Light Irradiation Type Heat Treatment Method And Heat Treatment Apparatus

A heat treatment method and technology of a heat treatment device, which are applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as interface property degradation and high resistance, and achieve the effects of preventing roll-up and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

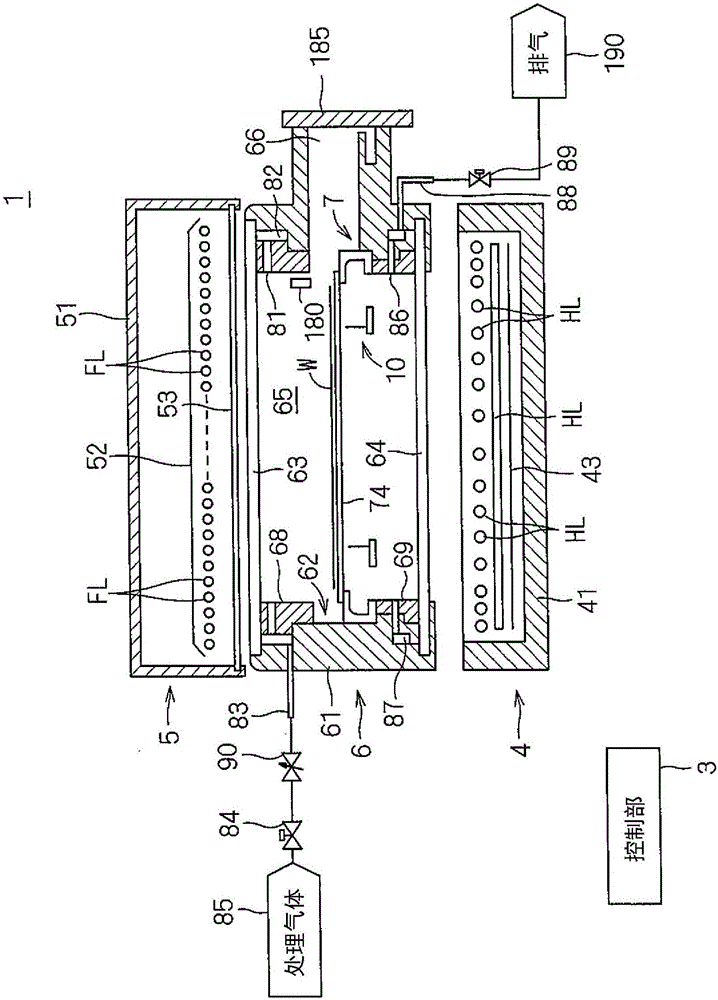

[0119] figure 1 It is a longitudinal sectional view showing the structure of the heat treatment apparatus 1 of the present invention. The heat treatment apparatus 1 of this embodiment is a flash lamp annealing apparatus which heats the semiconductor wafer W by irradiating flash light to the disc-shaped semiconductor wafer W which is a board|substrate. The size of the semiconductor wafer W to be processed is not particularly limited, for example, or A metal film such as nickel is formed on the semiconductor wafer W before being carried into the heat treatment apparatus 1 , and a silicide that is a compound of the metal and silicon is formed and grown by heat treatment in the heat treatment apparatus 1 . In addition, in figure 1 In each of the following figures, the size and quantity of each part are enlarged or simplified as necessary for ease of understanding.

