Patents

Literature

43results about How to "Slow down the winding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

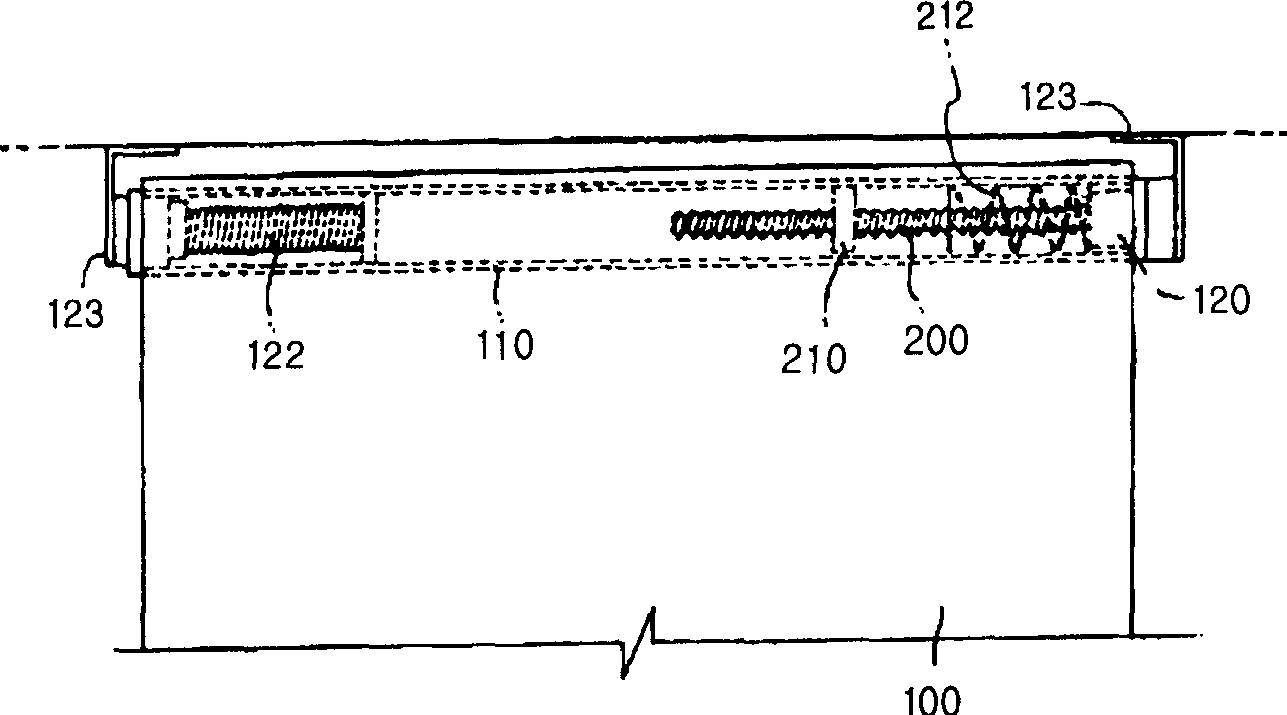

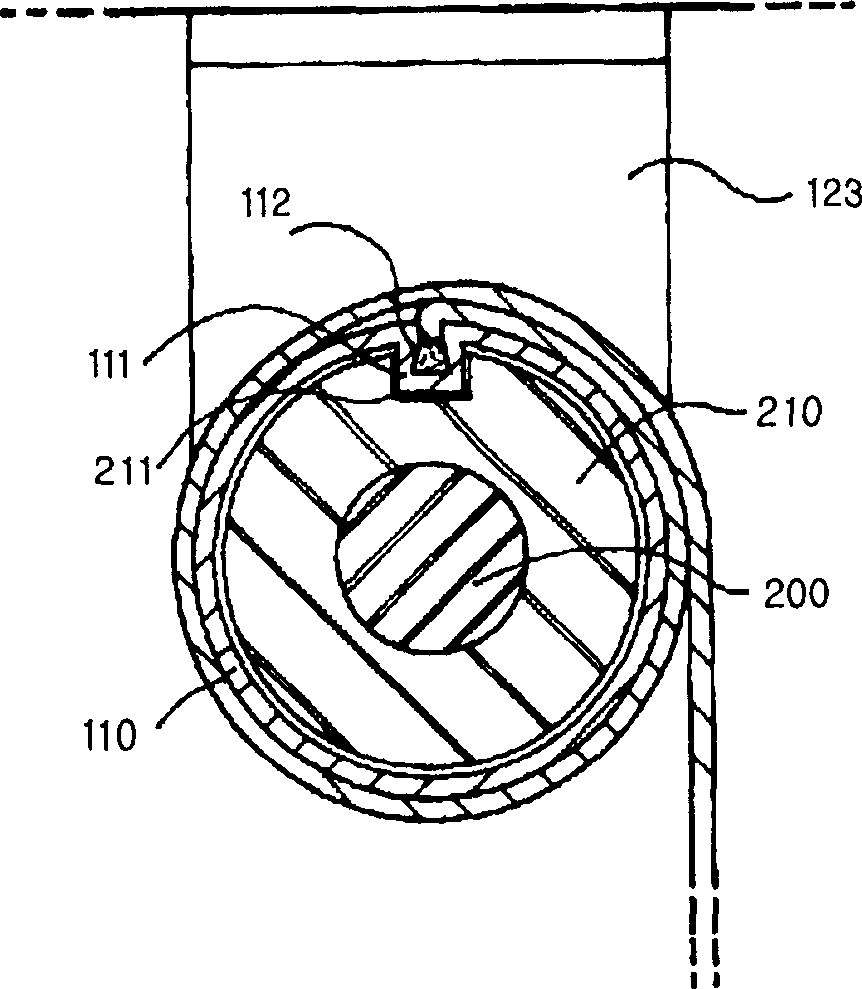

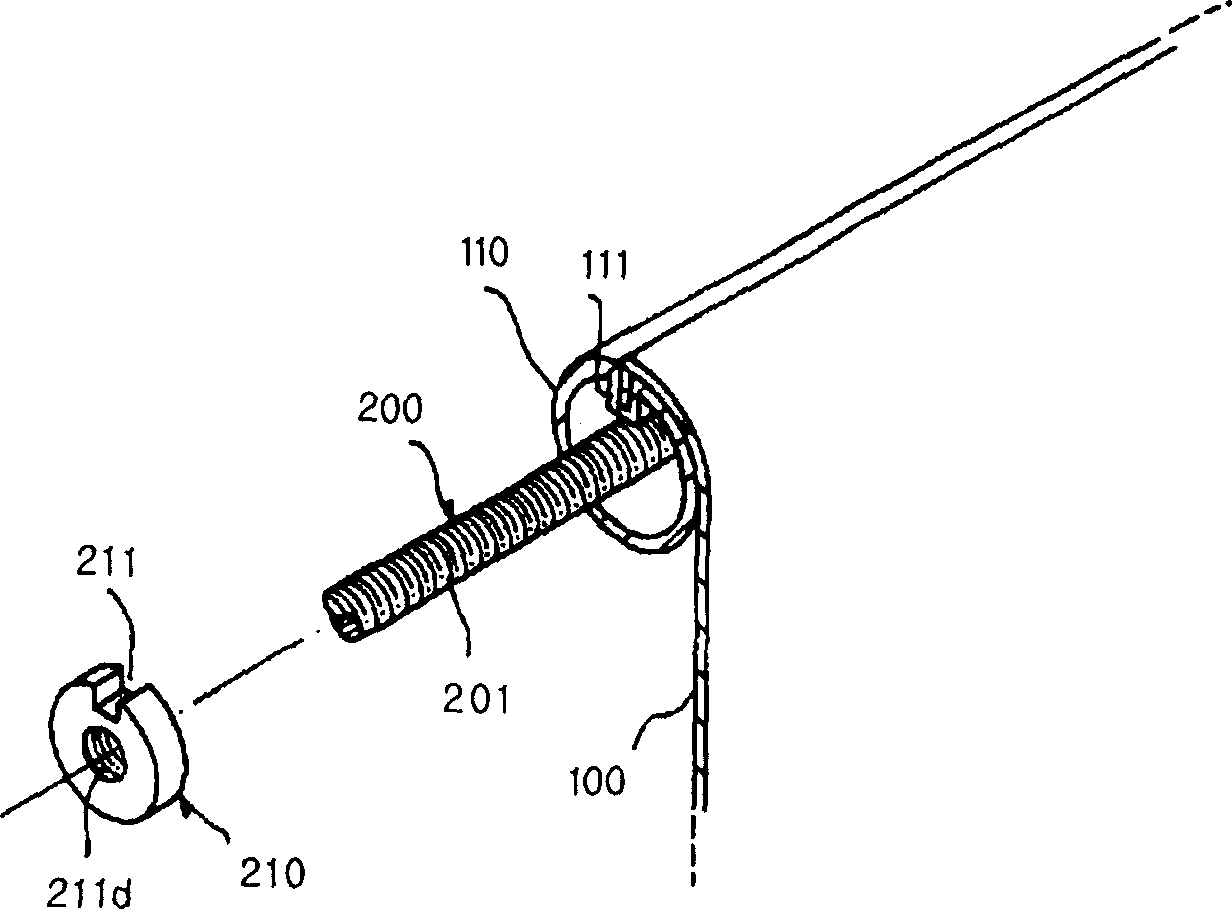

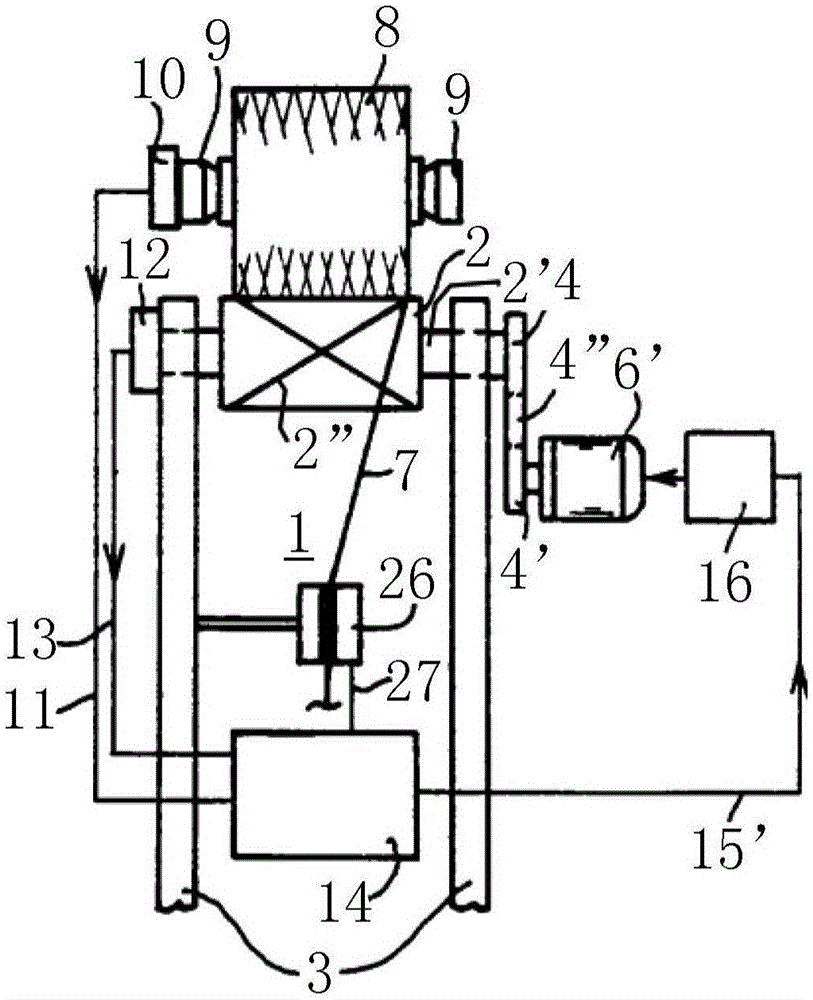

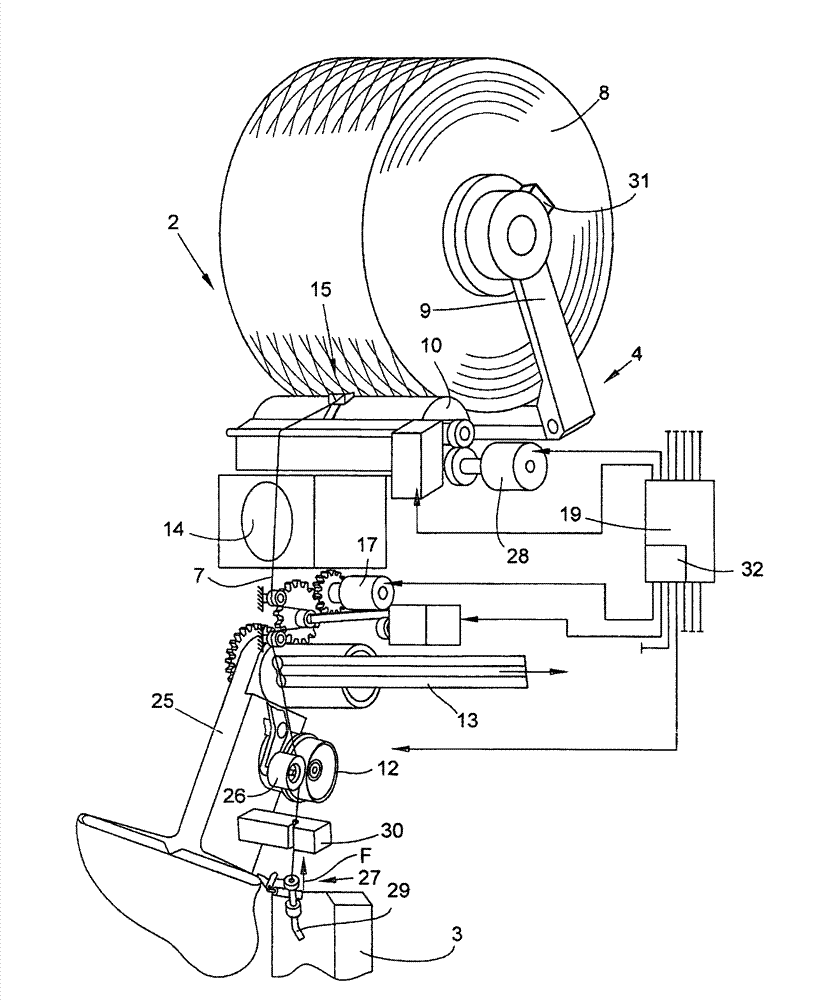

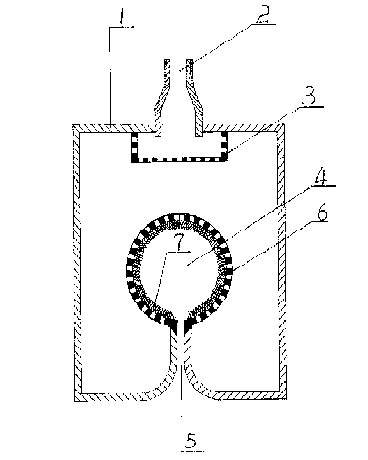

The roll screen for reduction device

InactiveCN1720384APrevent roll upEasy to useLight protection screensPulp and paper industryYounger people

The invention relates to a reduction gear for a roller shutter, wherein, the compressed piston of the reduction part can enter into a cylinder connected with one inner end of the roller pole. The invention also relates to a device which folds and unfolds the roller shutter simply and conveniently, in particular to a device which can fold the roller shutter by decreasing the folding speed at a certain section when folding the roller shutter, thereby has the advantages of avoiding noises, collisions and accidents, and easy operation without any limit by age or gender (the young people, the old people or male and female).

