Patents

Literature

105results about How to "Prevent roll up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

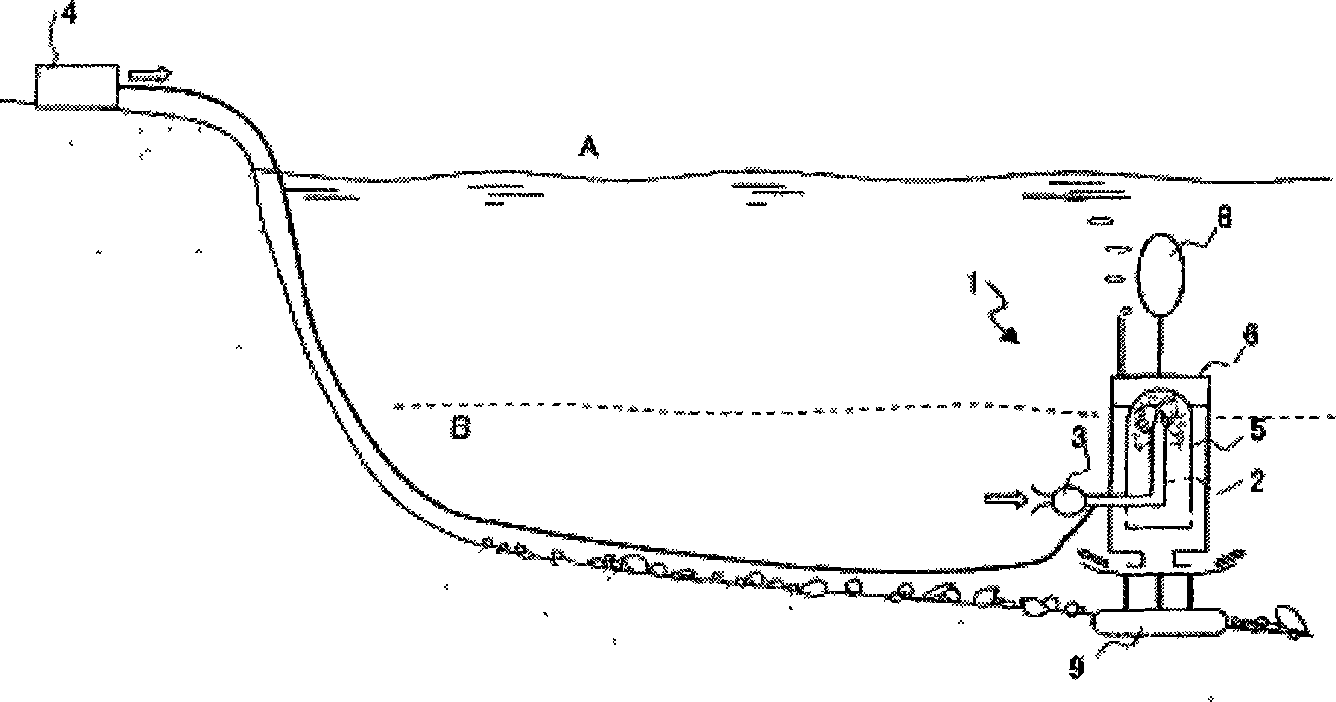

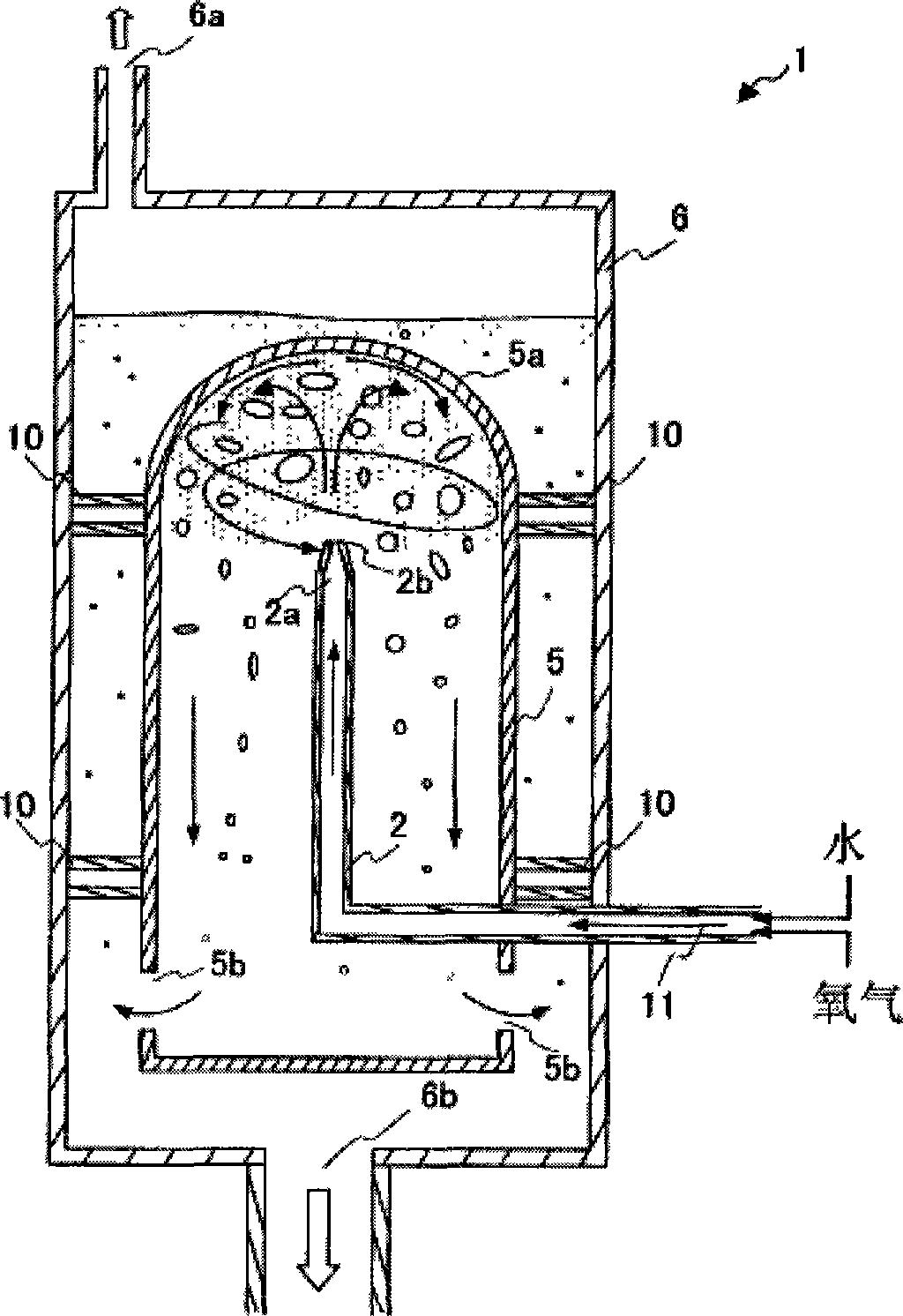

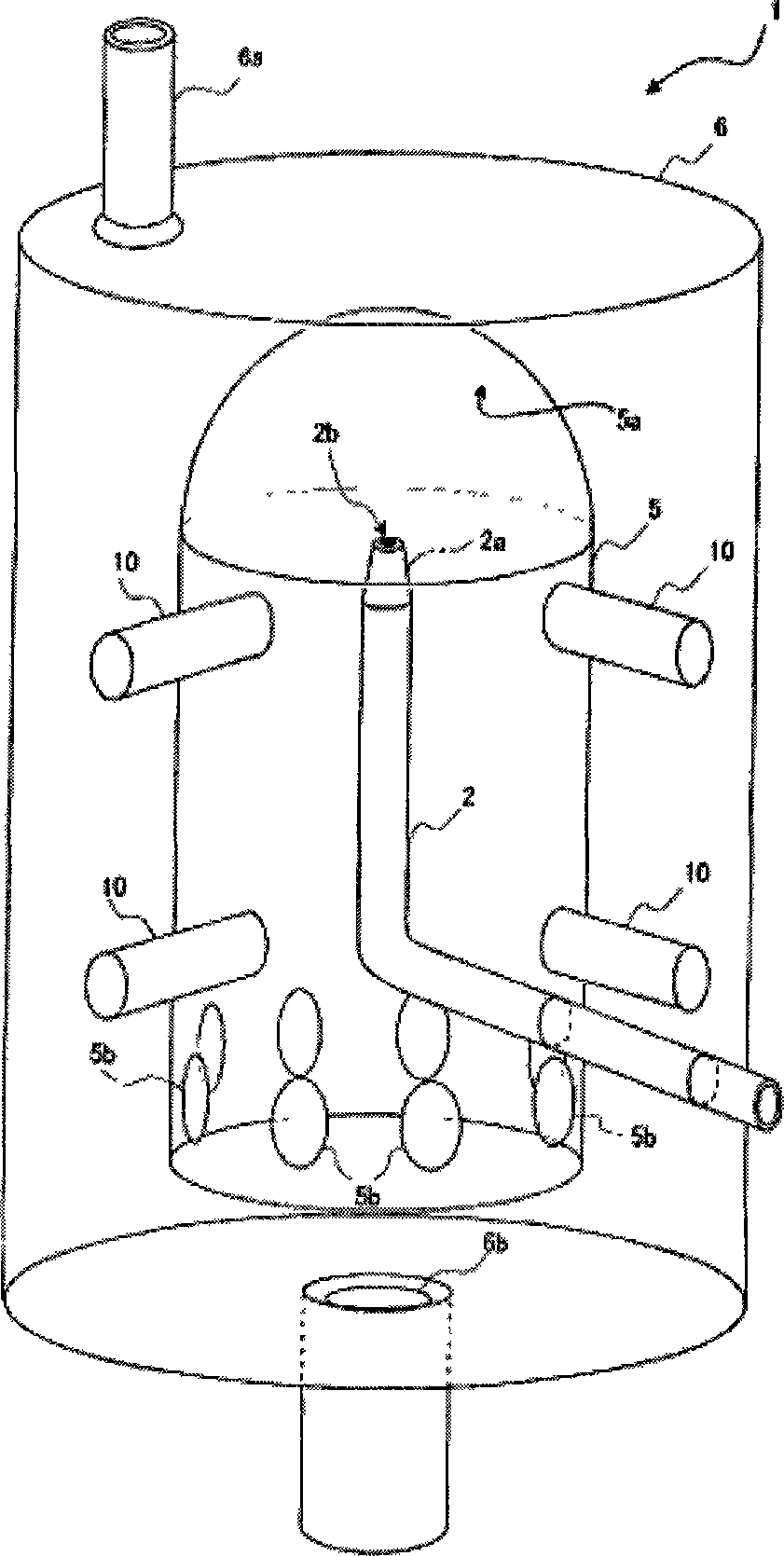

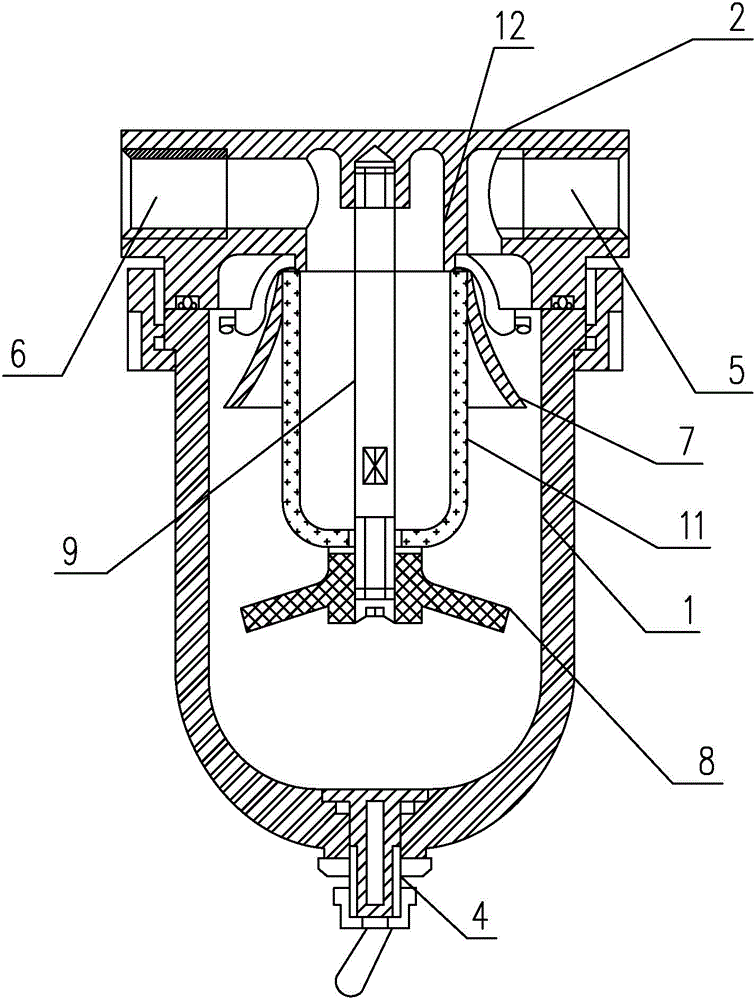

Gas-liquid dissolution apparatus

ActiveCN1914123ASimple structureIncrease contact areaTreatment using aerobic processesFlow mixersMomentumProduct gas

The invention relates to a gas-liquid dissolution apparatus that is capable of dissolving an oxygenic gas in water introduced from an oxygen-poor water zone to thereby increase the concentration of dissolved oxygen and feeding back the resultant water to the water zone. There is provided a gas-liquid dissolution apparatus including pump (3) for introducing water from an oxygen-poor water zone; oxygen supply unit (4) for supplying an oxygenic gas; gas-liquid dissolution chamber (5) of tubular form longer than is wide, the chamber (5) furnished at its lower part with at least one hole (5b) and furnished at its upper part with dome-shaped top board (5a); nozzle (2) with its distal end internal part tapered, which nozzle jets the gas from the oxygen supply unit (4) and the water from the pump (3) upward so as to collide with the internal wall of the top board (5a) of the gas-liquid dissolution chamber (5), thereby attaining vigorous agitation of gas and water by the momentum of the jet; gas-liquid separation chamber (6) which communicates through the hole (5b) with the gas-liquid dissolution chamber (5) so that the bubbles and water outflowing through the hole (5b) from the gas-liquid dissolution chamber (5) are stocked and separated from each other; and water delivery port (6b) for feeding back the water separated from bubbles toward the oxygen-poor water zone.

Owner:MATSUE DOKEN +1

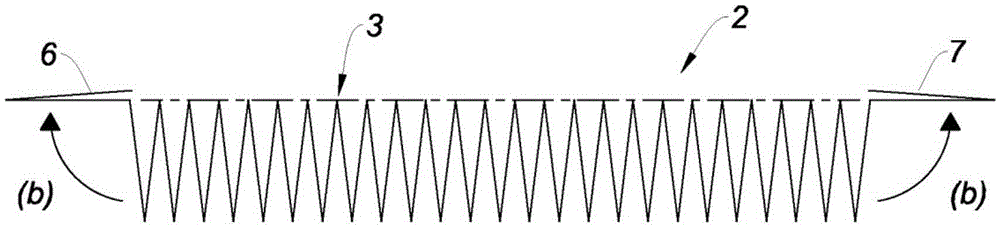

The roll screen for reduction device

InactiveCN1720384APrevent roll upEasy to useLight protection screensPulp and paper industryYounger people

The invention relates to a reduction gear for a roller shutter, wherein, the compressed piston of the reduction part can enter into a cylinder connected with one inner end of the roller pole. The invention also relates to a device which folds and unfolds the roller shutter simply and conveniently, in particular to a device which can fold the roller shutter by decreasing the folding speed at a certain section when folding the roller shutter, thereby has the advantages of avoiding noises, collisions and accidents, and easy operation without any limit by age or gender (the young people, the old people or male and female).

