Kitchen waste pretreatment system capable of efficiently recovering organic matters

A technology of food waste and organic matter, which is applied in the field of food waste pretreatment system for efficient recovery of organic matter, can solve the problems of underutilization, etc., and achieve the effects of saving labor costs, good separation effect, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

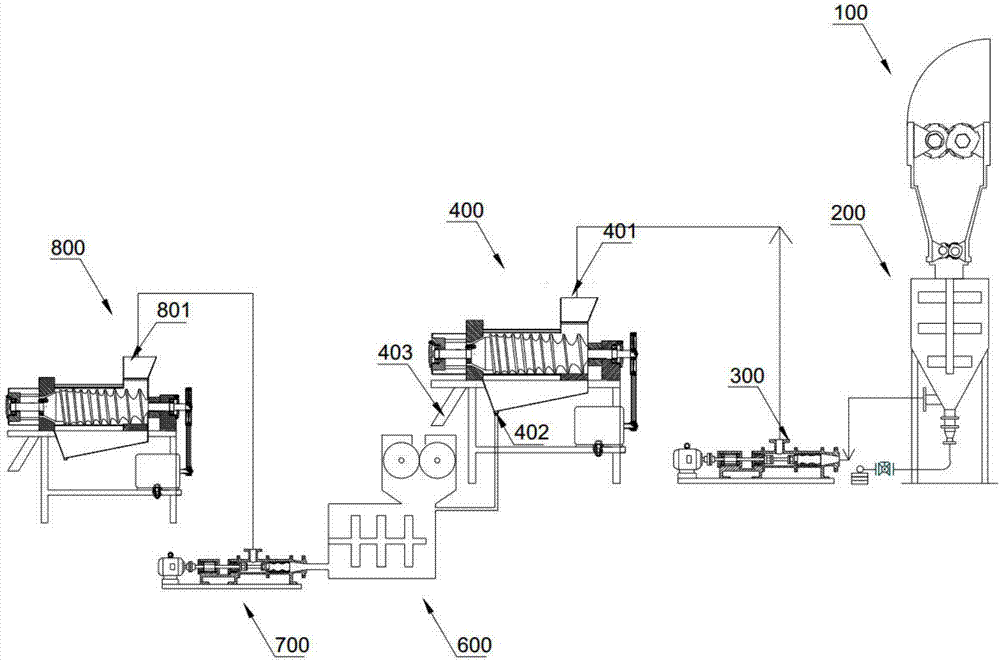

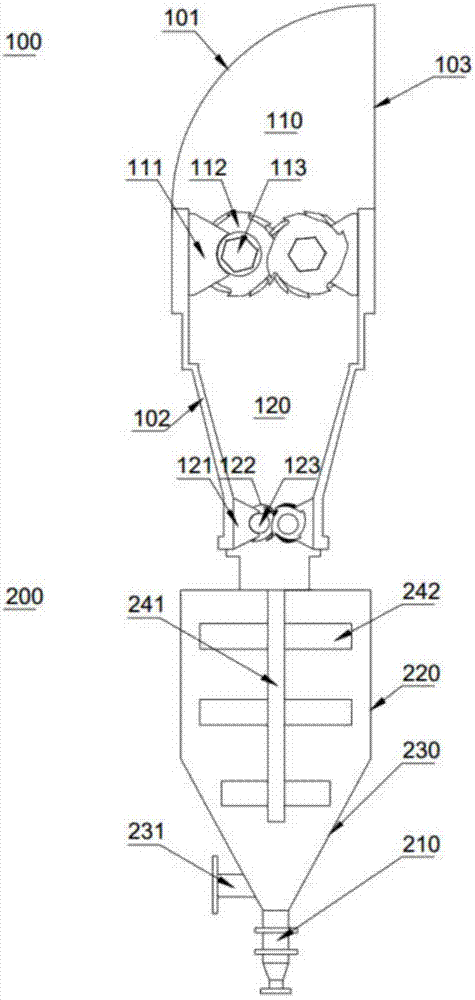

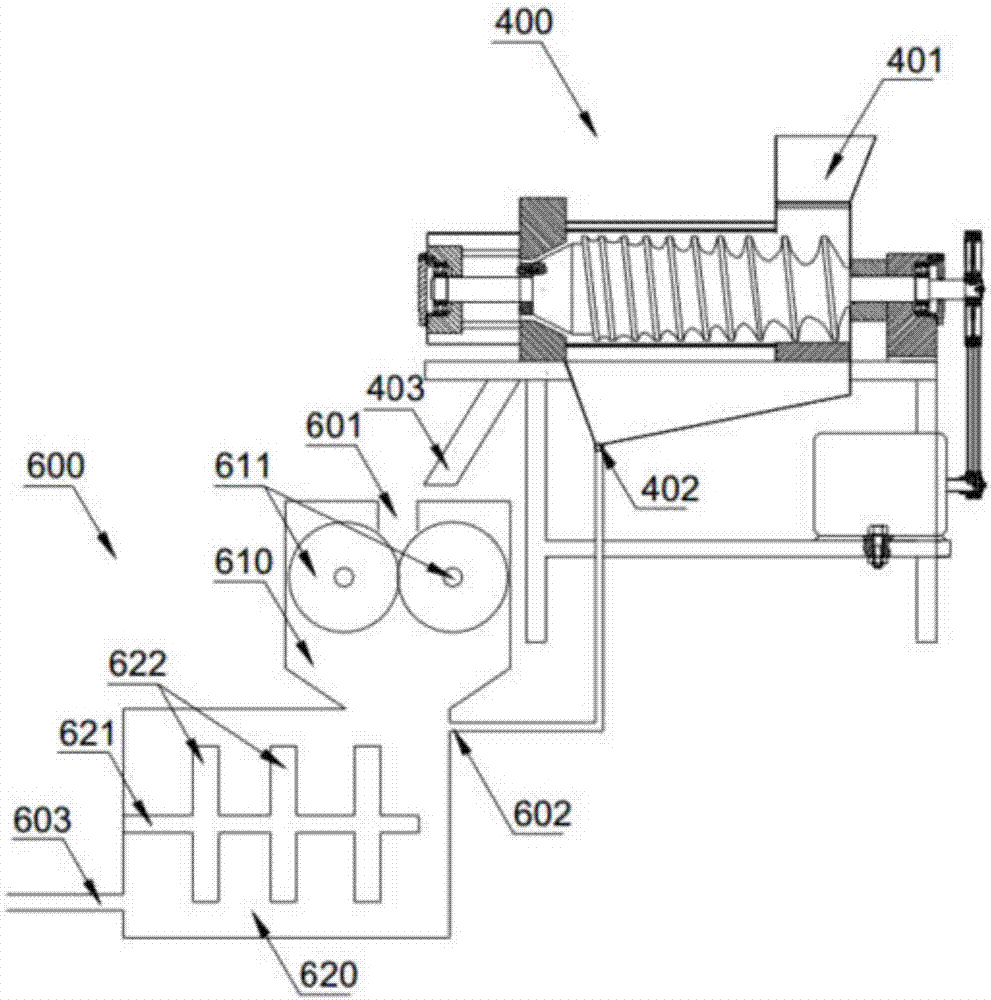

[0040] Such as Figure 1~3 As shown, a food waste pretreatment system capable of efficiently recovering organic matter includes a crushing device 100, a desanding device 200, a first squeezing device 400, a crushing slag crushing device 600, and a second squeezing device 800 arranged in sequence; The discharge port of the crushing device 100 communicates with the feed port of the sand removal device 200, and the discharge port 231 of the sand removal device 200 communicates with the feed port 401 of the first squeezing device 400 through the screw pump 300. The slag outlet 403 and the liquid outlet 402 of a squeezing device 400 communicate with the slag inlet 601 and the liquid inlet 602 of the squeezed slag rolling device 600 respectively, and the discharge port 603 of the squeezed slag rolling device passes through the screw pump 700 It communicates with the feed port 801 of the second squeezing device; the crushed slag rolling device 600 is provided with a residue rolling c...

Embodiment 2

[0048] This embodiment is similar to Embodiment 1, the difference is that, as Figure 4~9 As shown, this embodiment is similar to Embodiment 1, the difference is that it also includes an unloading device 500 matched with the crushing device, and the unloading device 500 includes a transportation mechanism 510 that can carry the kitchen waste bin, and can The pneumatic clamping mechanism 520 for clamping the kitchen garbage can (the kitchen garbage is stored in the garbage can 501), and the mechanism that drives the pneumatic clamping mechanism 520 to rise and dump the kitchen garbage in the garbage can into the feed port of the crushing device Lifting mechanism 530 .

[0049] The conveying mechanism 510 includes a plurality of rollers 511 arranged alternately, and a pair of conveying belts 512 arranged symmetrically above the rollers, and the conveying belts 512 are driven by a motor 513 . The trash can 301 containing kitchen waste is located between the conveyor belts 312, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com