Owner:郭在锡

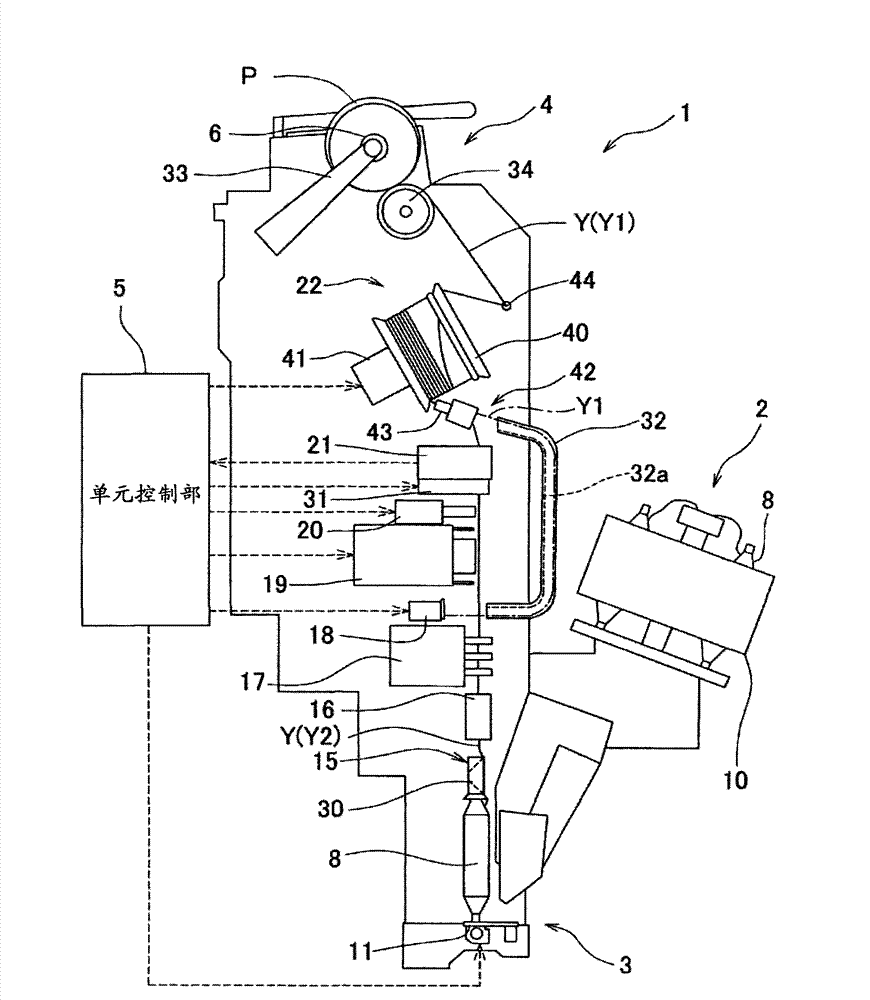

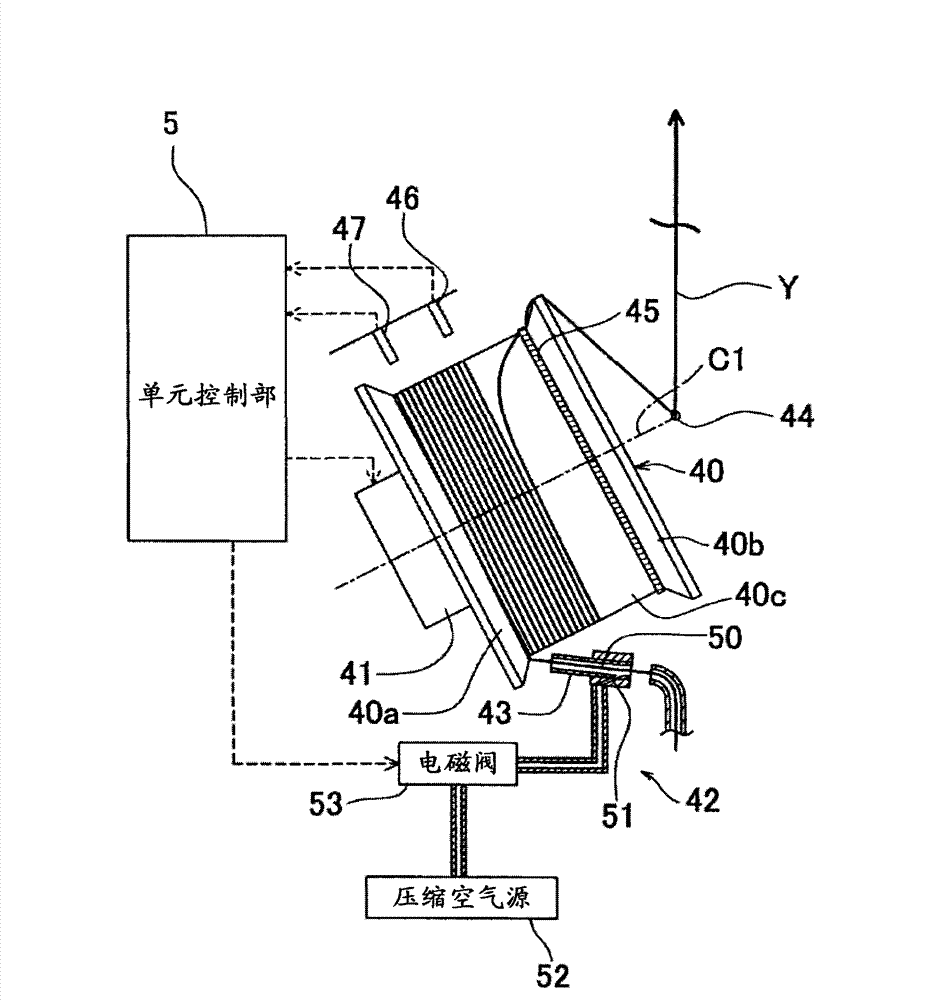

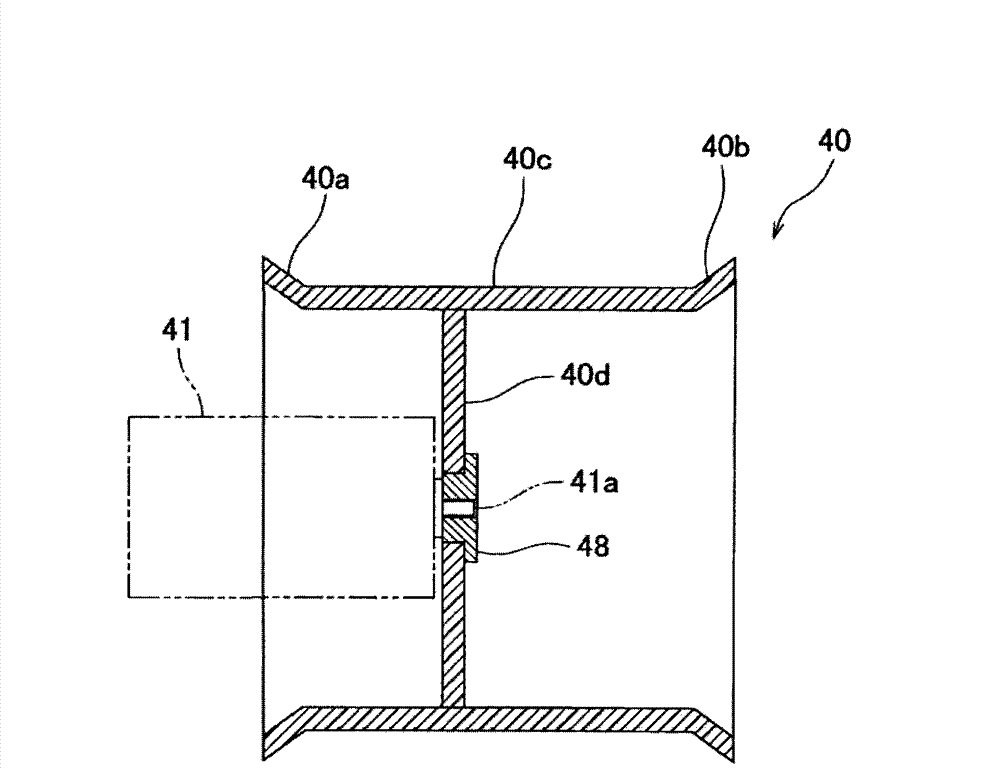

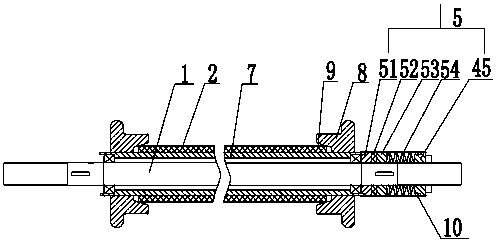

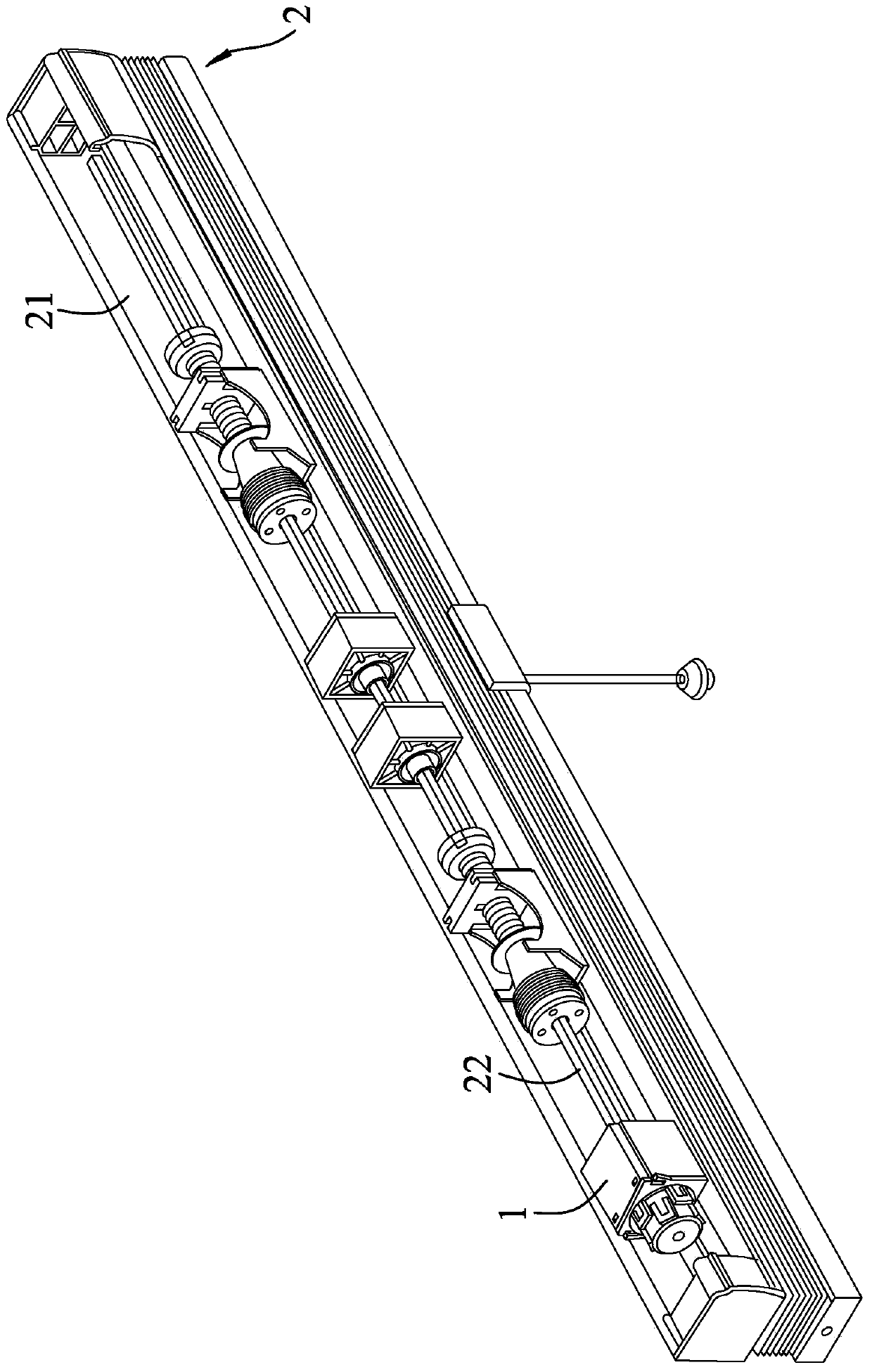

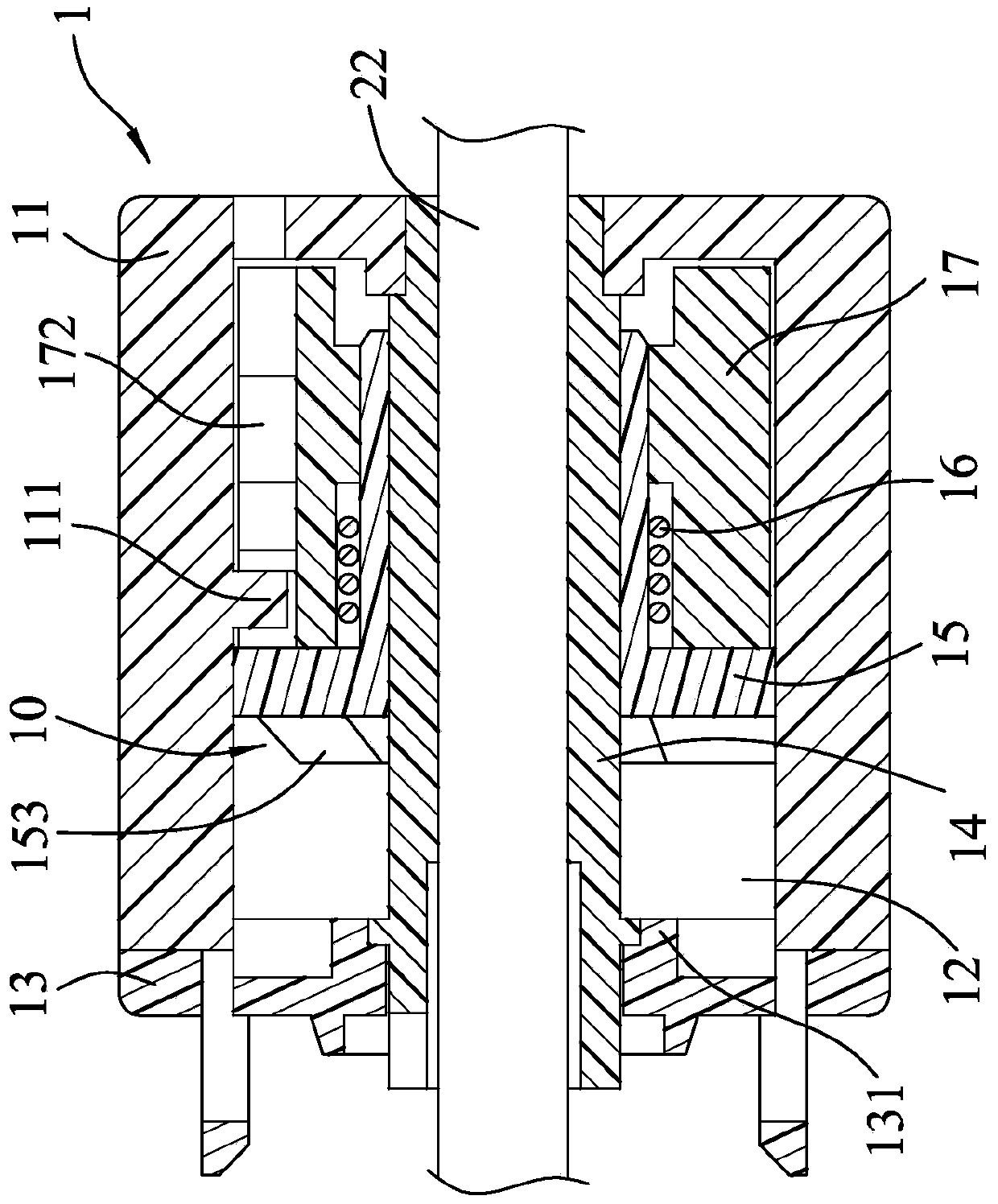

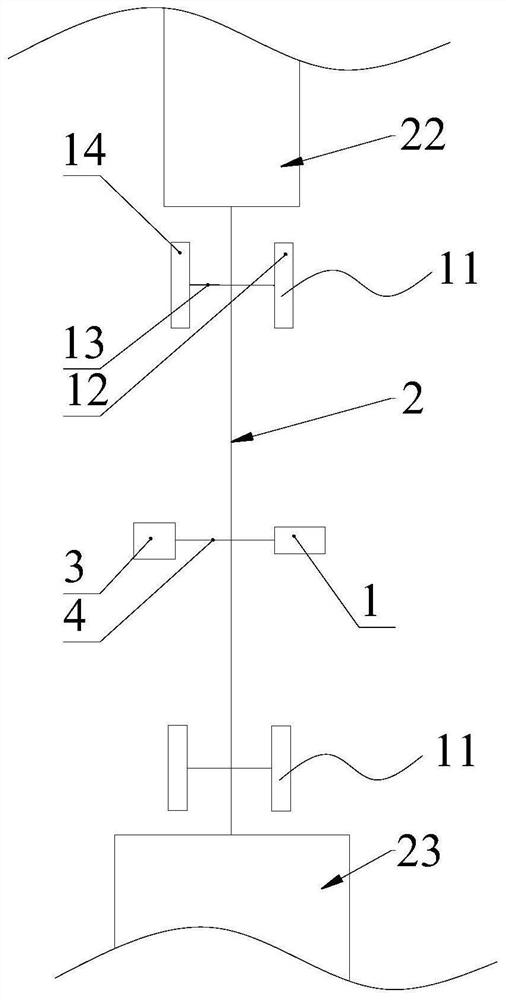

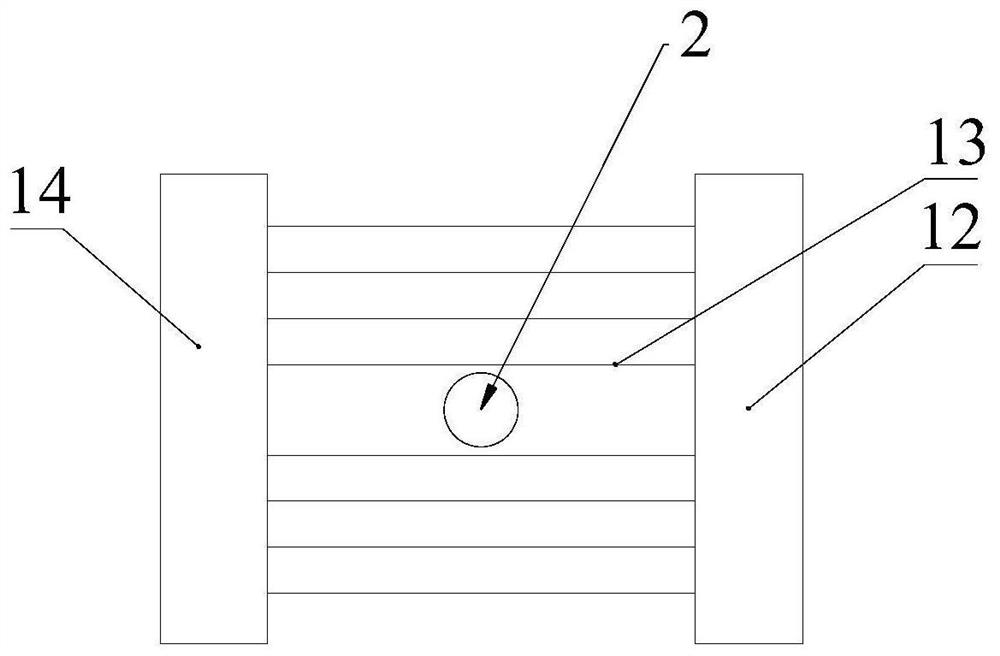

Yarn accumulating device and yarn winding device provided with the same

The invention provides a yarn accumulating device and yarn winding device provided with the same and aims to reduce a weight of a yarn accumulating roller and realize a quick rotational control of the yarn accumulating roller. A winding unit (2) includes a yarn supplying section (3), a package winding section (4), and a yarn accumulating device (22) arranged between the yarn supplying section (3) and the package winding section (4). The yarn accumulating device (22) includes a cylindrical yarn accumulating roller (40) around which a yarn (y) is wound by being rotated. The yarn accumulating roller (40) is formed of a resin material which is a non-metal material.