Owner:郭在锡

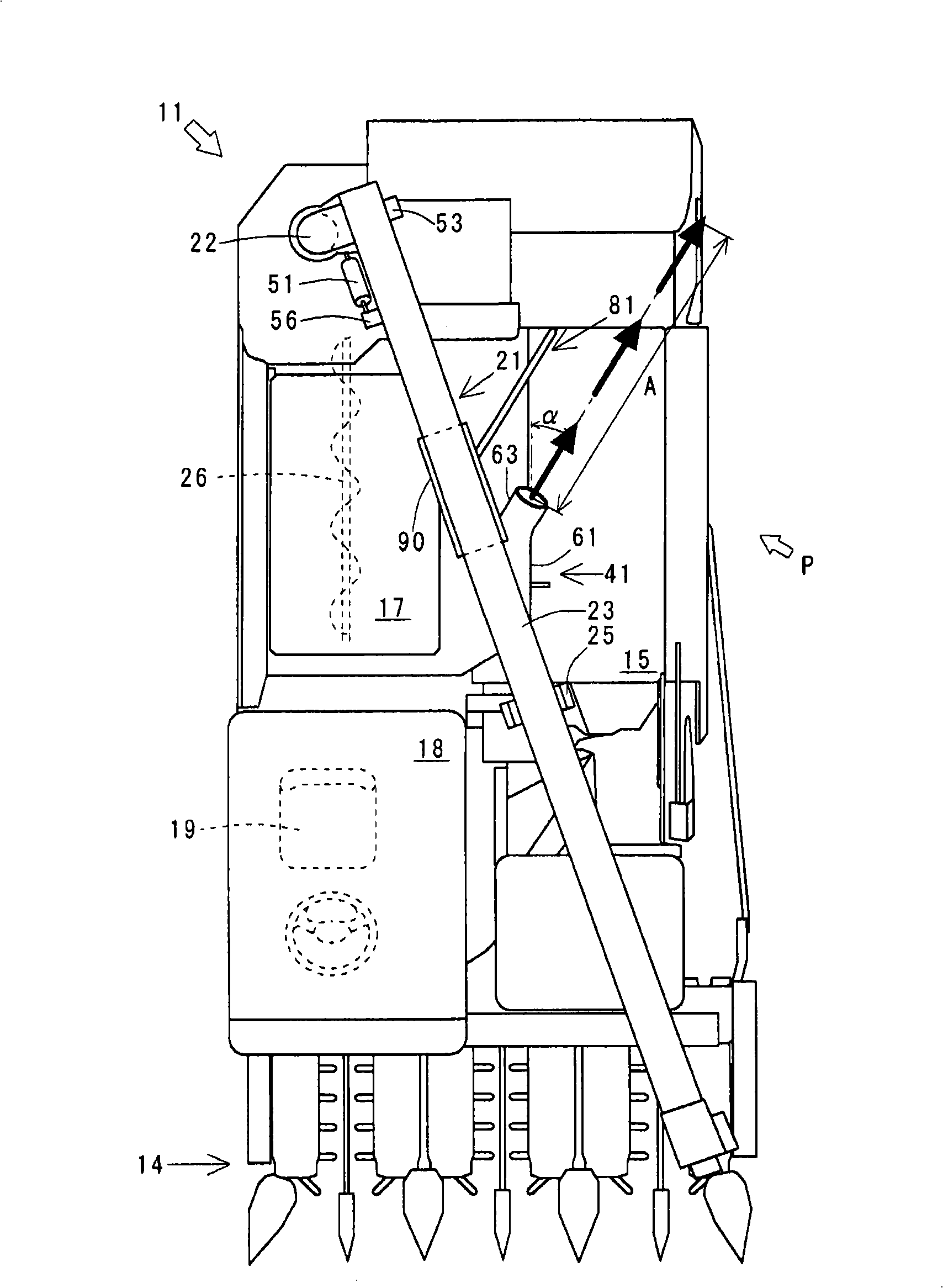

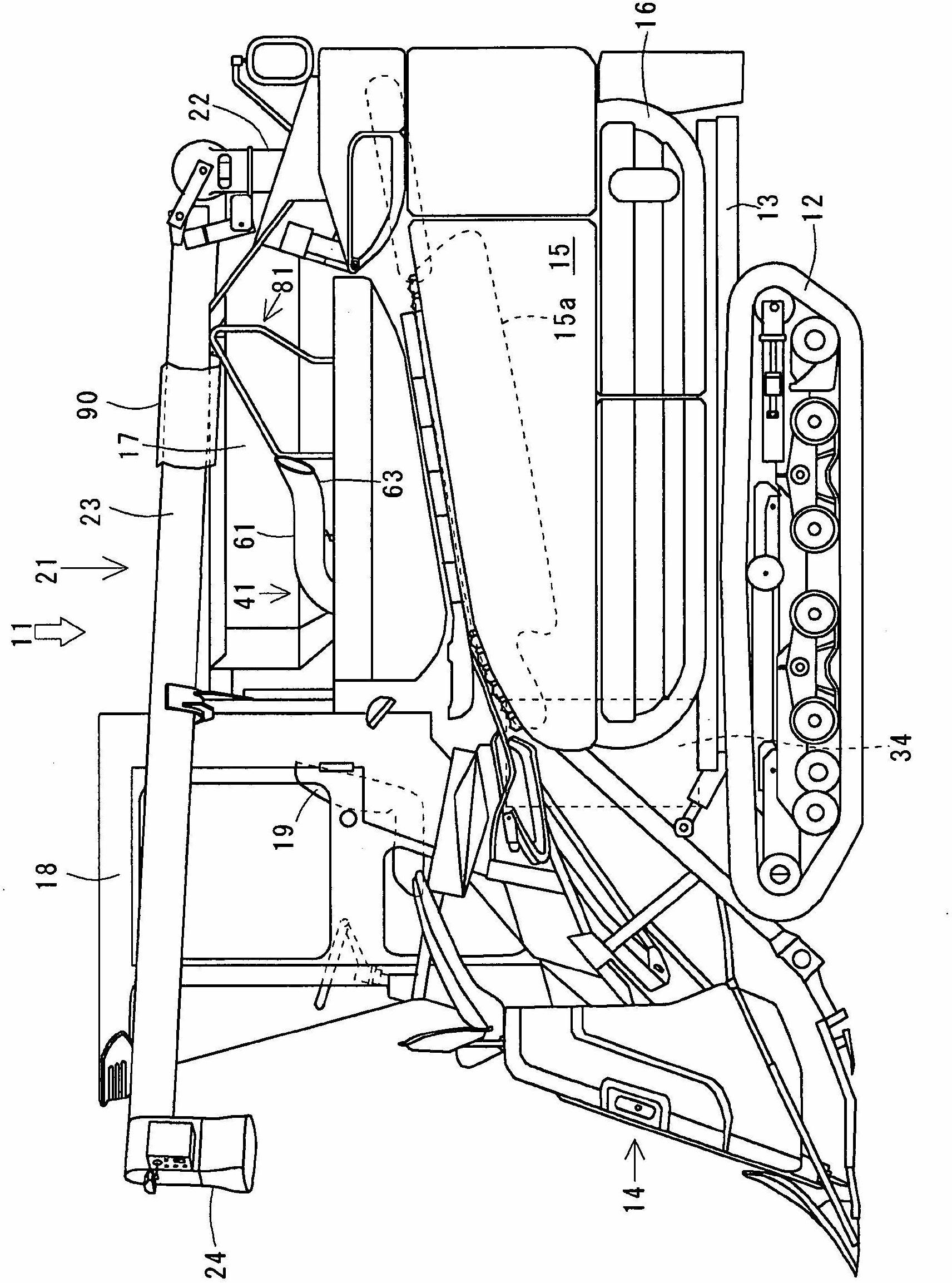

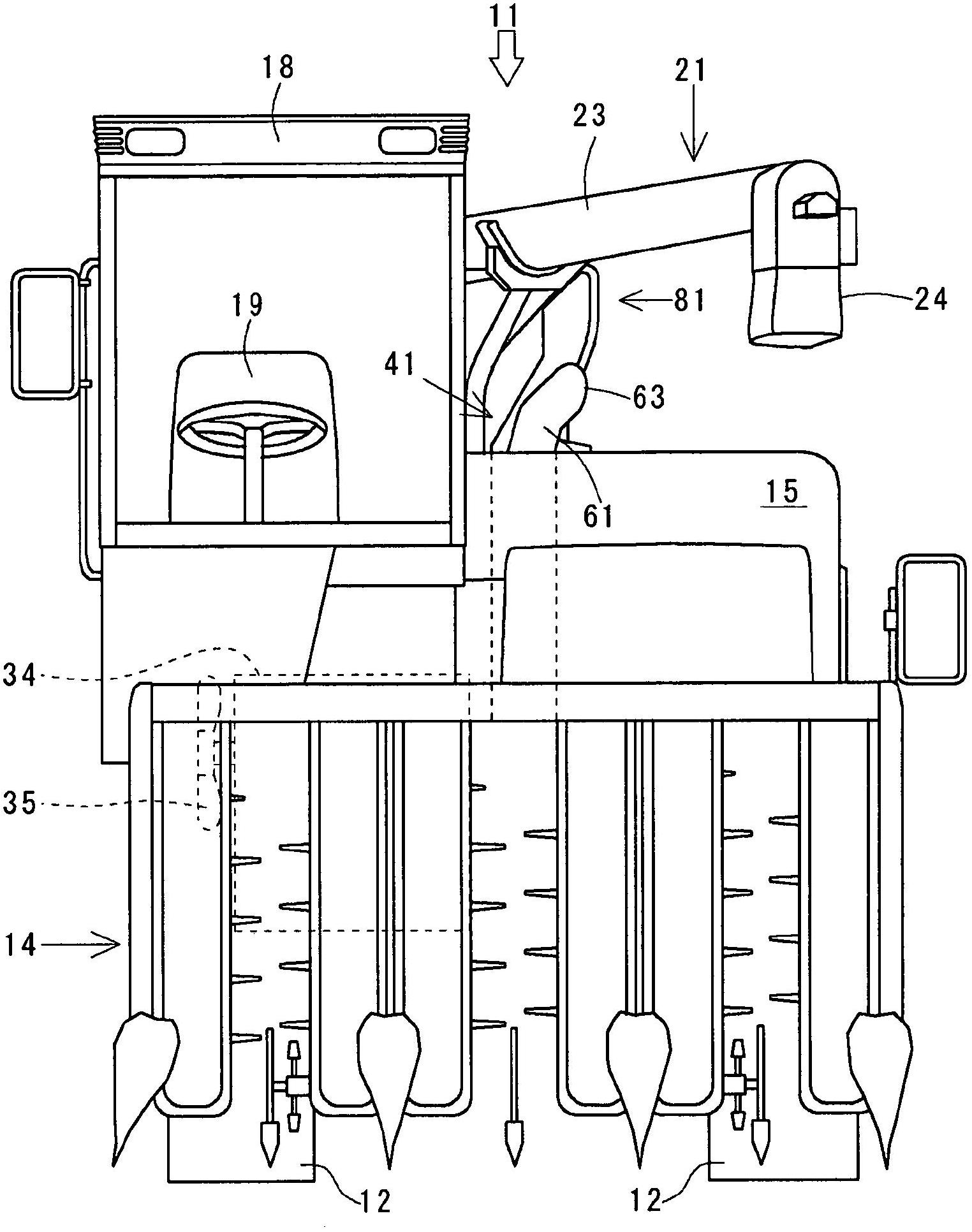

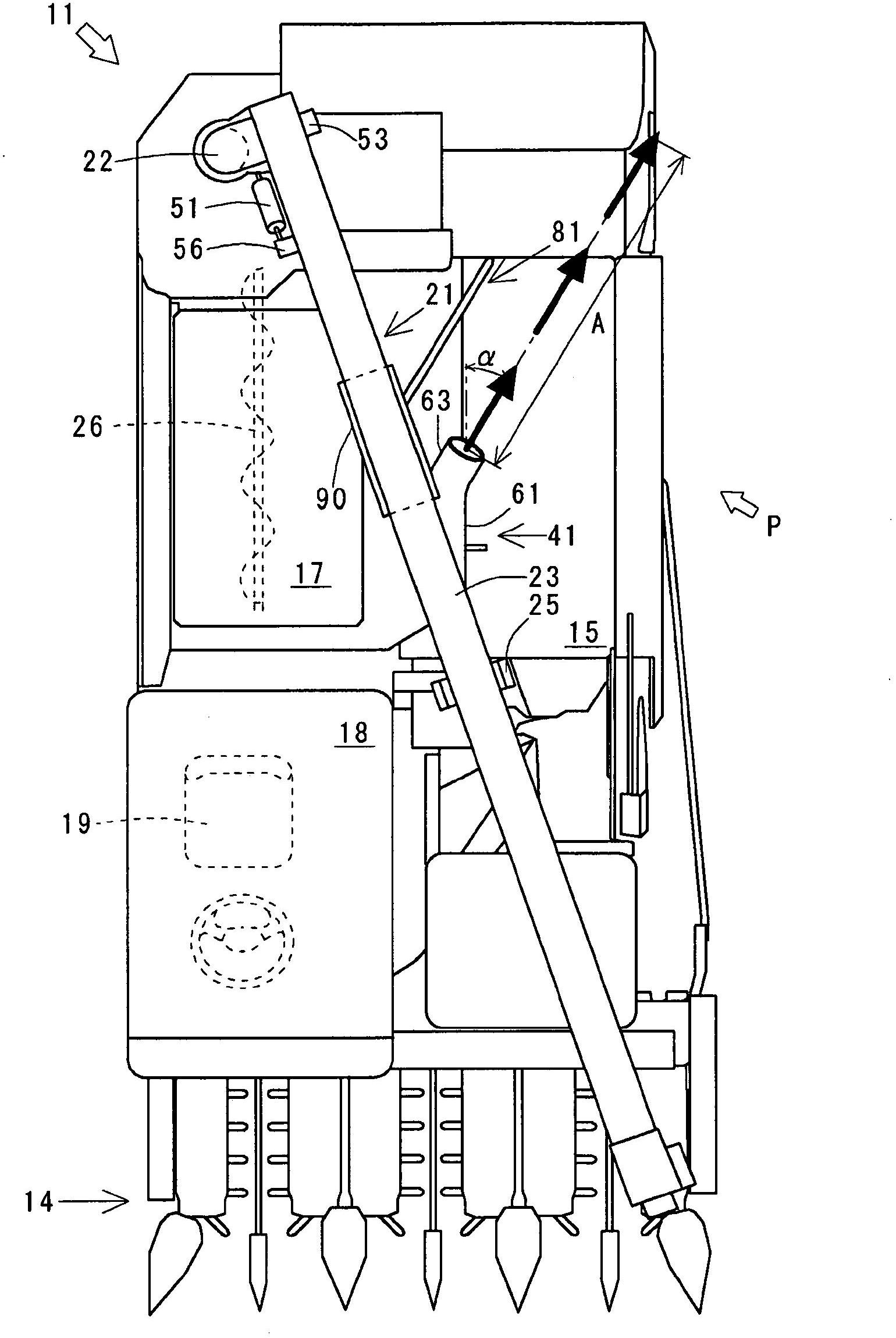

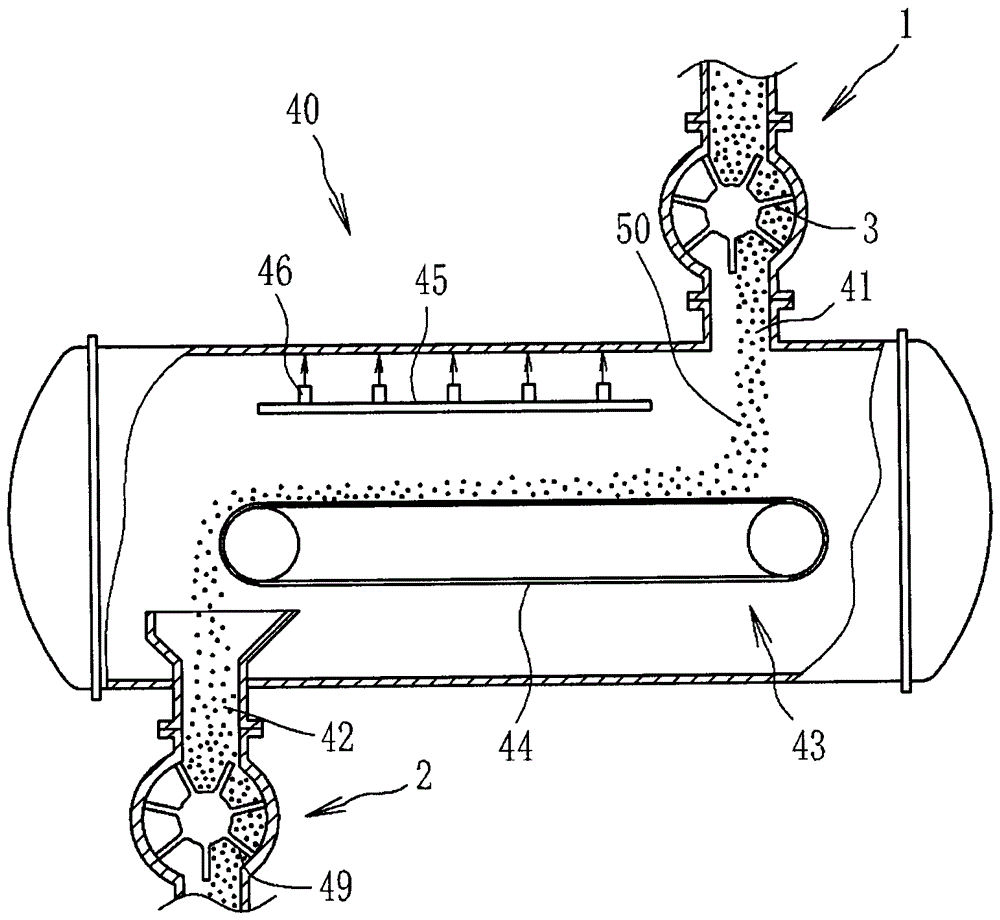

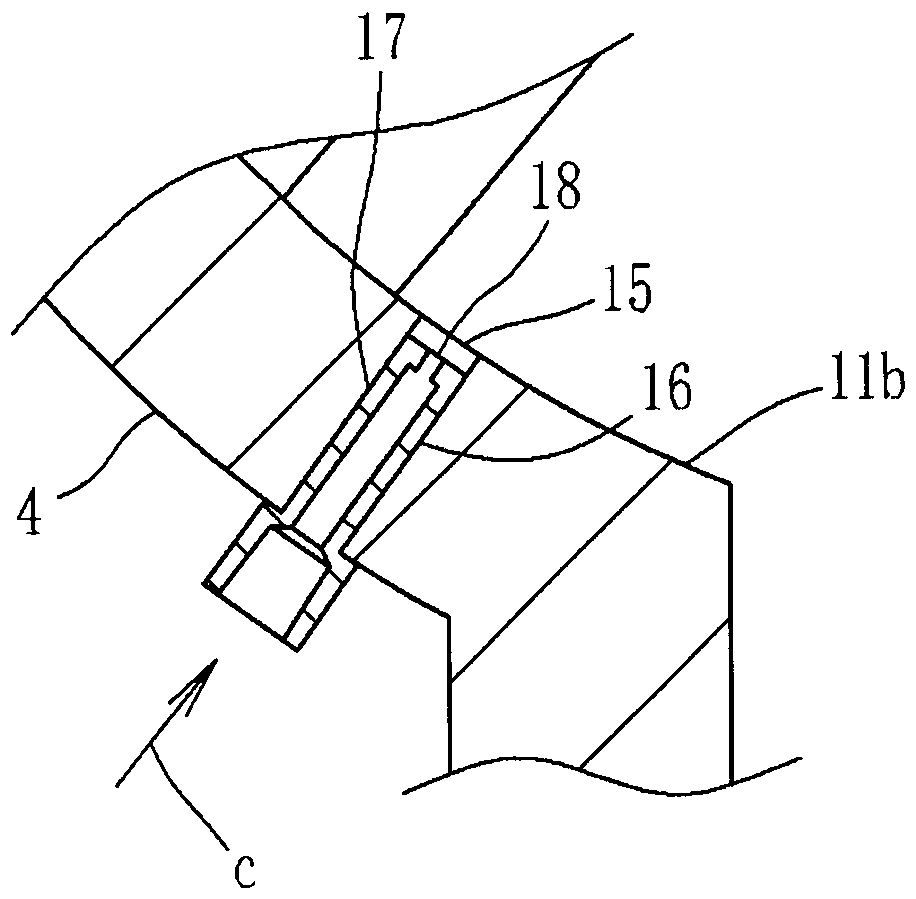

Combine

ActiveCN101516178AReduce surface temperatureIncreased durabilityExhaust apparatusMowersCombine harvesterExhaust manifold

A combine has an exhaust device capable of efficiently discharging exhaust gas in a direction away from a machine body. The combine has a grain tank (17) for containing hulls after harvesting, threshing, and sorting processes, and also has the exhaust device (41) constructed from a silencer (42), a tail pipe (61), etc., with one end of the exhaust device connected to an engine (34) mounted on the machine body and the other end extended between a threshing section (15) and the grain tank (17). The tail pipe (61) connected to an exhaust manifold (36) of the engine (34) on the upstream side of the exhaust device (41) is supported by support members (82, 83) arranged on the threshing section (15).

Owner:YANMAR POWER TECHNOLOGY CO LTD

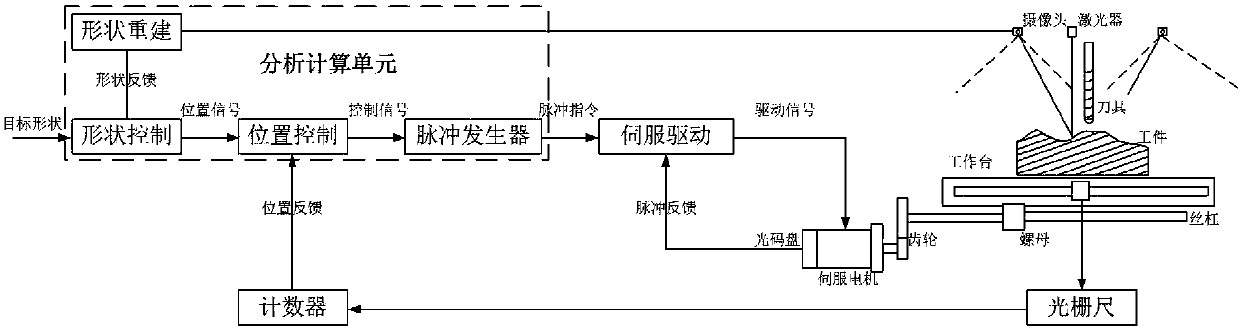

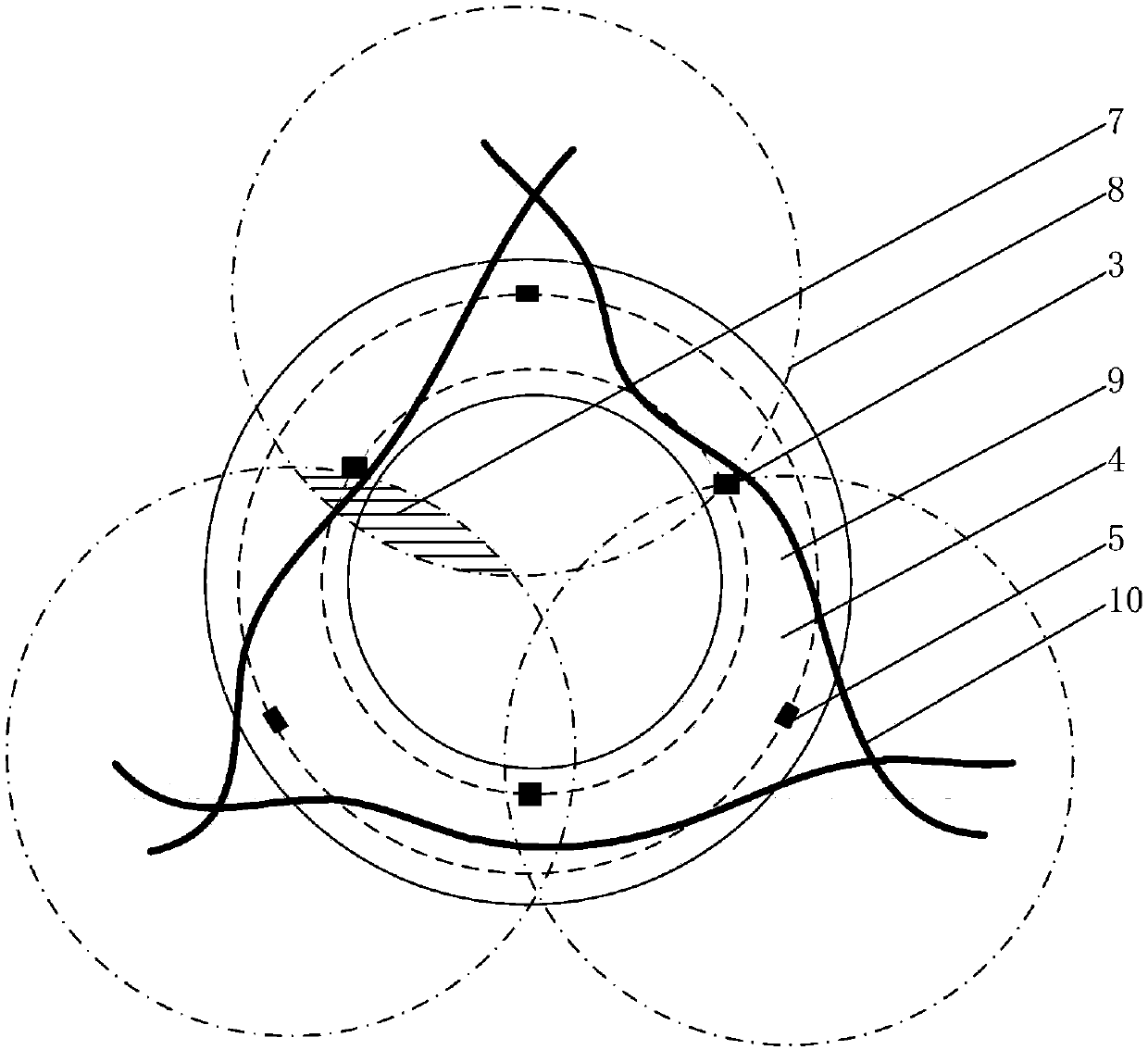

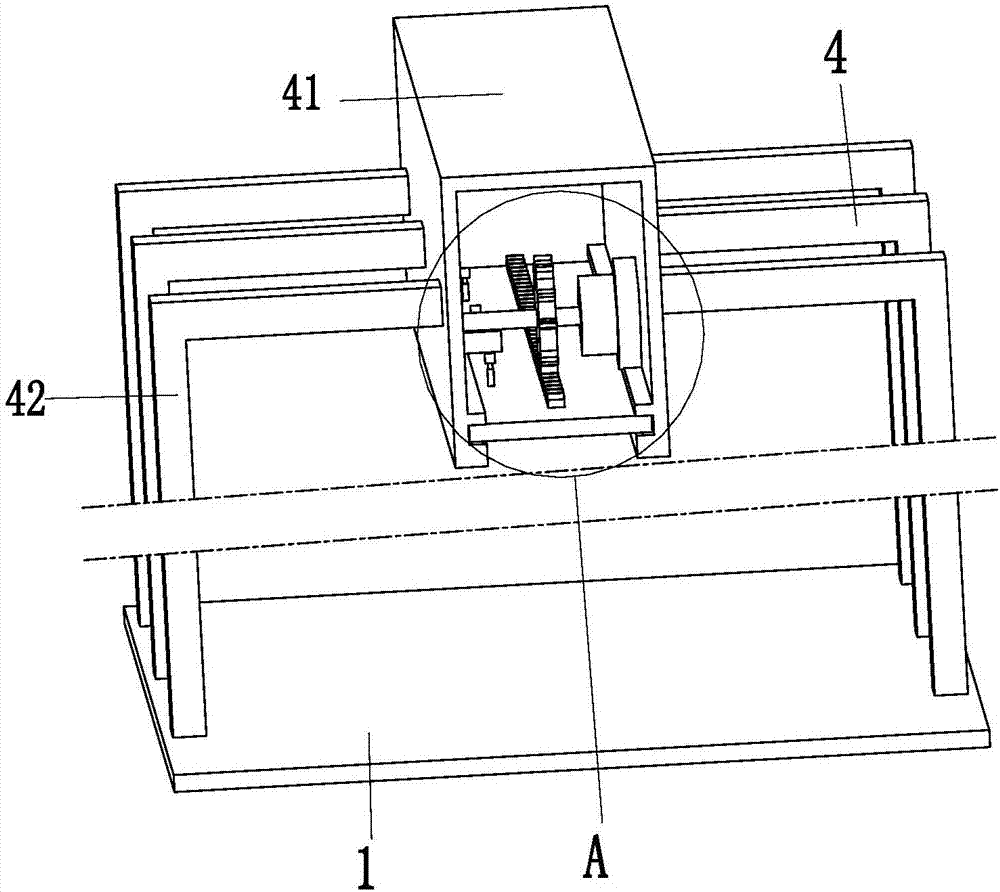

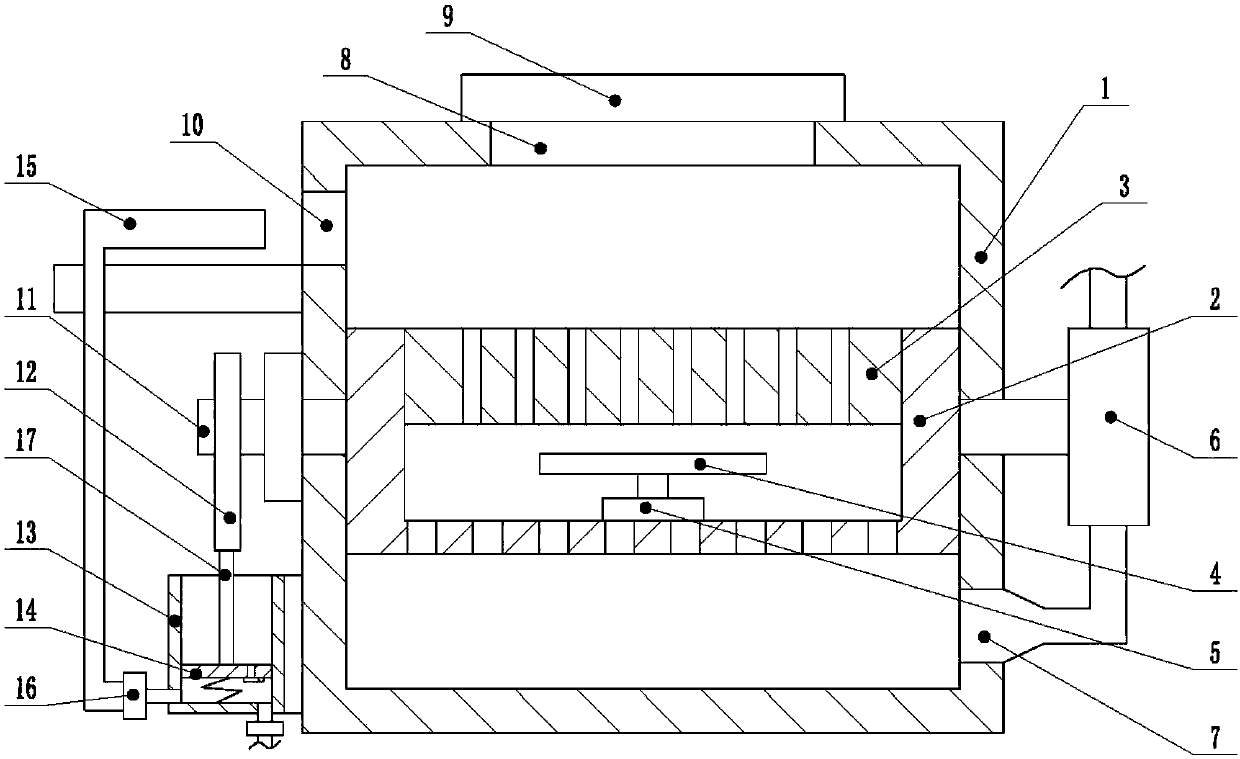

Numerical control machine tool full closed-loop system based on vision

InactiveCN107932185AAccurately identify parameters such as jitterAccurate identification of dynamic characteristicsAutomatic control devicesMeasurement/indication equipmentsMachining processEngineering

The invention provides a vision-based fully closed-loop system for CNC machine tools, including a semi-closed-loop controlled workbench, a measurement unit, an analysis and calculation unit, toolholders and tools for processing; the measurement unit is in the shape of a flange and is installed on the Next to the tool holder and on the tool handle, the analysis and calculation unit together with the original semi-closed-loop control workbench constitute a full-closed-loop system. The analysis and calculation unit calculates the shape of the workpiece surface according to the triangle rule according to the position and shape of the laser line collected by the detector head; it also introduces a processing method based on the vision-based CNC machine tool full-closed-loop system, and completes a processing including scanning the workbench, Fixture and modeling, scanning and modeling of faults, processing, and processing end four steps. The invention can measure the effect of the machining action after each movement of the tool in real time, reconstruct the shape during the machining process, and incorporate the machined surface quality such as roughness into the fully closed-loop control system, which can double the machining accuracy.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

Method and apparatus for prededusting

InactiveCN102240486AEasy to handlePrevent roll upDispersed particle separationDust controlEngineering

The invention discloses a method and an apparatus for prededusting. The method allows a dusty gas to enter into the prededusting apparatus at a tangent from an inlet. Dust in an airflow moves along the inner wall of a cylinder body, slides into a dust collector and is discharged from a dust discharge port because of centrifugal force generated by airflow rotation. A conical reflection screen is arranged in the cylinder body, most of the airflow entering into the cylinder body is reflected upward because of the effect of the reflection screen, and only a small amount of the gas enters into the dust collector with dust particles, so a case that the dust which has been already separated is rewinded up and taken away by a secondary gas can be prevented, thereby the dedusting effect is improved. A certain gap between the reflection screen and the cylinder body is kept, so the dust can enter into the dust collector through the gap; and simultaneously an air-vent is arranged on the top of the reflection screen, so the small amount of the gas entering into the dust collector can enter into the cylinder body through the air-vent. So the apparatus has the characteristics of low equipment cost, stable working condition, and simple and convenient maintenance.

