Exhaust port of composite gear tooth compressor and design method thereof

An exhaust port, compound wheel technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of small exhaust pressure loss, small clearance volume, low exhaust speed, etc., and achieve exhaust pressure. Effects of low loss, small clearance volume, and low exhaust velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

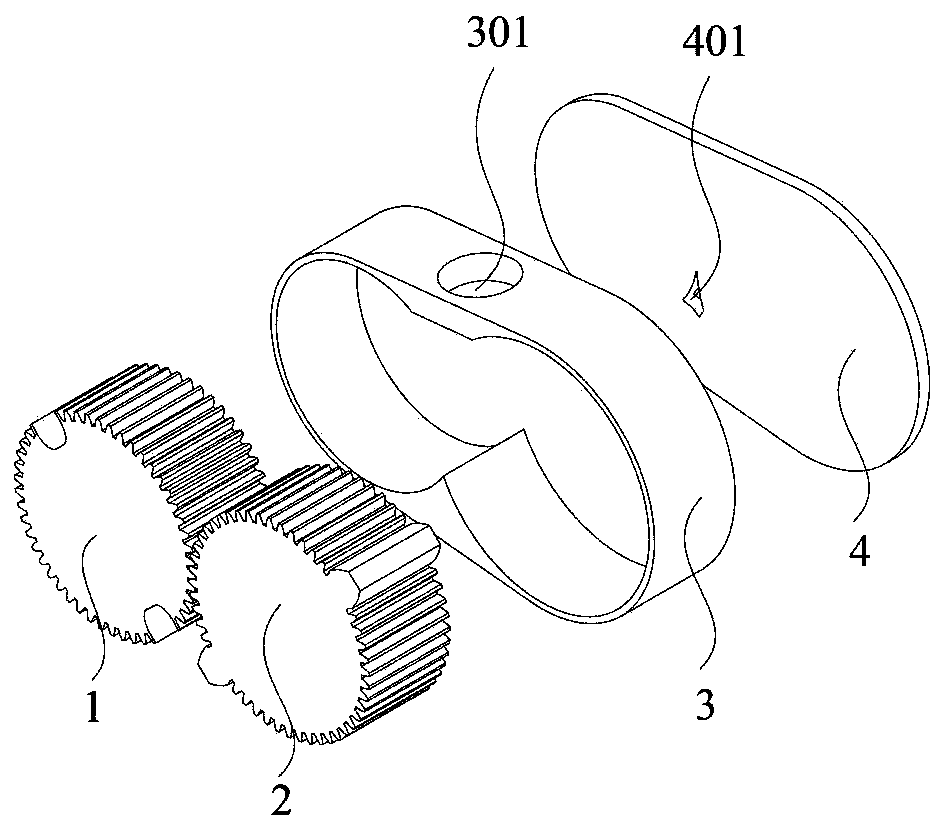

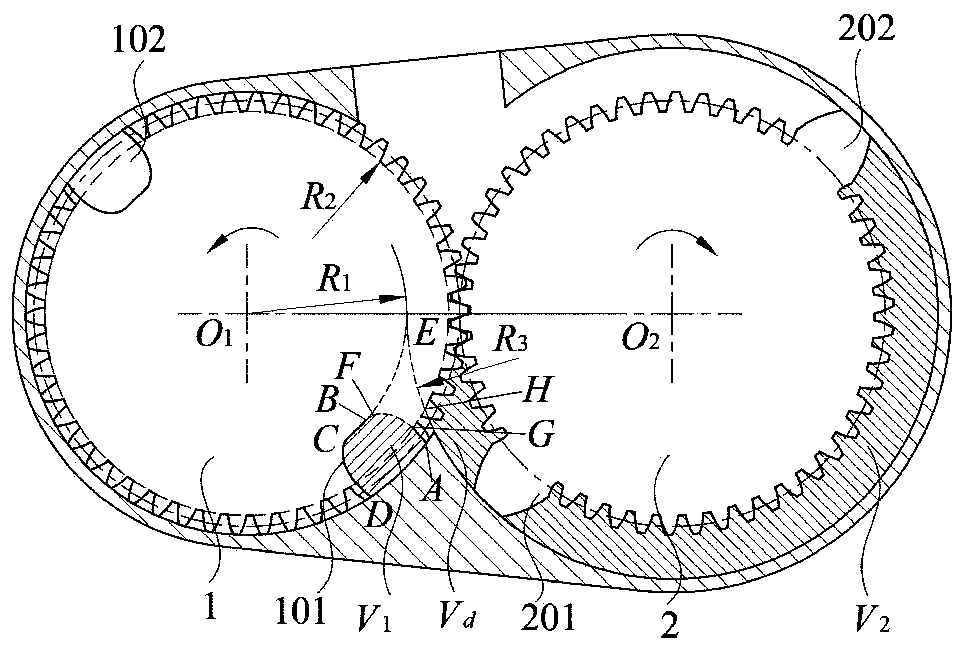

[0025] Such as figure 1 As shown, it is a structural diagram of a compound gear compressor, including: a left concave rotor 1, a right convex rotor 2, a casing 3 and an exhaust end cover 4, and an exhaust port 401 is opened on the exhaust end cover 