Owner:MURATA MASCH LTD

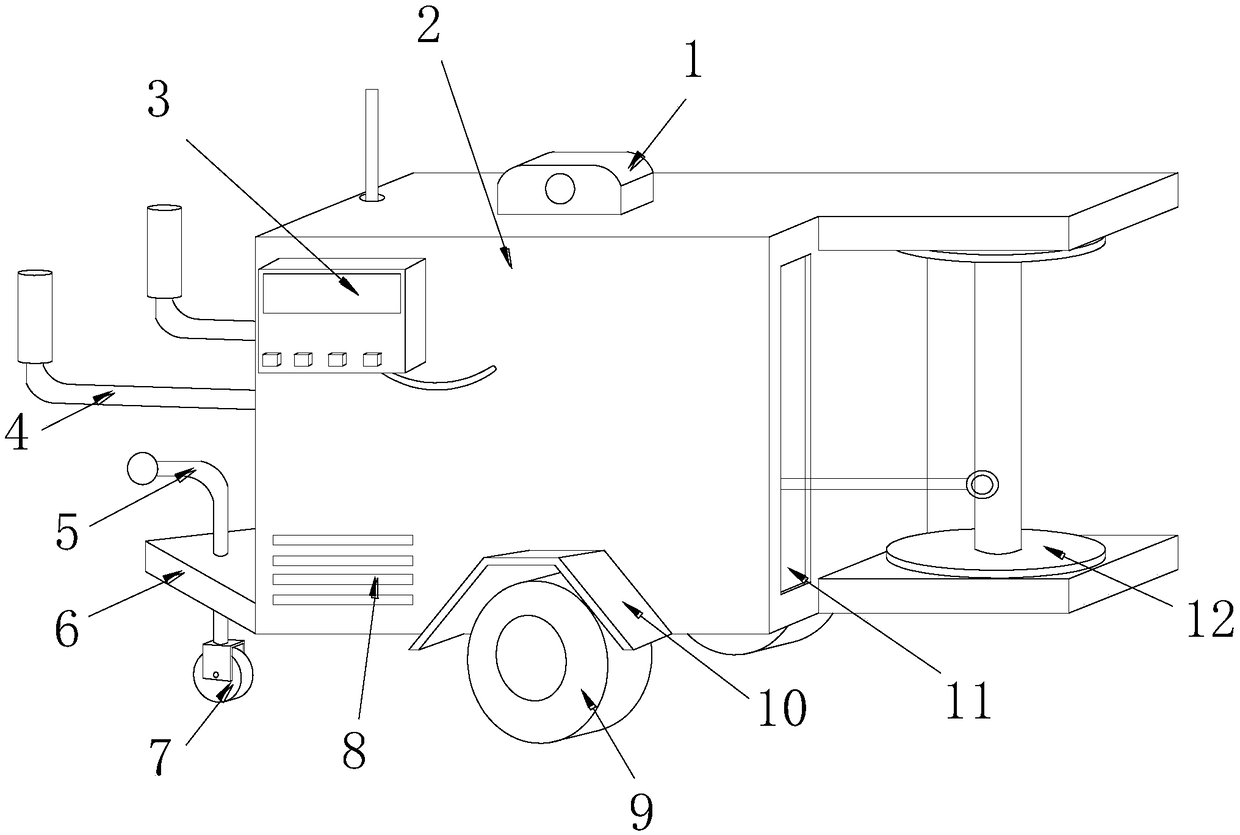

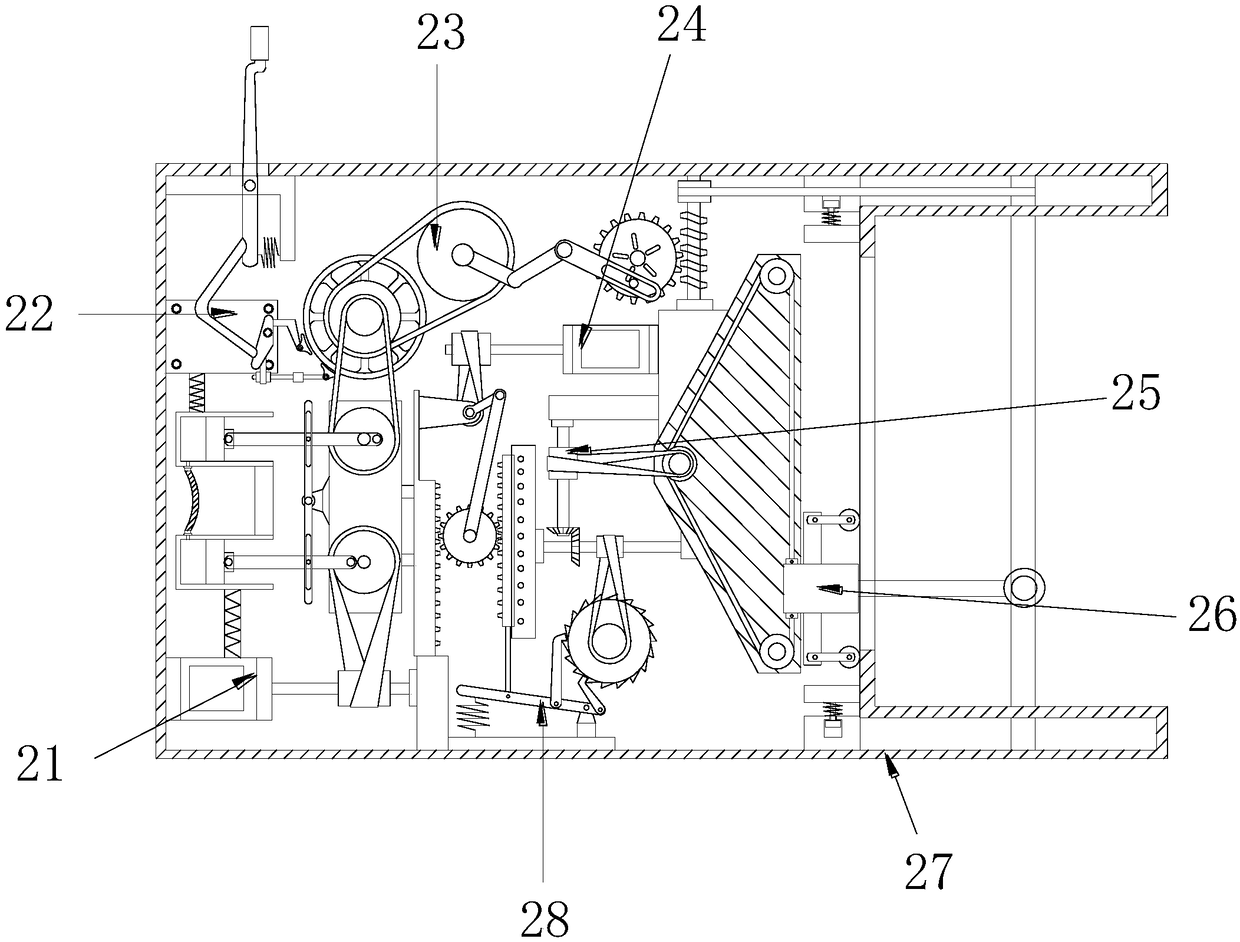

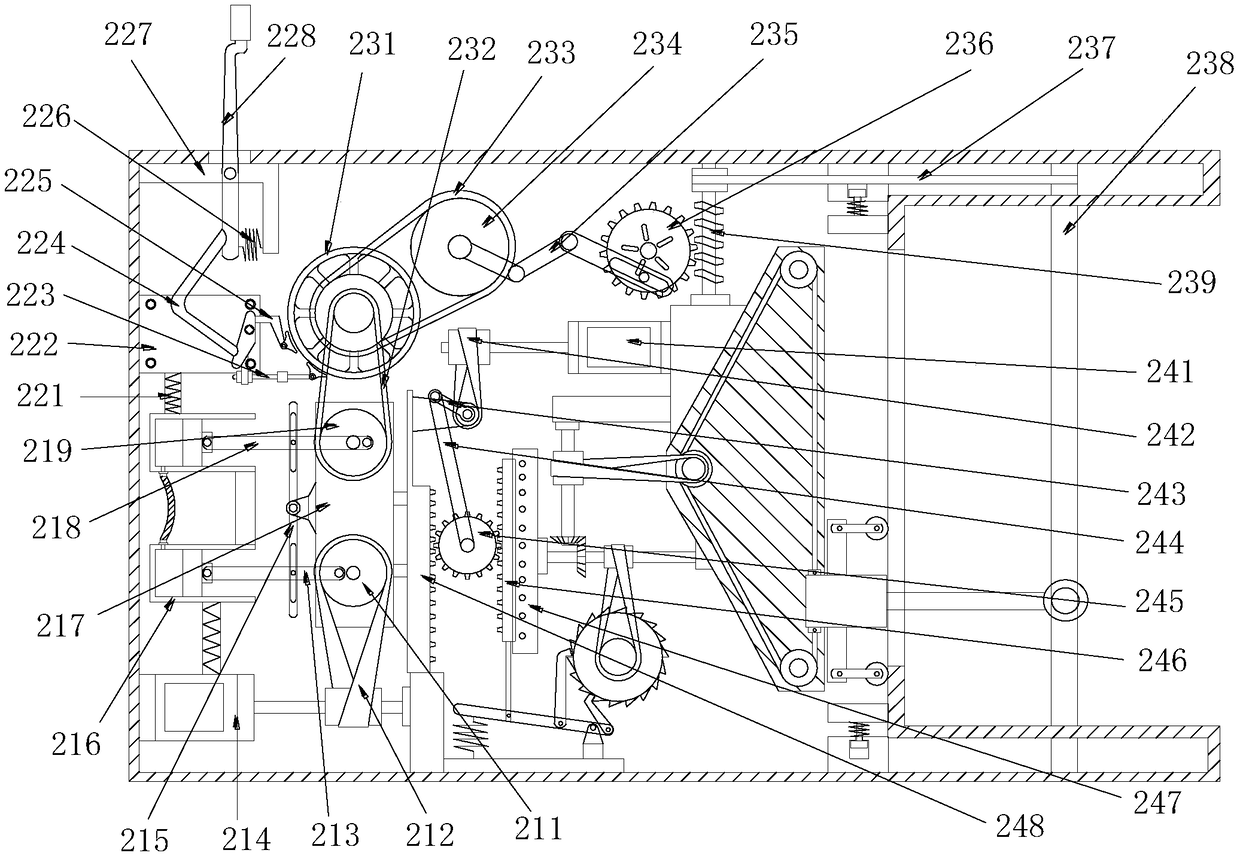

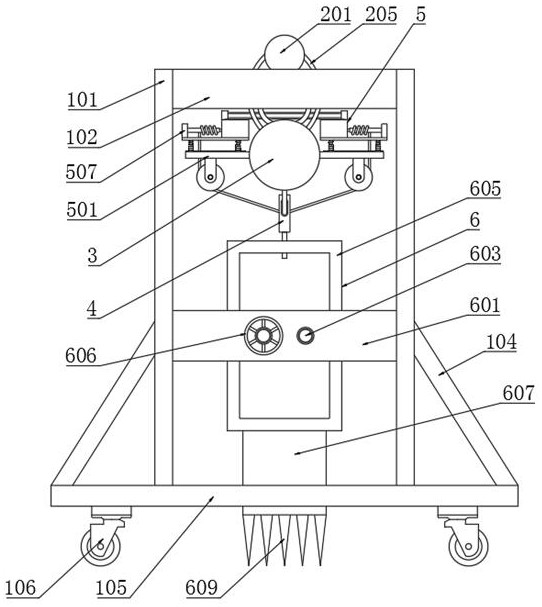

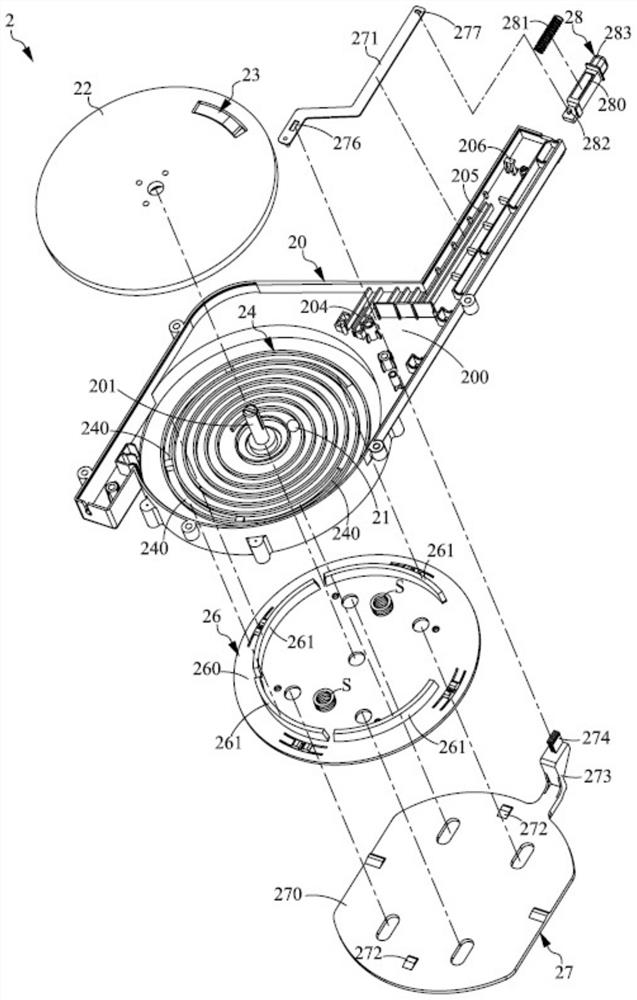

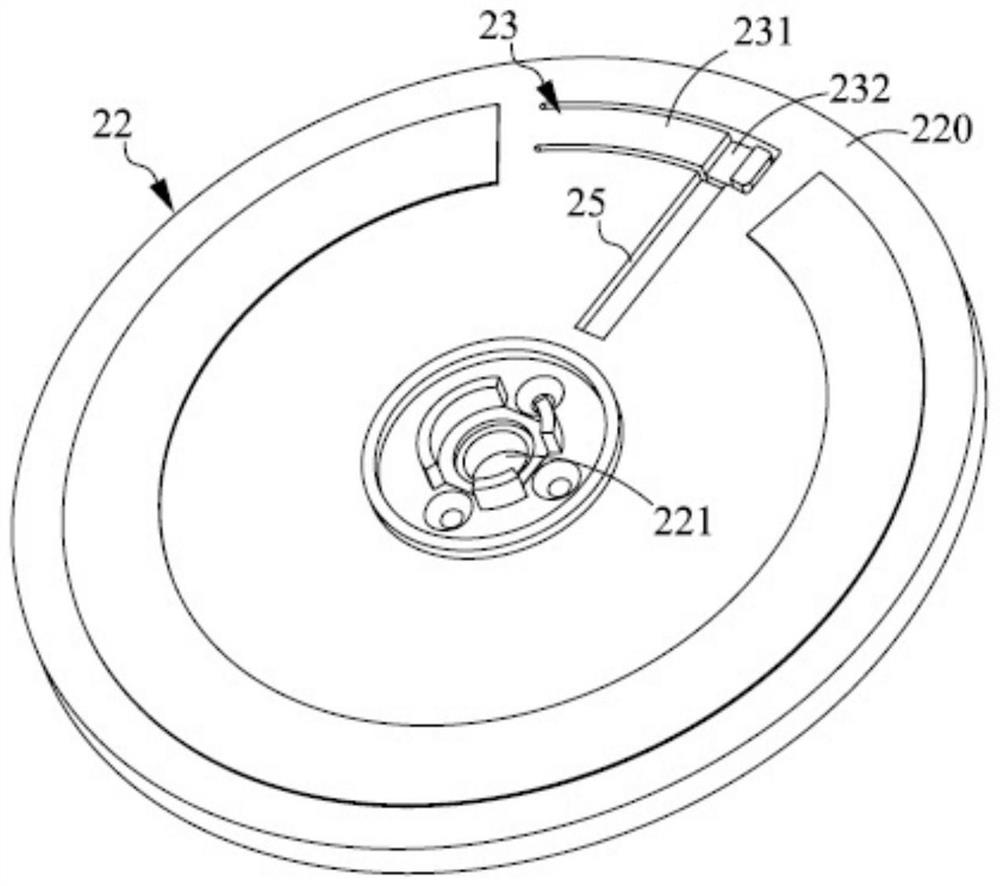

Efficient full-automatic cable taking-up and paying-off device

InactiveCN108609441AAvoid damageSlow down the winding speedPush and pullElectrical and Electronics engineering

The invention discloses an efficient full-automatic cable taking-up and paying-off device. The efficient full-automatic cable taking-up and paying-off device structurally comprises a lifting ring attached lug, a cable coiling device with a controllable rotation speed, a control panel, push-and-pull rods, a direction control rod, a control rod fixing plate, trundles, ventilation openings, trolley wheels, protective covers, an open groove and a coiling drum. The lifting ring attached lug is welded to the upper surface of the cable coiling device with the controllable rotation speed. The push-and-pull rods are embedded into the middle section of the left surface of the cable coiling device with the controllable rotation speed. The control rod fixing plate is welded to the lower end of the left surface of the cable coiling device with the controllable rotation speed. According to the efficient full-automatic cable taking-up and paying-off device, through the arranged cable coiling device with the controllable rotation speed, when the cable is taken up, if the cable bears excessively large tension, the rotation speed of a compound rotating disk 231 can be controlled, so that the taking-up speed is controlled, and the cable is prevented from being damaged; and during taking-up, the cable can be coiled into the coiling drum in tidy, and taking-up is rapid and convenient.

Owner:张晓双

Efficient charging pile for new energy vehicle

InactiveCN112659939AAvoid enteringImprove sealingCharging stationsElectric vehicle charging technologyNew energyStructural engineering

The invention discloses an efficient charging pile for a new energy vehicle, and relates to the technical field of automobile charging piles. In order to improve the safety during charging, The charging pile specifically comprises two main bodies symmetrically installed on a base, operation screens are arranged on the outer walls of one sides of the two main bodies correspondingly, second supports are fixed to the outer walls of the adjacent sides of the two main bodies through screws, handles are clamped to the second supports correspondingly, the handles are connected into internal circuits of the main bodies through roll type charging wires, and charging heads are arranged at one ends of the handles; and the circumferential outer wall, close to the charging head, of the handle is in threaded connection with a protective cover. By arranging the protective cover, the annular air cushion and other structures, the protective cover can be rotated to the handle through threads according to needs, then the charging head and a charging port of an automobile are protected, the automobile charging device is particularly suitable for external rainy and snowy weather, water can be effectively prevented from entering, and the size of the annular air cushion can be adjusted through the air bag according to actual conditions; therefore, the sealing performance is improved.