Owner:GUIYANG AL-MG DESIGN & RES INST

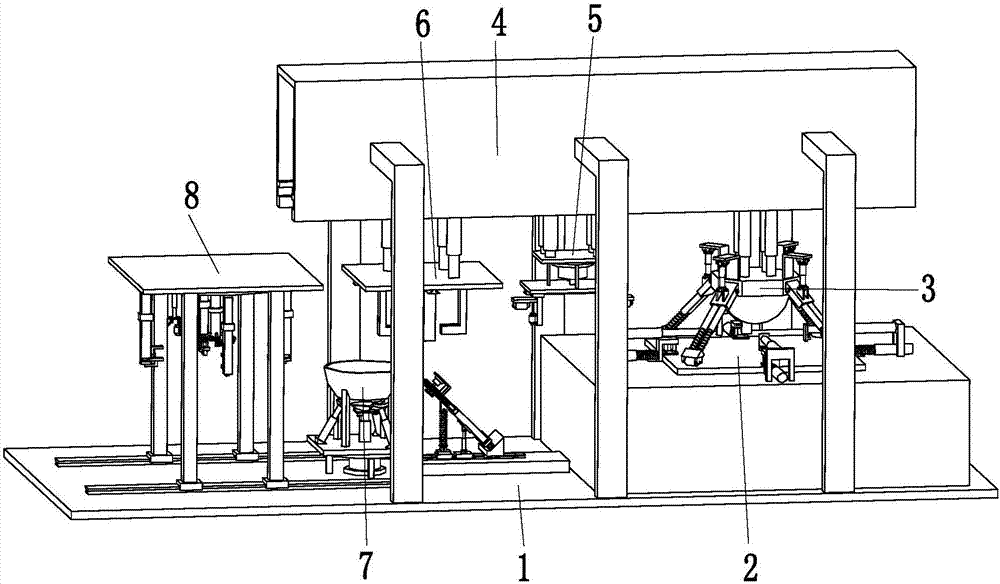

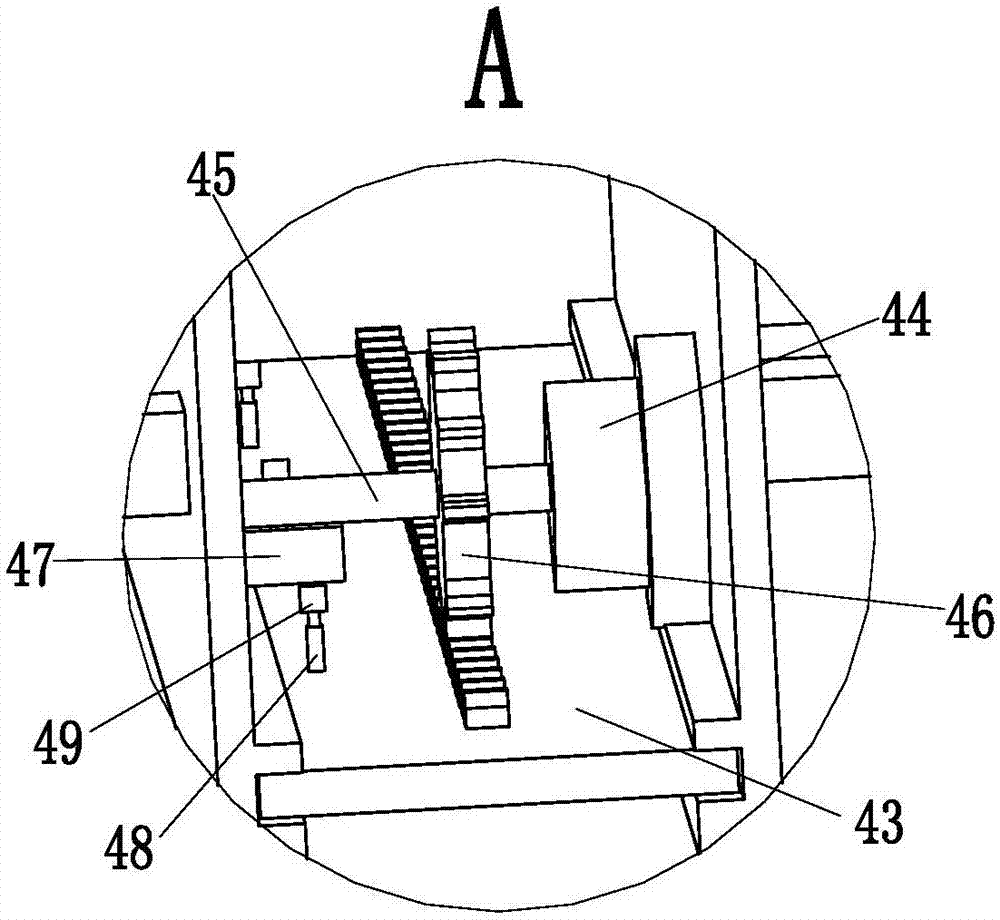

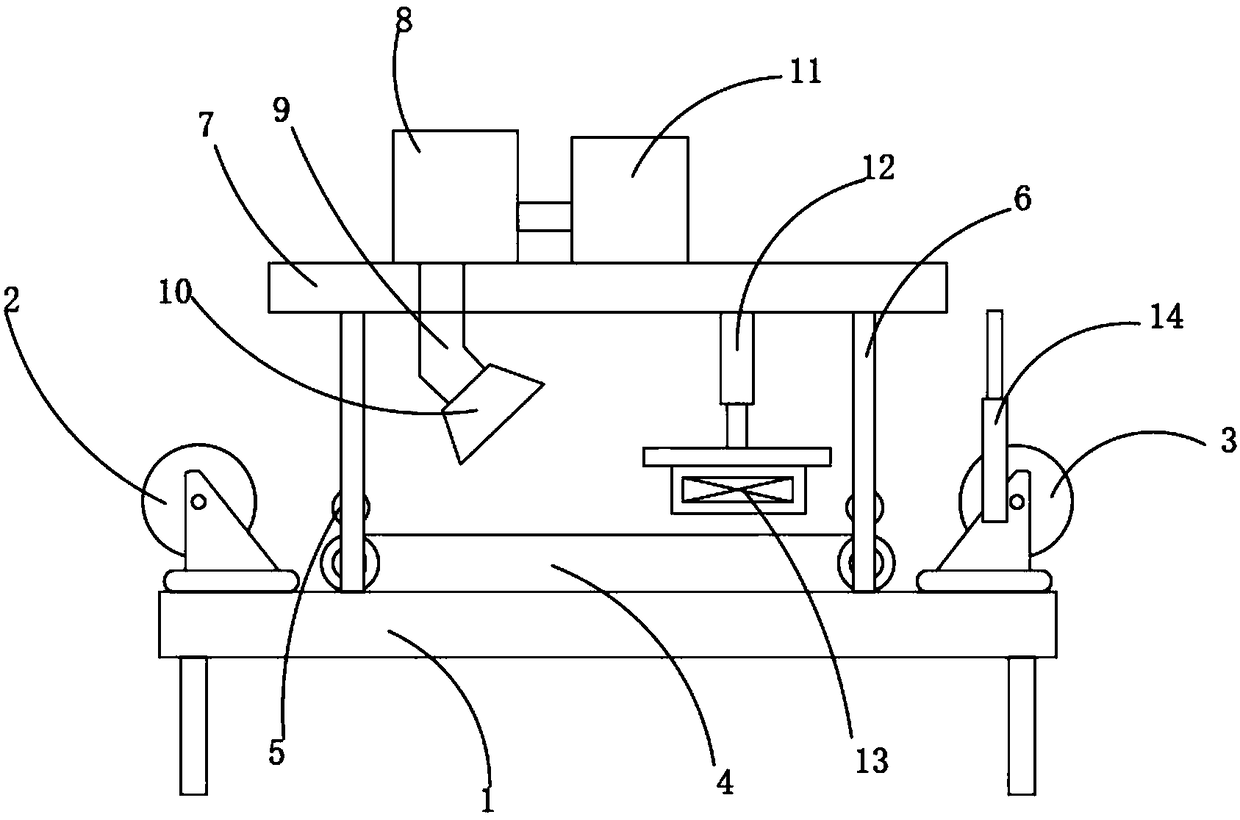

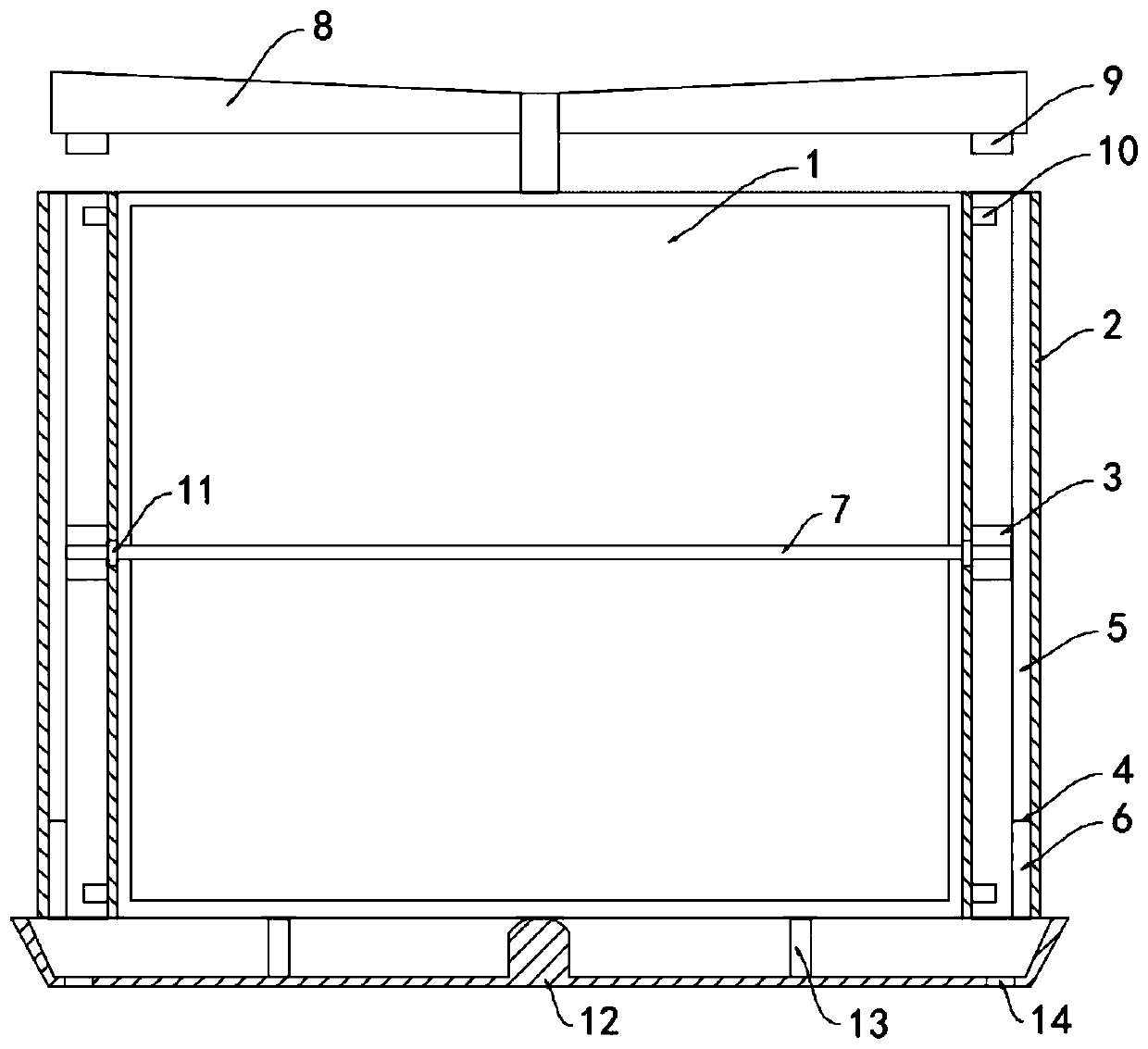

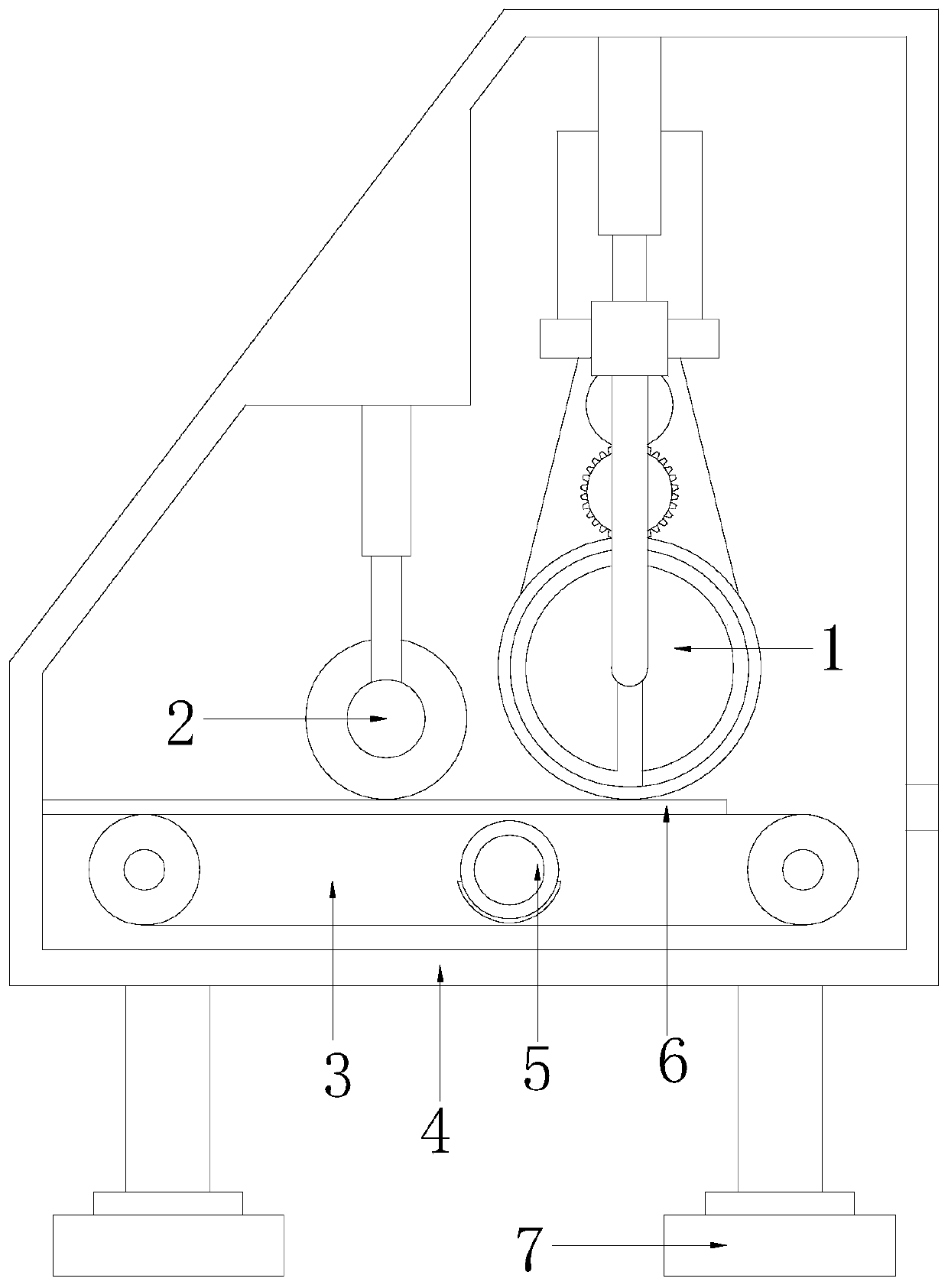

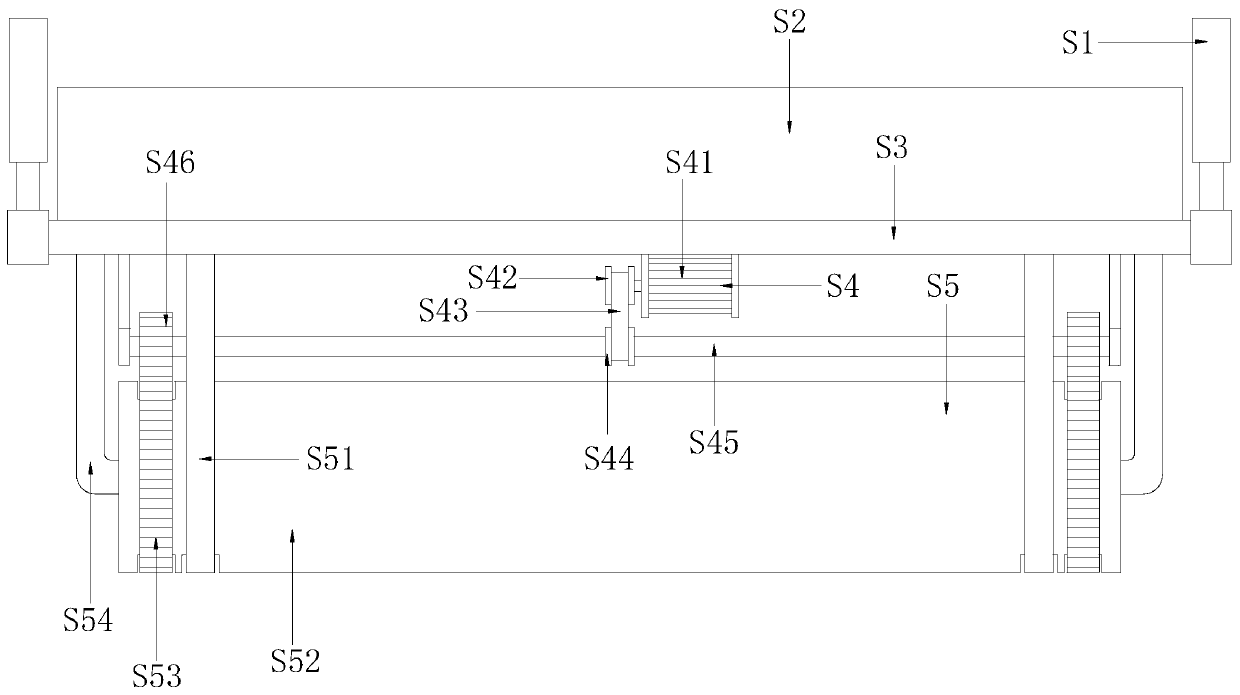

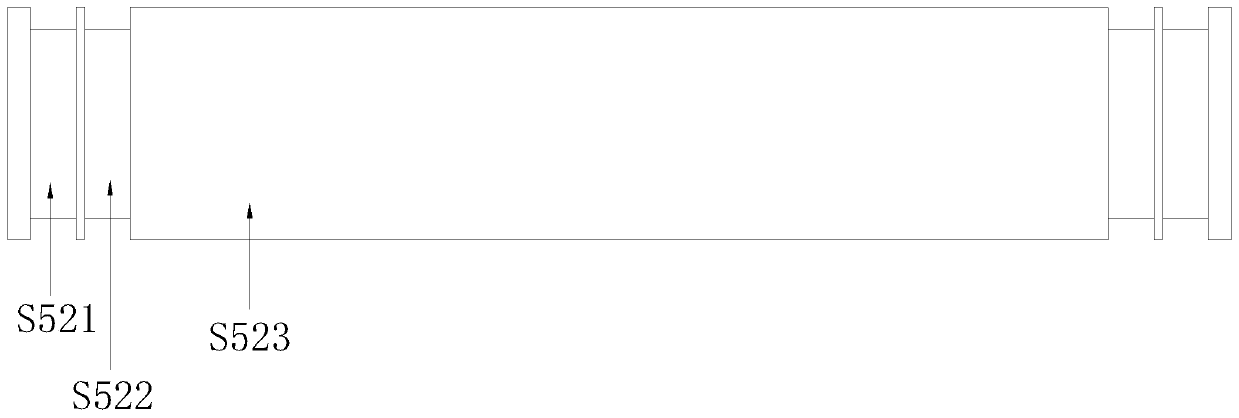

Steel structure assembly type building material producing and processing processor

InactiveCN108000161ASupport fixed and stableAutomatic grindingOther manufacturing equipments/toolsSteel platesBuilding material

The invention relates to a steel structure assembly type building material producing and processing processor. The steel structure assembly type building material producing and processing processor comprises a supporting bottom plate, a fixed device, an extruding device, a conversion device, a correcting device, a carrying device, a cutting device and a supporting grinding device, wherein the fixed device is mounted at the right end of the supporting bottom plate; the extruding device is connected with the right end of the conversion device; the conversion device is mounted on the supporting bottom plate; both the correcting device and the carrying device are mounted on the conversion device; the correcting device is positioned at the right side of the carrying device; the cutting device is mounted on the middle part of the supporting bottom plate; and the supporting grinding device is connected with the upper end surface of the left side of the supporting bottom plate. The steel structure assembly type building material producing and processing processor can solve the problems that all-around leveling cannot be performed when a steel plate is extruded, the extruded steel plate cannot be corrected, a cutting angle of the cut and extruded steel plate cannot be regulated, the cutting effect is poor, a cut ball body needs to manually grind, and the like during welding ball processing in the prior art.

Owner:黄远明

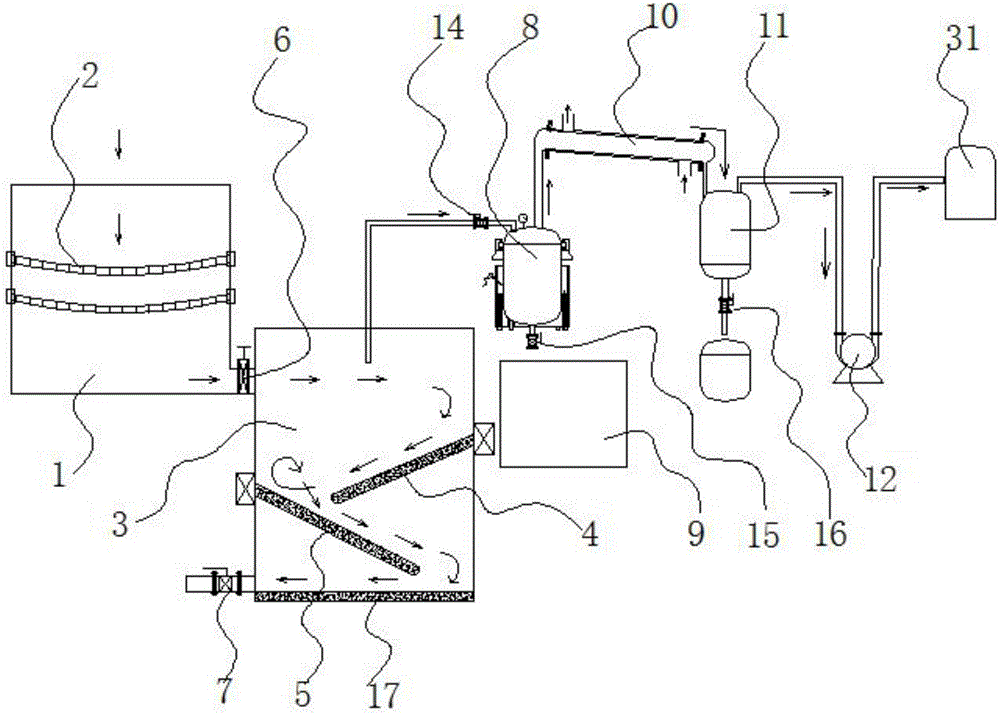

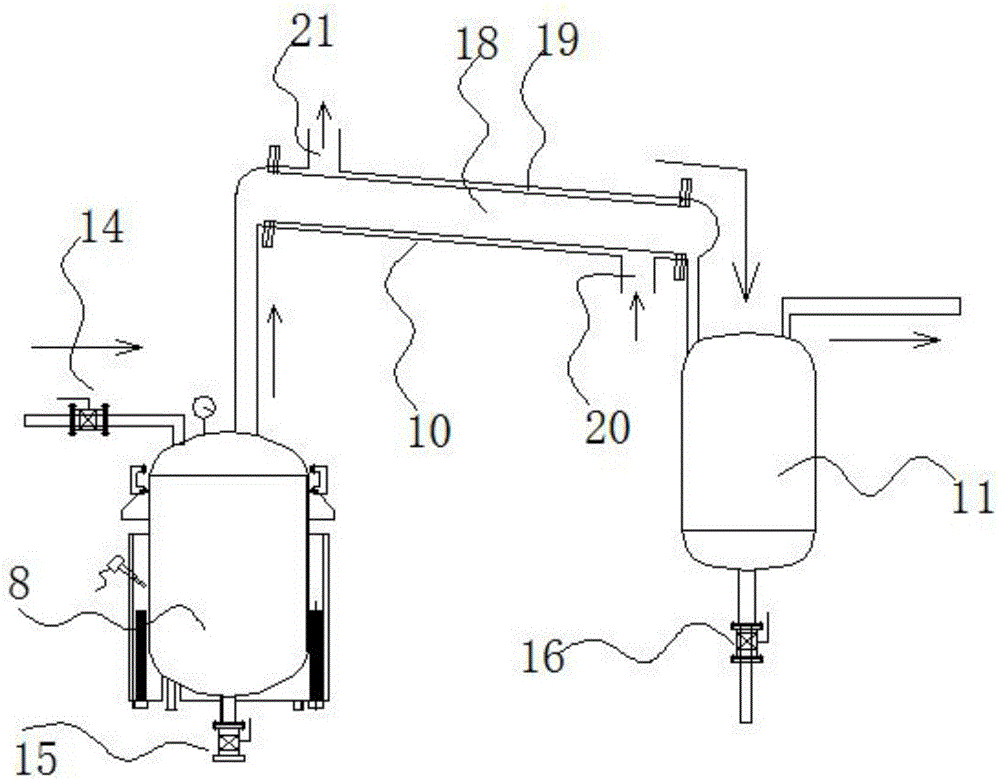

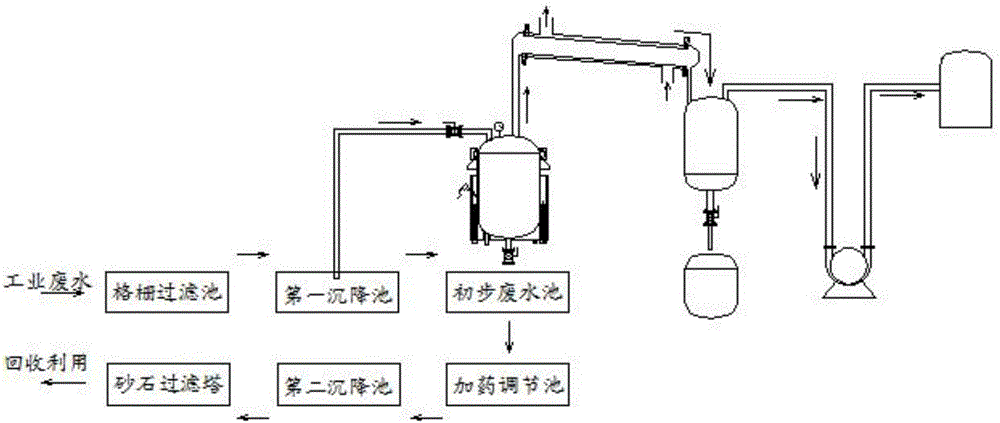

Method and system for treating industrial wastewater containing organic solvent

ActiveCN106746123AGuaranteed temperatureBlock and avoid roll upGas treatmentWater contaminantsOrganic solventSettling basin

The invention discloses a method and a system for treating industrial wastewater containing organic solvent, which are used for treating the industrial wastewater containing the organic solvent. A grid filtering tank, a first settling basin and an organic solvent recovering system are arranged for carrying out impurity filtering, static settling treatment and organic solvent recycling on the industrial wastewater; in addition, a series of problems in a process such as: filtering scientificity and late-stage cleaning of the impurities, rolling prevention and washing cleanness of sediments in a static settling process, adsorption treatment of waste gases generated by separation and extraction of the organic solvent at a negative pressure of -0.08 to 0.05kg / cm<2> and a high temperature of 70 to 120DEG C, and the like are solved. The method and the system for treating the industrial wastewater containing the organic solvent have the advantages that scientificity and reasonability are realized, the safety is guaranteed, and greenness, environmental protection, high efficiency and energy saving are realized; in addition, the organic solvent is recovered and the waste is avoided.

Owner:YANCHENG HAIDENENG WATER TREATMENT ENVIRONMENTAL ENG

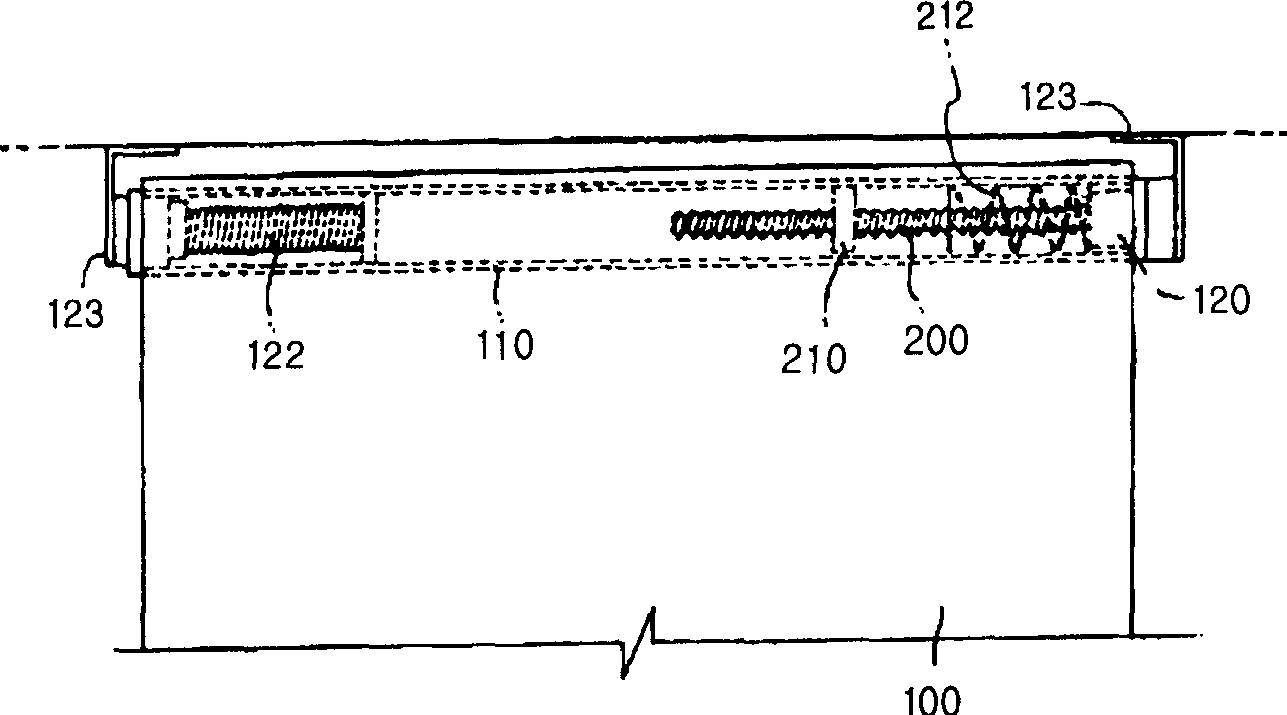

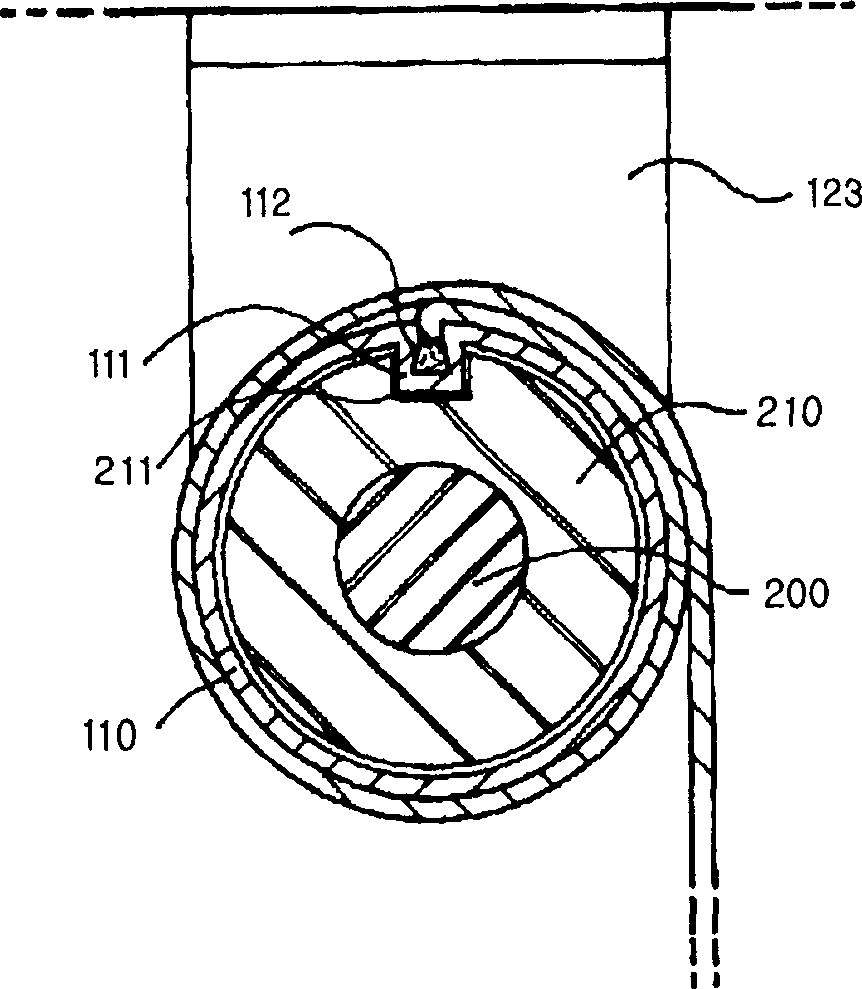

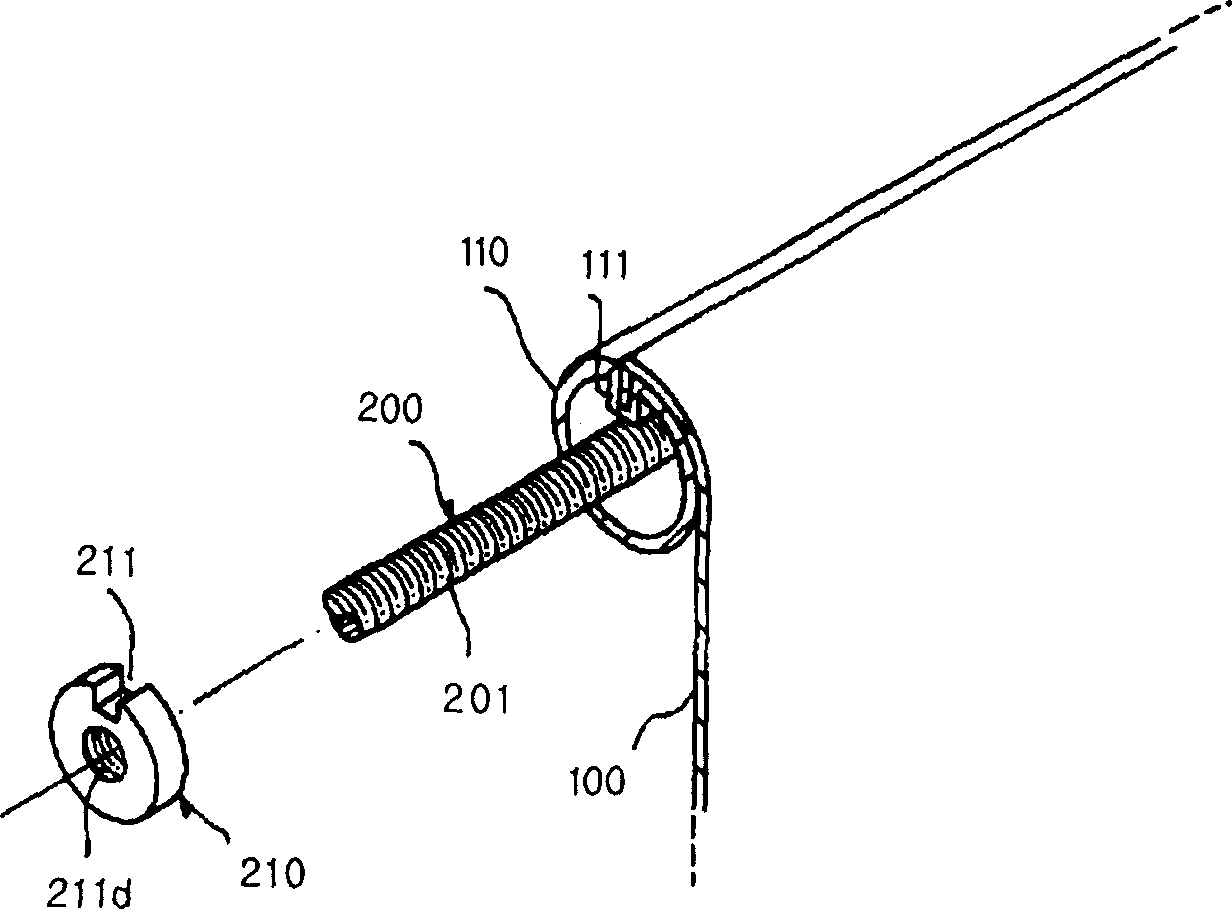

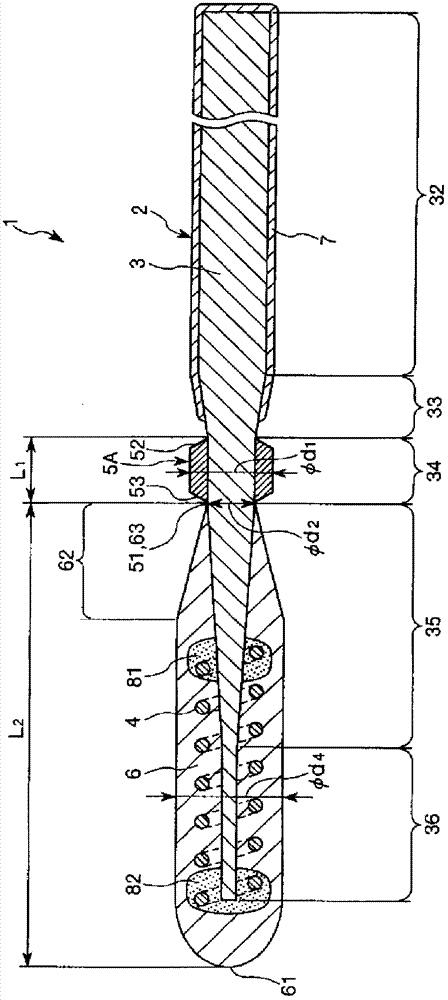

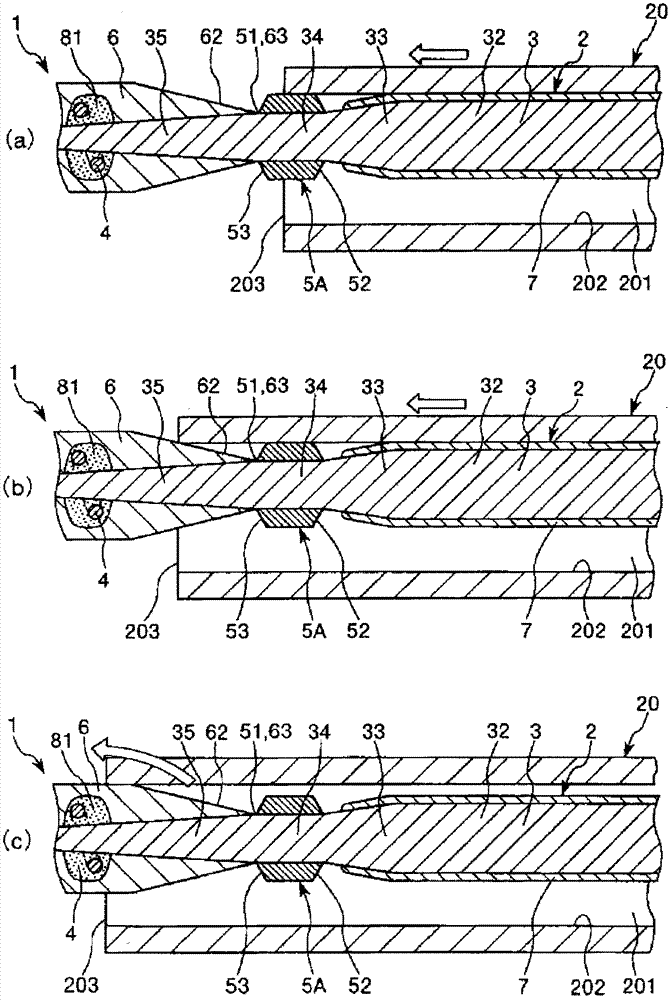

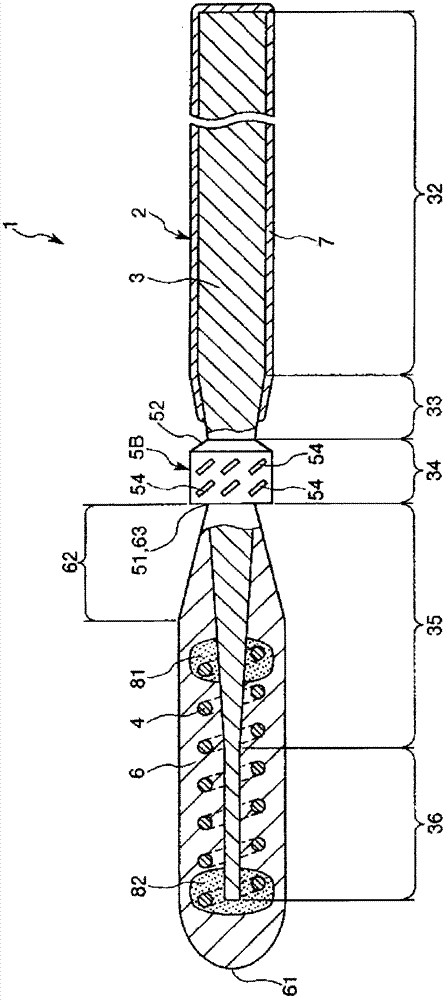

Guide wire

Disclosed is a guide wire which comprises: a flexible long wire main body; and a coating layer that covers the front end portion of the wire main body and is configured of a resin material. The wire main body of the guide wire is provided with a projection that protrudes along the entire outer circumference of the main body. The front end portion of the projection is in contact with the base end portion of the coating layer, and the maximum outer diameter of the projection is larger than the outer diameter of the coating layer that is in contact with the projection. The base end portion of the projection has an outer diameter tapering portion wherein the outer diameter is gradually reduced toward the base end.

