Combine Harvester

一种联合收割机、机体的技术,应用在收割机、切割器、机械设备等方向,能够解决联合收割机行驶性能降低等问题,达到防止行驶性能的降低、耐久性提高、提高耐久性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

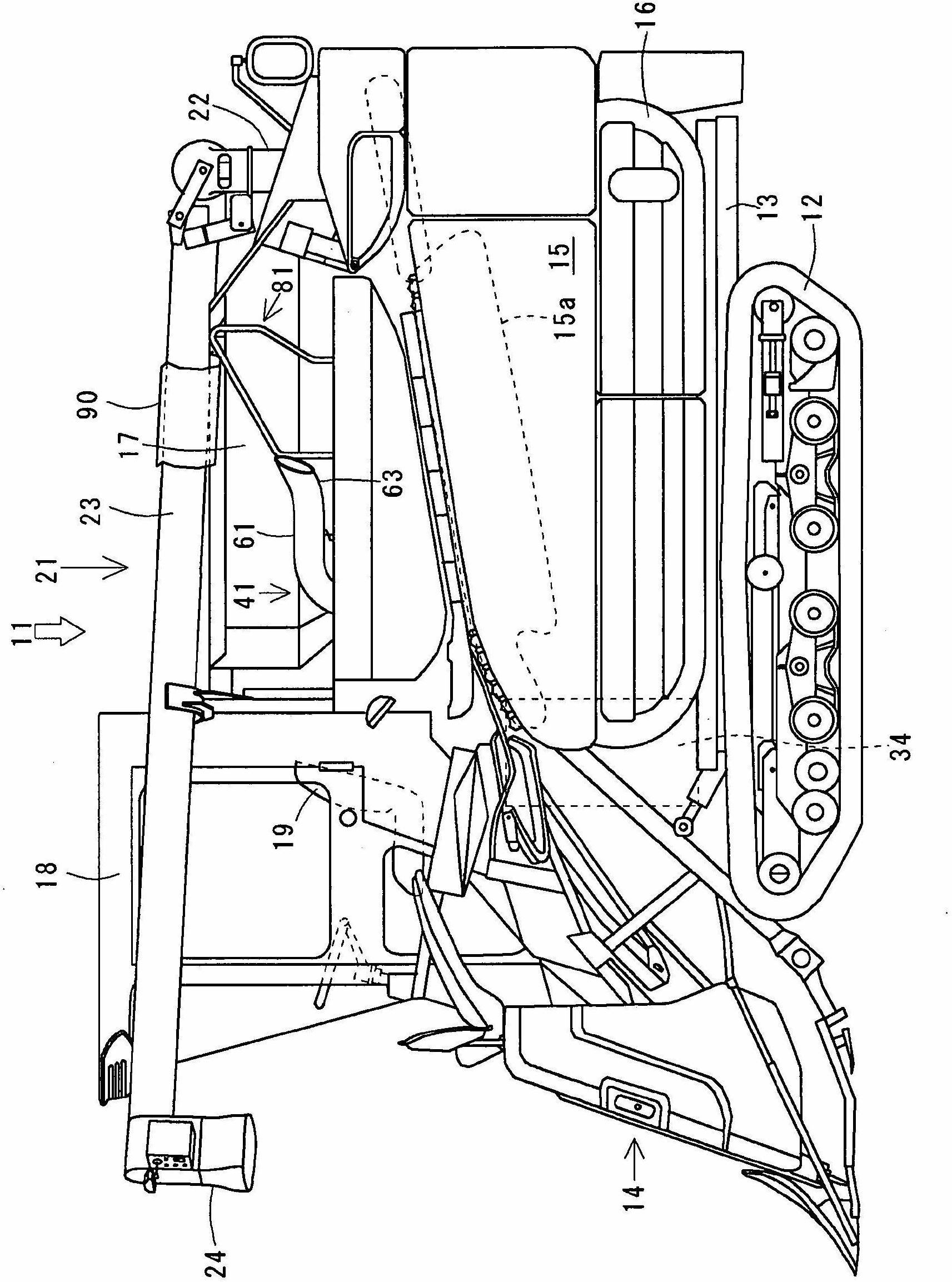

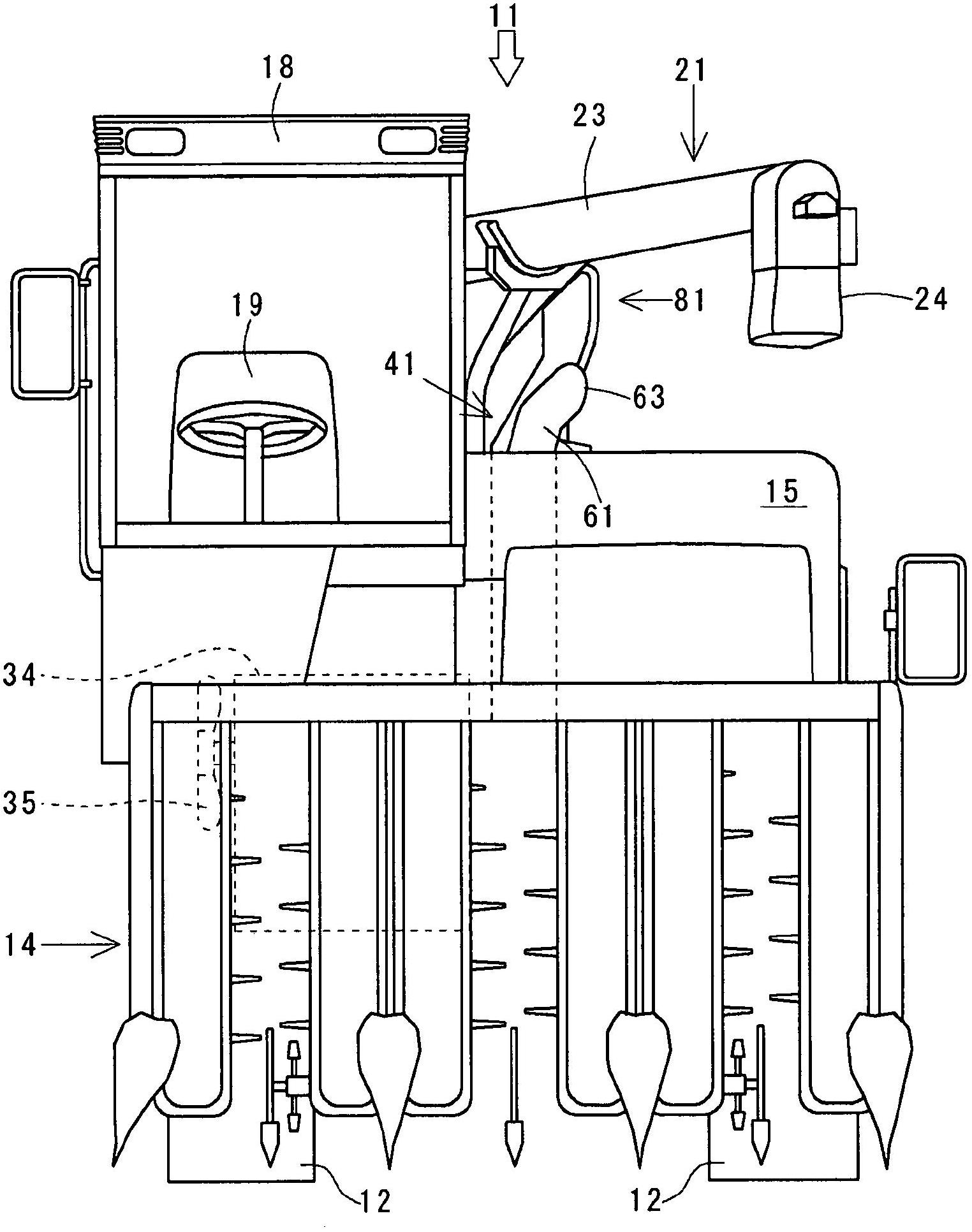

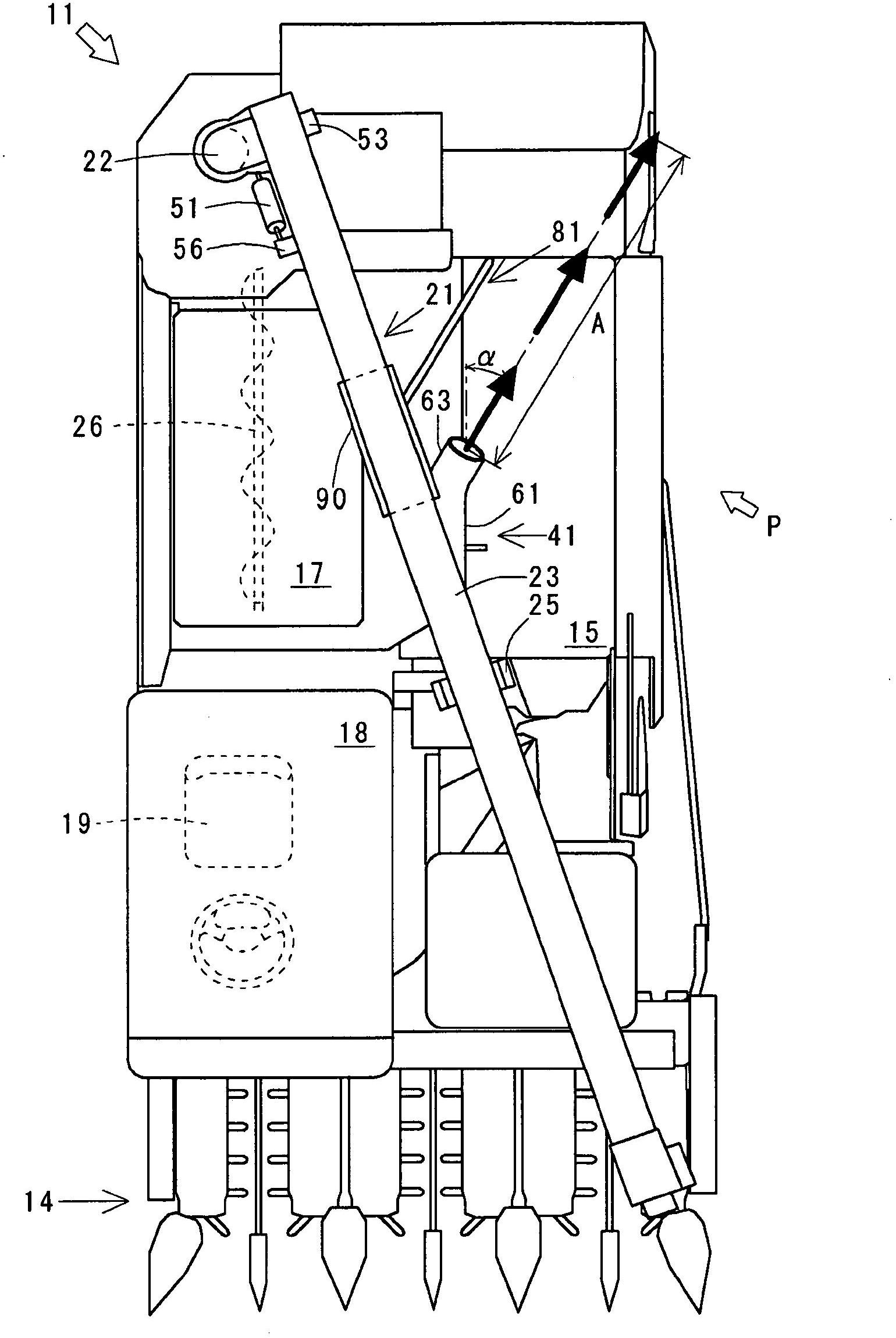

[0055] The combine 11 which concerns on 1st Example of this invention is demonstrated using a figure. figure 1 is an overall side view of the combine harvester 11, figure 2 is the front view of combine harvester 11, image 3 is a top view of the combine harvester 11, Figure 4 is a brief side view of the exhaust device 41, Figure 5 is a schematic front view of the exhaust device 41, Image 6 is a schematic top view of the exhaust device 41, Figure 7 is a schematic side view of the