Owner:陈秋霖

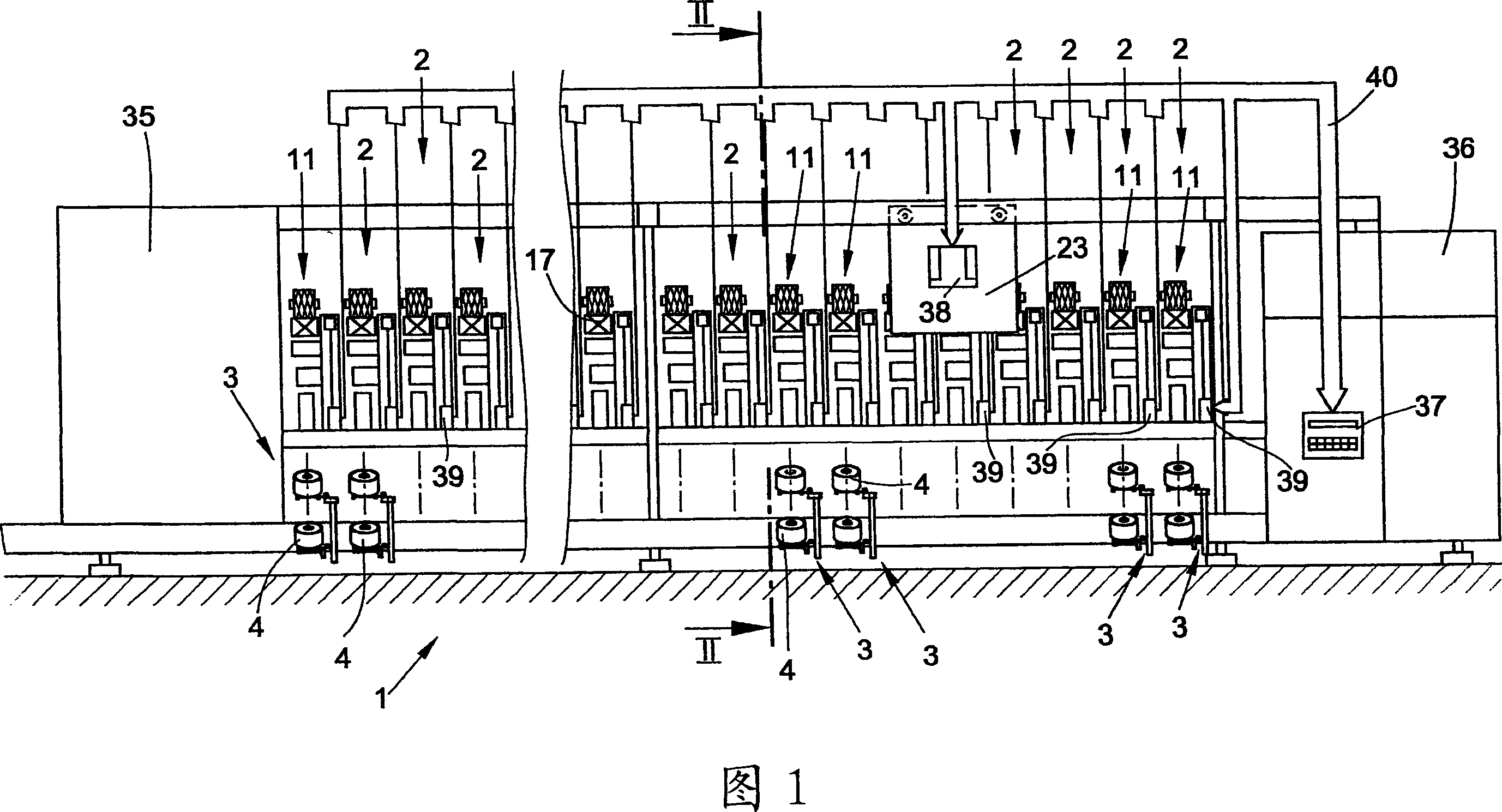

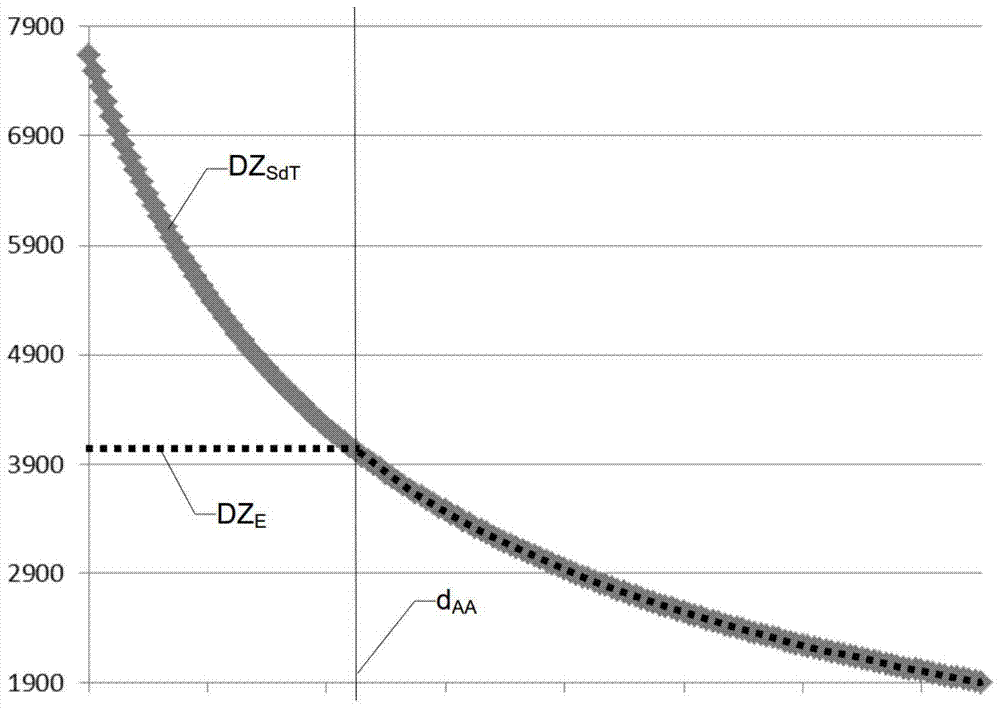

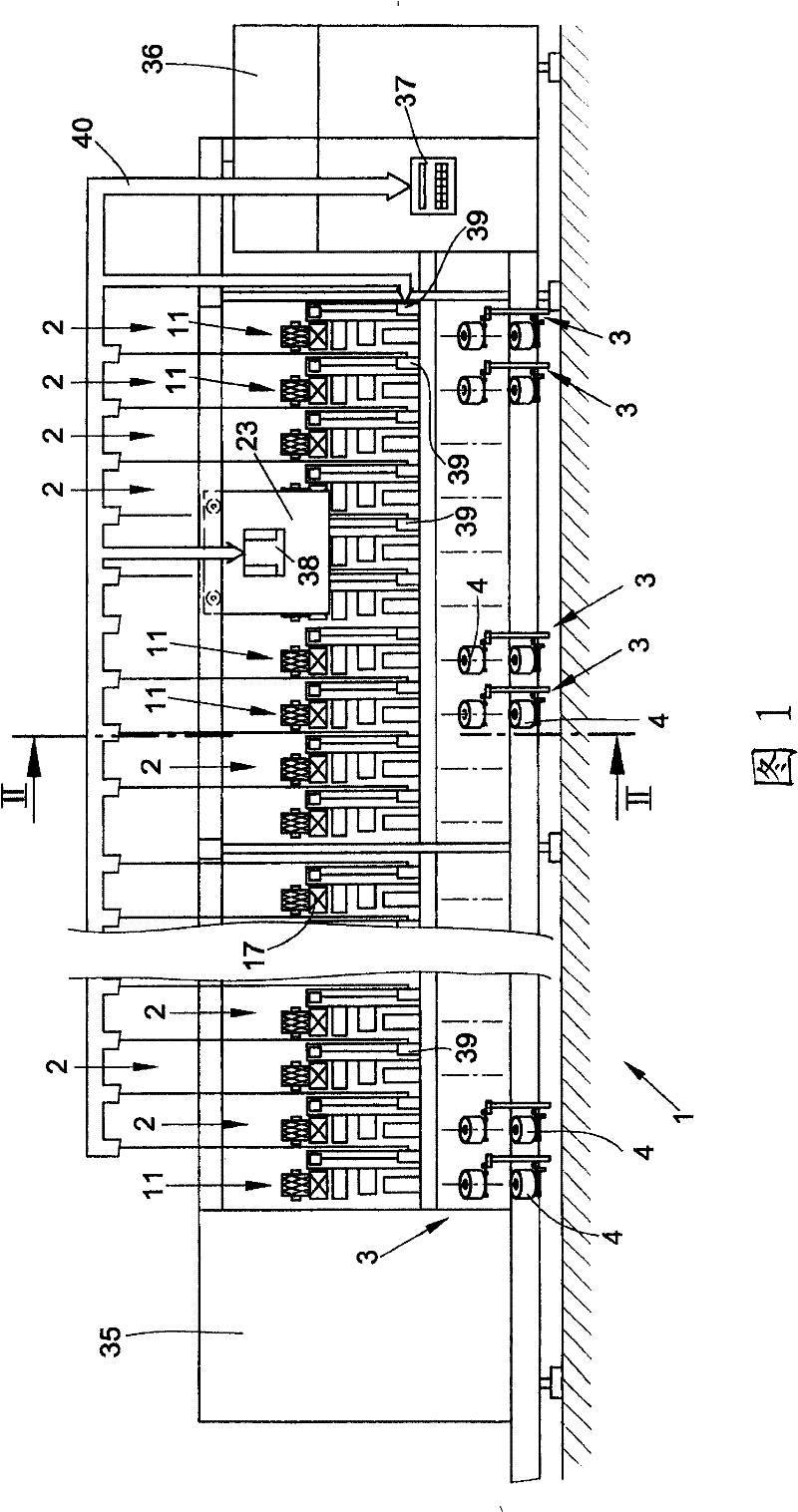

Method and device for winding a crosswound bobbin

The invention relates to a method and a device for winding a crosswound bobbin. The method is characterized in that winding operation is performed at the starting phase of a bobbin stroke at target value of winding speed; and the target value decreases relative to that of winding speed after the starting phase. The invention further relates to the device used for applying the method.