Owner:TERUMO KK

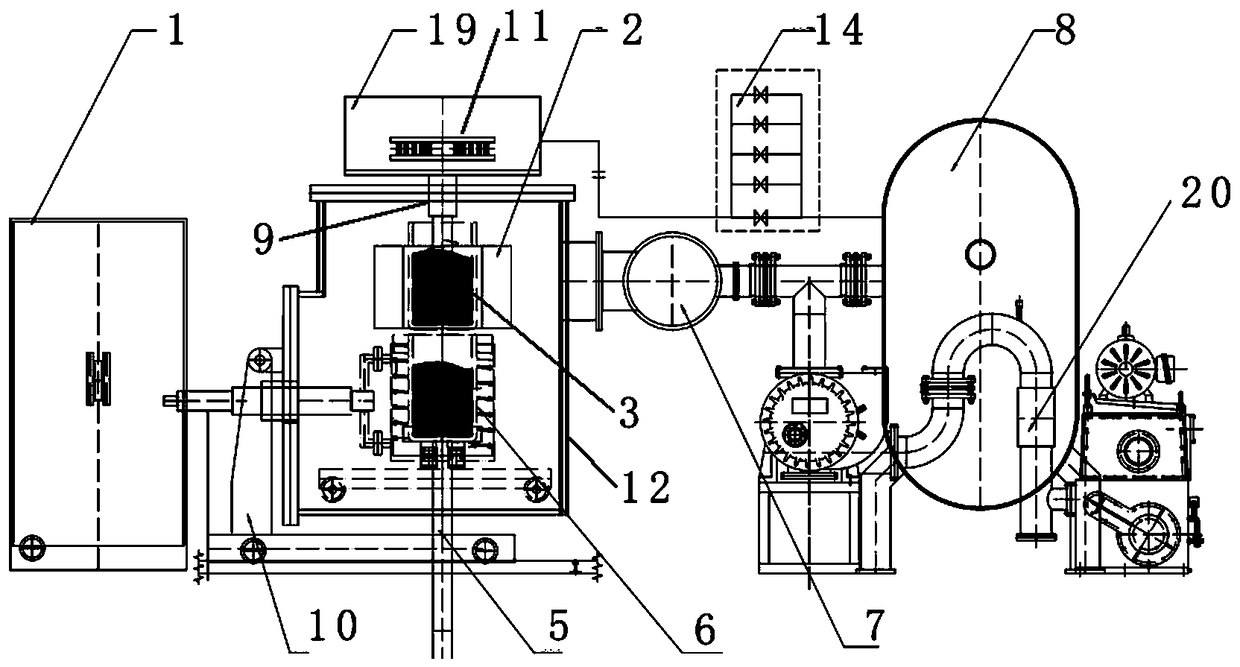

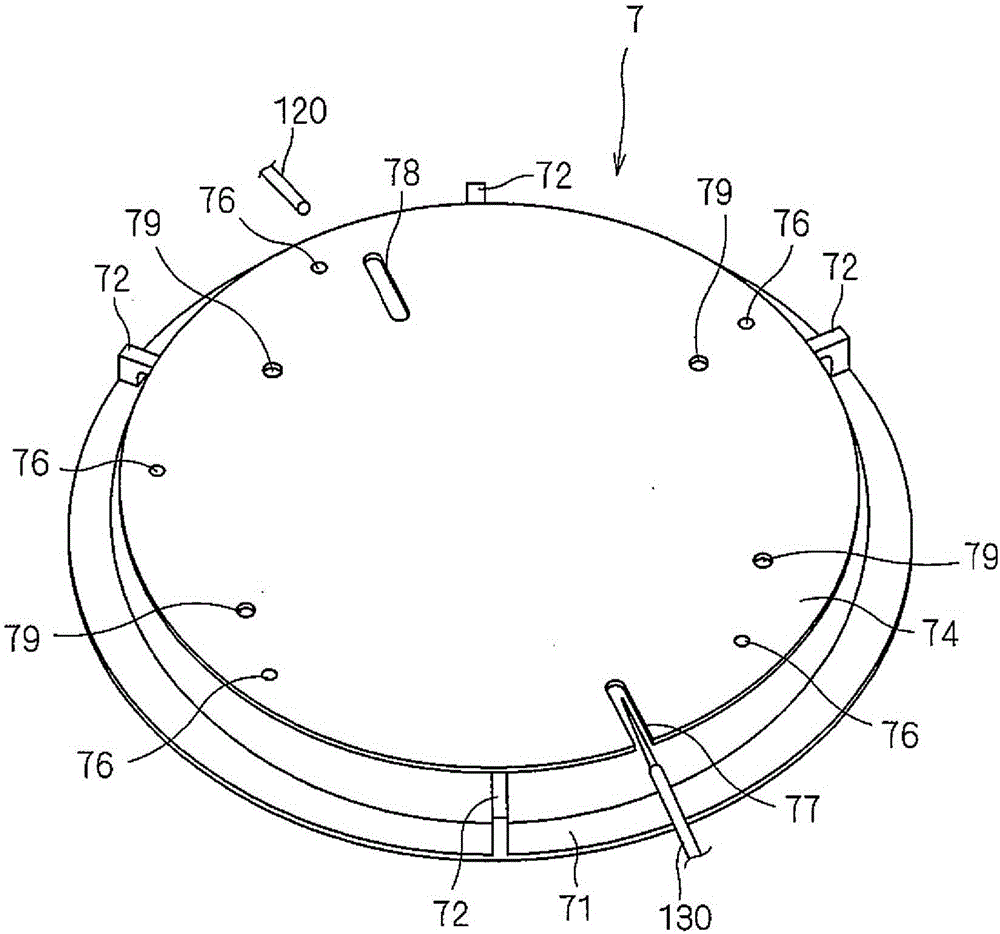

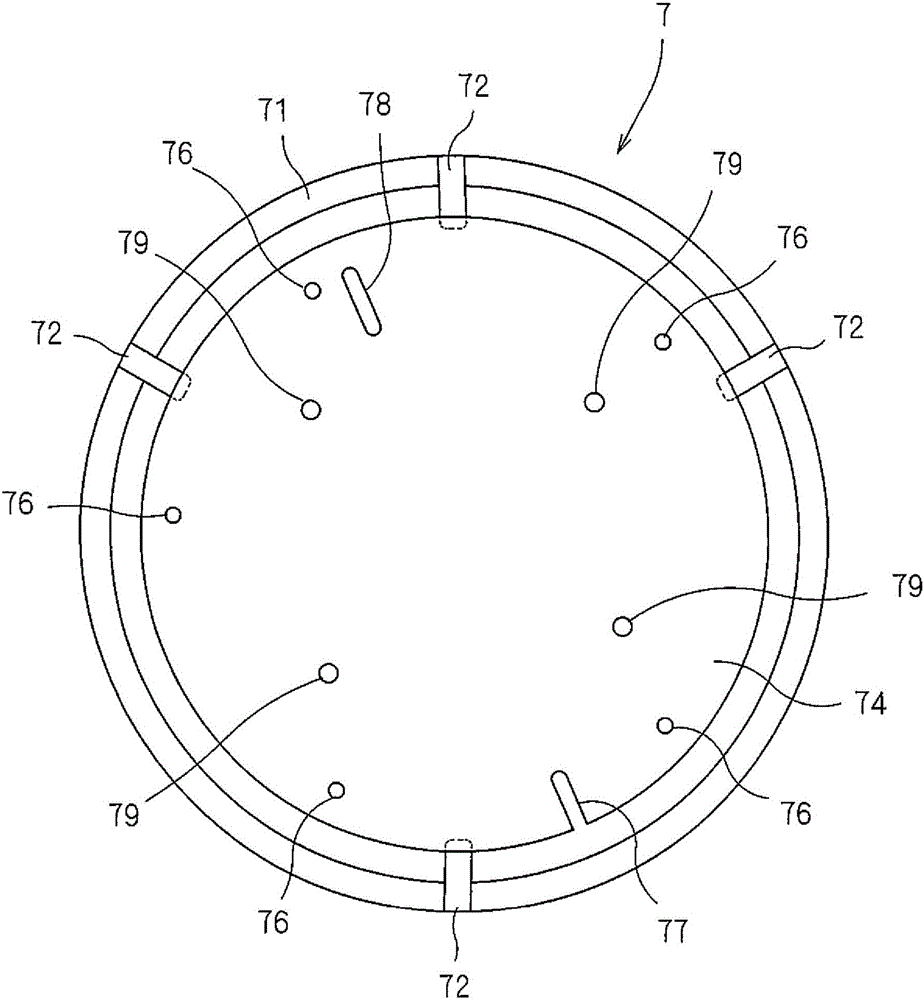

Vacuum electromagnetic stirring suction-casting system used for composite material

The invention provides a vacuum electromagnetic stirring suction-casting system used for a composite material. The system comprises a control cabinet, an electromagnetic stirring device, a crucible, acrucible lifting device, an induction smelting device, a dust filter pipe, a vacuum tank, a suction-casting pipe, a mould, a furnace and a controller. According to the scheme, a vacuum electromagnetic stirring suction-casting method is adopted for achieving smelting and casting of an alloy and the composite material thereof, and smelting and casting under vacuum can prevent air suction in the casting process; and the technical problems of poor fluidity of the alloy and the composite material thereof, alloy component segregation, easy enhanceosome settling, non-uniform enhanceosome distribution are solved, and castings, of the alloy and the composite material thereof, with uniform distribution of components and enhanceosomes and high performance can be obtained easily.

Owner:LOUDI WENCHANG TECH

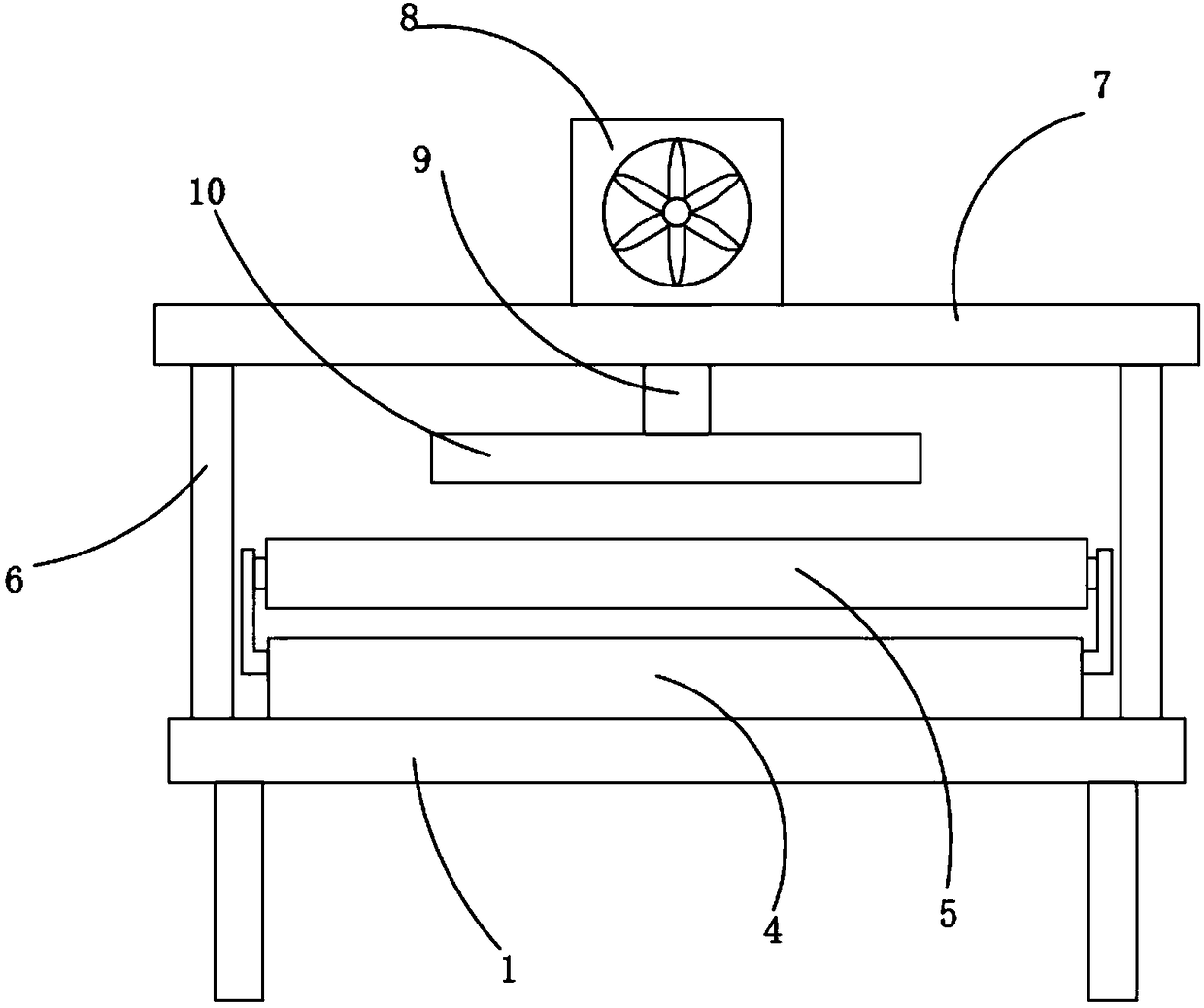

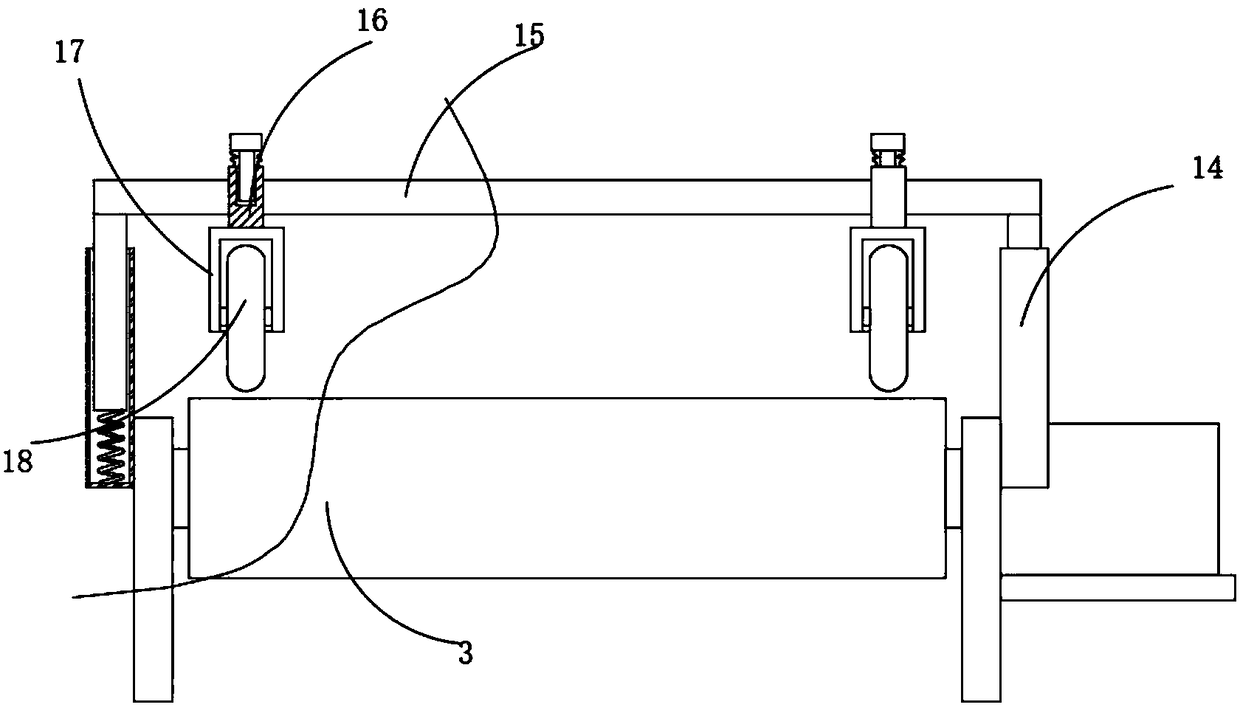

Transmission equipment for jacquard fabric

InactiveCN108438991AImprove cleanlinessReasonable structureJacquardsTextile shapingEngineeringTransmission equipment

The invention discloses transmission equipment for jacquard fabric. The transmission equipment comprises a transmission platform. An unrolling device and a rolling device are fixed to the two ends above the transmission platform correspondingly. A conveying belt is arranged between the unrolling device and the rolling device. Conveying pressing rollers are arranged at the two ends of the conveyingbelt correspondingly. Four supporting rods are vertically arranged above the transmission platform. Top plates are connected to the tops of the four supporting rods. A fan is fixed to the tops of thetop plates through screws. A waste box is arranged on one side of the fan. A ventilation pipe is connected between the waste box and the fan. A wind sucking pipe is connected to the bottom of the fan. The transmission equipment is reasonable in structure and novel in design, when the jacquard fabric is conveyed into the rolling device from the unrolling device, the jacquard fabric can be ironed fast, thread residues and crushed materials on the jacquard fabric are cleared away, the jacquard fabric is kept clean and smooth, when the jacquard fabric is rolled, two ends of the jacquard fabric are effectively prevented from rolling up, and therefore the jacquard fabric can be rolled conveniently.

Owner:ZHEJIANG XINGFEIER TECH CO LTD

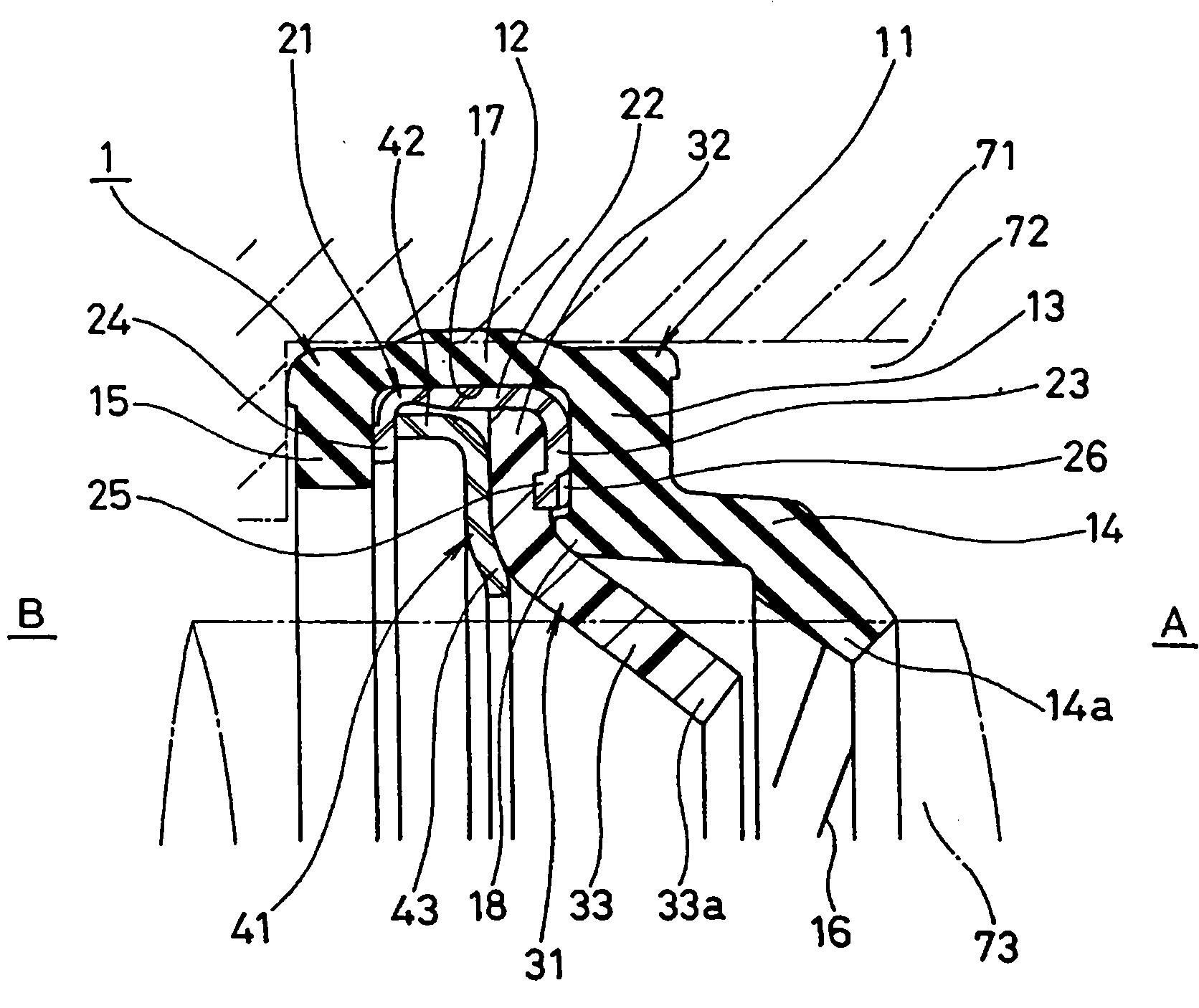

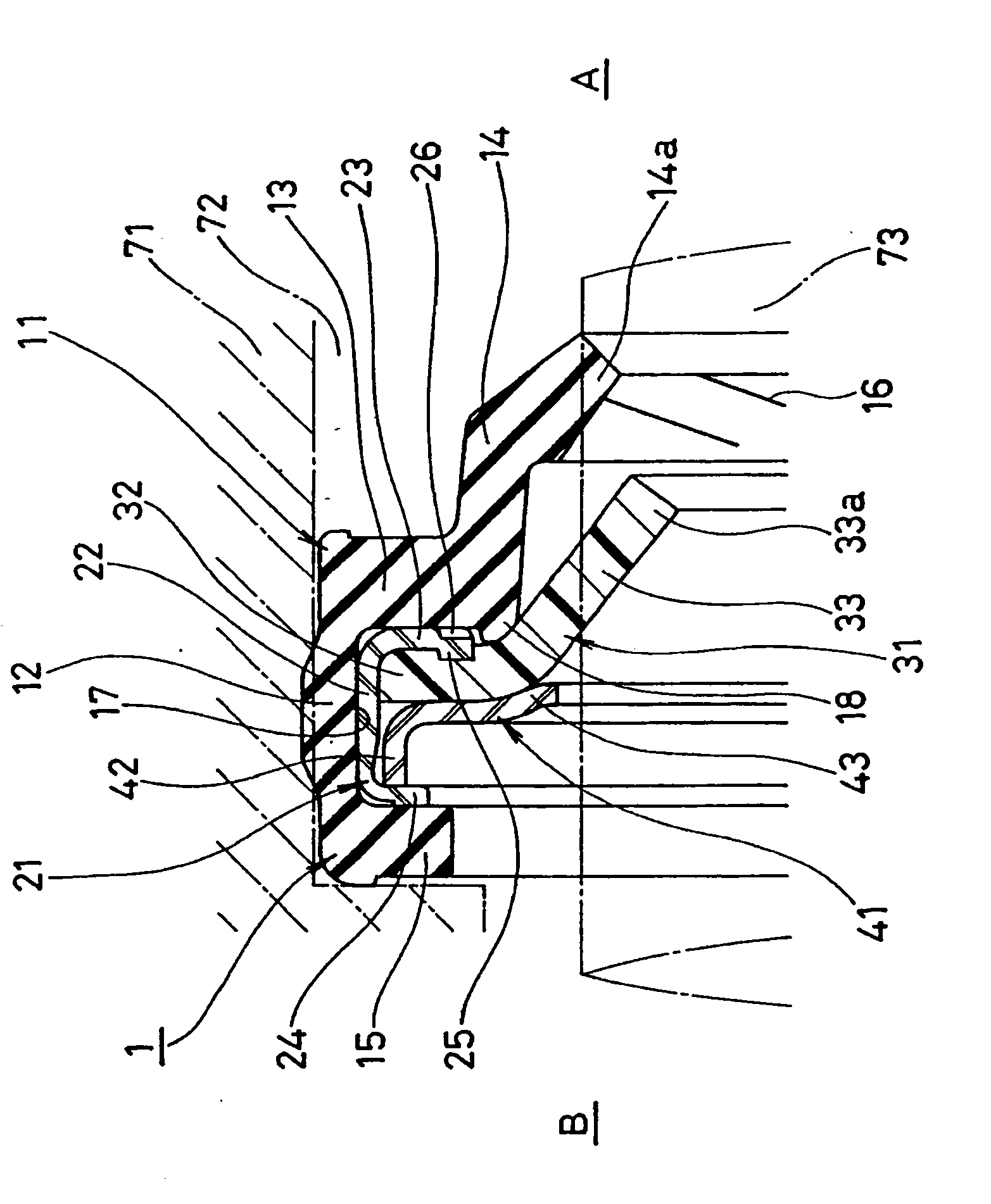

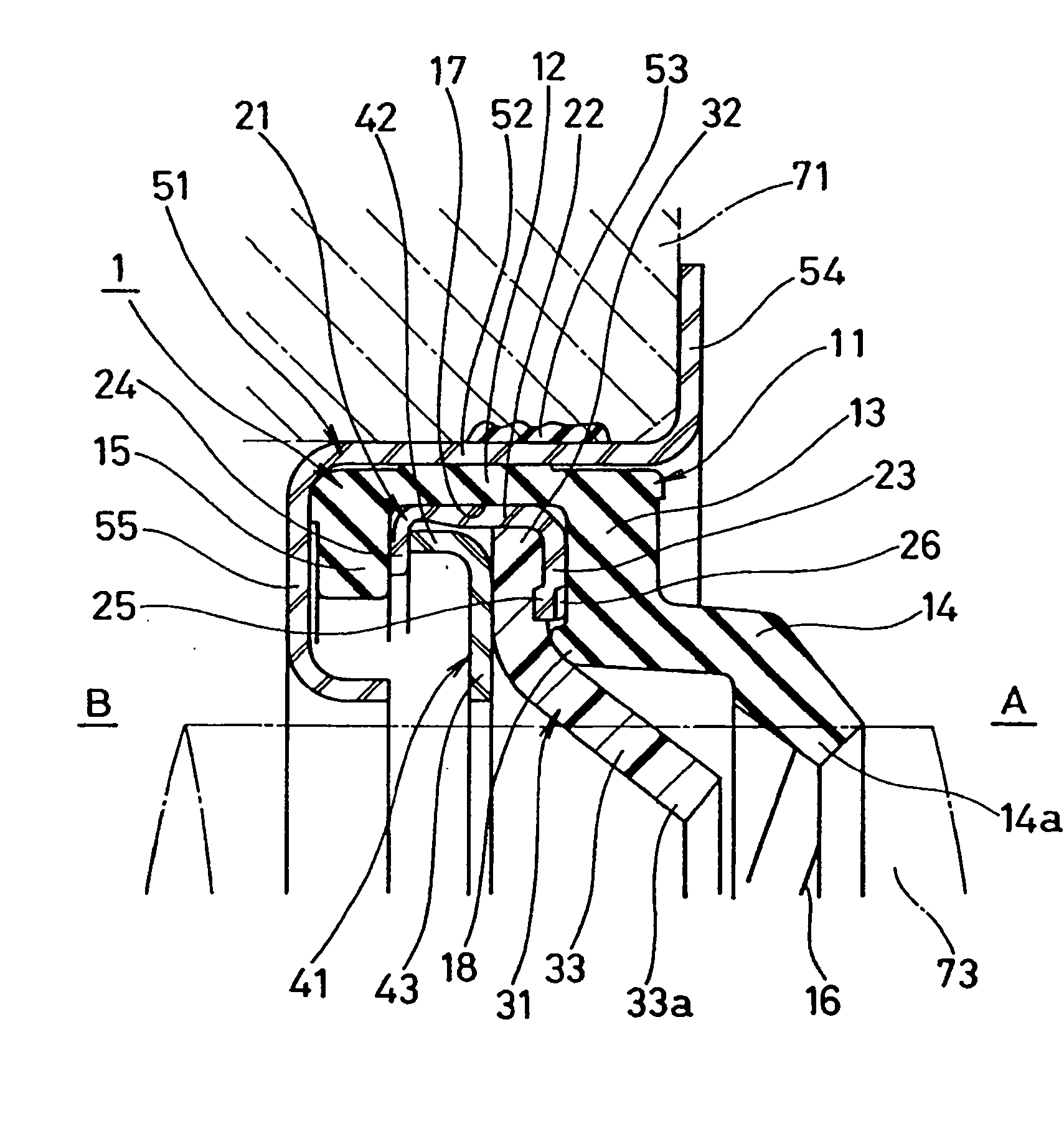

Lip type seal

InactiveCN101809344AEasy to separateEasy to separate/separateEngine sealsPositive displacement pump componentsEngineeringLip seal