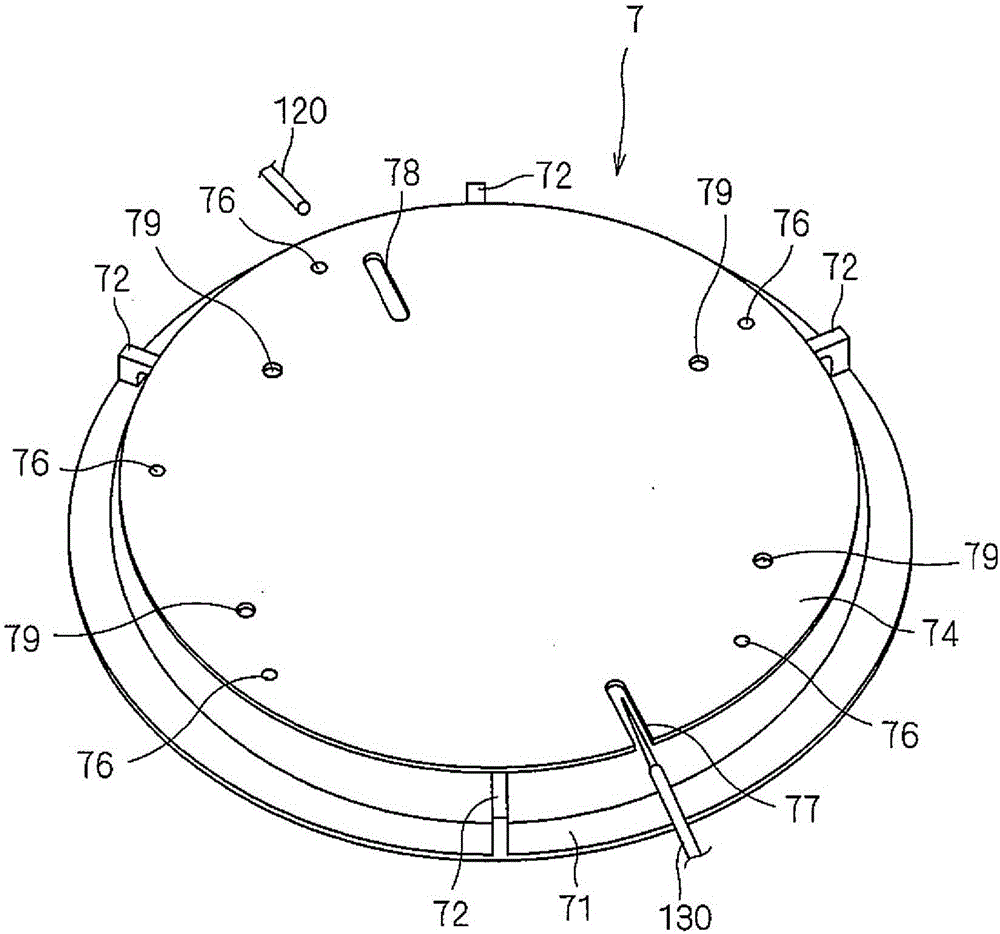

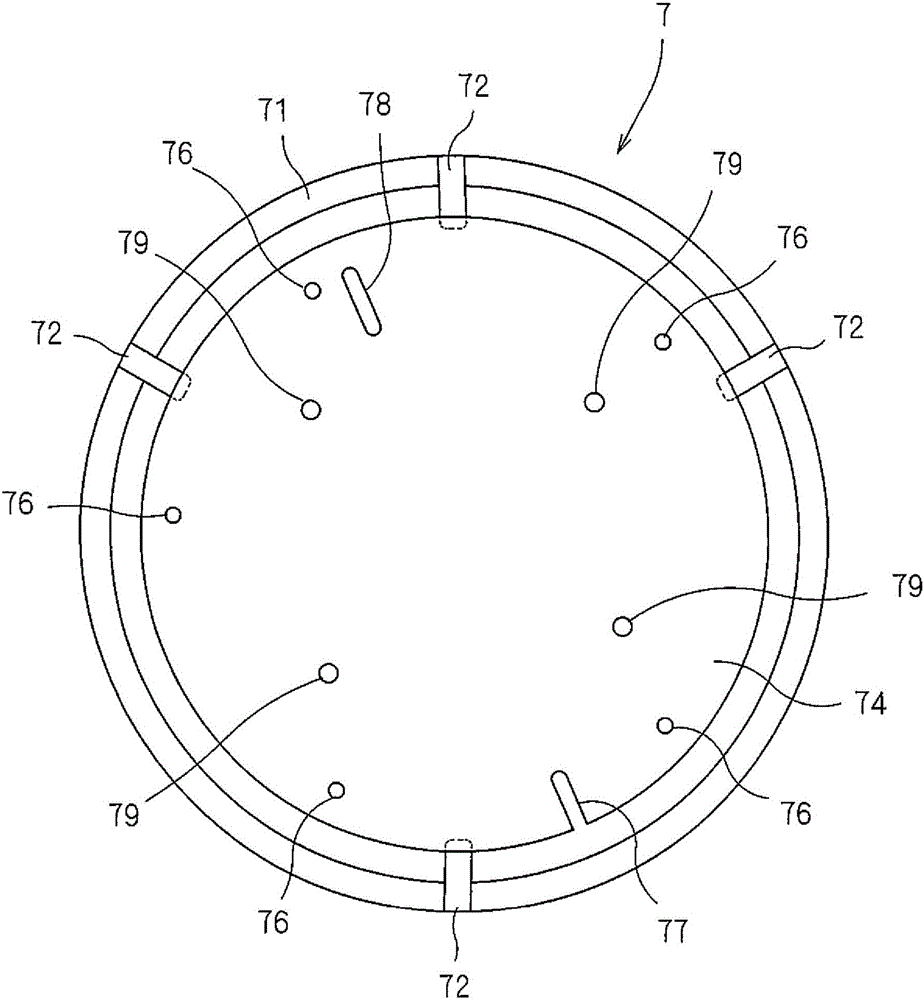

[0120] The thermal processing apparatus 1 has a chamber 6 for accommodating a semiconductor wafer W, a flash h...

no. 2 approach

[0184] Next, a second embodiment of the present invention will be described. The structure of the heat treatment apparatus 1 of the second embodiment is completely the same as that of the first embodiment. In addition, the processing procedure of the semiconductor wafer W in the thermal processing apparatus 1 of the second embodiment is also substantially the same as that of the first embodiment. The second embodiment differs from the first embodiment in that the pressure in the chamber 6 is restored after the pressure in the chamber 6 is decompressed once.

[0185] Figure 11 It is a figure which shows the pressure change in the chamber 6 in 2nd Embodiment. exist Figure 11 in, with Figure 10 Similarly, the horizontal axis represents the time, and the vertical axis represents the pressure in the chamber 6 . in addition, Figure 11 The pattern shown by the dotted line in is the pressure change pattern ( Figure 10 picture of).

[0186] As in the first embodiment, when...

no. 3 approach

[0201] Next, a third embodiment of the present invention will be described. The structure of the heat treatment apparatus 1 of the third embodiment is completely the same as that of the first embodiment. In addition, the processing procedure of the semiconductor wafer W in the thermal processing apparatus 1 of the third embodiment is also substantially the same as that of the first embodiment. The third embodiment differs from the first embodiment in that the pressure inside the chamber 6 changes.

[0202] Figure 12 It is a figure which shows the pressure change in the chamber 6 in 3rd Embodiment. exist Figure 12 in, with Figure 10 Similarly, the horizontal axis represents the time, and the vertical axis represents the pressure in the chamber 6 .

[0203] As in the first embodiment, when the semiconductor wafer W on which the metal film 108 is formed is accommodated in the chamber 6 and the transfer opening 66 is closed, the pressure in the chamber 6 is normal pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com