Owner:SAURER SPINNING SOLUTIONS GMBH & CO KG

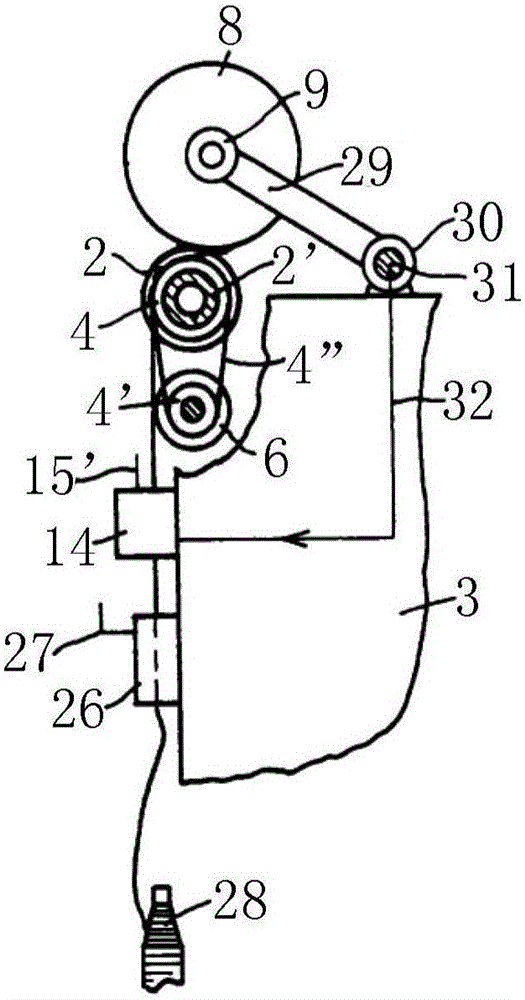

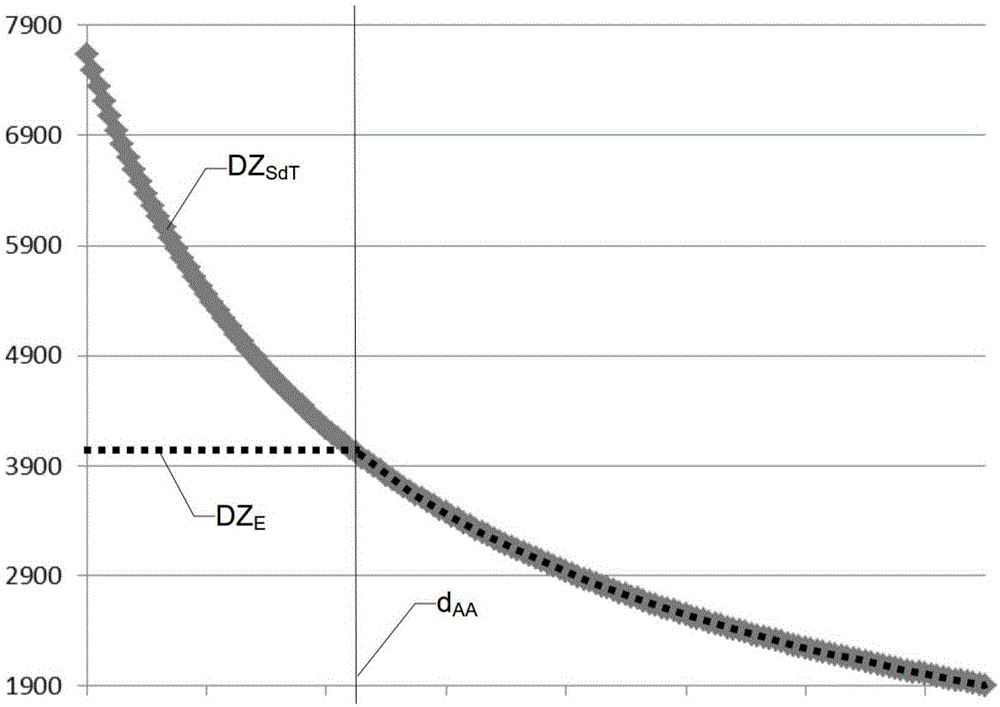

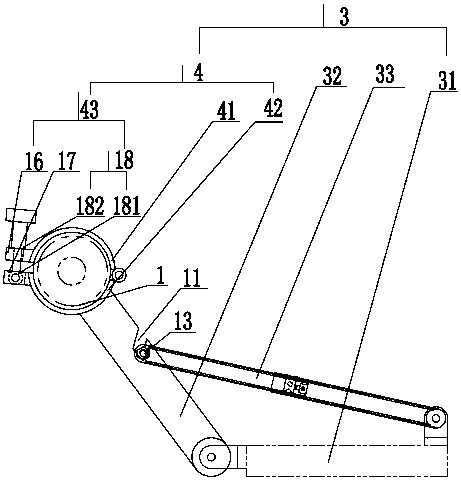

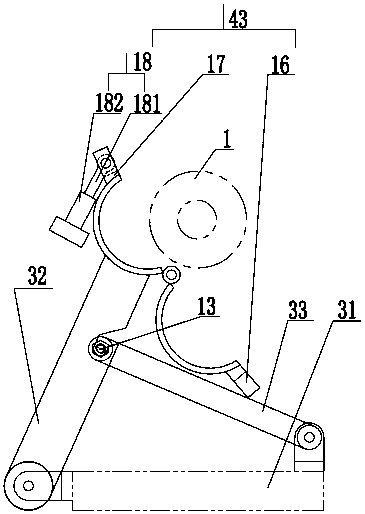

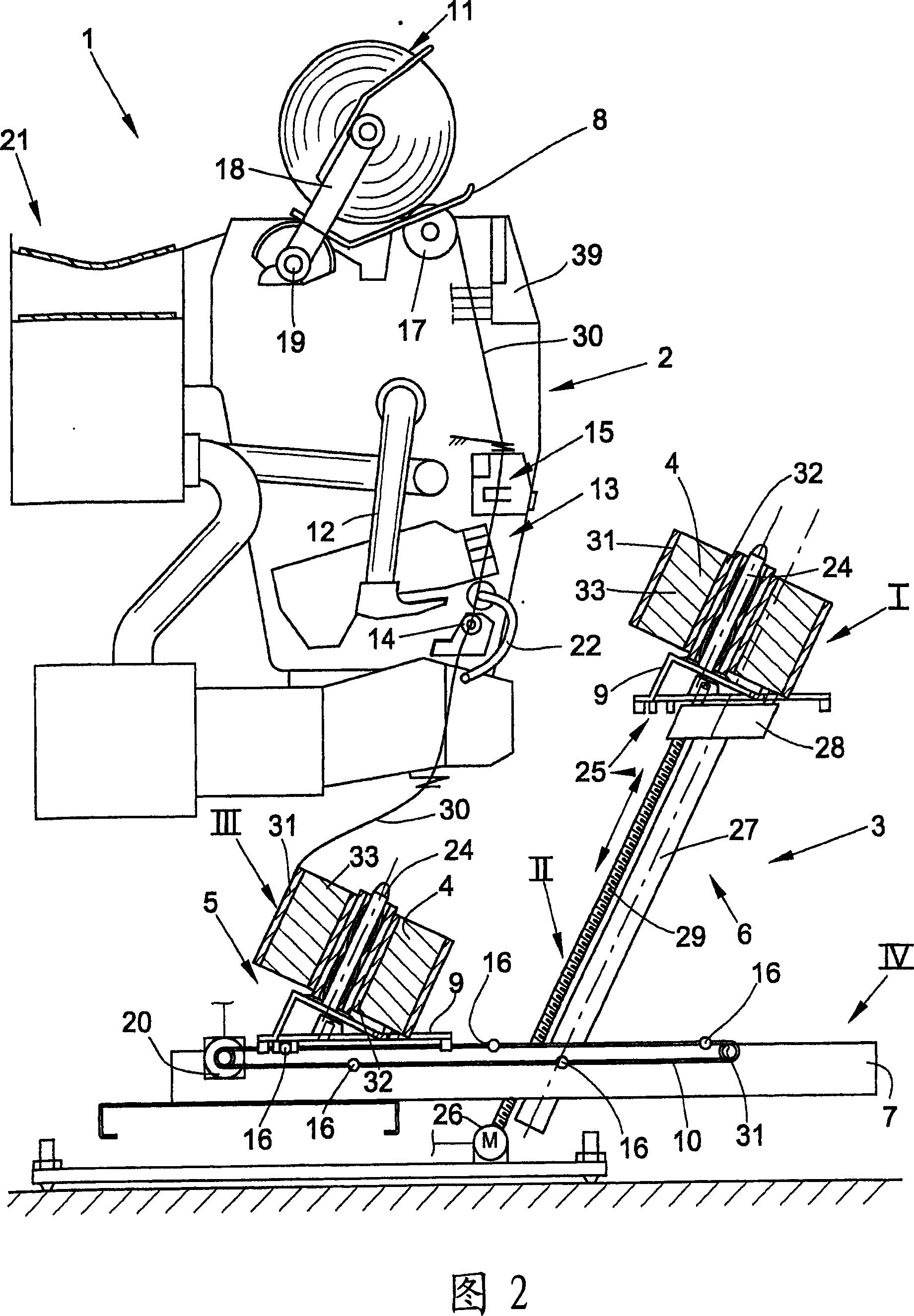

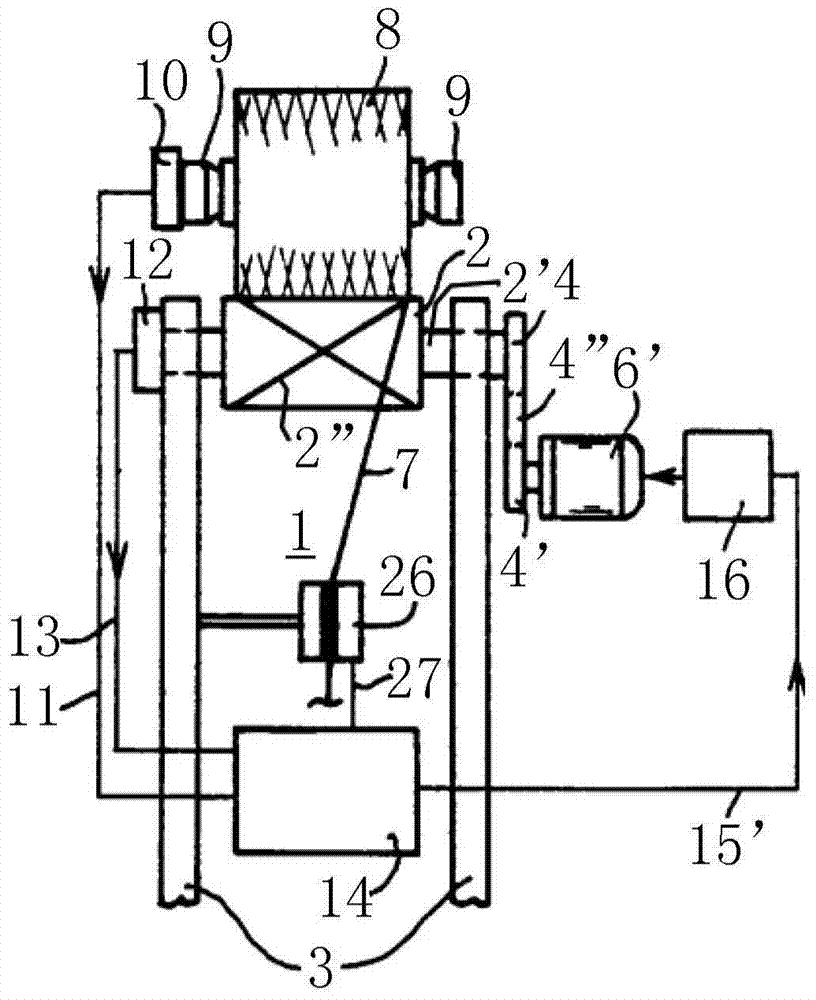

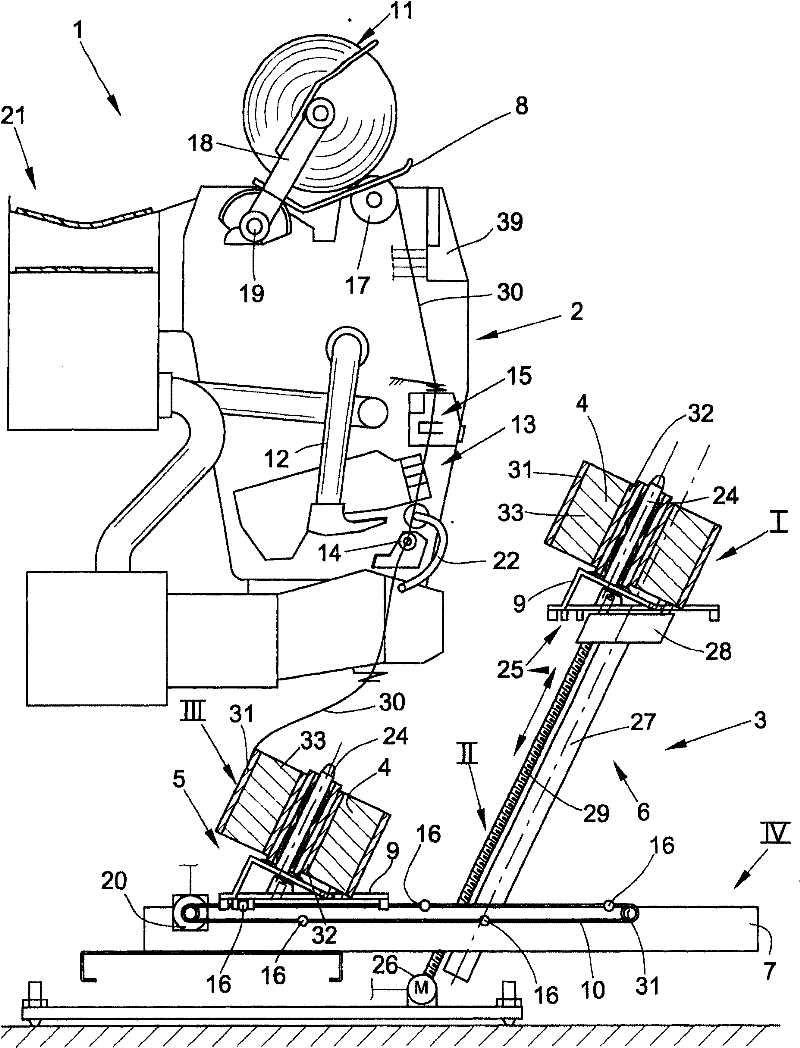

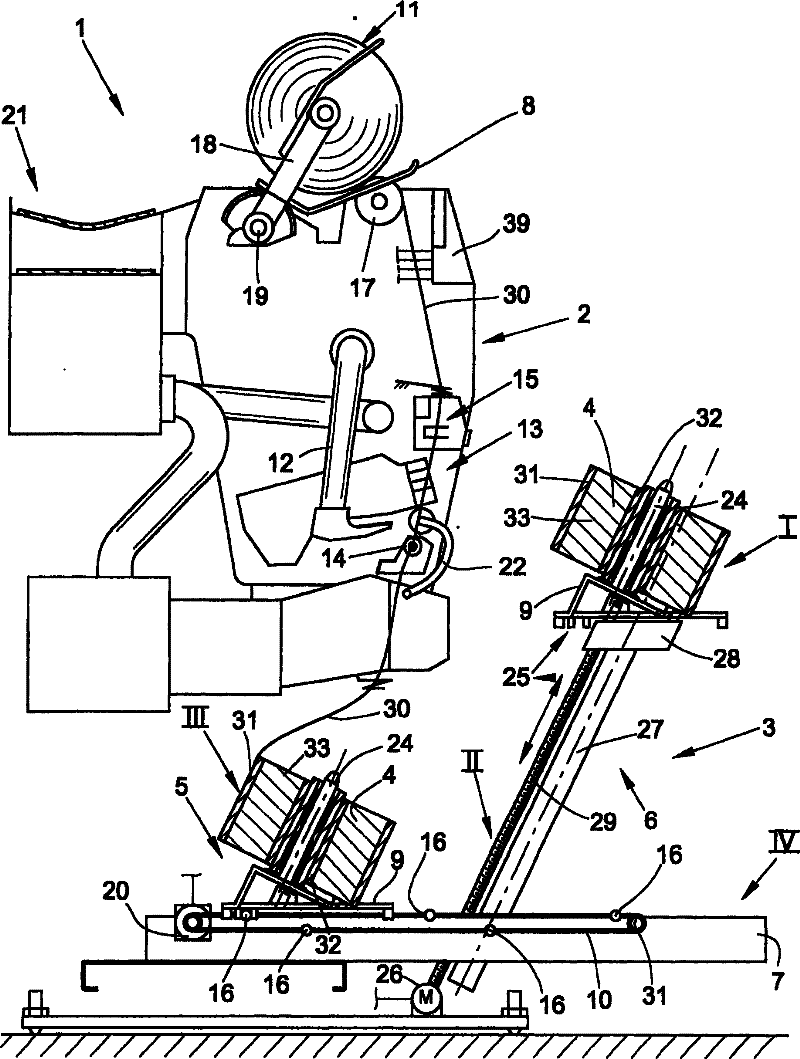

Method and device for determining the necessary speed of rotation of a coil drive roller

ActiveCN103241588AIncreased winding tensionSlow down the winding speedFilament handlingYarnEngineering

The present invention relates to a method and a device for determining the necessary speed of rotation of a coil drive roller, which particularly reduces rotation speed fluctuation of crossly wound coils (8) when a winding stroke is started. In a station (2) of a spinning machine (1), besides cylindrical crossly wound coils (8), conical crossly wound coils are manufactured in a so-called twisting winder (4). For the uniform roller structure, feeding of a constant winding tension to the yarn (7) is very important. Winding tension fluctuation can cause yarn fracture besides yarn layer loosening, and affects continuous spinning and winding processes. For preventing this effect, the invention prescribes that: angular momentum of the crossly wound coils (8) is detected through the sensor and calculated according to time sequence of a corresponding driving diameter before paving or splicing, so as to select the rotation speed of the coil drive roller (10) before the winding stroke.