Owner:EAGLE INDS

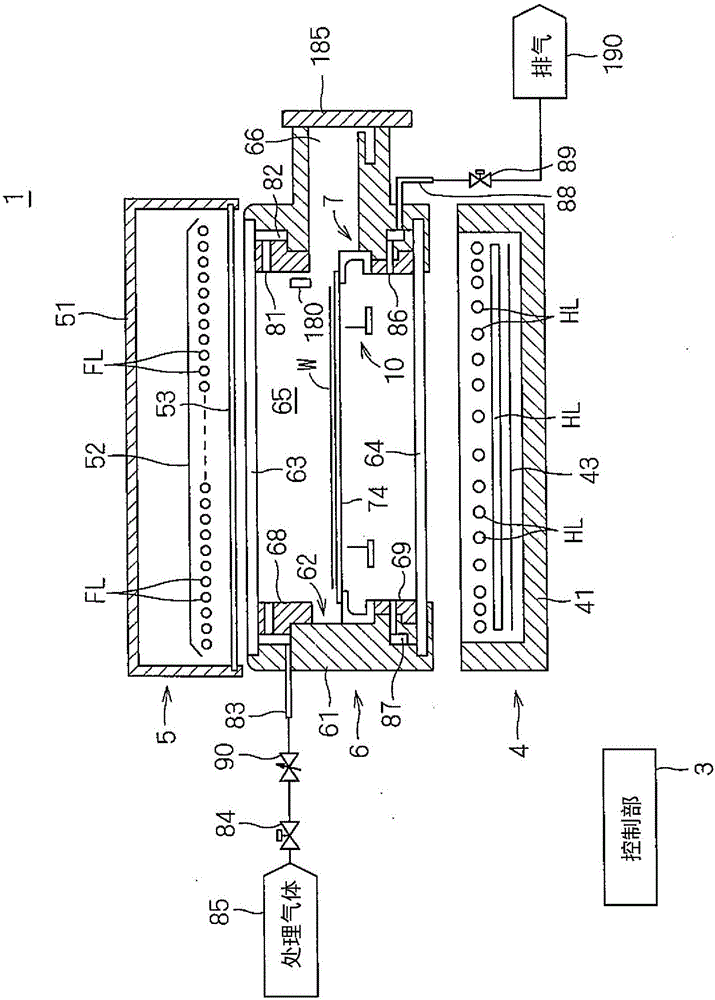

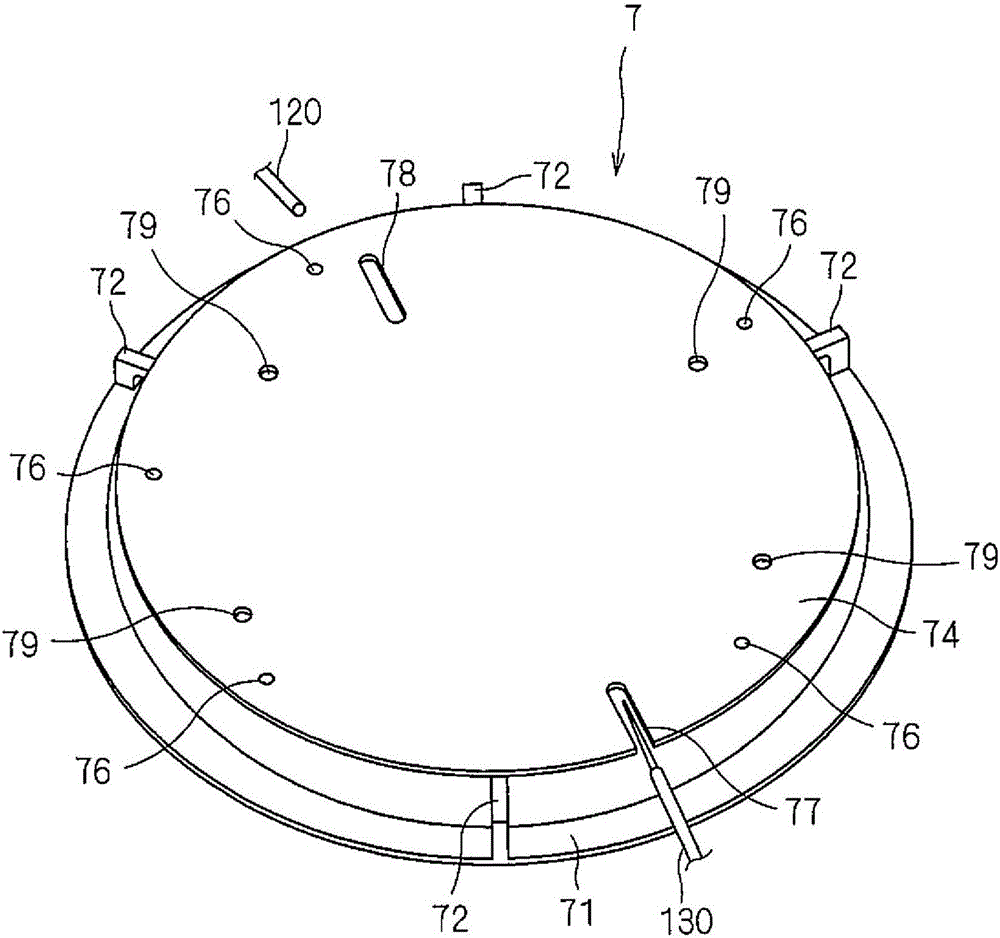

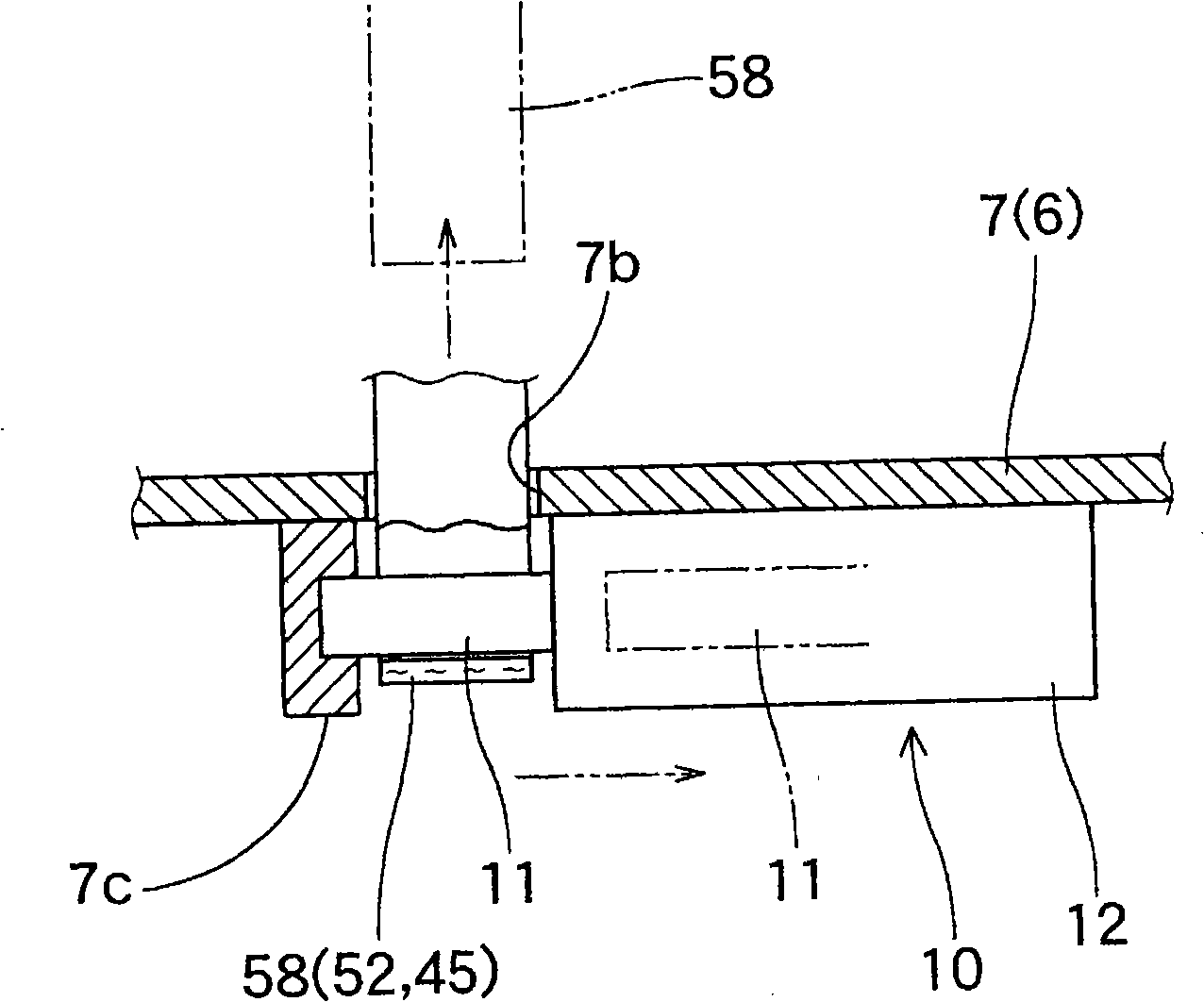

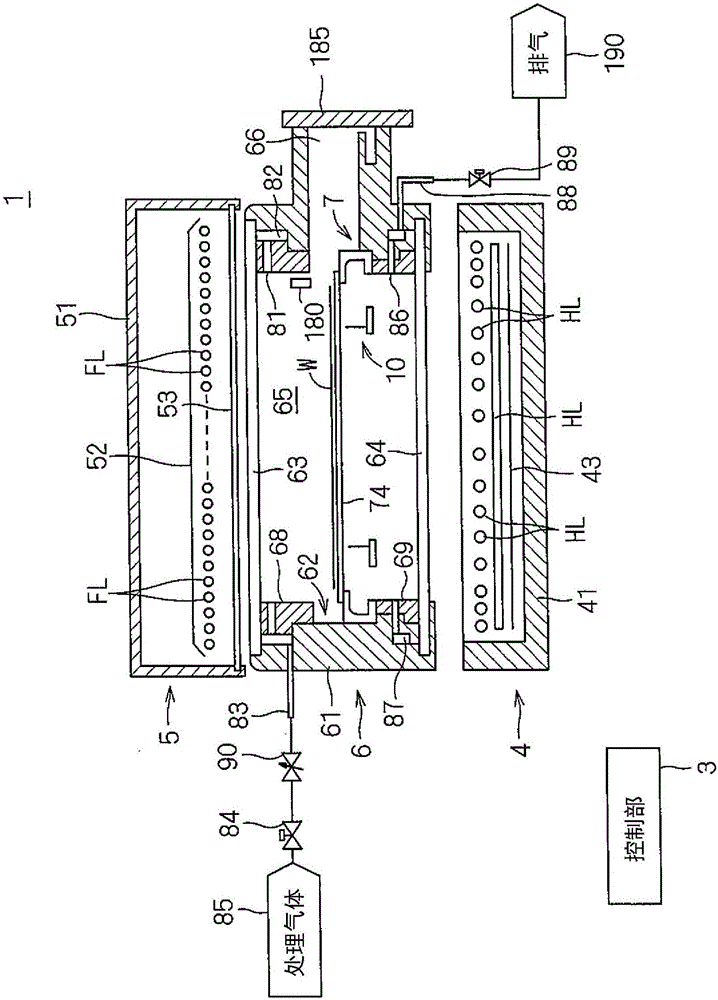

Heat treatment method and heat treatment apparatus

ActiveCN106486397AReduce oxygen concentrationReduce the impactSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSilicon oxide

Over a front surface of a silicon semiconductor wafer is deposited a high dielectric constant film with a silicon oxide film, serving as an interface layer, provided between the semiconductor wafer and the high dielectric constant film. After a chamber houses the semiconductor wafer, a chamber's pressure is reduced to be lower than atmospheric pressure. Subsequently, a gaseous mixture of ammonia and nitrogen gas is supplied into the chamber to return the pressure to ordinary pressure, and the front surface is irradiated with a flash light, thereby performing post deposition annealing (PDA) on the high dielectric constant film. Since the pressure is reduced once to be lower than atmospheric pressure and then returned to ordinary pressure, a chamber's oxygen concentration is lowered remarkably during the PDA. This restricts an increase in thickness of the silicon oxide film underlying the high dielectric constant film by oxygen taken in during the PDA.

Owner:DAINIPPON SCREEN MTG CO LTD

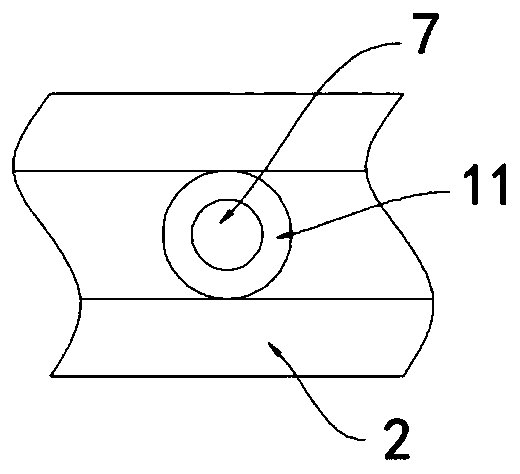

Water distribution filter

InactiveCN104436950AReduce volumeReduce manufacturing costCombination devicesStructural engineeringControl theory

The invention relates to the field of machinery and particularly relates to a water distribution filter. The water distribution filter comprises a cup body, a cover body which is in sealed connection with the cup body, and a filter element arranged in the cup body, wherein a transverse air inlet and a transverse air outlet are formed in the cover body and a pipe-shaped connector connected with the filter element is arranged at the center of the cover body; a connector wall is provided with an opening for communicating the air outlet with the filter element; the air inlet is communicated with the cup body; a cyclone blade is arranged at the connection part of the filter element and the connector, is in a trumpet shape and sleeves the filter element; one group of notches is formed in the edge of the cyclone blade; and a water draining valve is arranged at the bottom of the cup body.

Owner:CHONGQING XIHUA BELT PULLEY MACHINERY MFG CO LTD

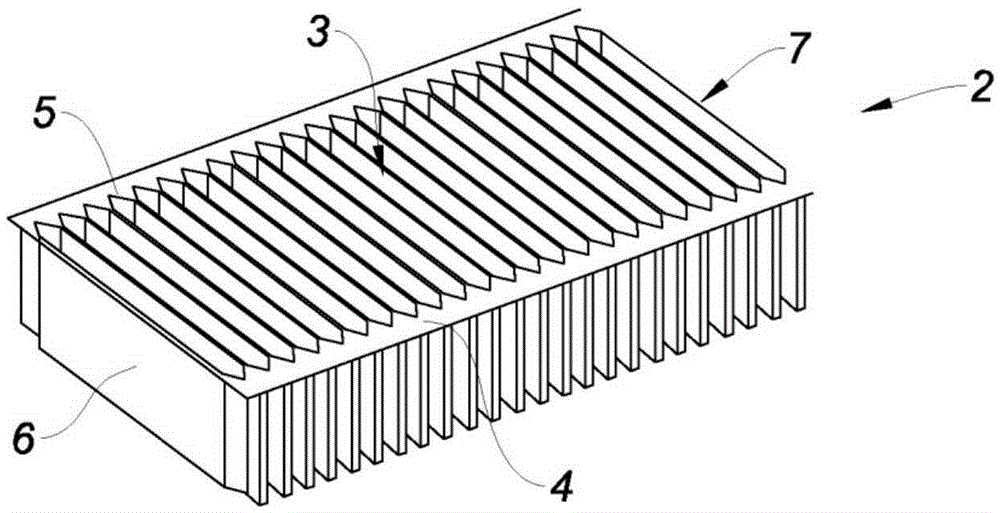

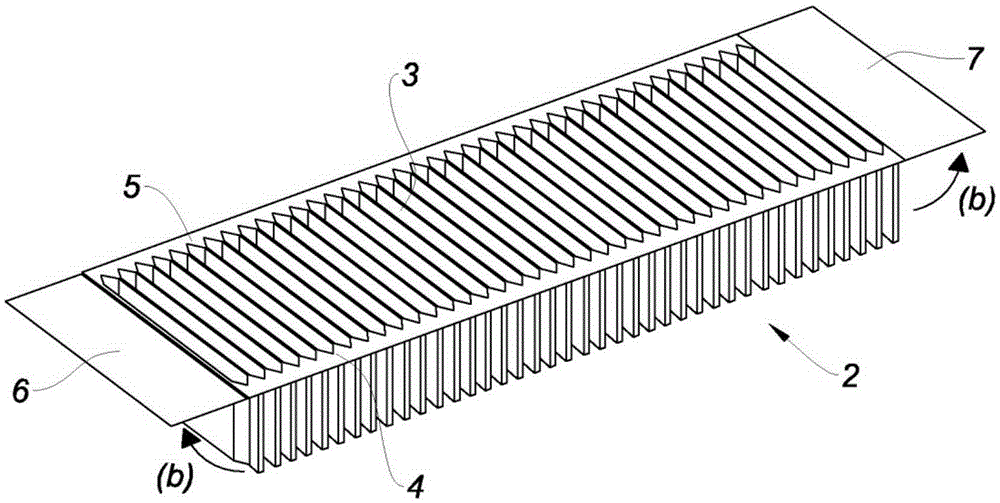

Method for producing a filtering element

ActiveCN105324168AAvoid manipulationAvoid interventionDispersed particle filtrationEngineeringFilter element

