Automobile tail gas particulate matter trap and filter element

A particle trap, automobile exhaust technology, applied in exhaust devices, machines/engines, mufflers, etc., can solve the problems of thermal stress damage of ceramic filter elements, high use and maintenance costs, and complex regeneration operation process. Small loss, low maintenance cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

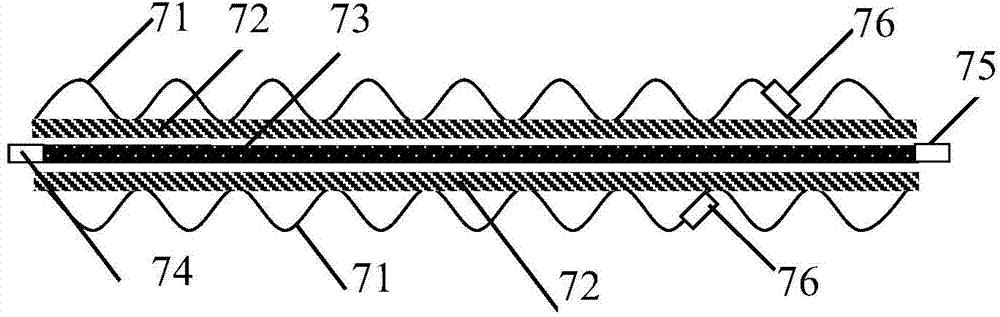

[0026] Such as figure 1 As shown, it is a kind of filter core of automobile exhaust particle trap, which is rolled into a cylindrical shape by a metal fiber board (70), and the metal fiber board (70) includes two metal fiber filter adsorption outer layers (71) and a The electrothermal film layer (73) has a thermally conductive insulating layer (72) between the metal fiber filter and adsorption outer layer (71) and the electrothermal film layer (73), and the electrothermal film layer (73) has heating power positive and negative terminals (74 , 75), the metal fiber filter adsorption surface layer (71) has electrode terminals (76), and the metal fiber filter adsorption surface layer (71) has corrugations in cross-section, and guides the exhaust gas along the longitudinal direction.

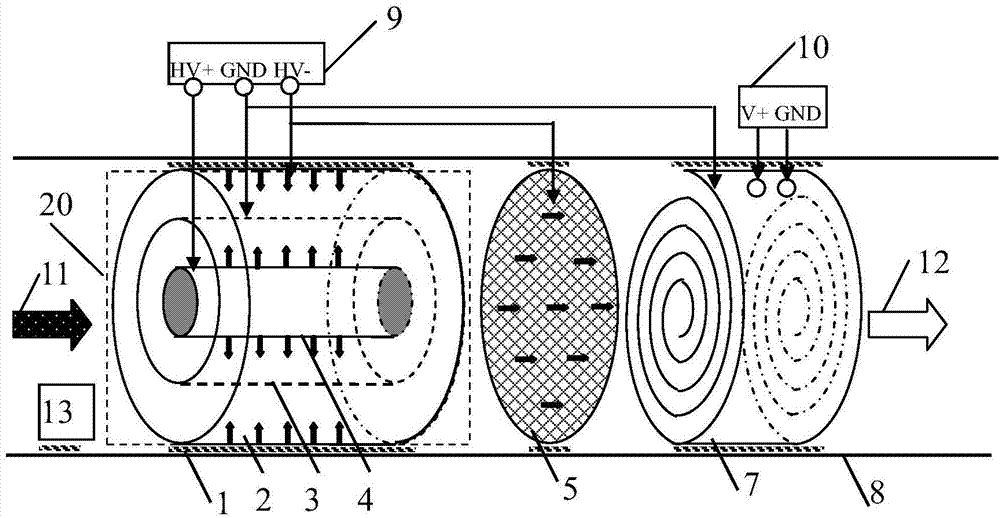

[0027] Such as figure 2 As shown, it is a kind of automobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com