Owner:SAURER GERMANY GMBH & CO KG

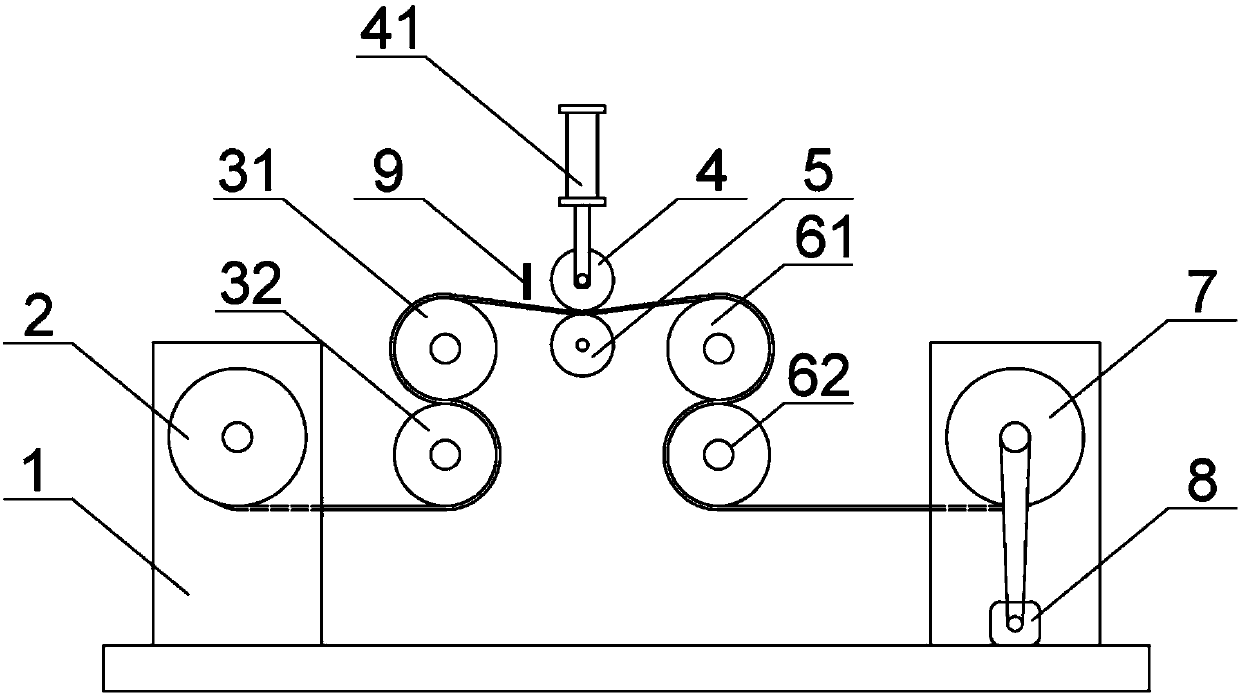

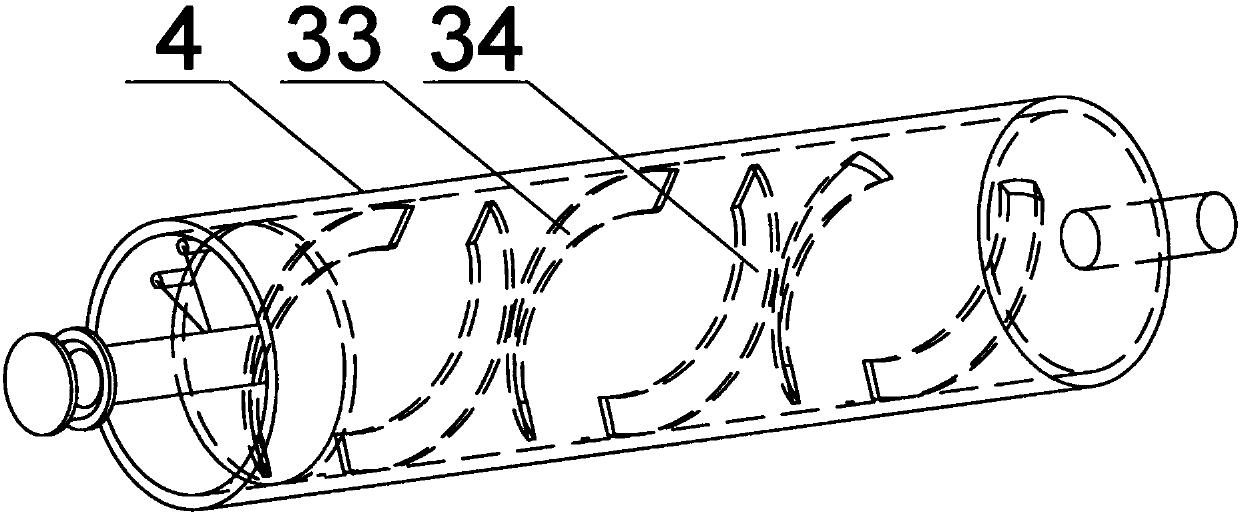

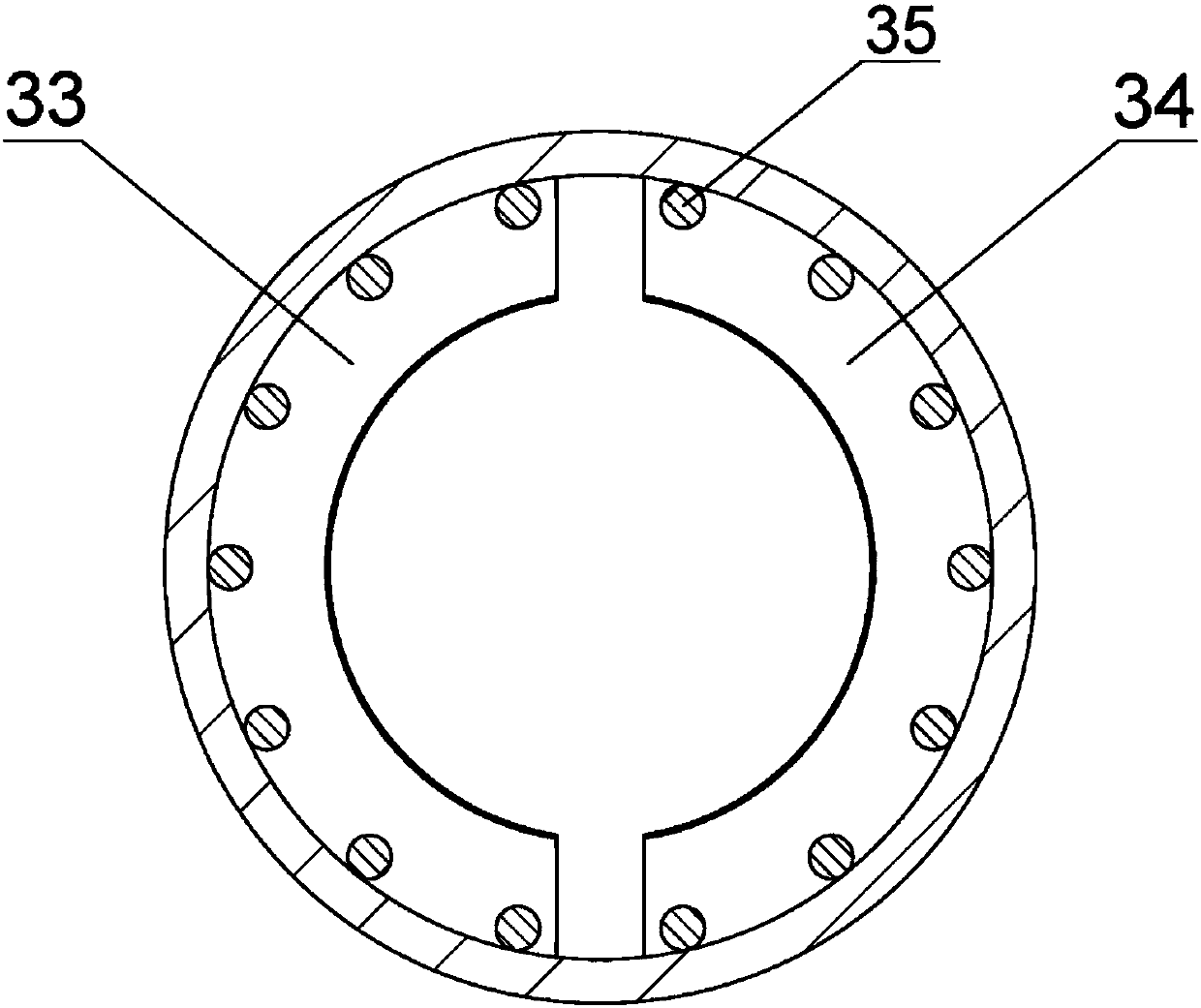

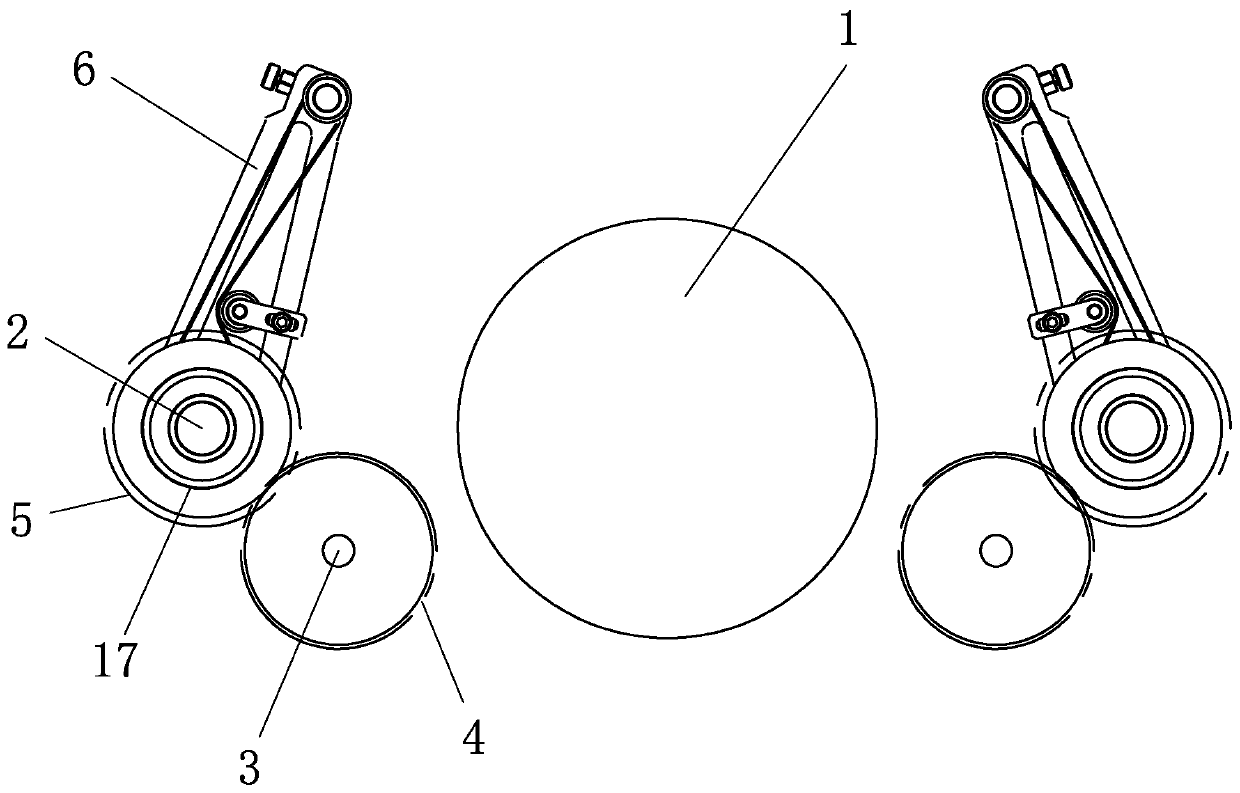

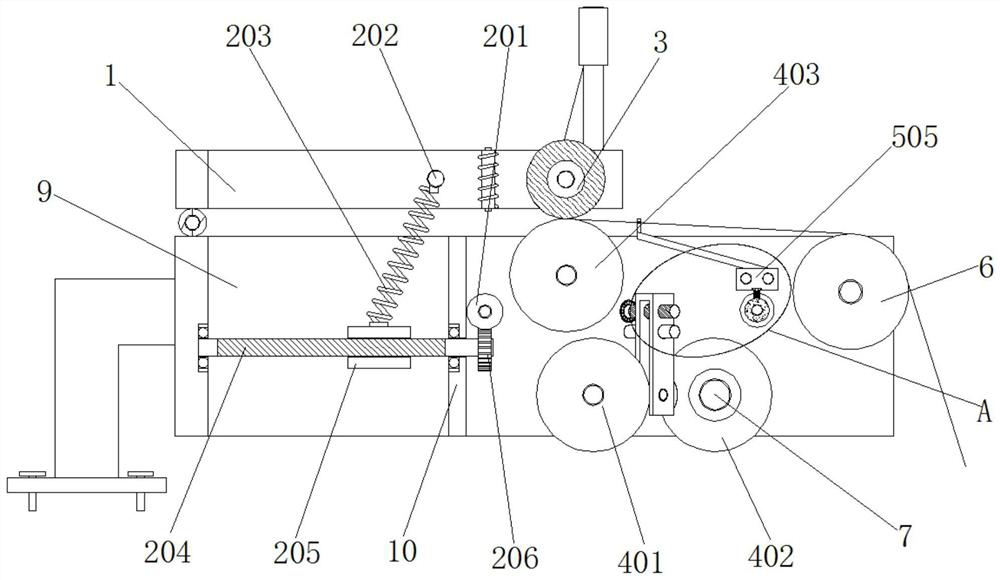

Material strap winding device

PendingCN108529339AGuaranteed winding qualityGuaranteed work efficiencyFilament handlingWebs handlingEngineeringWind speed

