Steel structure assembly type building material producing and processing processor

A construction material and assembly technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as inability to correct steel plates, cutting cannot be effectively fixed, and steel extrusion cannot perform all-round smoothing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

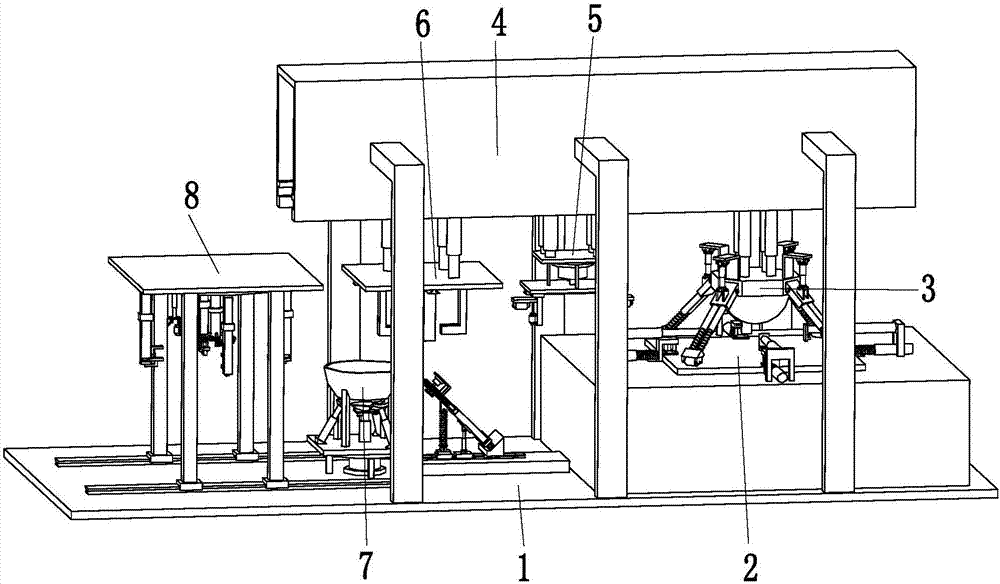

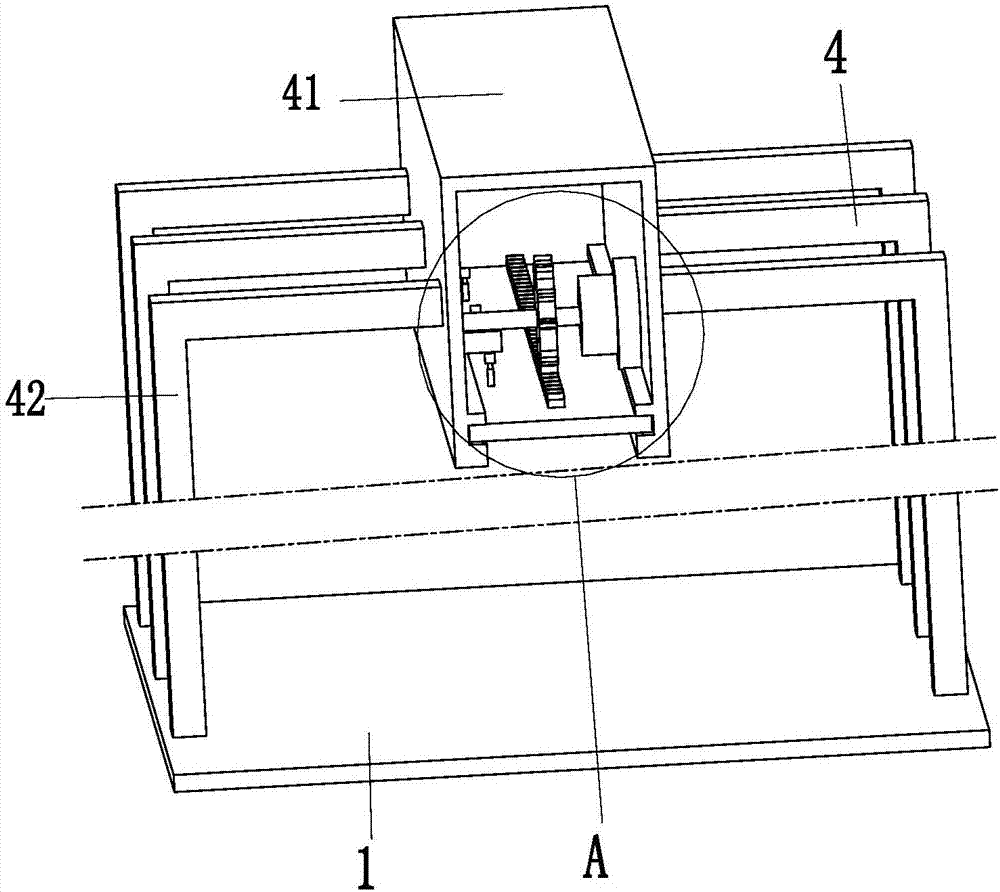

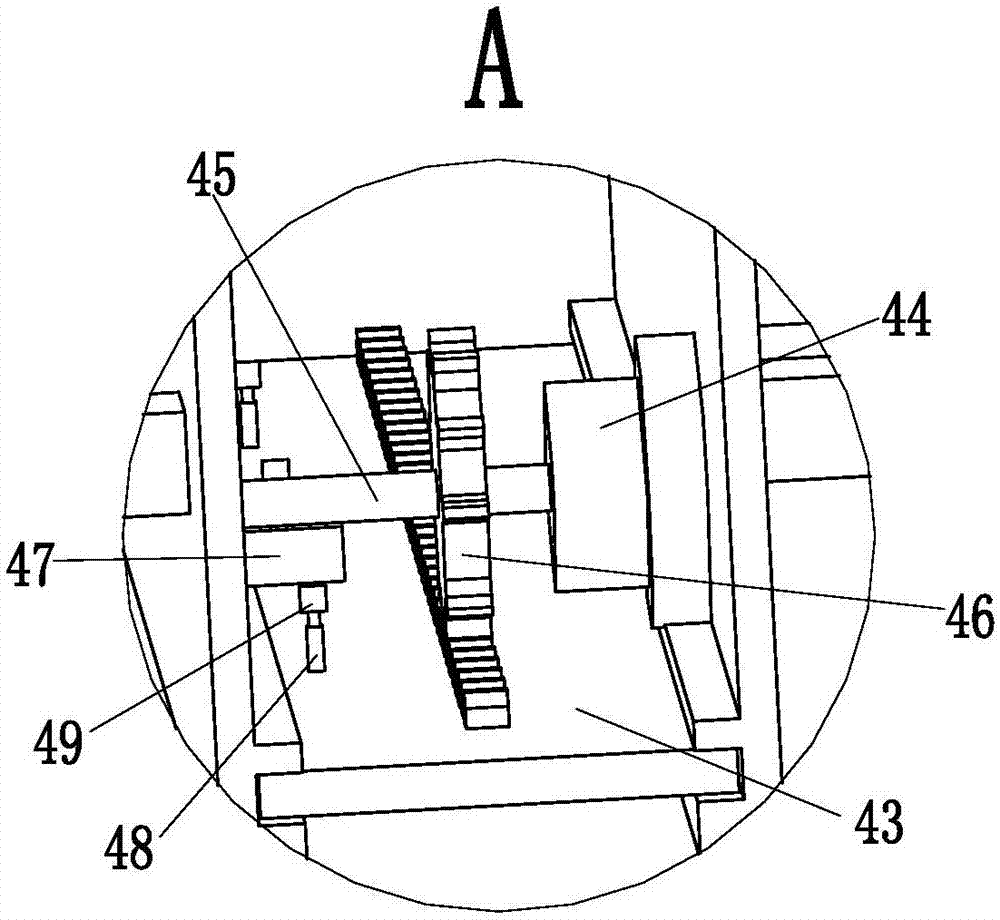

[0036] Such as Figure 1 to Figure 13 As shown, a steel structure assembled building material production and processing machine includes a supporting base plate 1, a fixing device 2, an extrusion device 3, a conversion device 4, a straightening device 5, a handling device 6, a cutting device 7 and a supporting grinding device 8 , the fixing device 2 is installed on the right end of the supporting base plate 1, the extruding device 3 is located above the fixing device 2, the extruding device 3 is connected to the right end of the converting device 4, and the converting device 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com