A self-cooling transmission housing for vibration suppression and noise reduction

A transmission housing, noise reduction technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problems of poor durability, not considering the softening of transmission rubber, etc., to achieve convenient disassembly, improve NVH level , easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further elucidated by taking the case of a self-cooling, vibration-suppressing and noise-reducing transmission housing partly laid with a vibration-suppressing and sound-insulating structure in conjunction with the accompanying drawings. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

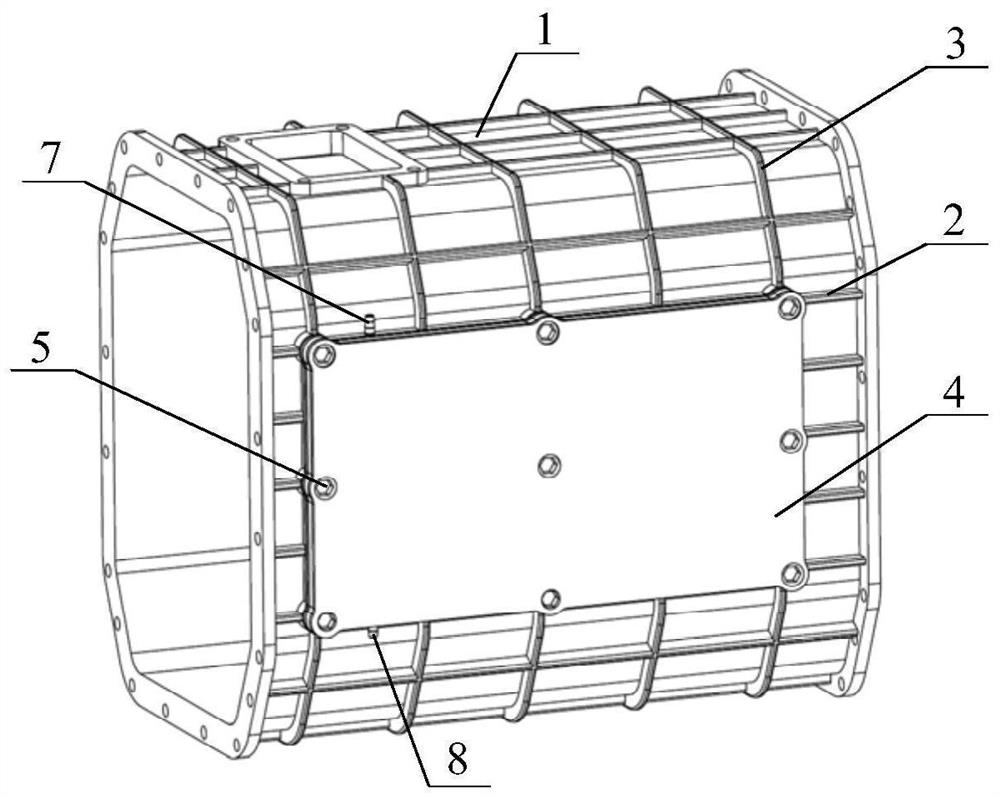

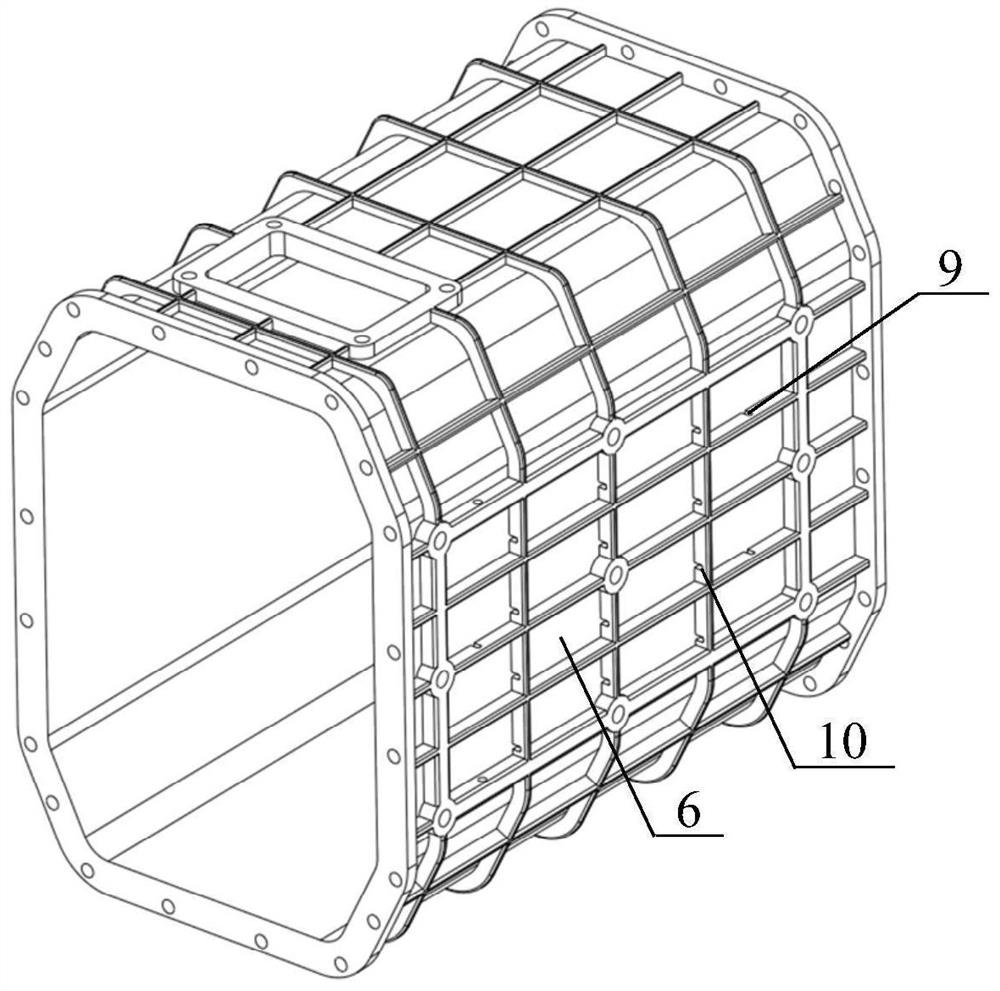

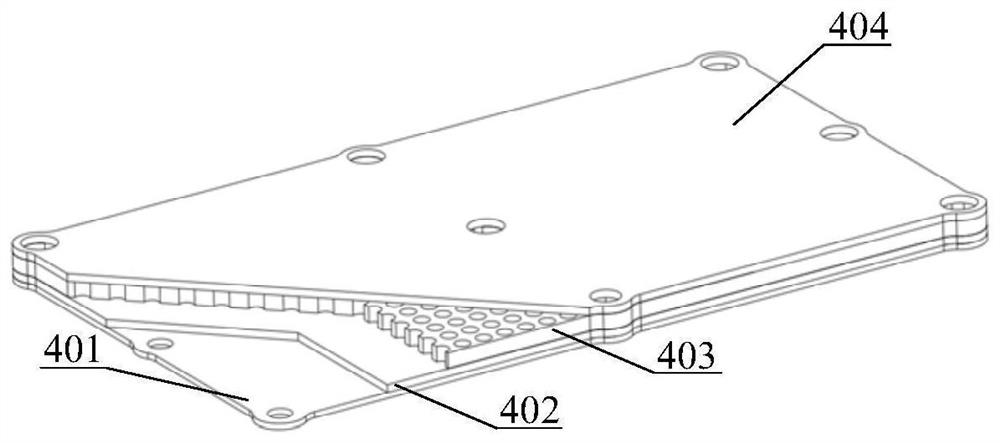

[0029] refer to figure 1 , 2 , 3. The self-cooling, vibration-suppressing and noise-reducing transmission housing of the present invention includes a main housing 1 and a vibration-suppressing and sound-insulating structure 4 . The surface of the main shell 1 is provided with a number of axial reinforcement ribs 2 and a number of circumferential reinforcement ribs 3 to enhance the structural strength, optimize the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com