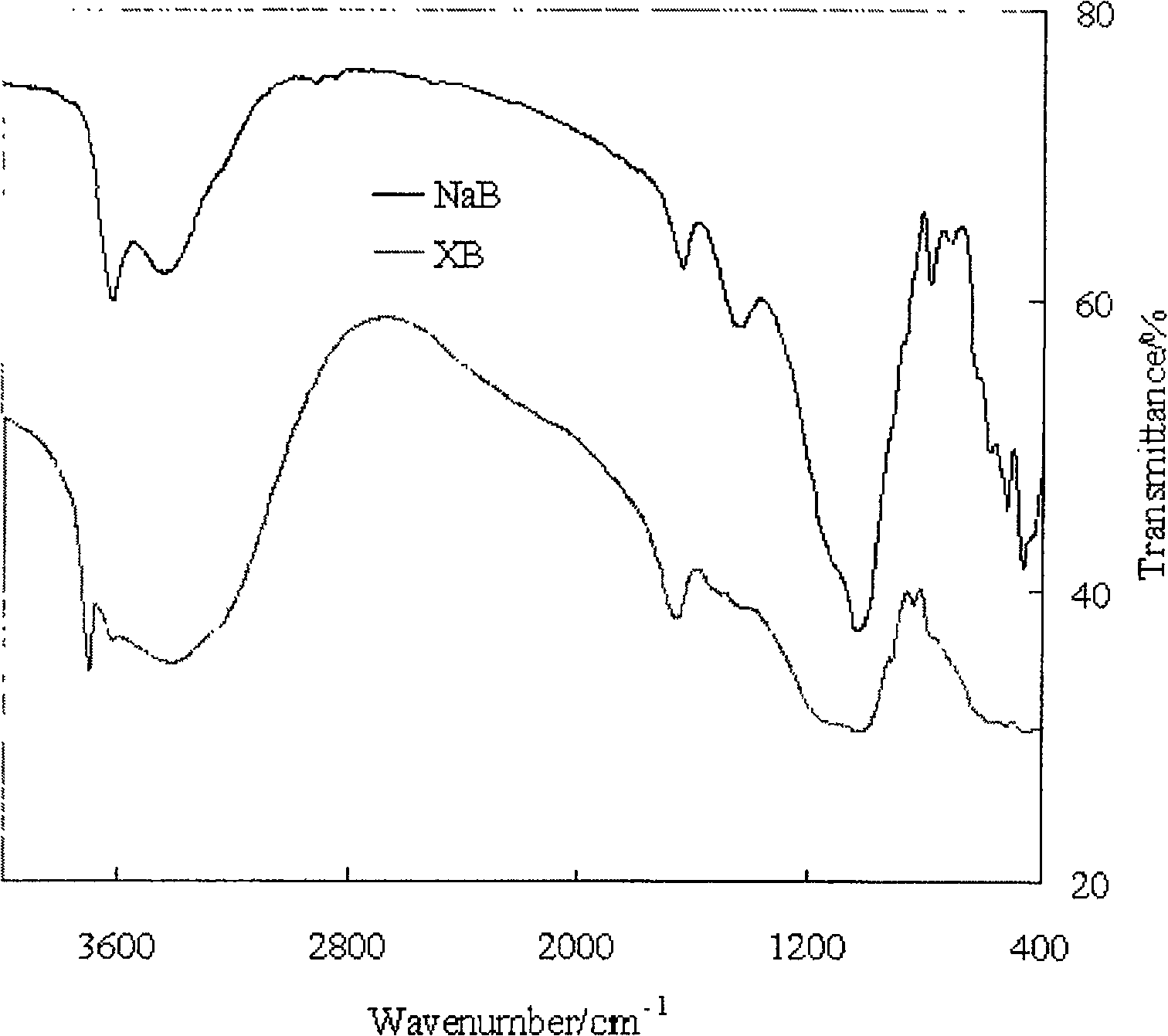

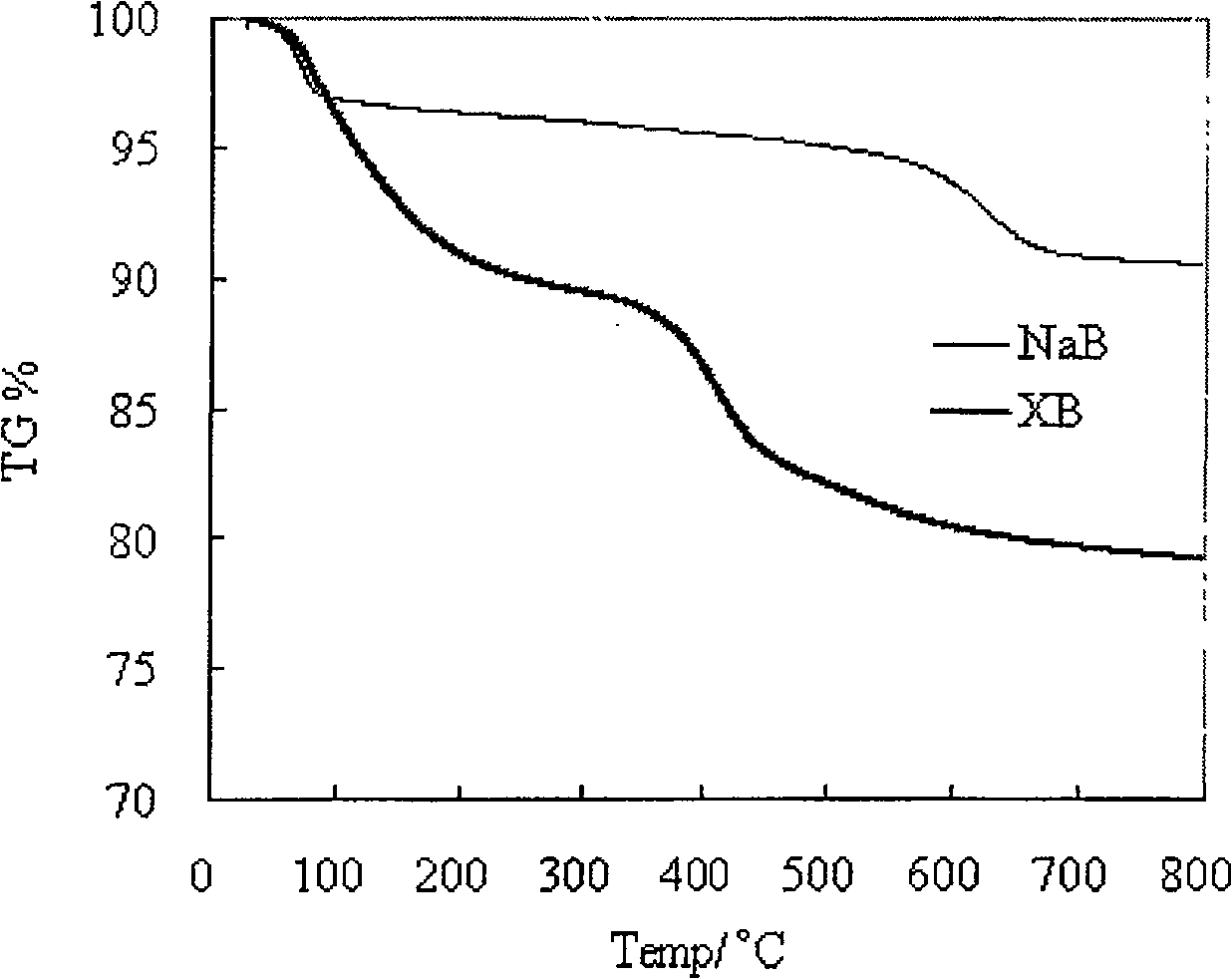

Aminoethylated piperazine and preparation method thereof, carbon dioxide absorbent and application of carbon dioxide absorbent

ActiveCN113477052ANo reduction in capture capacityDecreased capture capacityGas treatmentDispersed particle separationSide chainPhysical chemistry

The invention provides aminoethylated piperazine and a preparation method thereof, a carbon dioxide absorbent and application of the carbon dioxide absorbent, belonging to the technical field of carbon dioxide trapping. According to the aminoethylated piperazine with a structure as shown in a formula I, piperazine is introduced to serve as a framework, the stability of aminoethylated piperazine molecules is enhanced through the structural toughness of a piperazine ring, and then, thermal degradation of aminoethylated piperazine in a heating desorption process is inhibited; an aminoethyl side chain is bonded on a nitrogen atom of the piperazine framework, so polar nucleophilic reaction sites are increased, and the mobility and the water solubility of the absorbent are enhanced while the carbon dioxide capture capacity of the absorbent is improved; and the side chain nitrogen atom is bonded with an alkyl group so as to convert the side chain nitrogen atom into tertiary amine, and the number of N-H bonds in an aminoethylated piperazine structure is controlled so as to reduce reaction heat during carbon dioxide absorption, so carbon dioxide desorption efficiency is improved, the energy consumption of desorption is reduced, and the recycling performance of the captured carbon dioxide is excellent.