Owner:NOVARES FRANCE

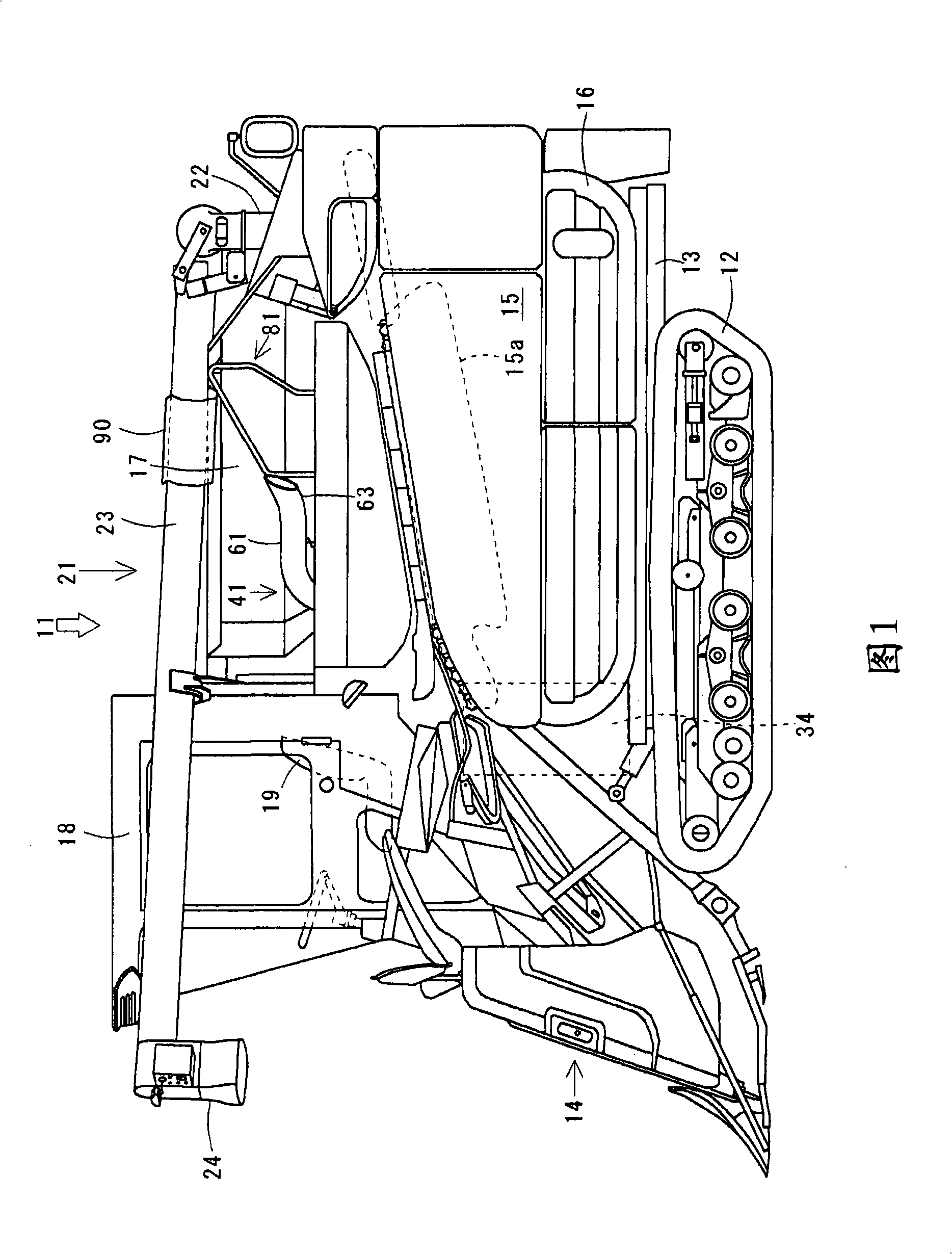

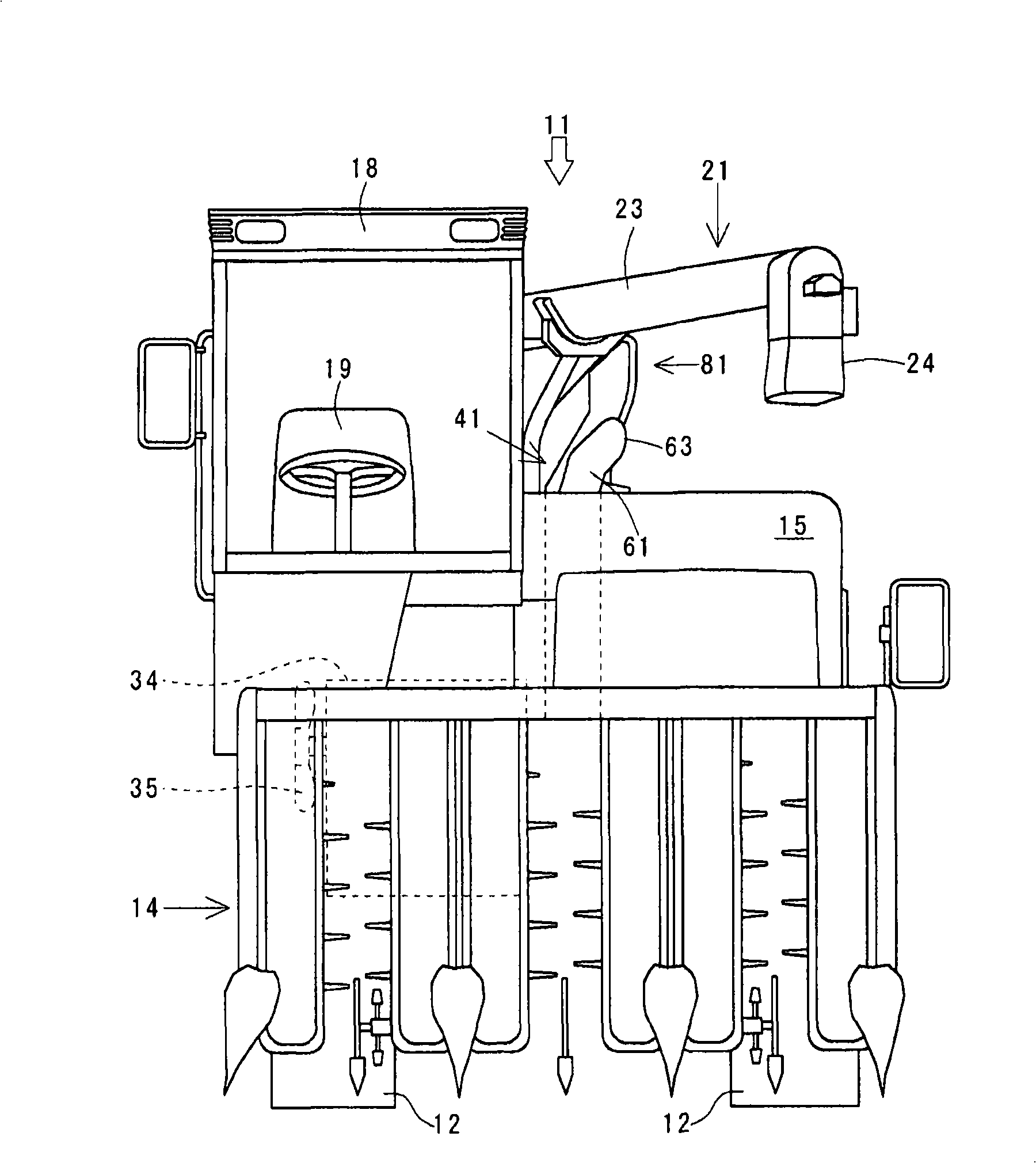

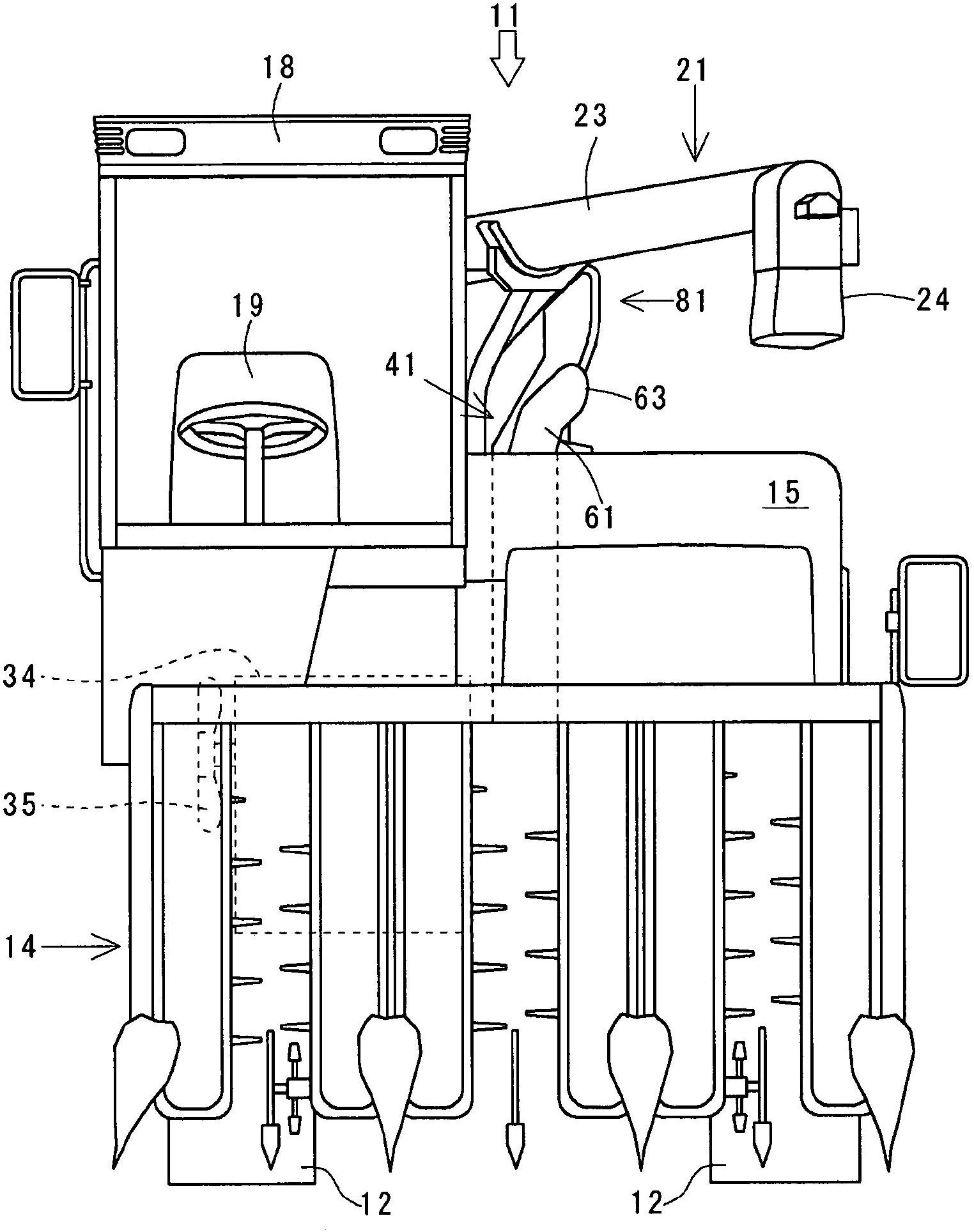

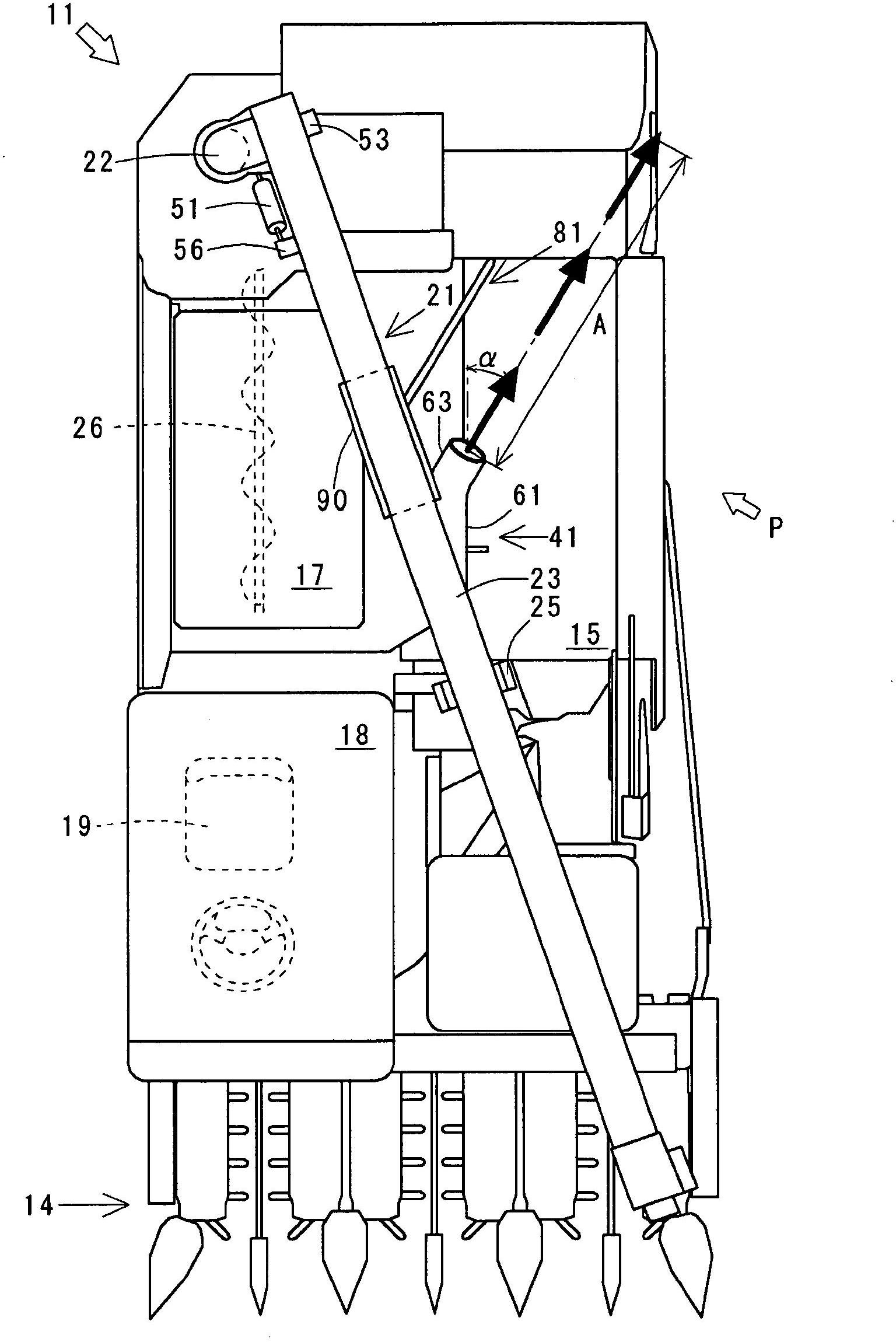

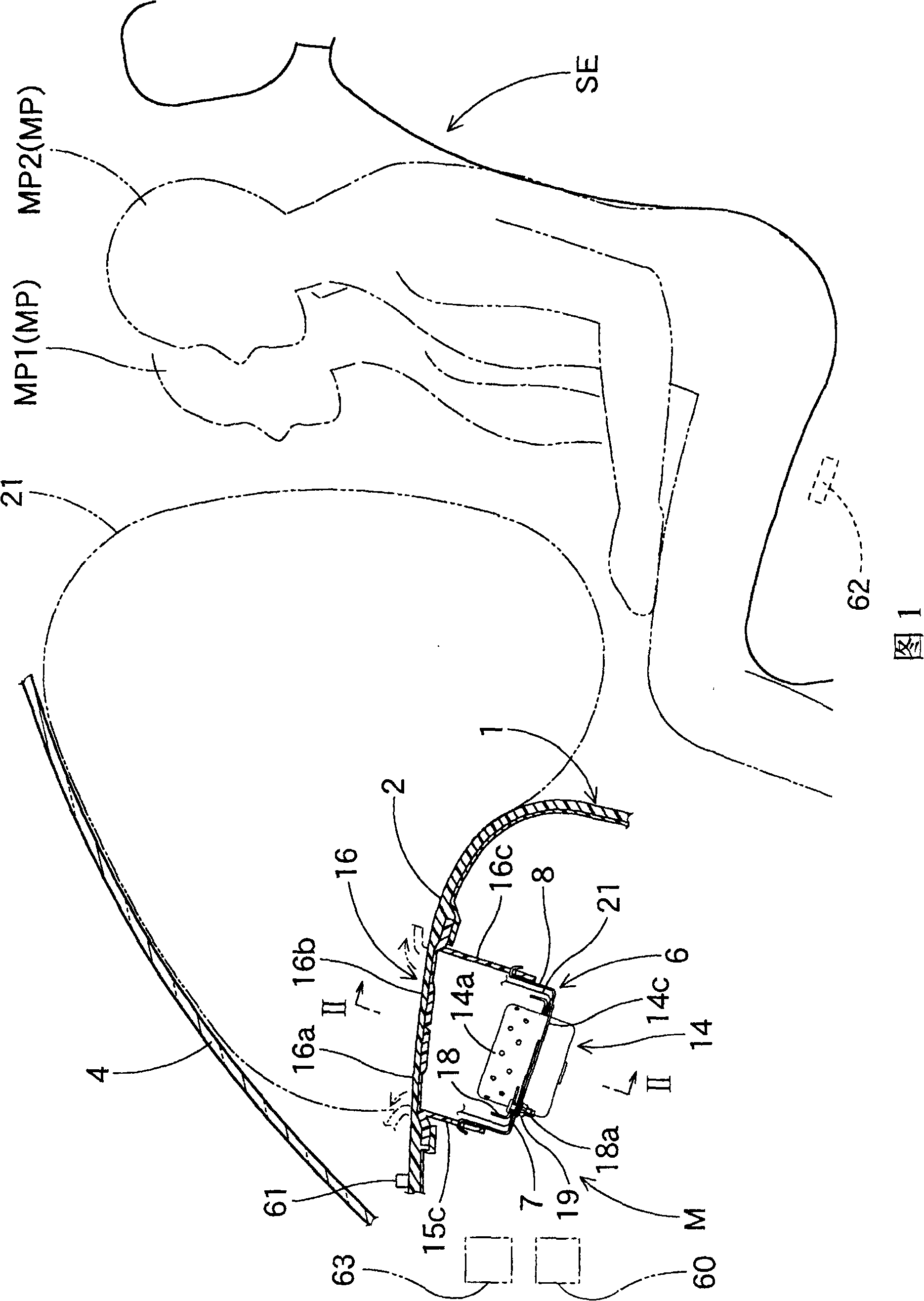

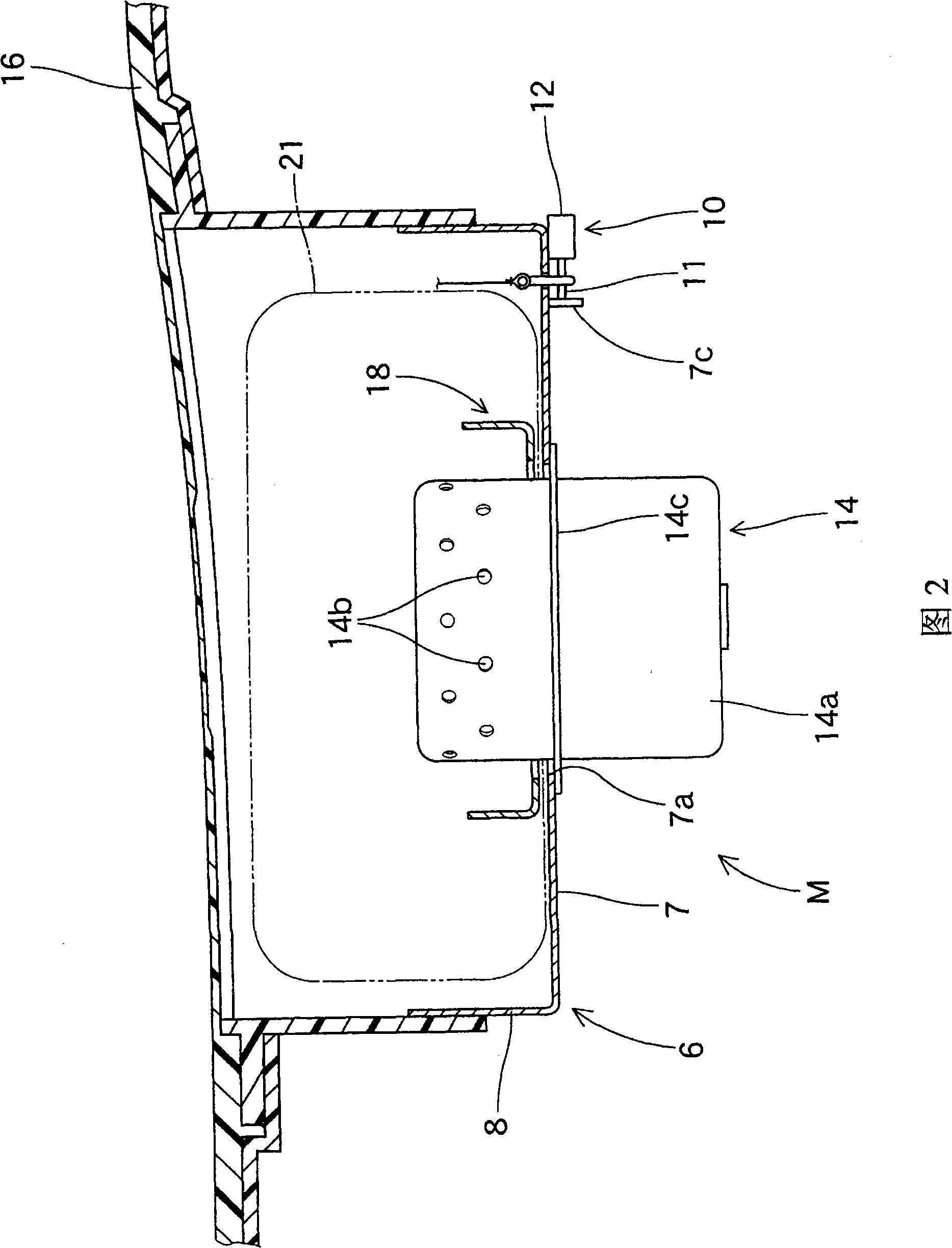

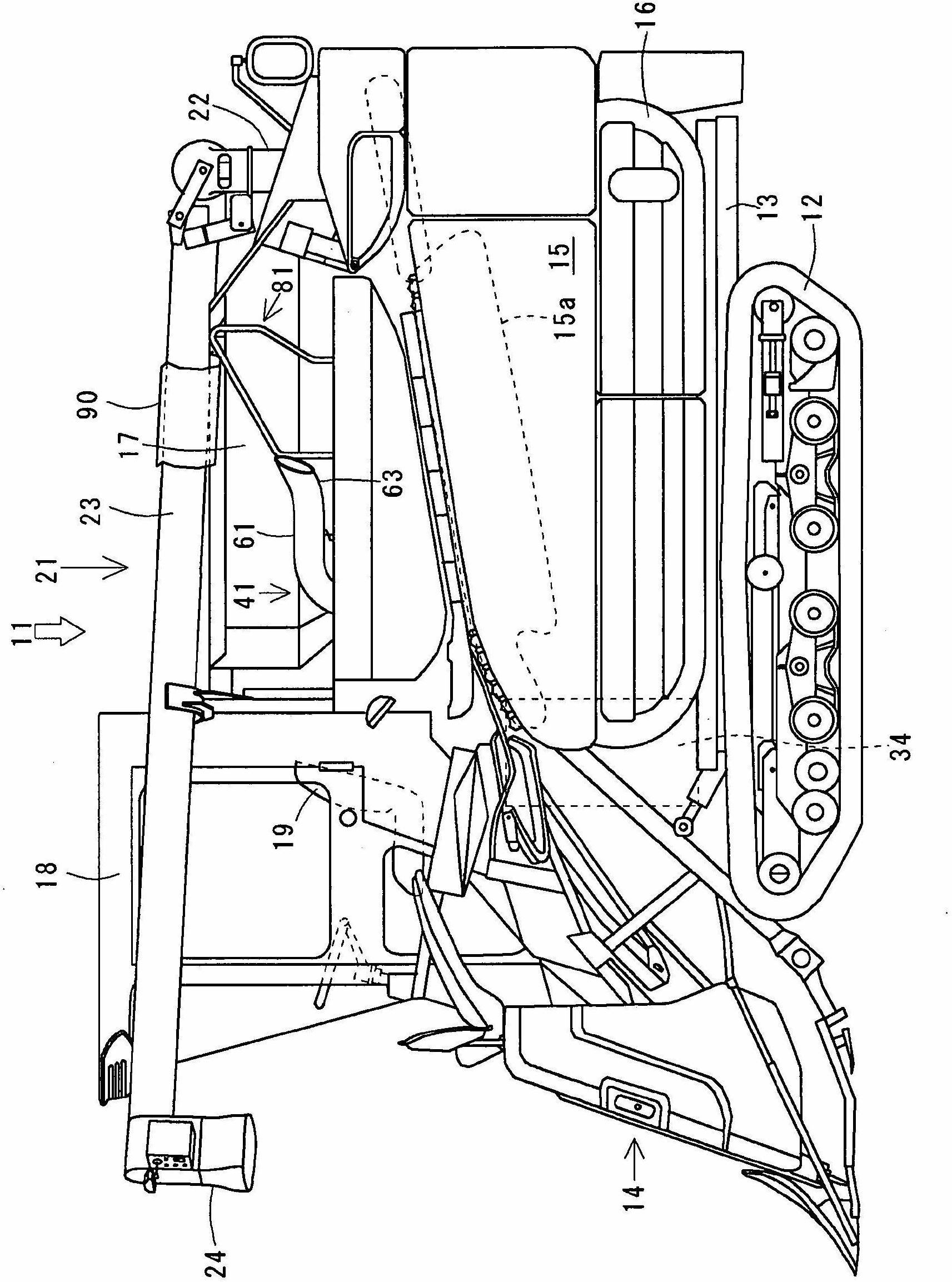

Combine harvester

ActiveCN102656991AReduce surface temperatureIncreased durabilityExhaust apparatusMowersCombine harvesterExhaust manifold

A combine harvester having an exhaust device capable of efficiently discharging exhaust gas in a direction away from a machine body. The combine harvester has a grain tank (17) for containing hulls after harvesting, threshing, and sorting processes, and also has the exhaust device (41) constructed from a silencer (42), a tail pipe (61), etc., with one end of the exhaust device connected to an engine (34) mounted on the machine body and the other end extended between a threshing section (15) and the grain tank (17). The tail pipe (61) connected to an exhaust manifold (36) of the engine (34) on the upstream side of the exhaust device (41) is supported by support members (82, 83) arranged on the threshing section (15).

Owner:YANMAR POWER TECHNOLOGY CO LTD

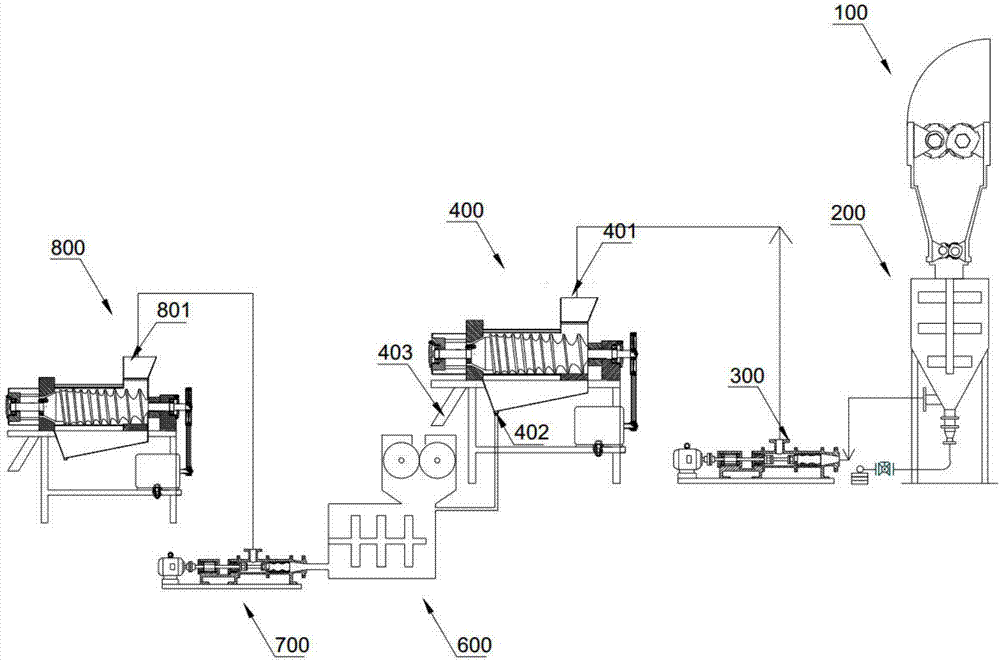

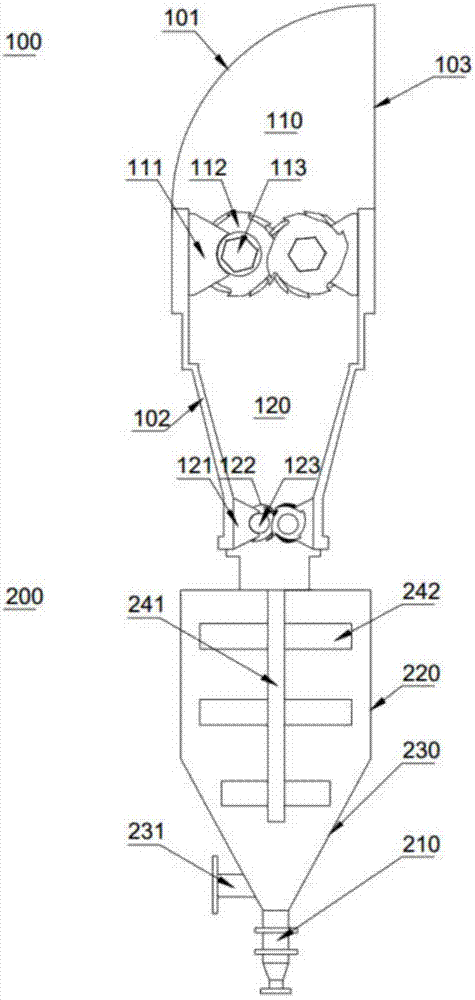

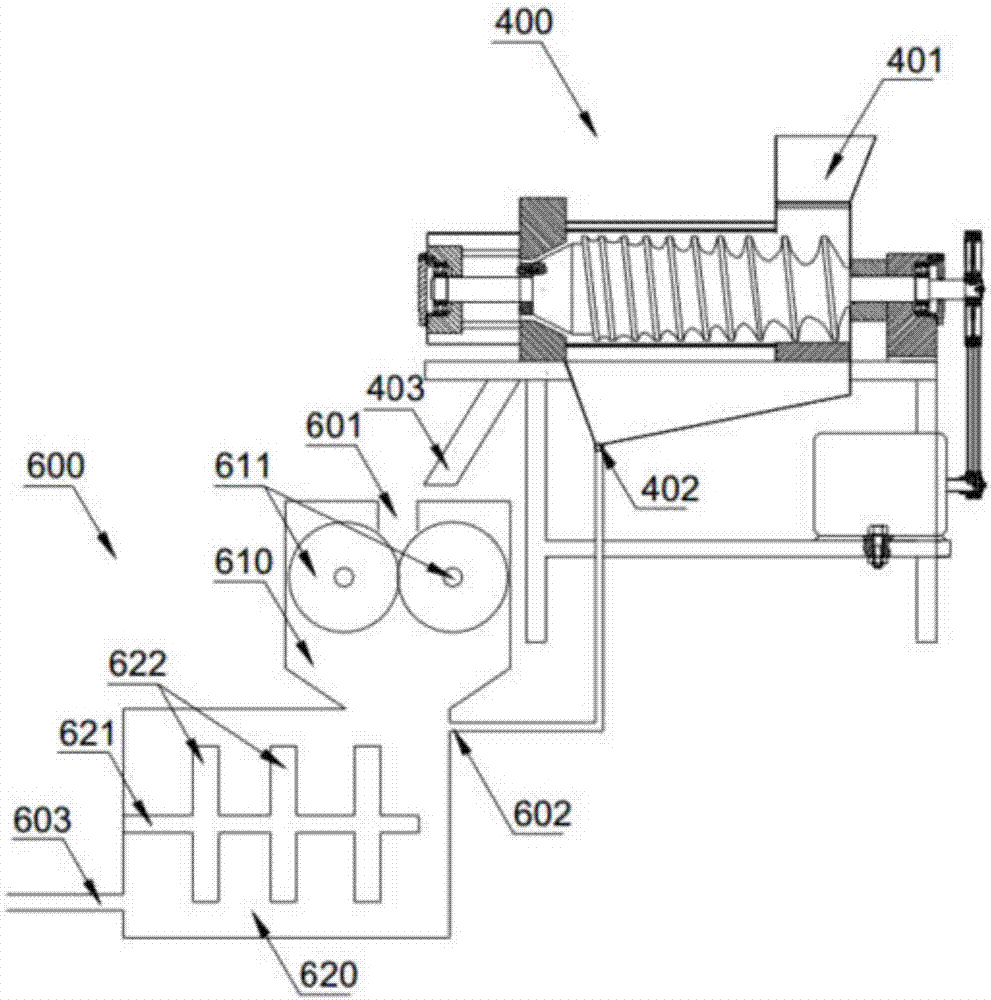

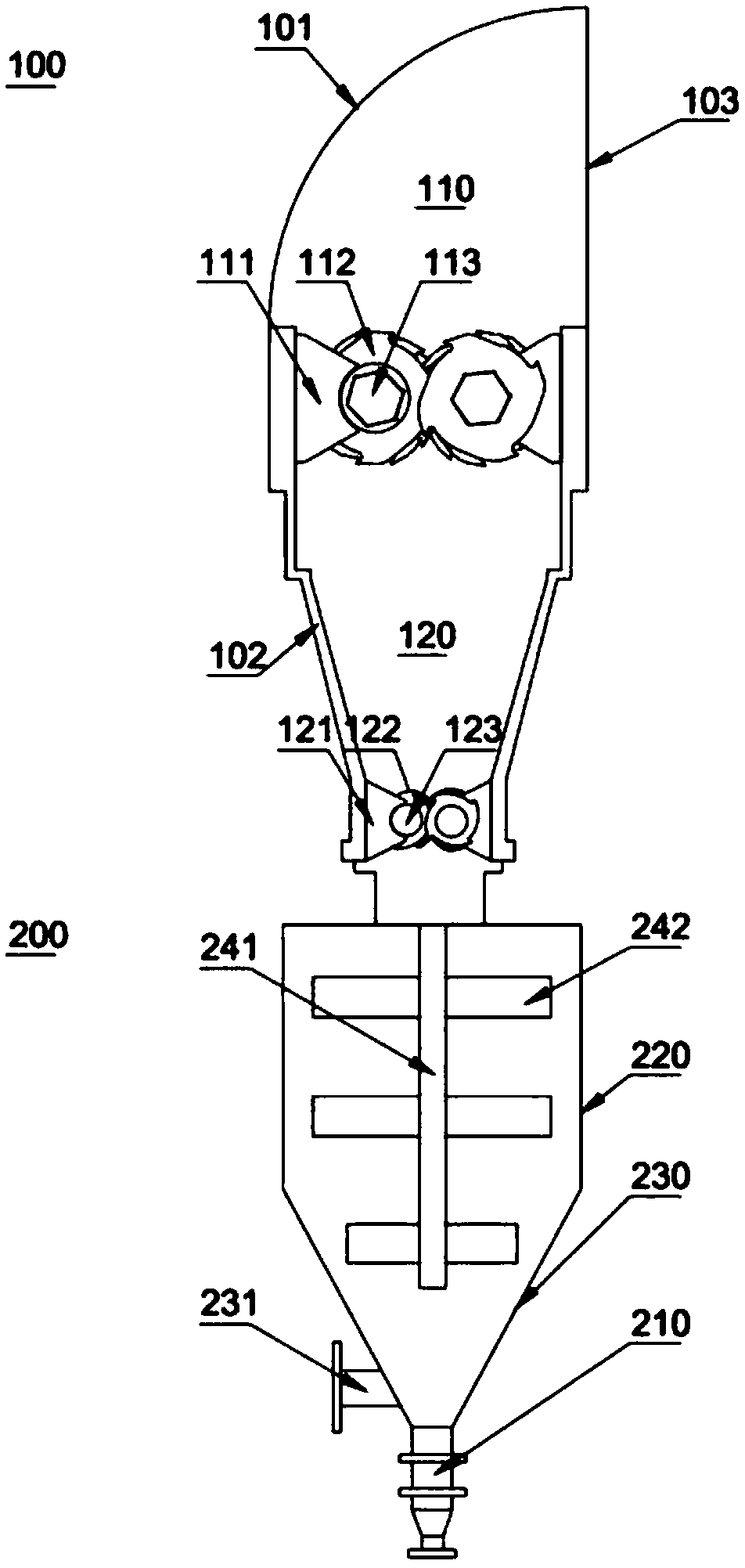

Kitchen waste pretreatment system capable of efficiently recovering organic matters

ActiveCN107876550AAvoid cloggingFacilitated releaseSolid waste disposalWaste based fuelFluid phaseEnvironmental engineering

The invention discloses a kitchen waste pretreatment system. The system comprises a crushing device, a desanding device, a first squeezing device, a squeezing residue rolling device and a second squeezing device which are sequentially arranged, wherein the squeezing residue rolling device is provided with a residue rolling chamber and a stirring chamber communicating with the residue rolling chamber; the residue rolling chamber is provided with a rolling mechanism; a residue inlet of the squeezing residue rolling device is arranged on the residue rolling chamber, so that residues entering thesqueezing residue rolling device from the residue inlet of the squeezing residue rolling device enter the stirring chamber after passing through the rolling mechanism; the stirring chamber is providedwith a stirring mechanism; and a liquid inlet and a discharging port of the squeezing residue rolling device are arranged on the stirring chamber, so that the residues passing through the rolling mechanism are mixed with a squeezing liquid and then are discharged. According to the kitchen waste pretreatment system, the residues subjected to the first squeezing are subjected to rolling treatment,and then are mixed with the squeezing liquid, so that more organic matters in the residues are dissolved into the liquid phase and the organic matters can be efficiently recovered during the second squeezing process.

Owner:GUANGDONG QIZHI BIOTECHNOLOGY CO LTD

Electrostatic self-dedusting photovoltaic panel based on triboelectricity generation principle

InactiveCN110995143AAchieve dust removal effectImprove conductivityElectrostatic separationPhotovoltaicsLight spotNew energy

The invention belongs to the field of new energy. The invention in particular relates to an electrostatic self-dedusting photovoltaic panel based on a triboelectricity generation principle. The electrostatic self-dedusting photovoltaic panel comprises a photovoltaic panel body fixedly mounted on the ground, sliding grooves are fixedly formed in the two sides of the photovoltaic panel body, the sliding grooves are made of an insulating material, sliding blocks are slidably connected to the inner side walls of the sliding grooves, friction plates are fixedly connected to the inner side walls ofthe sliding grooves, each friction plate is composed of a glass plate and a conductive plate, each conductive plate is connected with the ground through a wire, silk cloth adheres to the side walls, close to the friction plates, of the sliding blocks, a corona wire is arranged on the upper surface of the photovoltaic plate body, the corona wire is made of indium tin oxide materials, and the two ends of the corona wire are fixedly connected with the two sliding blocks respectively. The sliding blocks can be driven by wind power to slide up and down in the sliding grooves and rub with the friction plate to generate negative charges to attract dust on the photovoltaic panel, the self-dedusting effect is good, and the light spot effect is effectively avoided.

Owner:刘浩

Airbag apparatus

InactiveCN101306672ASmooth breakBreaks smoothly and quicklyPedestrian/occupant safety arrangementEngineeringAirbag

The airbag apparatus includes an airbag provided with a flap element for opening and closing an exhaust hole. The flap element includes a flap and an adjusting belt. The leading end region of the adjusting belt is sewn to the flap by a generally straight sewn seam and acts as a joint portion to the flap. The root region of the adjusting belt is joined to an open / close mechanism. A first terminal of the sewn seam disposed proximate a root region of the joint portion is located farther away from the open / close mechanism relative to a second terminal disposed proximate a leading end of the joint portion. The sewn seam is configured rupturable from the first terminal when the airbag inflates with the adjusting belt engaged with the open / close mechanism to separate the joint portion of the adjusting belt from the flap body so the flap uncovers the exhaust hole.