connecting portion of the longitudinal conveying screw 22 and the transverse conveying screw 23, Figure 8 yes image 3 The arrow P of the protective plate 90 in the view, Figure 9 is a side view of the fender 90, Figure 10 is a top view of the protective plate 90, Figure 11 is a cross-sectional view of the fender 90, Figure 12 (a) is a top view of a conventional outside air introduction part 71, (b) is a top view of the outside air introduction part 71 when opening the upstream end p...

Embodiment 2

[0098] A second embodiment of the present invention will be described below using the drawings.

[0099] The combine which concerns on this Example is demonstrated using a figure. Figure 16 is the overall side view of the combine harvester, Figure 17 is the main view of the combine harvester, Figure 18 is a top view of the combine harvester, Figure 19 is a brief side view of the exhaust, Figure 20 is a simplified front view of the exhaust, Figure 21 is a simplified top view of the exhaust.

[0100] First, the overall structure of the combine 111 is demonstrated. Such as Figure 16 to Figure 18 As shown, the combine harvester 111 is equipped with a body (underframe) 113 on a crawler belt traveling device 112 that supports left and right crawlers, and an engine 134 is mounted on the right side of the front part of the body 113 (see Figure 19 ). In front of the machine body 113, a transmission case 131 (refer to Figure 21 ), on the gearbox 131 the axles of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com