Owner:DALIAN UNIV OF TECH

Xanthation bentonite absorbingsubstance and method for preparing the same

InactiveCN100558460CImprove stabilityHigh ion exchange capacityOther chemical processesWater/sewage treatmentSodium BentoniteMagnesium salt

The invention provides a metal ion adsorbent with high adsorption capacity—xanthated bentonite and a preparation method thereof. The high adsorption capacity metal ion adsorbent is prepared by taking sodium bentonite as raw material, reacting with carbon disulfide after dispersion and alkalization, and then transforming with magnesium salt to generate stable magnesium salt of xanthate-based bentonite. The xanthate-based bentonite has strong adsorption capacity for heavy metal ions, and can be applied to the treatment of wastewater containing heavy metal ions. The process of the invention is used for the treatment of heavy metal wastewater, and has the characteristics of simple and easy operation, fast and convenient operation, high removal rate of metal ions, easy separation of solid and liquid, and the like.

Owner:NORTHWEST NORMAL UNIVERSITY

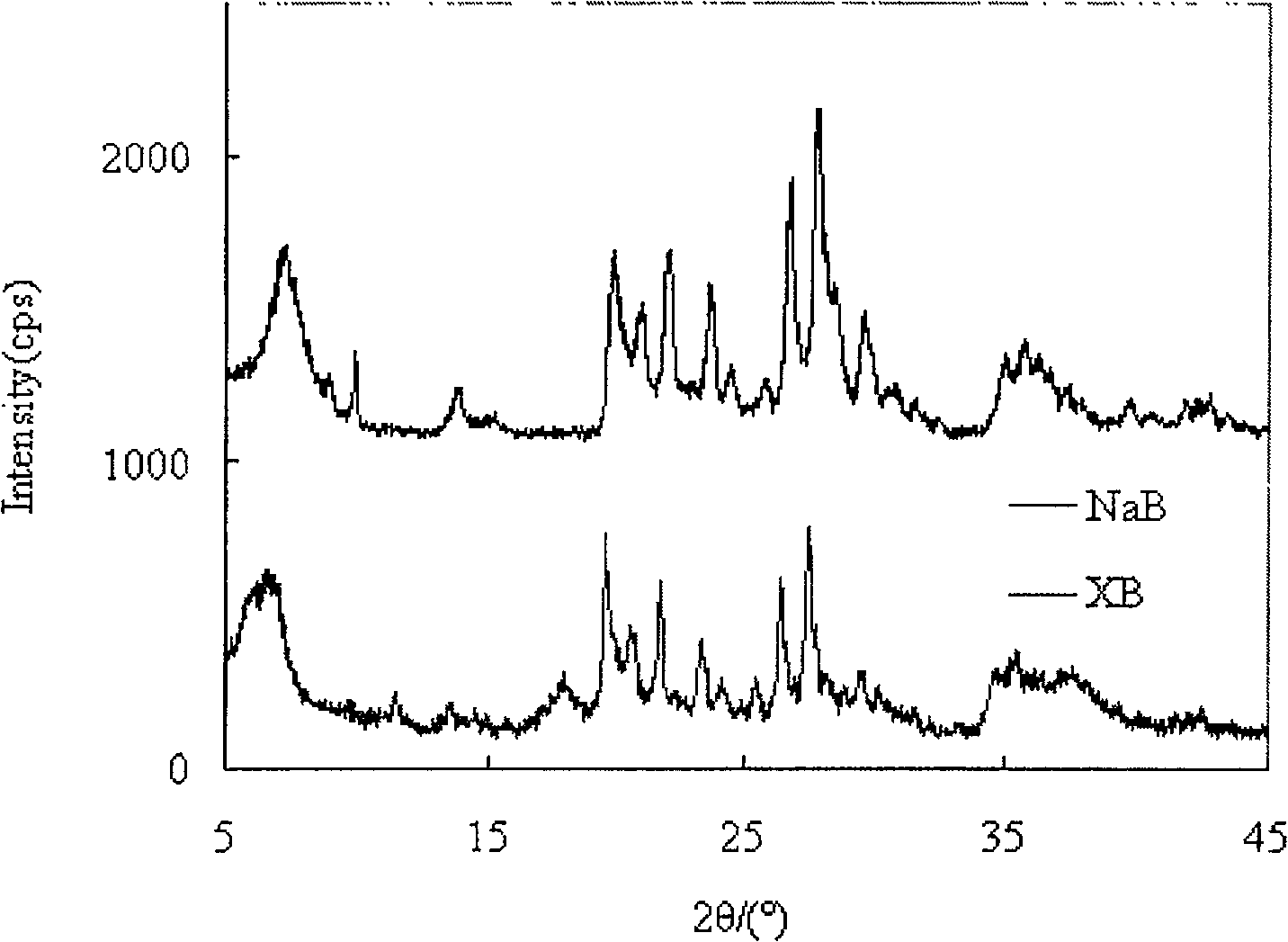

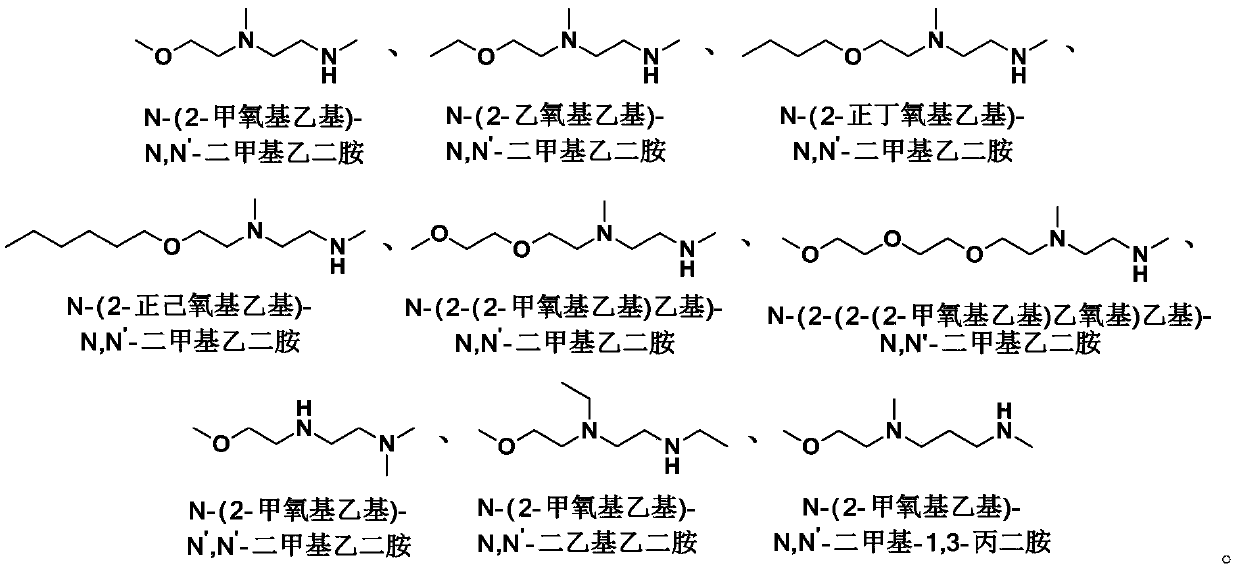

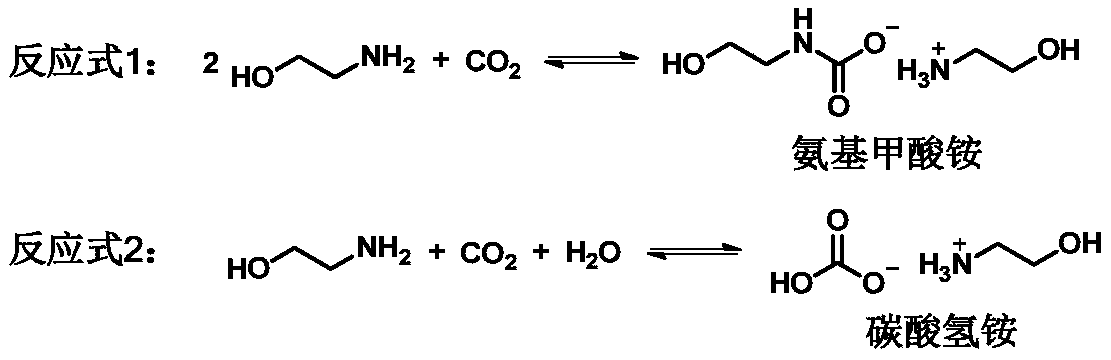

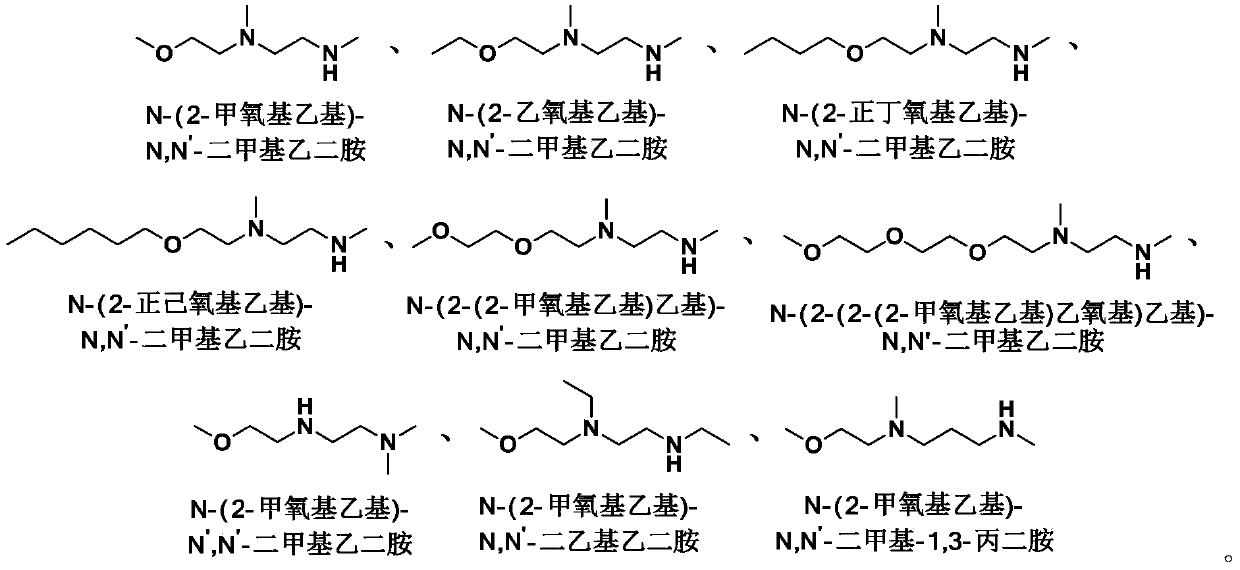

Efficient energy-saving non-aqueous absorbent used for capturing carbon dioxide and application

InactiveCN110743326AReduce desorption energy consumptionImprove mass transfer effectProductsOrganic chemistryEnvironmental engineeringAlkoxyl radicals

The invention discloses an efficient energy-saving non-aqueous absorbent used for capturing carbon dioxide and application, and belongs to the technical fields of capture of carbon dioxide and reduction of carbon emission. According to the method, by introducing a flexible alkoxy functional group to increase the molecular volume of the absorbent, improvement of the viscosity in an absorption reaction process is reduced; and meanwhile, an amino group in a molecular structure of the absorbent is subjected to alkylation treatment, and intermolecular hydrogen-bond interaction of the absorbent is reduced, so that similarly, an effect of controlling the viscosity is achieved. According to the efficient energy-saving non-aqueous absorbent used for capturing the carbon dioxide and application, through low-viscosity functionalization treatment on a molecular design level, the flowing capability and the mass transfer capability of an aliphatic diamine non-aqueous absorption system are improved,so that low-energy-consumption high-capability capture of the carbon dioxide is achieved.

