An Automobile Muffler for Controlling Airflow Regeneration Noise

A car muffler and airflow control technology, applied in the direction of muffler, exhaust device, machine/engine, etc., can solve the problems of muffler loss of muffler effect, increase of regenerative noise of muffler, decline of muffler muffler effect, etc., to achieve noise reduction effect Obvious, reduced air regeneration noise, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

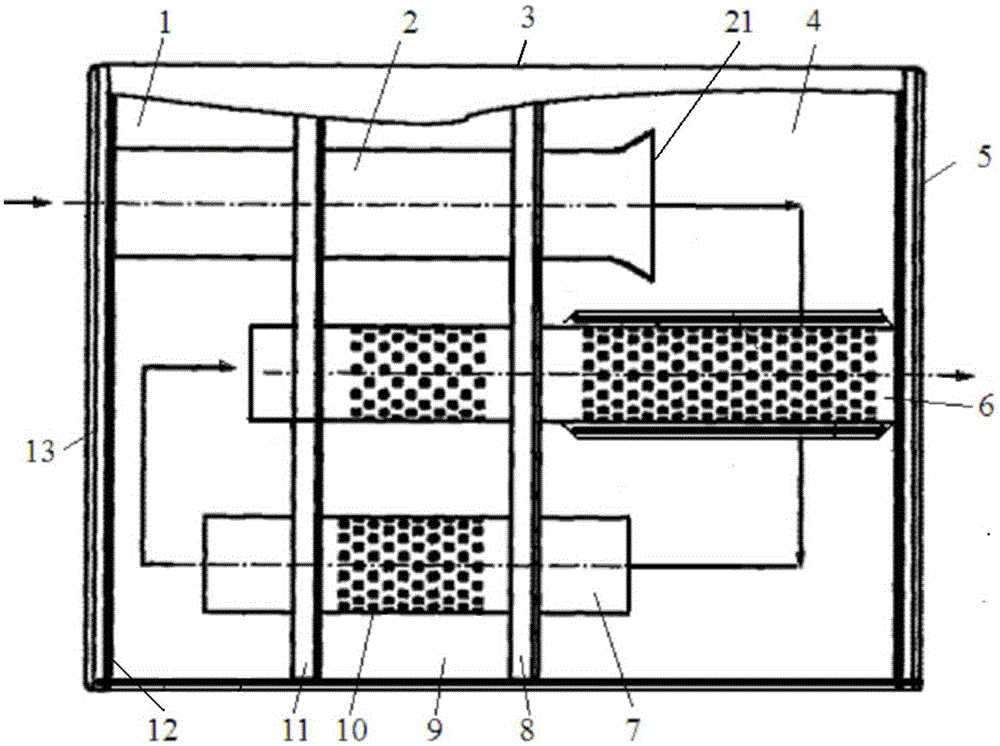

[0021] see figure 1 , the automobile muffler housing 3 for controlling airflow regeneration noise is provided with a first partition 11 and a second partition 8 perpendicular to the axial direction of the housing 3, and the inside of the housing 3 is sequentially isolated into the first expansion chamber 1, The resistive muffler chamber 9 and the second expansion chamber 4 are three chambers; the ratio of the axial lengths of the first expansion chamber 1, the resistive muffler chamber 9 and the second expansion chamber 4 in this example is 3:2:5 .

[0022] The air inlet pipe 2 , the transition pipe 7 and the air outlet pipe 6 are axially parallel to the casing 3 and arranged in the casing 3 at intervals. This example intake pipe 2, transition pipe 7 and outlet pipe 6 pipe diameters are identical. The inlet of the air intake pipe 2 is the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com