Owner:TOYODA GOSEI CO LTD

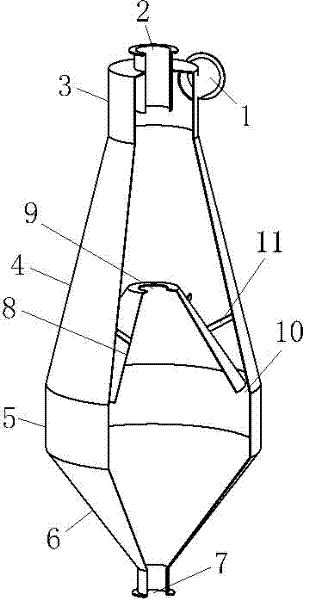

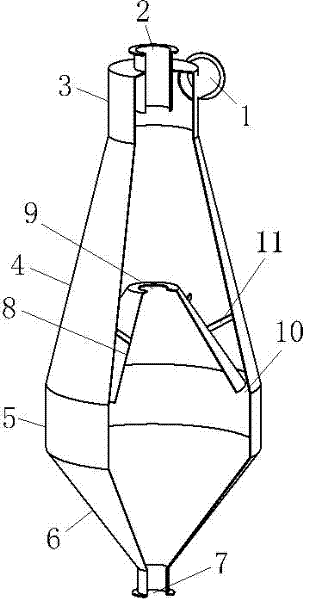

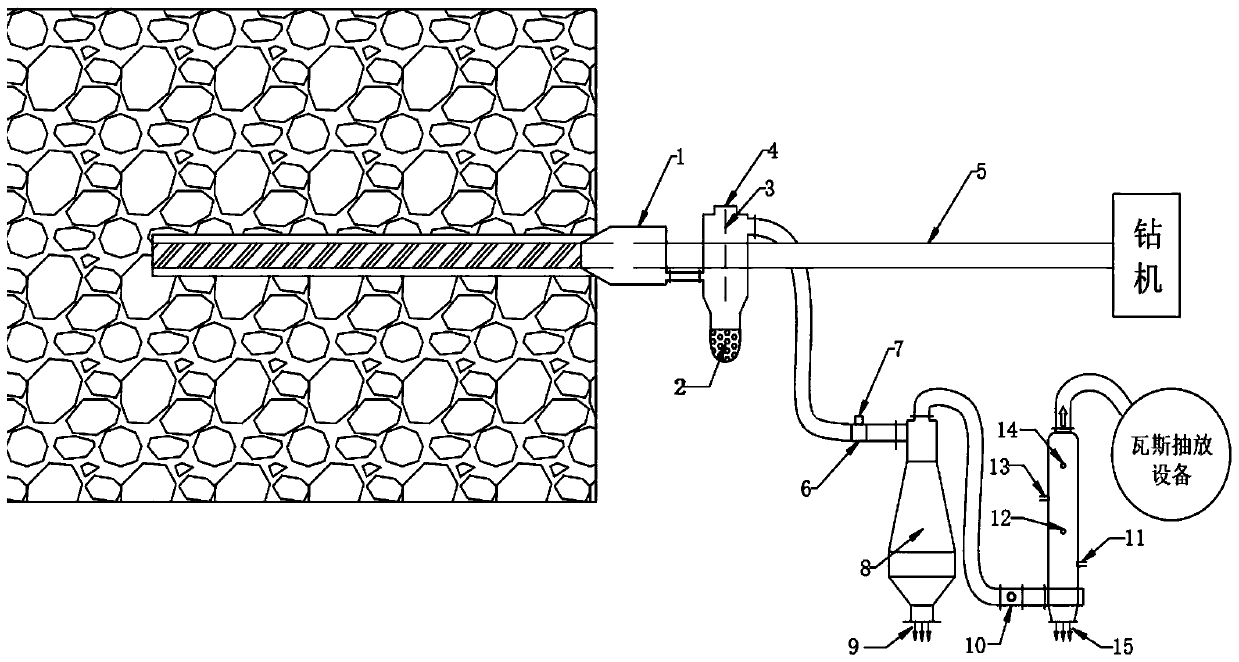

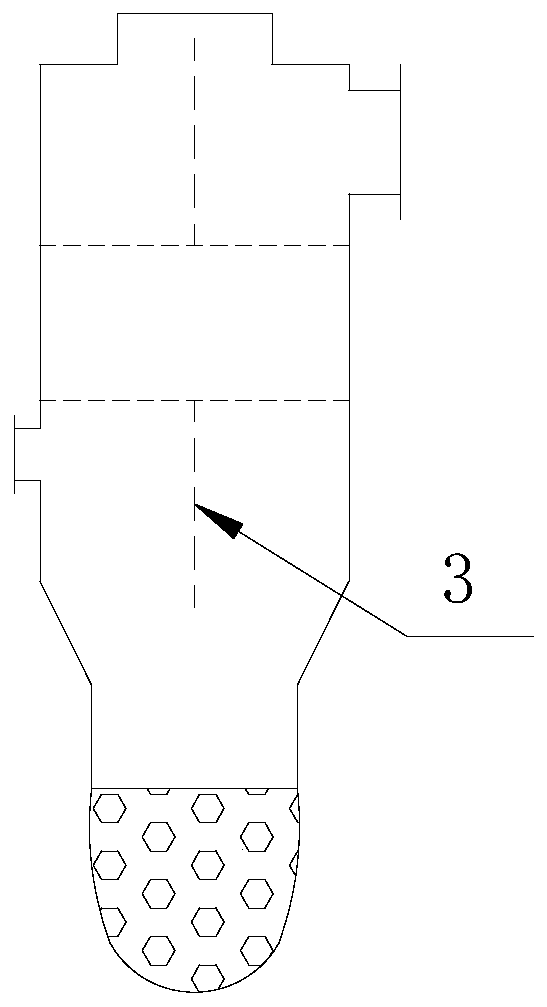

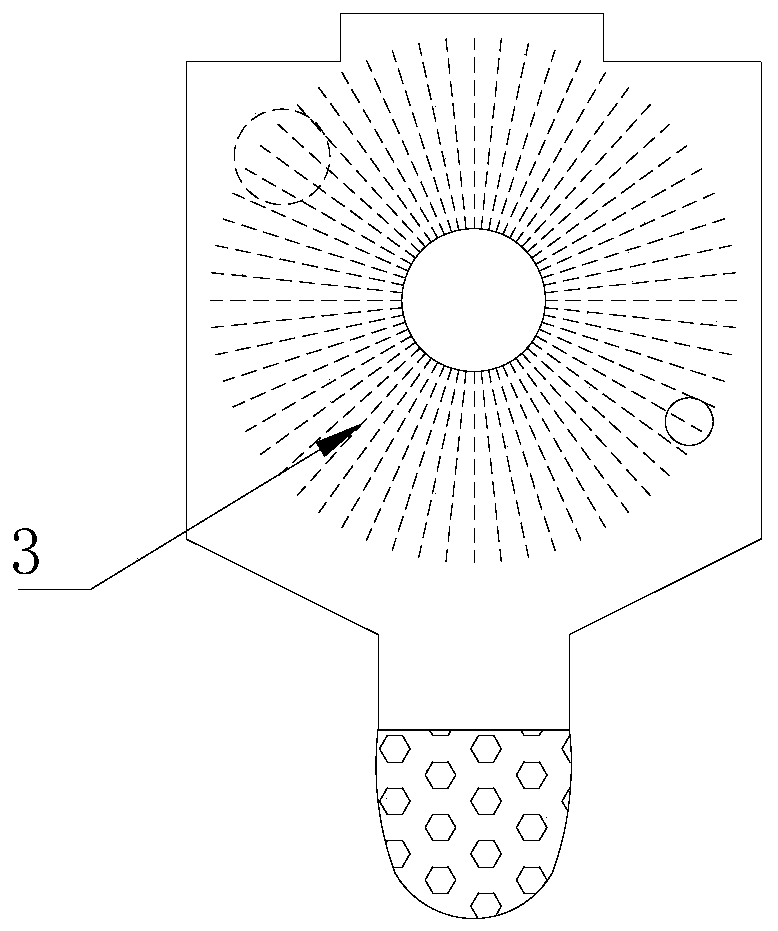

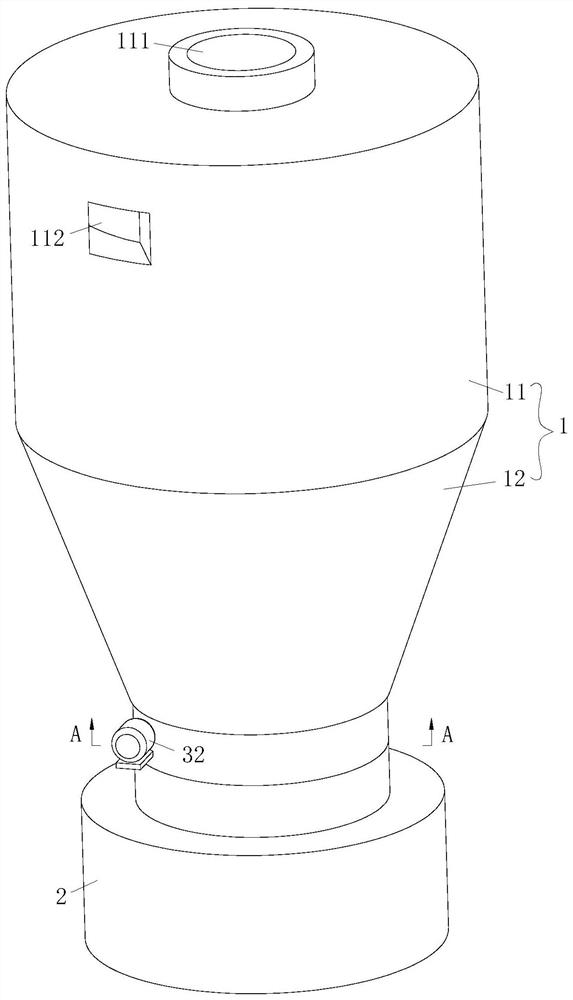

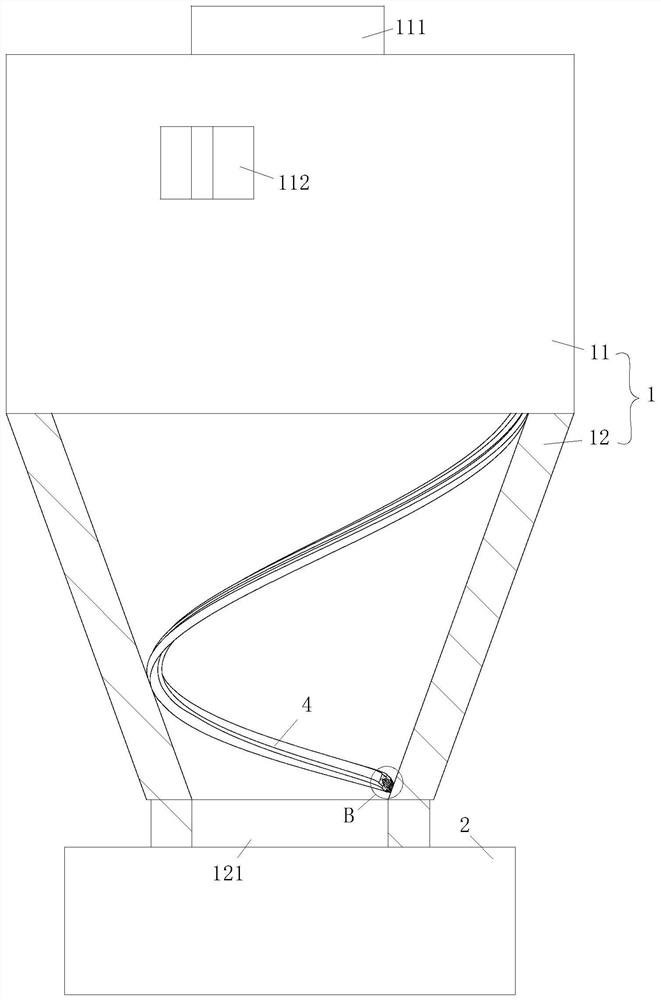

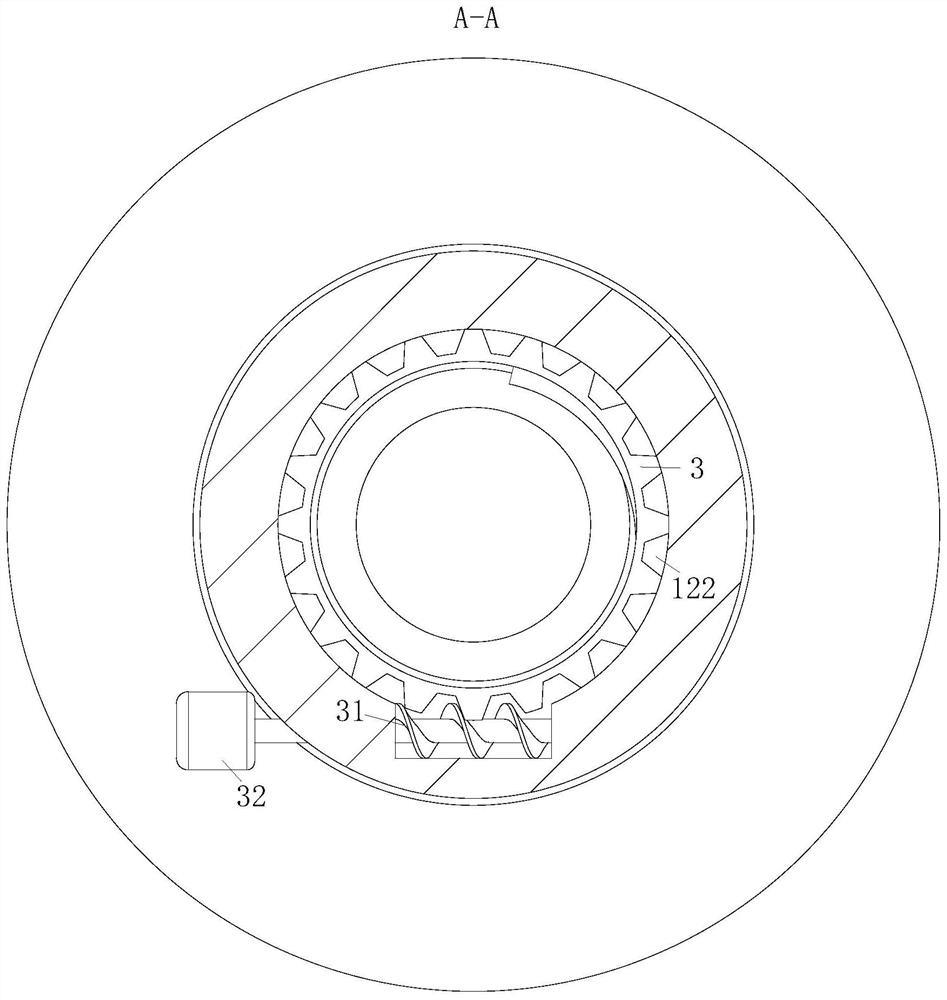

Cyclone foam integrated drilling and dust removing device and using method thereof

PendingCN111535761AEasy constructionImprove dust removal efficiencyConstructionsCleaning apparatusThermodynamicsDust control

The invention discloses a cyclone foam integrated drilling and dust removing device and a using method thereof, and belongs to the technical field of mine drilling and dust removing. The device comprises an orifice dust exhaust unit and a secondary treatment and recovery unit, wherein the orifice dust exhaust unit is used for removing large-particle-size dust generated in the drilling process, thesecondary treatment and recovery unit comprises a gas amplification mechanism, a cyclone dust collector, a spray dust collector and a laser dust measuring mechanism, the gas amplification mechanism is located on a pipeline connected between the orifice dust exhaust unit and the cyclone dust collector, the cyclone dust collector comprises a container body, the lower half part of the container bodyis conical, the upper half part of the container body is inverted conical, and airflow subjected to cyclone treatment is exhausted through a gas outlet. According to the device, dust is captured according to the principles of centrifugation and foam dust removal, the cyclone dust collector and the spray dust collector are used for dust removal, an optical sensor is used for regulating and controlling work of a foam generator, and convenient, intelligent and efficient dust removal can be achieved.

Owner:XIANGTAN UNIV

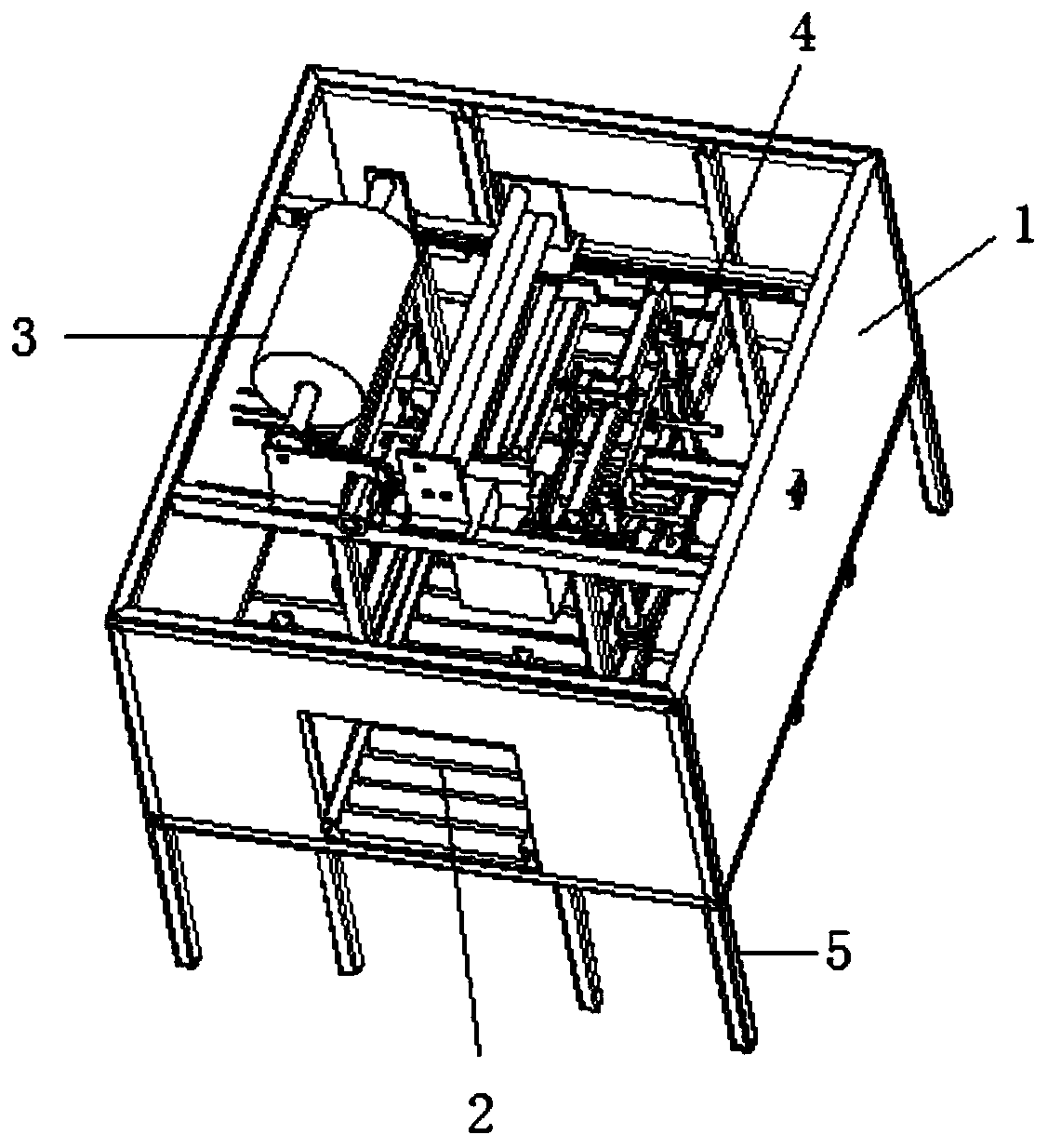

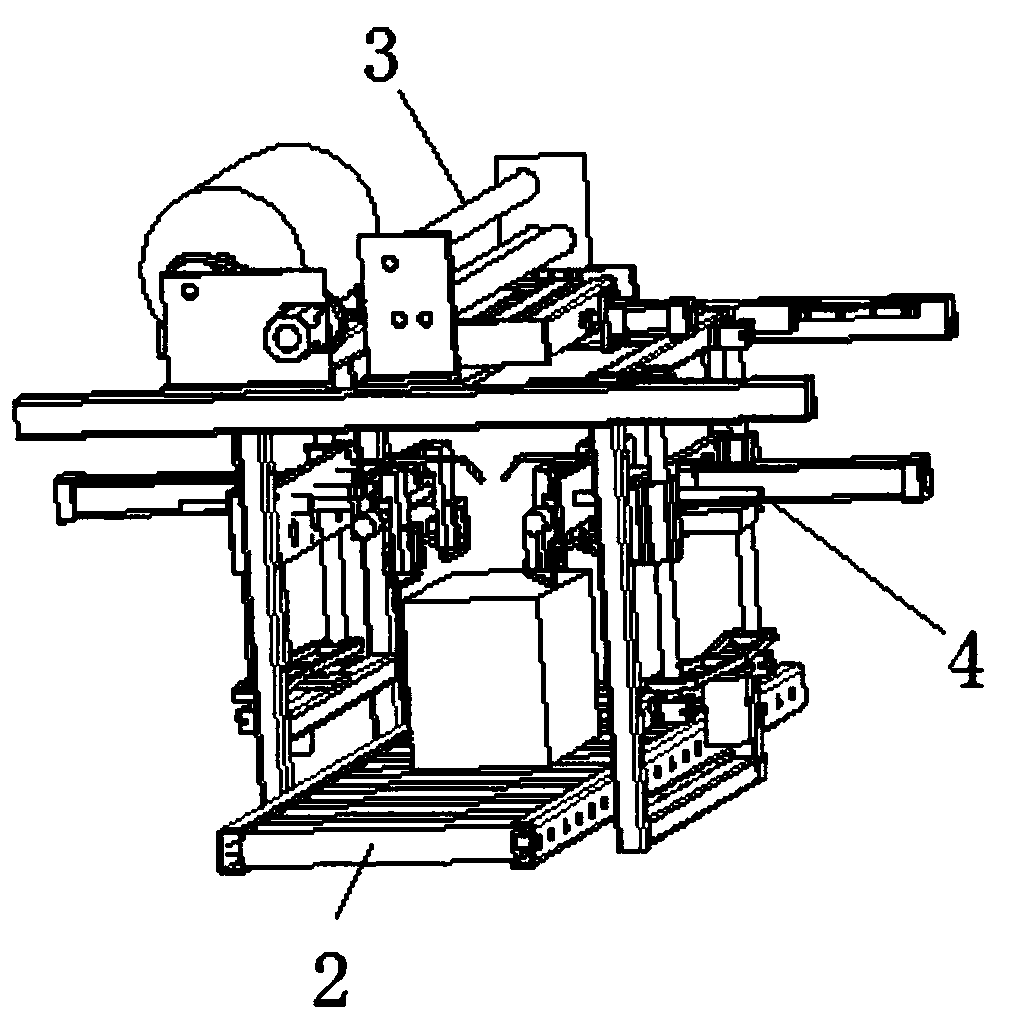

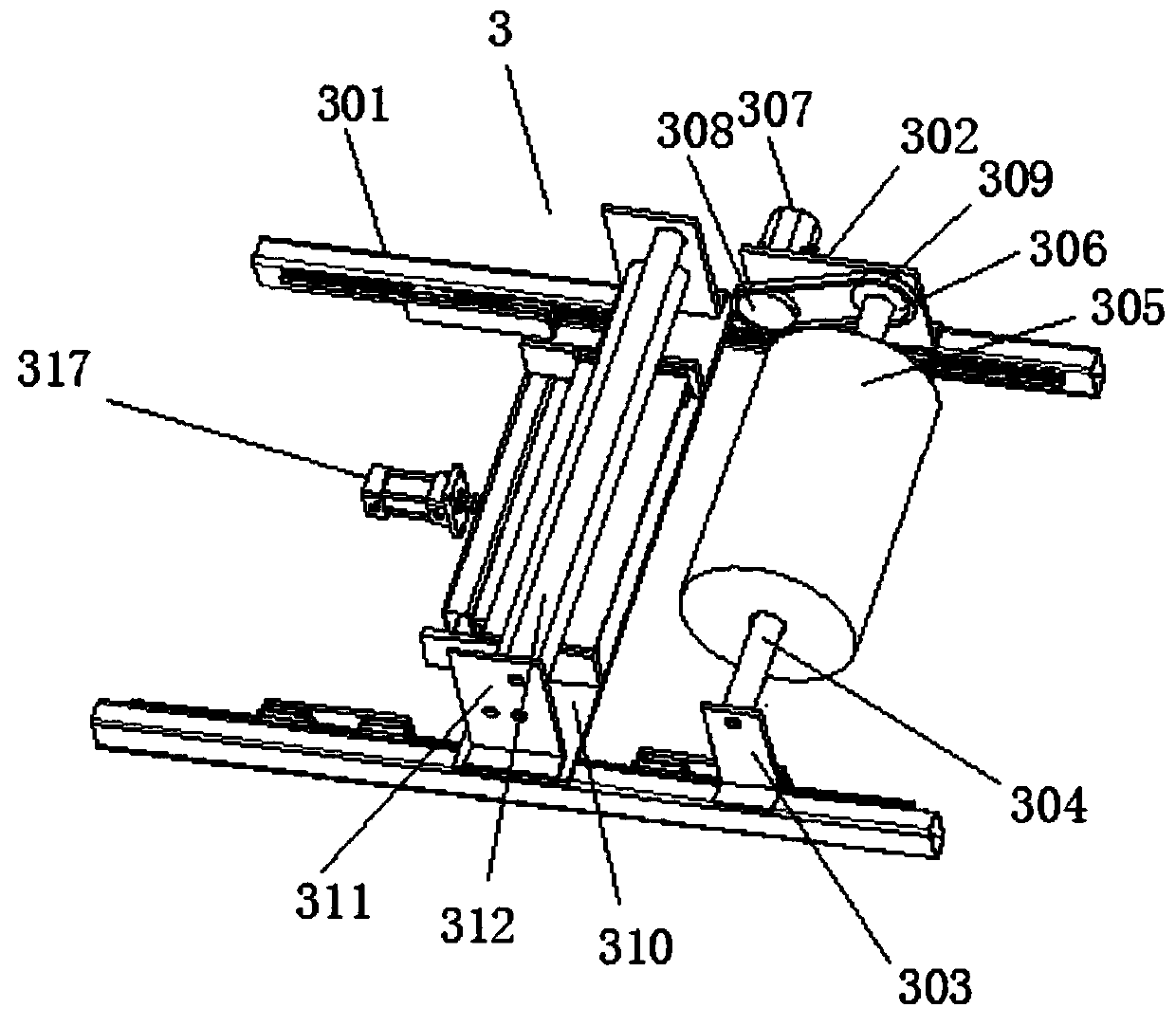

Film sleeving device for processing agricultural products and working method of film sleeving device

InactiveCN109956091AReduce work intensityCoating speed is fastWrapping material feeding apparatusWrappingAgricultural engineeringEngineering

The invention discloses a film sleeving device for processing agricultural products and a working method of the film sleeving device. The film sleeving device includes a shell, a roller conveyor belt,a feeding mechanism and film sleeving mechanisms, the roller conveyor belt is fixedly installed on the bottom surface of the shell, the feeding mechanism is located on the upper part of the shell, and the film sleeving mechanisms are arranged between the roller conveyor belt and the feeding mechanism. According to the film sleeving device for processing the agricultural products and the working method of the film sleeving device, the agricultural products are transferred through the roller conveyor belt, films are transported through the feeding mechanism, meanwhile, the films are cut, and the agricultural products are subjected to film sleeving through the two oppositely arranged film sleeving mechanisms; the mechanisms are mutually use cooperatively, pipeline type batch film sleeving can be conducted, operation is completely automatic, the film sleeving speed is high, the working efficiency is high, and the working intensity of labor personnel is lowered; an air guiding pipe is arranged to blow the films, the film surface is flat, and a film sleeving hook hooks and clamps the films conveniently; and the films are cut through a fixed blade and a moving blade, the speed is high, and the film cutting effect is good.

Owner:张帅

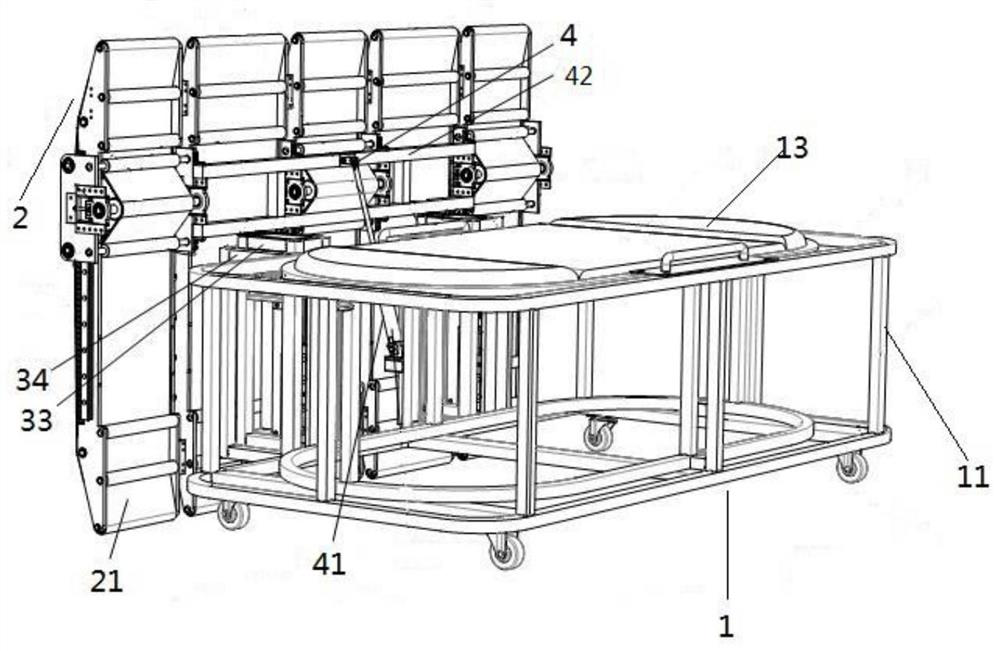

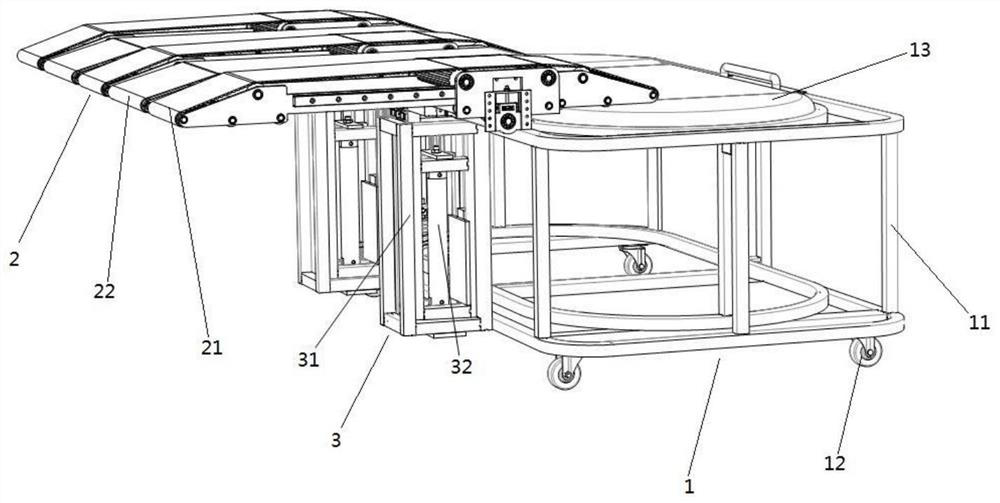

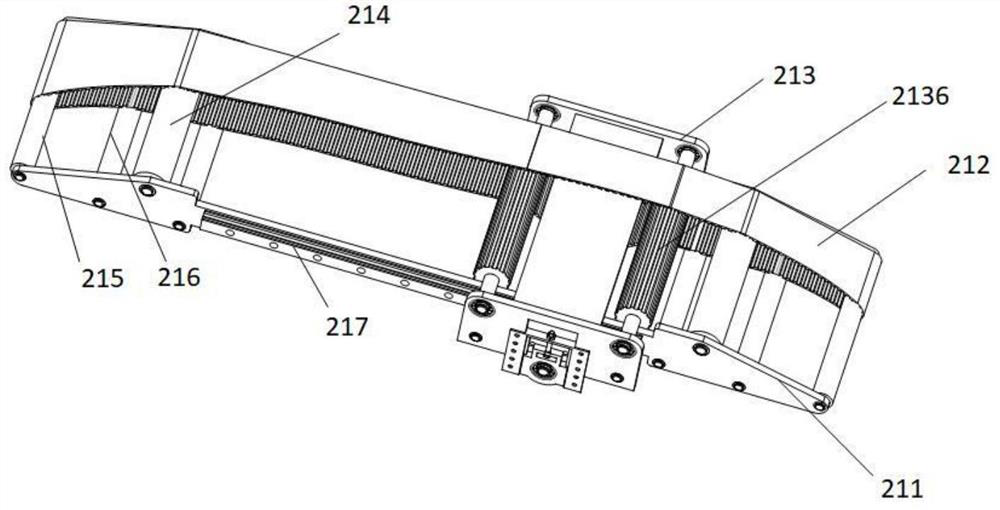

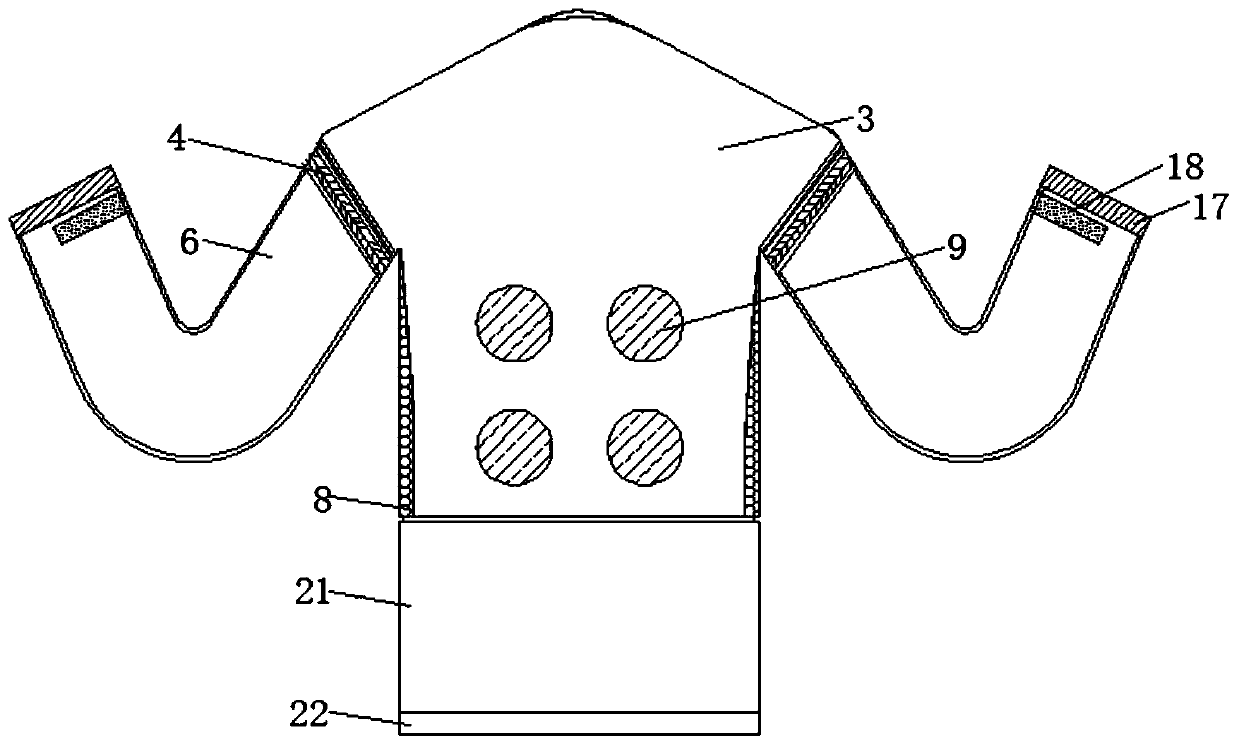

Movable auxiliary bathing device and operation method thereof

The invention relates to the technical field of nursing equipment, and in particular, relates to a movable auxiliary bathing device and an operation method thereof. The movable auxiliary bathing device comprises a main body mechanism, a transferring mechanism, a jacking mechanism and an overturning mechanism, the jacking mechanism and the overturning mechanism are fixed to the side face of the main body mechanism, and the jacking mechanism and the overturning mechanism are connected with the transferring mechanism. The movable auxiliary bathing device solves the problems that an existing nursing bath auxiliary device is poor in work space transferring capacity, poor in adaptability to different work scenes and poor in comfort and safety in the patient transferring process.