Owner:DALIAN UNIV OF TECH

Industrial wastewater heavy metal ion capturing agent, preparation method and wastewater treatment method

PendingCN114162949AImprove capture capacityReduce dosageWater contaminantsWater/sewage treatment by neutralisationIndustrial waste waterManganese

The invention discloses an industrial wastewater heavy metal ion capturing agent, a preparation method and a wastewater treatment method, and relates to the technical field of industrial wastewater treatment. The water-soluble sulfur-containing cleaning agent is composed of 0.5-5 wt% of a chelating agent, 0.01-2 wt% of inorganic sulfur, 0-2 wt% of a complexing agent, 0-2 wt% of a cosolvent, 0-2 wt% of a stabilizer and the balance of deionized water. The method comprises the following steps: taking corresponding heavy metal wastewater, adjusting the pH value of the wastewater, adding a capturing agent and stirring, dropwise adding a flocculating agent and a coagulant aid and stirring, and finally sampling and detecting the concentration of heavy metal ions. Through the chelation between the heavy metal ion chelating agent and heavy metal ions, the heavy metal ion chelating agent achieves the removal effect, and is a green heavy metal wastewater treatment agent which is high in trapping capacity, small in actual dosage, low in cost and easy to operate. The heavy metal ion capturing agent has a good capturing effect on various heavy metal ions such as nickel, copper, zinc, chromium, mercury, aluminum, manganese, iron and the like, the removal rate reaches 98.5% or above, and the national emission standard is met.

Owner:HENGLI ELETEK

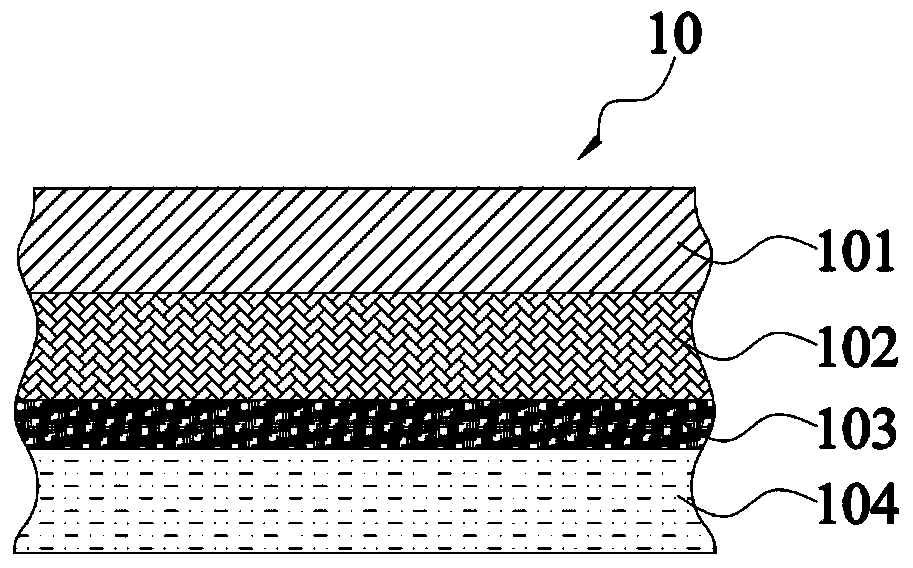

Gas-phase filter material and filter unit

PendingCN110613978AImprove the capture effectImprove capture capacitySemi-permeable membranesMembranesMicro nanoParticulates

The invention provides a gas-phase filter material and a filter unit, and belongs to the technical field of air filtration. According to the gas-phase filter material, a breathable covering layer, a pre-trapping layer, a main trapping layer and a breathable support layer are sequentially laminated from the upstream side of an air flow; the main trapping layer comprises a porous PLA micro-nano fiber membrane doped with rGO-g-PLLA nano particles. The filter unit comprises the gas-phase filtering material and a frame body. The filter material and the filter unit are simple and feasible to prepare, high in yield and capable of increasing the softness of the surfaces of the micro-particles, so that the micro-particles are easier to swell and modify. The porous PLA micro-nano fiber membrane forthe main trapping layer of the gas-phase filter material is small in fiber diameter, large in specific surface area and large in pore volume; the gas-phase filter material has excellent mechanical properties, antibacterial activity and high-temperature resistance, has strong trapping capability on particulate matters such as PM2.5, reduces the resistance pressure, and also has excellent air filtering performance when the thickness of the main trapping layer is relatively low.