4, In the working process, a suction chamber, a constant-volume closed chamber, a compression chamber and an exhaust chamber can be formed, which are respectively used for gas suction, constant-volume delivery, compression and exhaust; the volume of the suction chamber gradually increases Large and always communicated with the suction port 301, the volume of the equal-volume closed chamber is constant and closed, the volume of the compression chamber is closed and gradually decreases, and the volume of the exhaust chamber is gradually reduced and Always communicate with exhaust port 401.

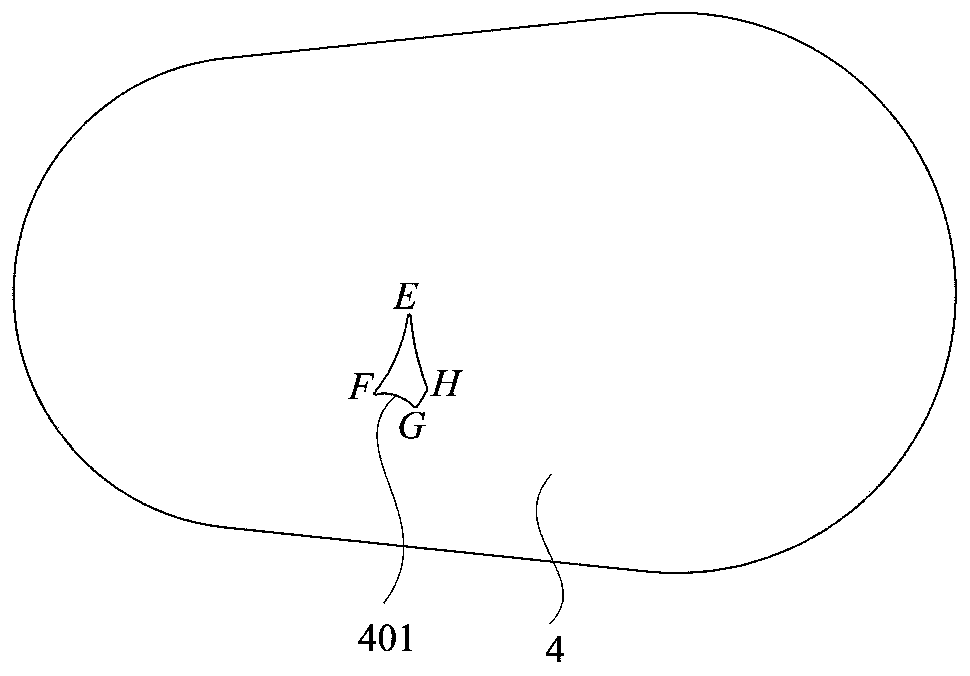

[0026] Such as figure 2 As shown, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com