Owner:YANSHAN UNIV

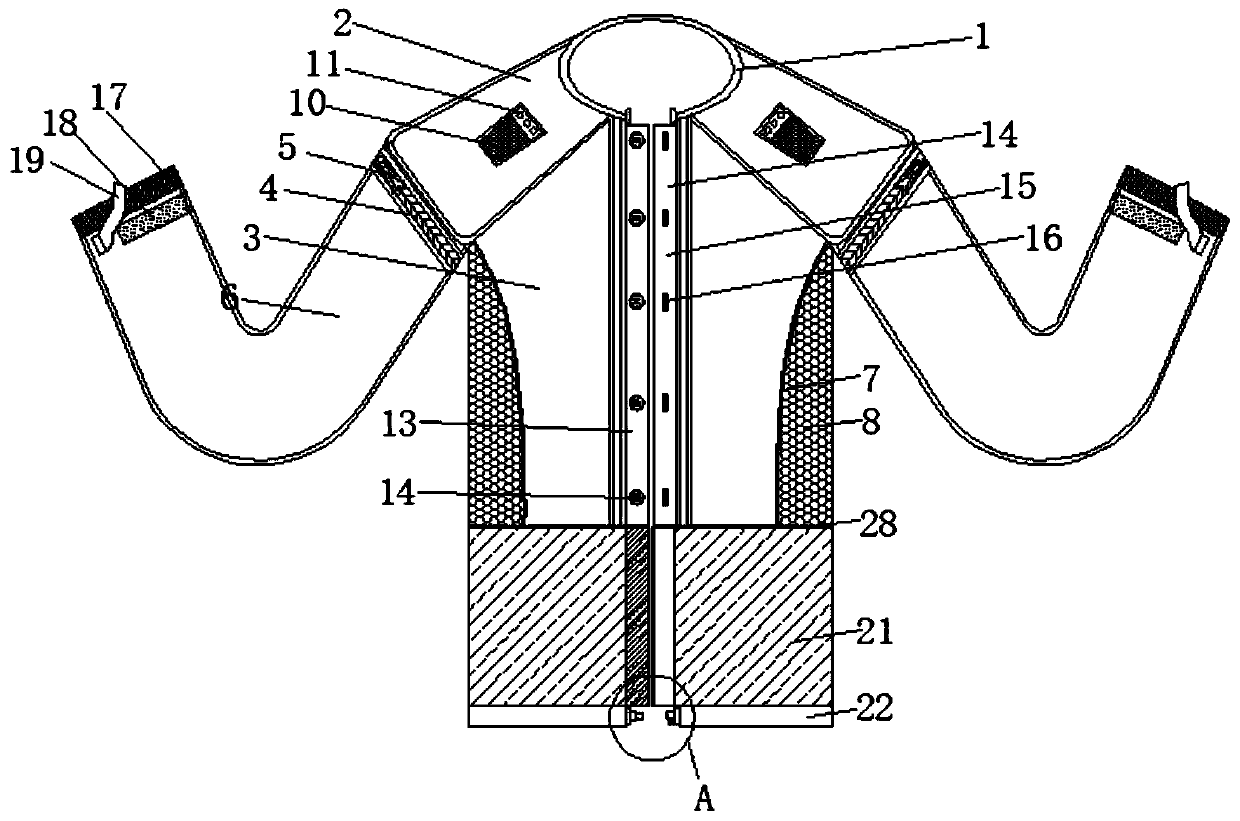

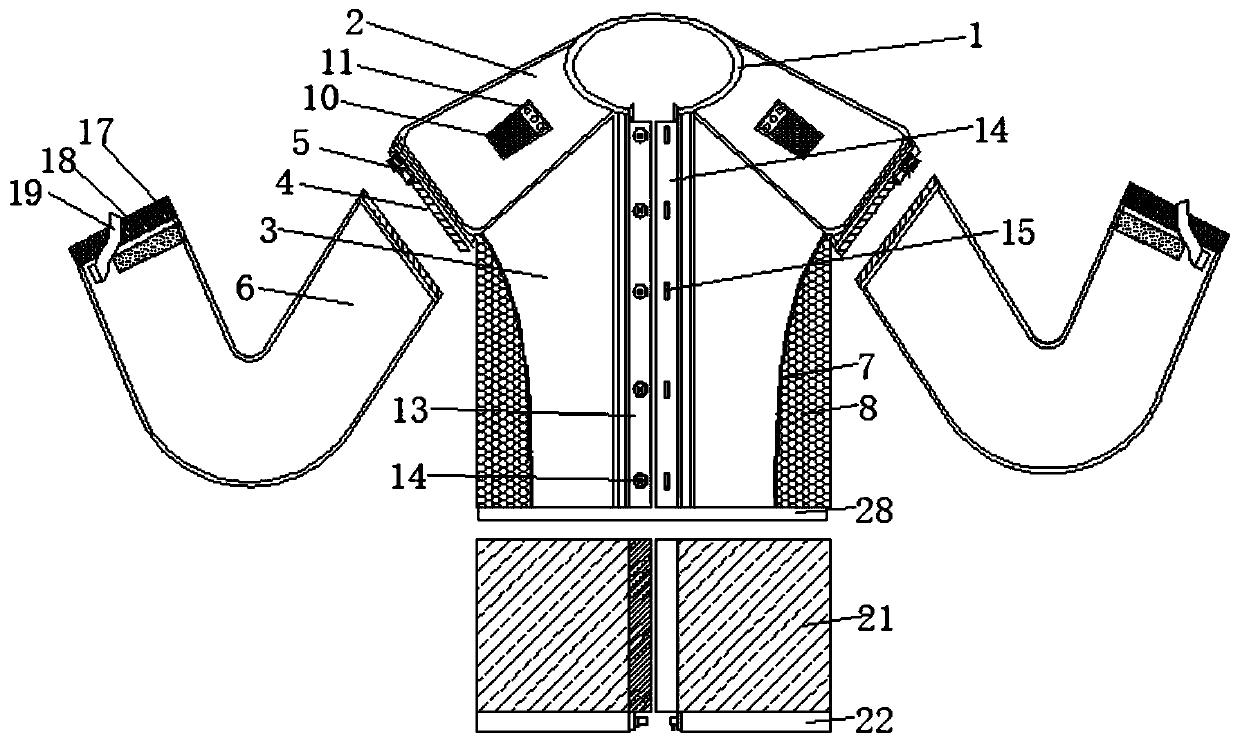

Pressure sore prevention intelligent protective clothing for neurology department

PendingCN110089789AAvoid pressure soresPractical designProtective garmentNeurology departmentEngineering

The invention discloses pressure sore prevention intelligent protective clothing for the neurology department. The clothing comprises a protective clothing airbag collar; chemical protective clothingshoulder collars are fixedly connected to one side of the outer surface of the protective clothing airbag collar; a chemical protective clothing upper garment body is fixedly connected to one side ofthe chemical protective clothing shoulder collars; a zipper strip is fixedly connected to the side, close to the chemical protective clothing upper garment body, of each chemical protective clothing shoulder collar; a zipper buckle is slidably connected to the interior of each zipper strip, and a protective clothing oversleeve is fixedly connected to one side of each zipper strip. The invention discloses pressure sore prevention intelligent protective clothing for the neurology department. A pressure sensor assembly is arranged; when the pressure sore prevention intelligent protective clothingfor the neurology department is used, after a patient wears the pressure sore prevention intelligent protective clothing for the neurology department and lies on a bed, the weight borne by the patient can be recognized through a pressure sensor detection block; when the local pressure reaches a certain value, a connected alarm gives a whistling alarm to make medical staff or family members stay alert, and pressure sores of a patient are prevented.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Chain grate-rotary kiln denitration system

PendingCN113975899AAvoid accumulationPrevent roll upDispersed particle separationThermodynamicsDust control

The invention belongs to the technical field of rotary kiln denitration, and particularly relates to a chain grate-rotary kiln denitration system which comprises a cyclone dust collector. The cyclone dust collector further comprises a machine body, a dust collecting box and a controller; the machine body comprises a cylinder and a cone; the cylinder is fixedly connected with the cone, an exhaust port is formed in the upper end of the cylinder, and an air inlet is formed in the inner wall of the cylinder; a scraping plate is arranged, the scraping plate can scrape off dust accumulated on the inner wall of the cone and prevent the dust from being accumulated on the inner wall of the cone, on one hand, the dust is prevented from blocking the dust discharging opening, on the other hand, the dust accumulated on the inner wall of the cone is prevented from being rolled up by airflow, and therefore the dust removal effect is improved; and rotation of the scraping plate not only increases the flow rate of airflow in the cyclone dust collector, increases the centrifugal force on dust particles and accelerates the separation of dust, but also plays a role in guiding smoke entering through the air inlet and accelerates the entering of the smoke, so that the dust collection efficiency of the cyclone dust collector is improved, and the practicability of the cyclone dust collector is further improved.

Owner:杨 志彬

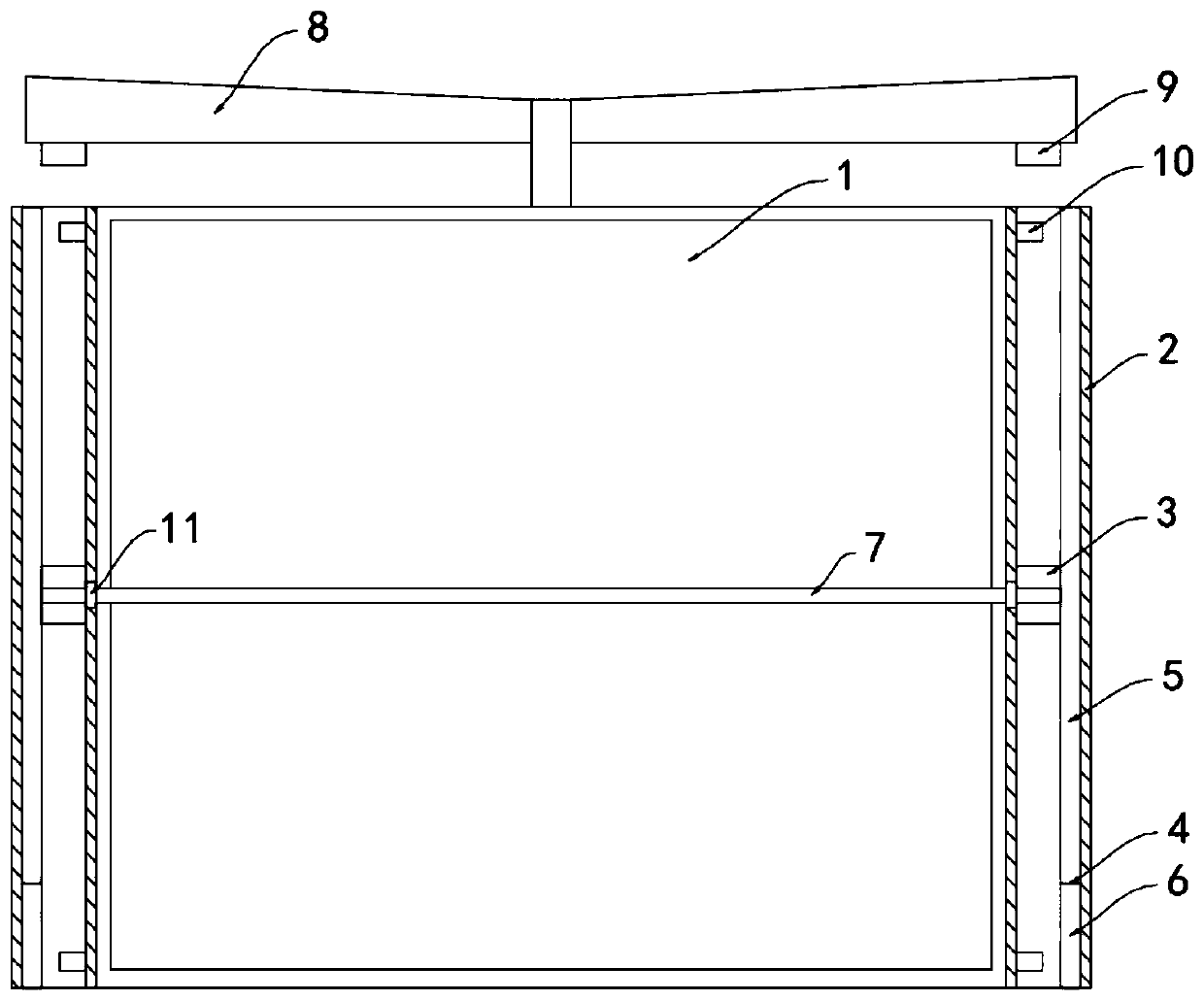

Coating equipment for carton production and processing

InactiveCN110884213AAvoid blowingPrevent roll upPaper-makingBox making operationsHydraulic cylinderCarton

The invention discloses coating equipment for carton production and processing. The coating equipment structurally comprises a carton board cooling device, a lifting heating roller assembly, a conveying device, a machine body, a carton board adsorption device, a carton board and support legs, wherein the support legs are perpendicularly fixed to the bottom of the machine body, the conveying deviceis arranged in the machine body, and the carton board is placed on the conveying device. Compared with the prior art, the coating equipment has the beneficial effects that a hydraulic cylinder, a coolant circulation tank, a mounting plate, a rotary power supply, a cooling roller assembly and other components are combined, so that the coated carton board can be adsorbed by an adsorption assembly after being heated by the lifting heating roller assembly, the carton board is attached to the conveying device, then the carton board is quickly cooled by a cooling roller so as to prevent the cartonboard from rolling, the carton board can be kept flat, the carton board is prevented from automatically rolling into a cylindrical shape, the folding forming of the subsequent carton is facilitated, the quality of the carton is increased, and the carton is prevented from deforming.

Owner:佛山市顺德区迅创印刷包装有限公司

Light Irradiation Type Heat Treatment Method And Heat Treatment Apparatus

ActiveCN106486351AIncrease production capacityInhibition of diffusion rateSemiconductor/solid-state device manufacturingLight irradiationAtmospheric air

A metal film is deposited on a front surface of a semiconductor wafer of silicon. After the semiconductor wafer is received in a chamber, the pressure in the chamber is reduced to a pressure lower than atmospheric pressure. Thereafter, nitrogen gas is supplied into the chamber to return the pressure in the chamber to ordinary pressure, and the front surface of the semiconductor wafer is irradiated with a flash of light, so that a silicide that is a compound of the metal film and silicon is formed. The oxygen concentration in the chamber is significantly lowered during the formation of the silicide because the pressure in the chamber is reduced once to the pressure lower than atmospheric pressure and then returned to the ordinary pressure. This suppresses the increase in resistance of the silicide resulting from the entry of oxygen in the atmosphere in the chamber into defects near the interface between the metal film and a base material.

Owner:DAINIPPON SCREEN MTG CO LTD

Kitchen waste desanding device

PendingCN107803279APrevent roll upAvoid cloggingReversed direction vortexGrain treatmentsEnvironmental engineeringWaste treatment

The invention relates to a kitchen waste treatment device, and discloses a kitchen waste desanding device, which comprises a sand-settling device. The sand-settling device is provided with a feed inlet and a discharge hole; a stirring mechanism is arranged in the sand-settling device; an impurity collecting chamber for collecting gravel, metal, ceramics, glass, bones and other impurity granules ina large proportion is arranged on the bottom part of the sand-settling device; a longitudinal size of the impurity collecting chamber is larger than a horizontal size of the impurity collecting chamber; a discharge gate is arranged. The sand-settling device comprises an upper barrel and a lower cone; the impurity collecting chamber is communicated with the bottom part of the lower cone; the discharge hole of the sand-settling device is formed on the lower cone body; the feed inlet is formed on the upper barrel. According to the kitchen waste desanding device, the sand-settling device is improved, and the impurity collecting chamber is designed to be with the longitudinal size being larger than the horizontal size, so that impurities entering the impurity collecting chamber can be prevented from being rolled up again; the sand-settling device comprises the upper barrel and the lower cone, the lower cone is connected with the impurity collecting chamber, and the impurities can be accelerated to enter the impurity collecting chamber through the arrangement of the lower cone.

Owner:GUANGDONG QIZHI BIOTECHNOLOGY CO LTD

Combine Harvester

ActiveCN102656990AReduce surface temperatureIncreased durabilityExhaust apparatusMowersCombine harvesterExhaust manifold

A combine harvester having an exhaust device capable of efficiently discharging exhaust gas in a direction away from a machine body. The combine harvester has a grain tank (17) for containing hulls after harvesting, threshing, and sorting processes, and also has the exhaust device (41) constructed from a silencer (42), a tail pipe (61), etc., with one end of the exhaust device connected to an engine (34) mounted on the machine body and the other end extended between a threshing section (15) and the grain tank (17). The tail pipe (61) connected to an exhaust manifold (36) of the engine (34) on the upstream side of the exhaust device (41) is supported by support members (82, 83) arranged on the threshing section (15).

Owner:YANMAR POWER TECHNOLOGY CO LTD

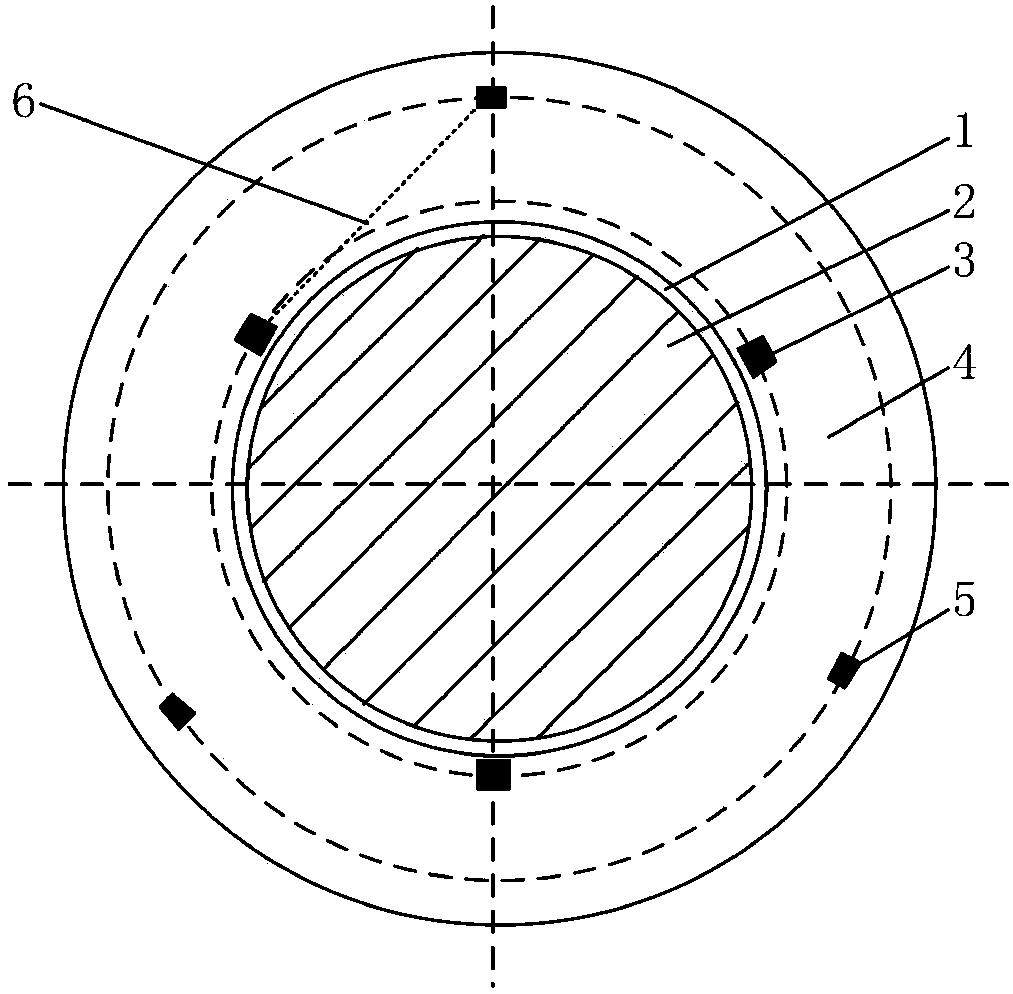

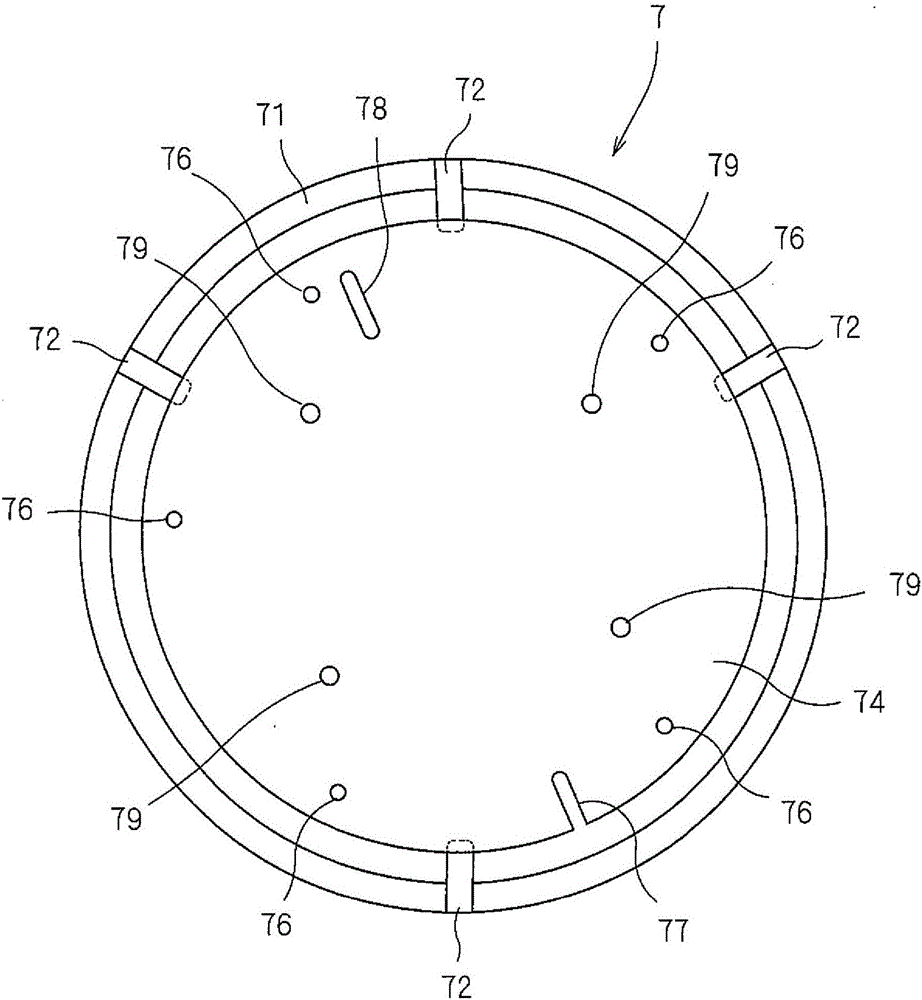

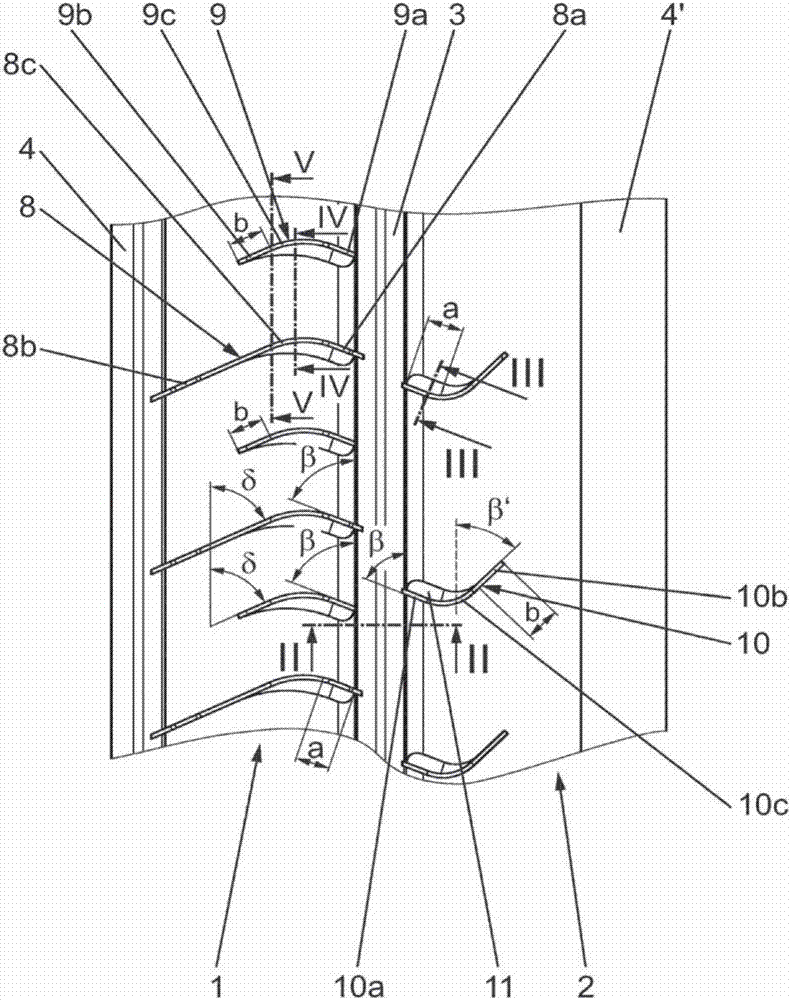

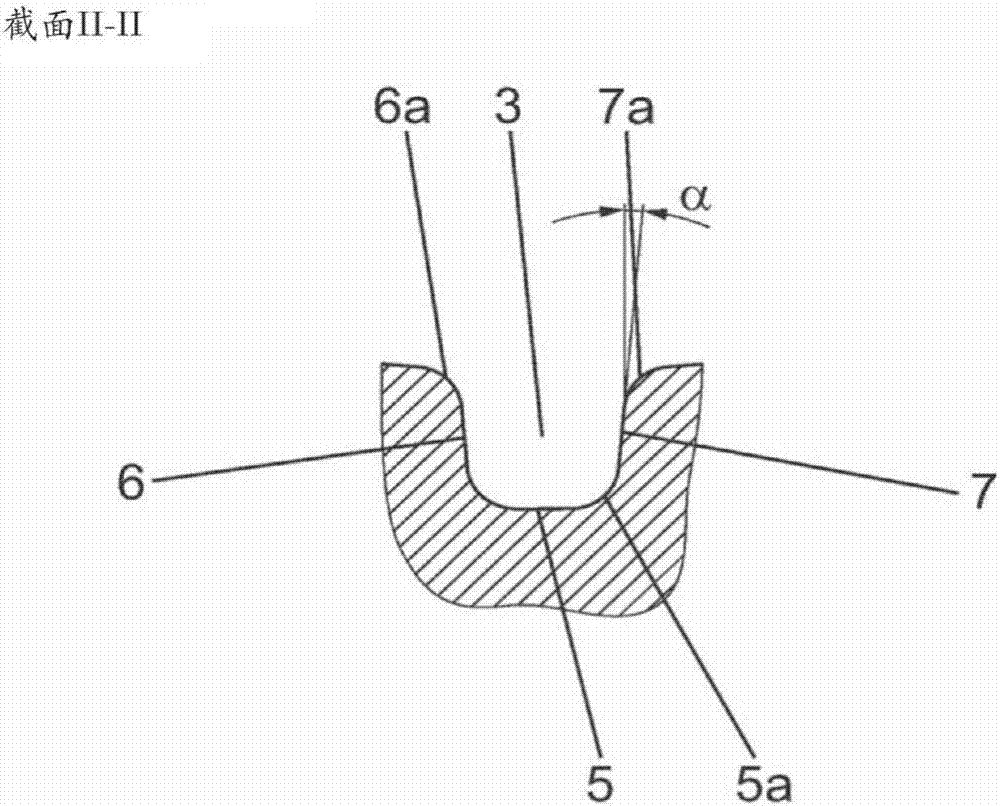

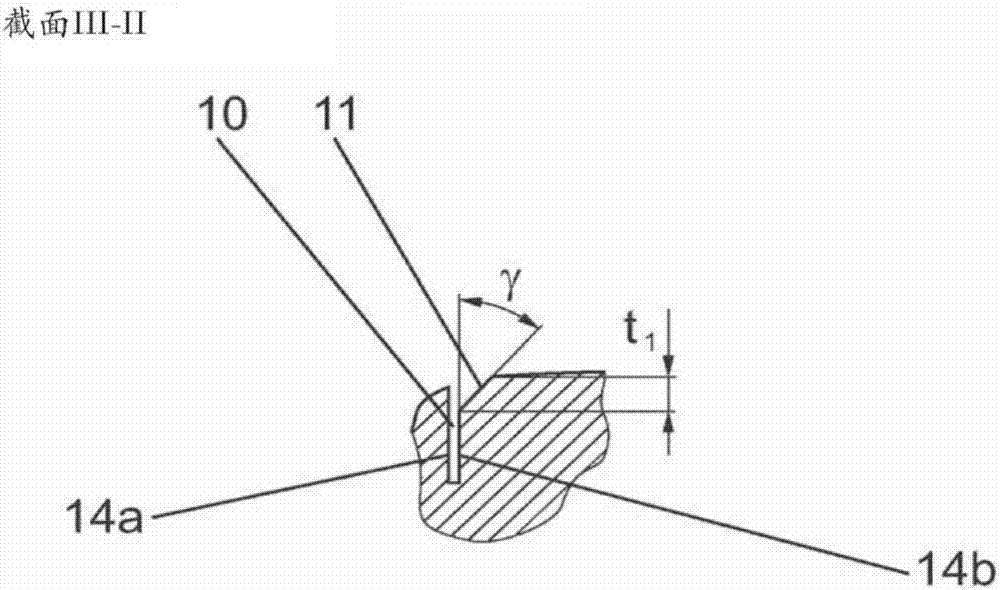

Pneumatic vehicle tyre

ActiveCN107249906AEasy accessPrevent roll upTyre tread bands/patternsEngineeringMechanical engineering

The invention relates to a pneumatic vehicle tyre having a tread which is divided by circumferential channels (3, 4) into profile positives which run in encircling fashion in a circumferential direction, wherein said profile positives include at least one profile rib (1, 2) which runs in encircling fashion in the circumferential direction and in which there run transverse channels (8, 9, 10), which transverse channels are formed parallel to one another in the manner of sipes and issue into at least one circumferential channel (3, 4) which delimits the profile rib (1, 2), and which transverse channels, at least in a section of the extent thereof close to the rib outer surface, are widened by way of a bevel (11, 12, 13). The transverse channels (8, 9, 10), which are formed in the manner of sipes, run in arcuate fashion relative to the circumferential channel (3, 4), wherein the bevels (11, 12, 13) are formed in each case on that channel flank (14b, 14'b, 14''b) of the transverse channels (8, 9, 10) which runs at the inner side of the arc, and wherein the transition region (6a, 7a) between that channel flank (6, 7) of the circumferential channel (3) into which the transverse channels (8, 9, 10), which are formed in the manner of sipes, issue and the outer surface of the profile rib (1, 2) is of rounded form.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Cotton fabric drying device

InactiveCN107916552APrevent roll upAvoid wrinklesTextiles and paperLaundry driersState of artPulp and paper industry

The invention relates to a cotton fabric drying device which comprises a drying cylinder, wherein a rotating shaft is rotationally connected inside the drying cylinder; a collection tank is fixedly connected with the rotating shaft; a collecting disc is fixed on the collection tank; vent holes are formed in the bottom of the collection tank; drying holes are formed in the collection disc; negativepressure blades are rotationally connected inside the collection tank; the negative pressure blades are positioned bellow the collection disc; an air inlet hole is formed in the drying cylinder abovethe collection disc; an electric heating wire is arranged inside the air inlet hole; an air outlet hole is formed in the drying cylinder below the collection tank; an air outlet tube is communicatedto the air outlet hole; a turbine is rotationally connected inside the air outlet tube; and the turbine is fixed on the rotating shaft. Compared with the prior art, the cotton fabric drying device provided by the scheme of the invention is capable of sucking and fixing clothes on the collection disc through the collection tank, the drying cylinder, the turbine and the like, and is capable of drying clothes through hot air along with rotation of the collection tank, not only is air flowing around the clothes intensified, but also the clothes are prevented from being tangled together and prevented from wrinkles, the contact area of hot air with the clothes is ensured, and the drying efficiency is increased.

Owner:NINGBO WENZE TEXTILE CO LTD

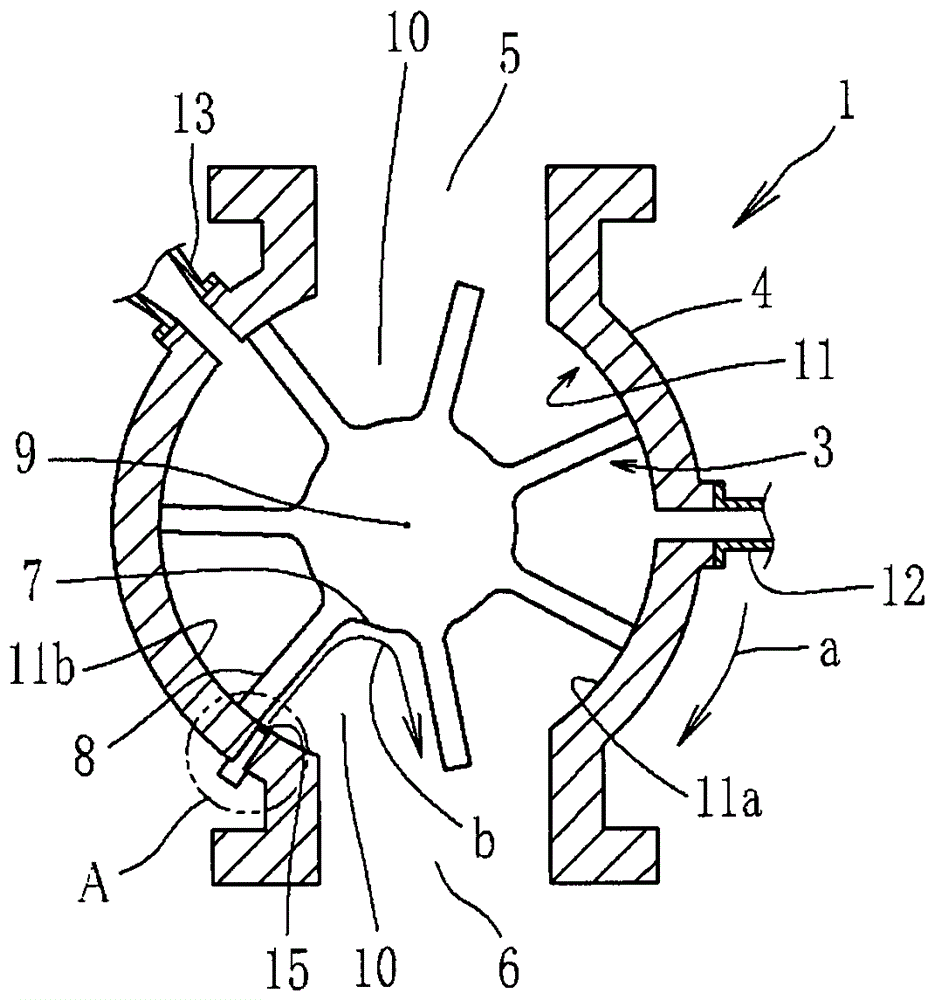

rotary valve

ActiveCN103287809BStrong adhesionStripping of material that adheres reliably to the rotorRotary conveyorsRotary valveEngineering

Owner:FUJIWARA TECHNO ART CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com