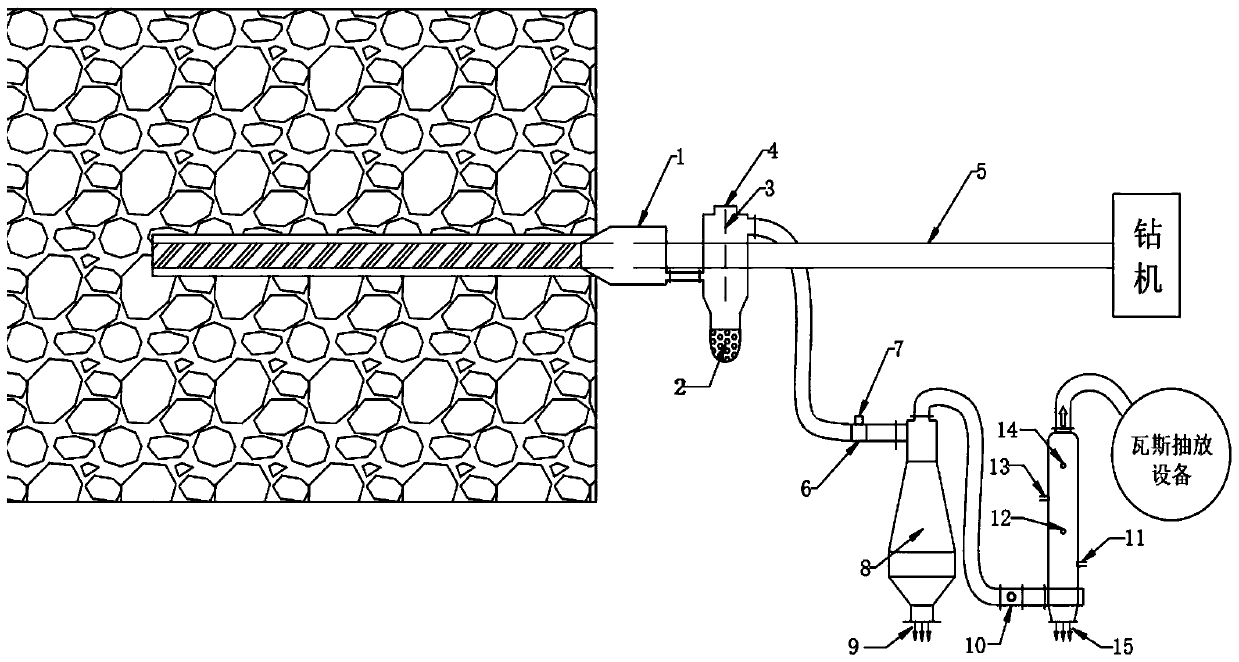

Cyclone foam integrated drilling and dust removing device and using method thereof

A technology of dust removal device and cyclone dust collector, which is applied in the direction of measuring device, safety device, earthwork drilling and mining, etc. It can solve the problems of poor slag discharge conditions, uneven mixing of wind and water, difficulty in controlling the pressure of wind and water volume, etc., and achieves simple and easy construction performance, improved dust removal efficiency, intelligent and efficient dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In a coal and gas outburst mine, the absolute emission of mine gas is 58.85m 3 / min, the relative gas emission is 32.29m 3 / t. The mine adopts vertical shaft development, single-level downhill mining, the elevation of the main wellhead is +37.5m, the production level elevation is -850m, and the mining depth is about 930m. The maximum gas pressure of the coal seam is 9.2MPa (elevation -973.7m). Gas disaster management is very difficult.

[0056] The above cyclone foam integrated drilling dust removal device specifically includes the following steps:

[0057] Step 1. Put the air pressure hole sealer into the drill hole and start to inflate. Inflate until you can’t directly press it manually. The source of inflating gas is the downhole compressed air system. The general inflation pressure is 0.2-0.3MPa. Then connect the input port of the coal dust treatment device and the hole sealing device by the dust delivery connecting pipeline;

[0058] Step 2. After turning on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com