Pump components, compressors and air conditioners

A technology of components and pump bodies, applied in pump components, machines/engines, liquid fuel engines, etc., can solve the problems of small exhaust passage area, increased exhaust speed, increased exhaust loss, etc., and achieve increased exhaust gas. Effect of hole area, reduction of exhaust velocity, and reduction of exhaust loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

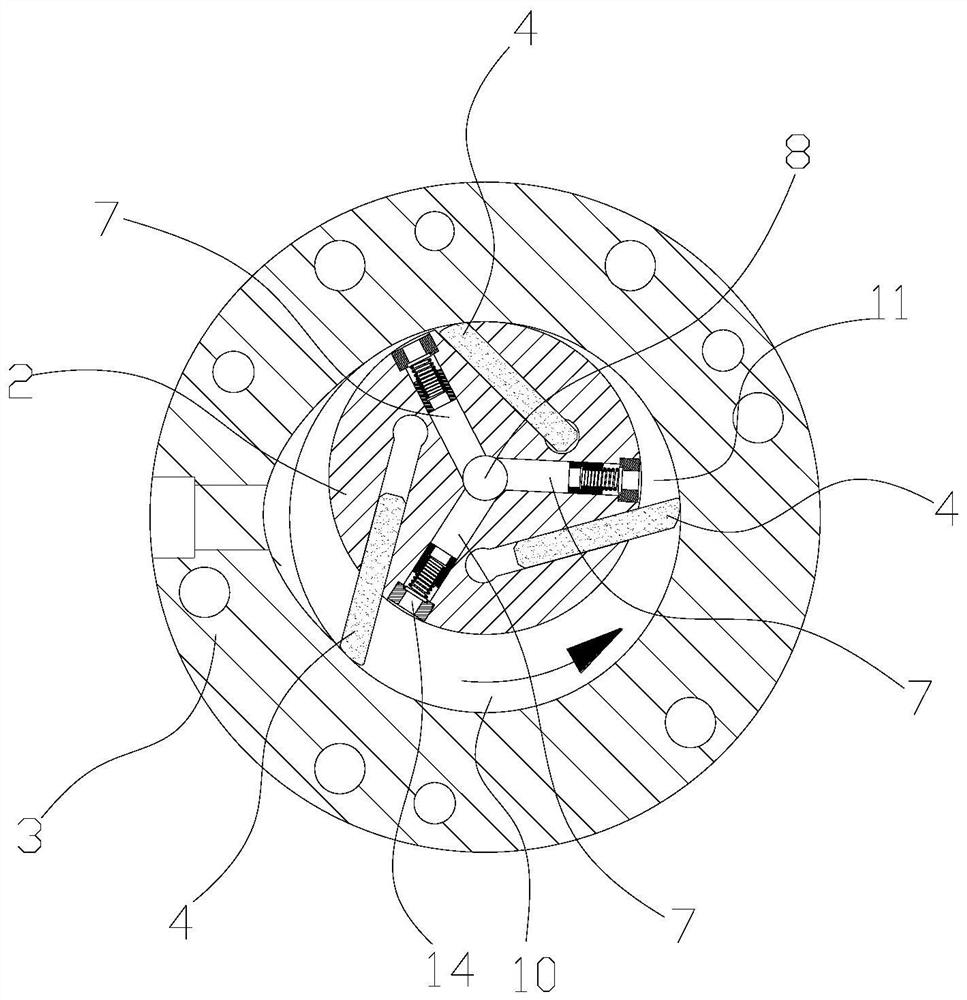

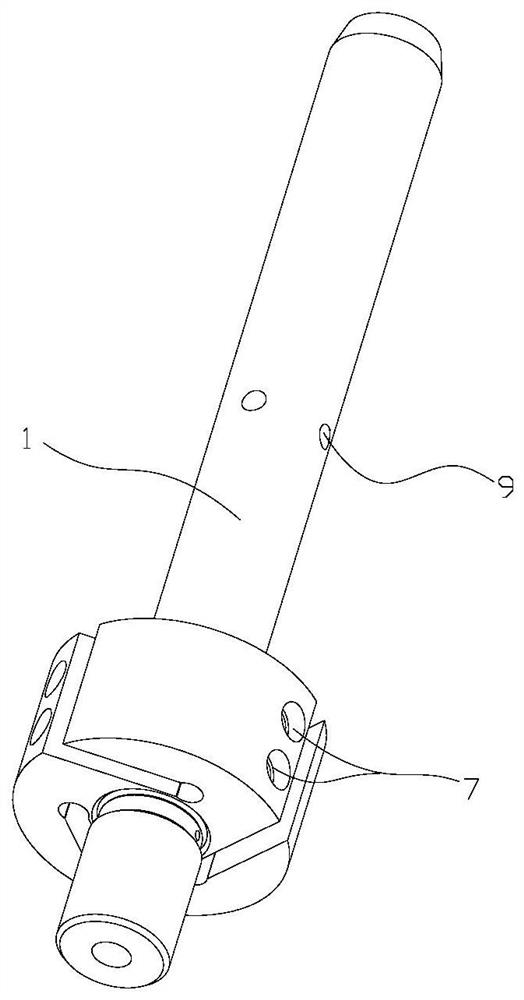

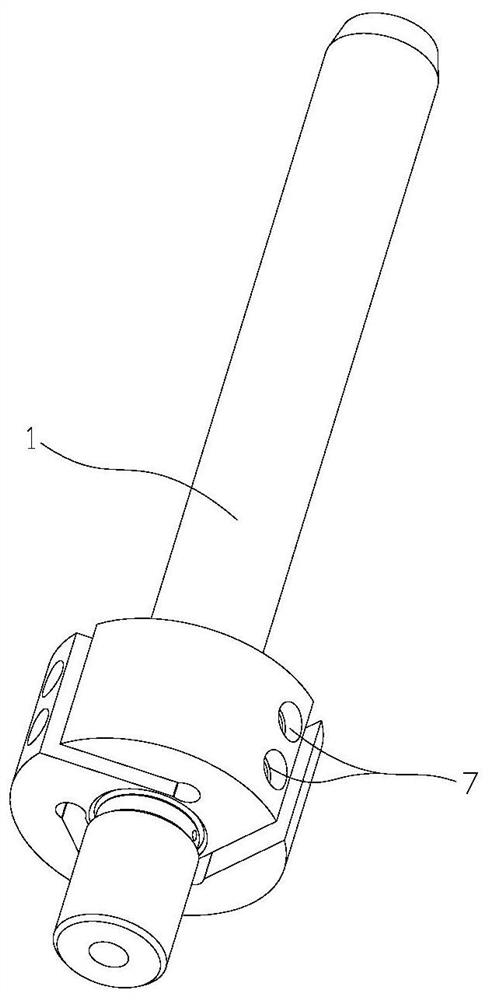

[0041] see in conjunction Figure 1 to Figure 18 As shown, according to the embodiment of the present application, the pump body assembly includes a main shaft 1, a flange, a cylinder 3 and a sliding piece 4, the main shaft 1 includes a convex portion 2, and a plurality of sliding pieces 4 are arranged on the convex portion 2 at intervals along the circumferential direction, The flange, the cylinder 3, the sliding plate 4 and the protrusion 2 enclose a compression chamber 10. The protrusion 2 is provided with at least one radial exhaust passage 7 corresponding to each compression chamber 10, and the main shaft 1 is also provided with an axial exhaust passage. The air channel 8 and the axial exhaust channel 8 extend along the axial direction of the main shaft 1 to the outside of the matching area between the flange and the main shaft 1, and communicate with the space outside the pump body assembly. The radial exhaust channel 7 is provided with an exhaust valve Assembly 11, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com