Hoisting machine for manufacturing large-caliber reinforced concrete drainage pipe

A technology for reinforced concrete and drainage pipes, which is applied in the direction of lifting equipment braking devices, hoisting devices, transportation and packaging, etc. It can solve the problems of drainage pipe shaking, low hoisting efficiency, poor device stability, etc., and achieve fast fixation and improved hoisting Efficiency, vibration prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

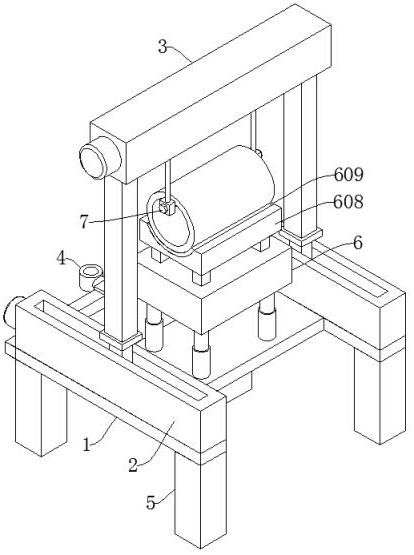

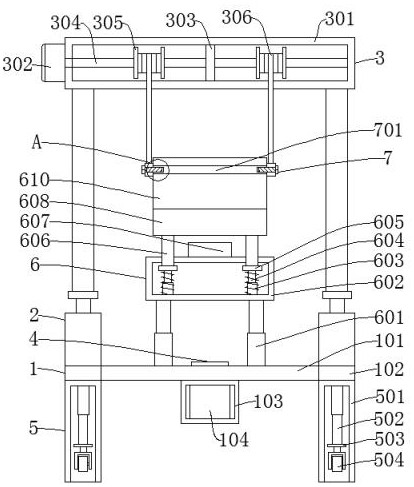

[0045] Such as figure 1 , image 3 , Figure 5 , Figure 7 , Figure 8 As shown, a hoisting machine for the manufacture of large-diameter reinforced concrete drainage pipes, including a control mechanism 1, an adjustment mechanism 2, a winding and unwinding mechanism 3, and a traction mechanism 4 for connecting driving equipment. An adjustment mechanism is installed above the control mechanism 1 Mechanism 2, a retracting and unwinding mechanism 3 is fixed above the adjusting mechanism 2, a traction mechanism 4 is installed at the rear of the control mechanism 1, and a moving mechanism 5, a supporting mechanism 6, and a fixing mechanism 7 are also included. The moving mechanism 5 is installed below the control mechanism 1, The supporting mechanism 6 is arranged on the control mechanism 1, and the fixing mechanism 7 is installed on the winding and unwinding mechanism 3;

[0046] The control mechanism 1 includes a horizontal plate 101, a side plate 102, a control box 103, and...

Embodiment 2

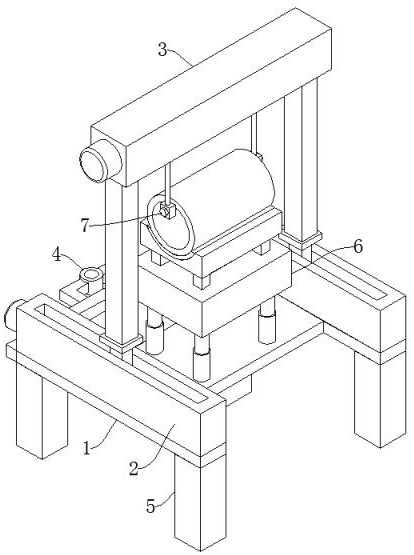

[0056] Such as figure 2 , Figure 4 , Figure 6 , Figure 7 , Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the connection block 4021, the support rod 4022, and the connection column 4023 are replaced by the connection rod 4024 and the connection frame 4025. When using the device, the device is connected to the driving device through the traction ring 401 Up, the connecting rod 4024 and the connecting frame 4025 work together to support and fix the traction ring 401 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com