Owner:宋恩

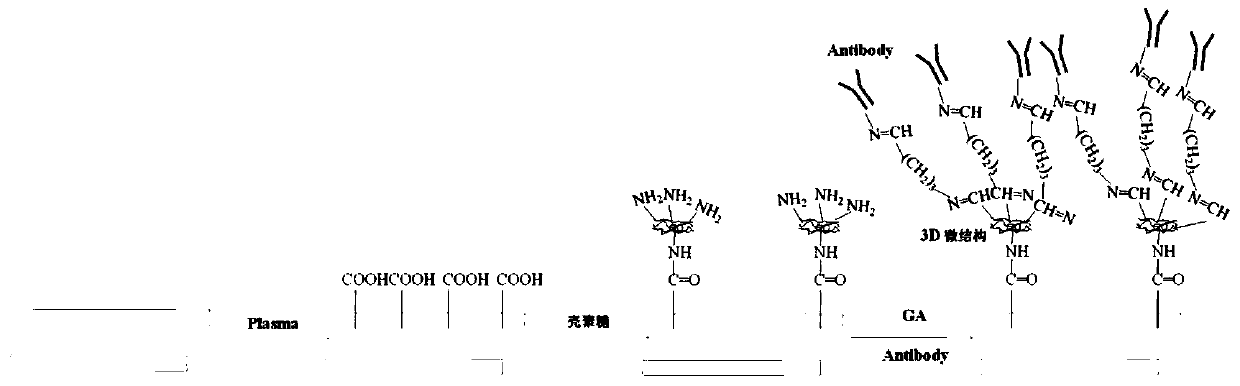

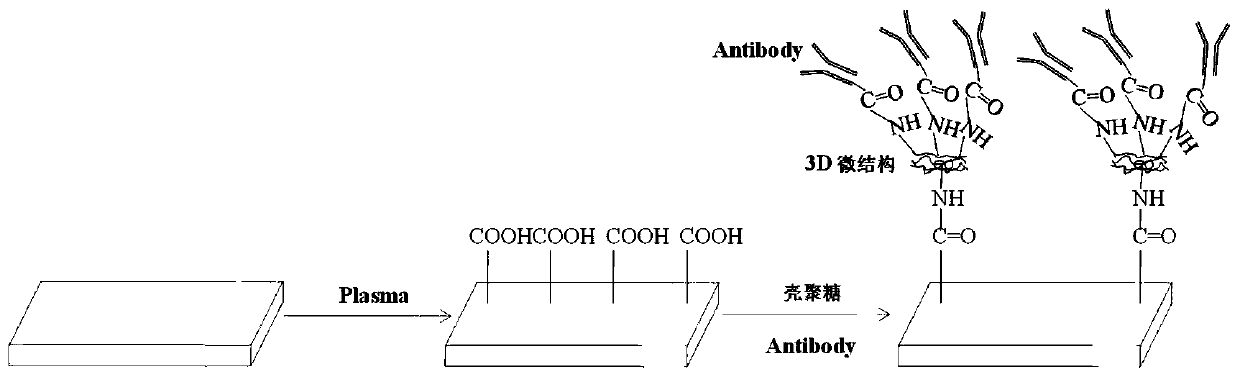

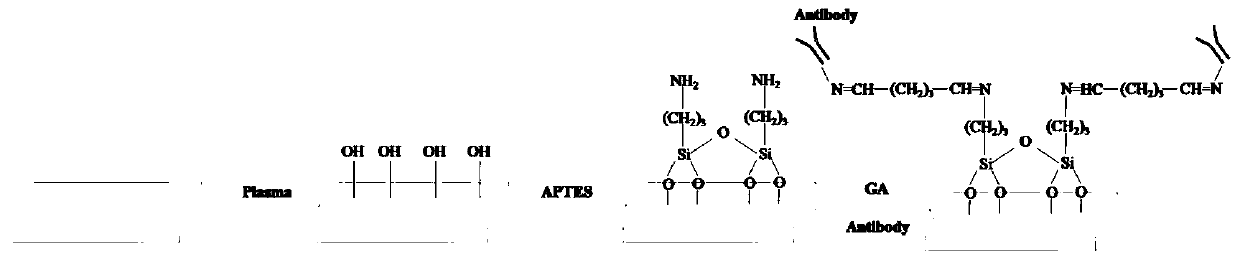

High-efficiency antibody fixing method of biological chip

PendingCN110297084ALarge specific surface areaIncrease contact areaBiological testingFluorescence/phosphorescenceChemistryAntibody

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com