The invention discloses a material strap winding device. The winding device solves the problem that a traditional winding device is low in material strap winding quality and low in working efficiency.The winding device comprises a winding shaft, the winding shaft is connected with a power device, a material winding pipe used for winding a film is arranged on the winding shaft, the winding shaft and the material winding pipe are concentrically matched, a friction type differential device is arranged between the winding shaft and the material winding pipe, the winding shaft drives the materialwinding pipe to rotate through the friction type differential device and is provided with a rocker arm loading and unloading mechanism. According to the winding device, the friction type differentialdevice drives the material winding pipe to rotate for material winding, when a relatively thick material is wound around the material winding pipe, the tightening force of the material winding pipe isincreased, the friction type differential device and the material winding pipe slide relative to each other, the winding speed of the material winding pipe is decreased, the tightness degrees of material straps with the thickness difference wound around the winding pipe are the same in unit time, so that the winding quality can be ensured, the winding shaft can be directly disassembled through the rocker arm loading and unloading mechanism after winding is completed, quick unloading can be carried out, and the working efficiency can be guaranteed.

Owner:ZHOUSHAN JINQIU MACHINERY

Synthetic leather embossing equipment

The invention discloses synthetic leather embossing equipment. A feeding roller, a heating roller, an embossing roller, a backpressure roller, a cooling roller and a collecting roller are rotatably mounted on a rack, the heating roller and the cooling roller are positioned between the feeding roller and the collecting roller, a gap for synthetic leather to pass is reserved between the embossing roller and the backpressure roller which are arranged oppositely, the collecting roller is driven by a servo motor, an infrared temperature sensor for detecting temperature of the synthetic leather is arranged between the heating roller and the embossing roller, and a control system controls rotating speed of the servo motor according to the temperature detected by the infrared temperature sensor tocontrol speed of the collecting roller in rolling the synthetic leather, controls the rotating speed of the servo motor to be increased when the temperature of the synthetic leather is too high and controls the rotating speed of the servo motor to be decreased when the temperature of the synthetic leather is too low, so that the temperature of the synthetic leather after being heated is constantly maintained within a certain temperature range to realize optimal embossing effect.

Owner:GUANGDE DAJIN MACHINERY

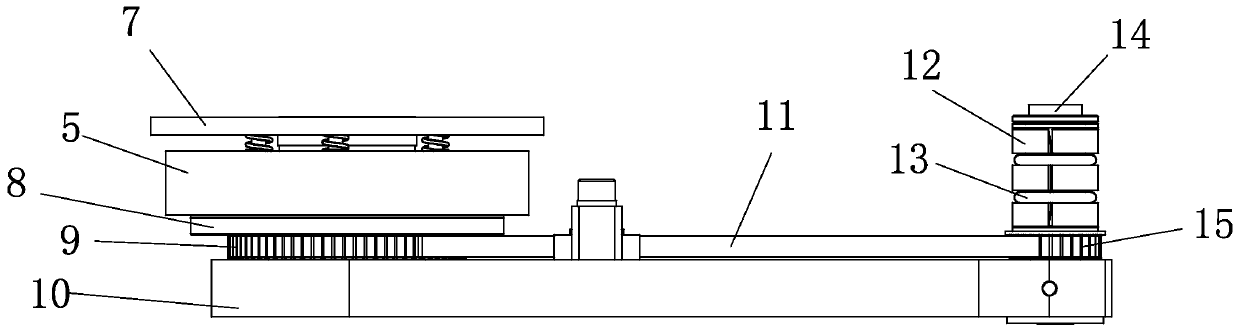

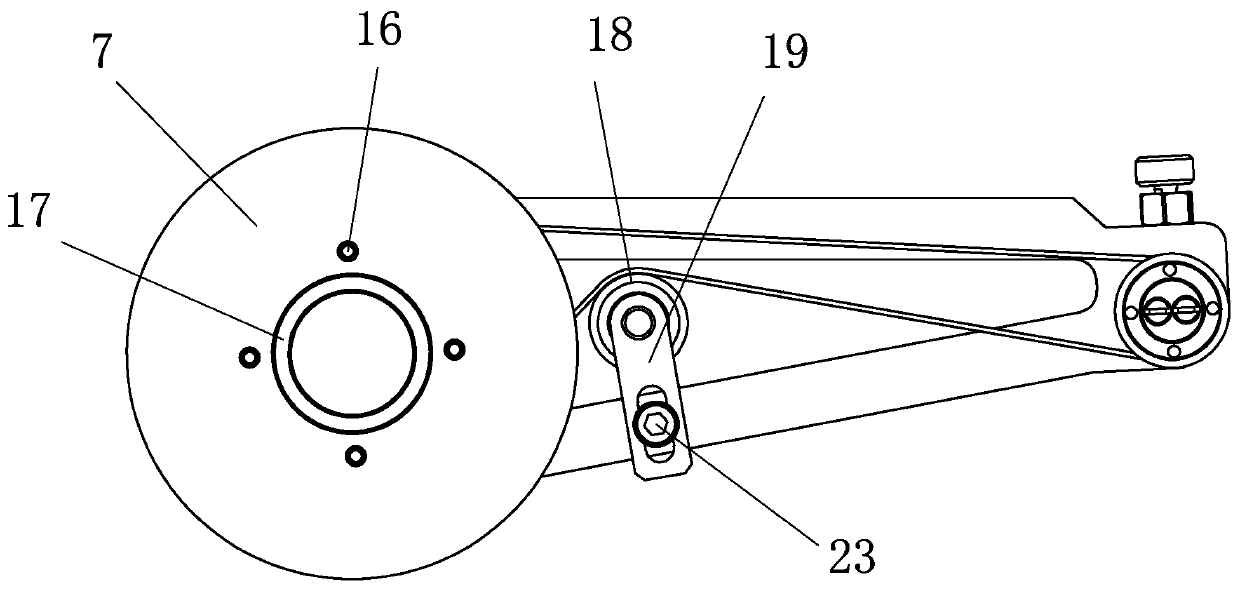

Winding device

InactiveCN110371727ADoes not affect transmissionImprove efficiencyWebs handlingPull forceDrive wheel

Owner:江门市利业机电设备有限公司

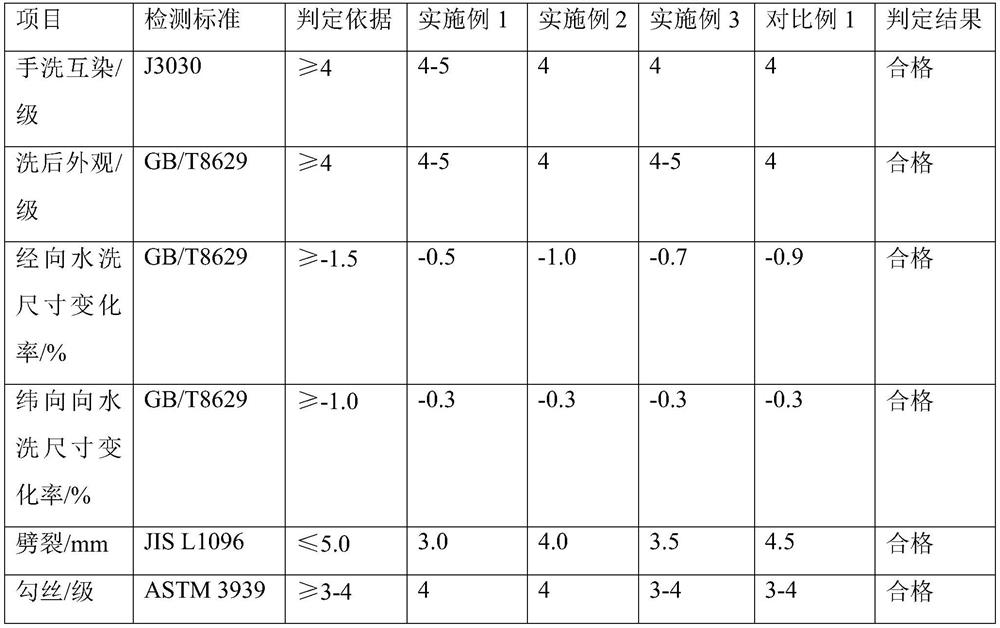

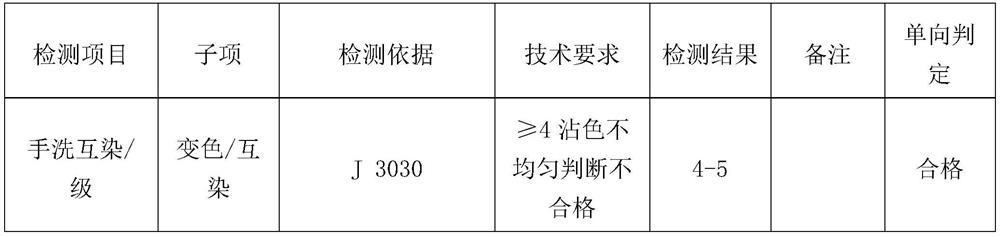

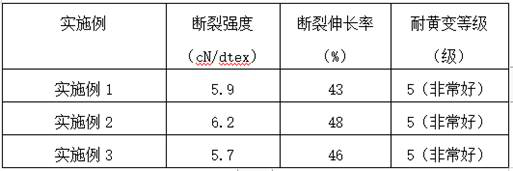

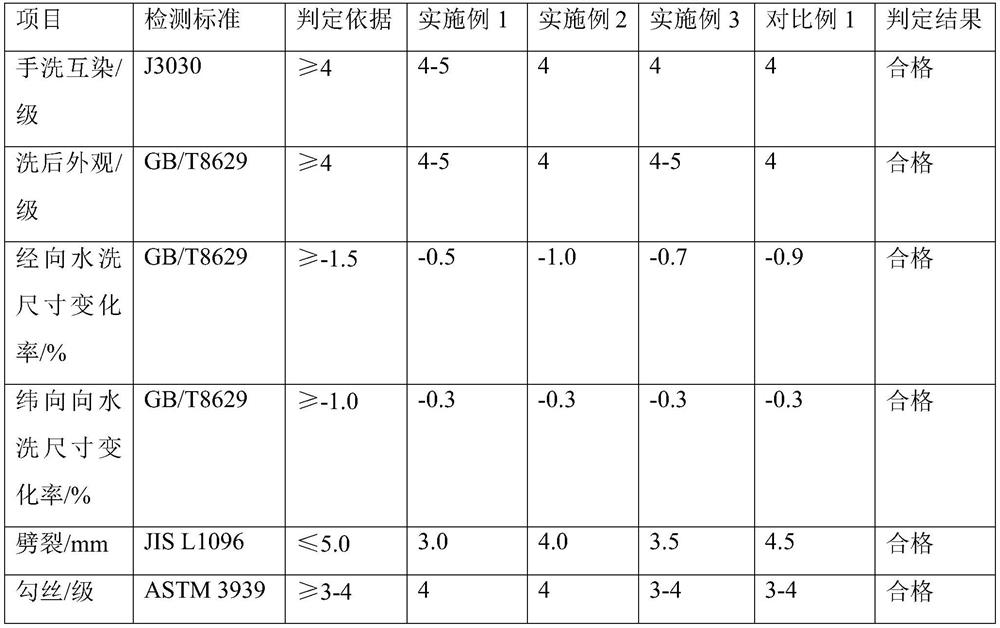

Preparation method of superfine-denier nylon fibers and ultra-light fabric, and ultra-light coat

ActiveCN112301441AStrongHigh strengthElectroconductive/antistatic filament manufactureOvergarmentsPolymer sciencePhosphite salt

The invention discloses a preparation method of superfine-denier nylon fibers. The preparation method comprises the following steps that (1) the following components are weighed in parts by weight: 96-99 parts of nylon 66 chips, 0.35-2 parts of TiO2 extinction master batch, 0.05-1 part of a phosphite antioxidant, 0.05-0.5 part of fatty alcohol phosphate and 0.05-0.5 part of a polyethylene glycol antistatic agent, wherein the model of the nylon 66 chips is CM3006, the relative molecular weight is 25000-30000, and the viscosity is 2.8-2.9; (2) the raw materials weighed in the step (1) are prepared into nylon fibers with the filament number being 0.3-0.5 dtex through a melt spinning method, wherein in the melt spinning process, the melting temperature is 260-290 DEG C, the number of holes ofa spinneret plate is 5-30, the hole diameter is 0.1-0.2 mm, the winding speed is 300-500 m / min, the winding temperature is 18-19 DEG C, and the finished product ratio is 92% or above. The invention meanwhile provides a preparation method of a ultra-light fabric and an ultra-light coat. According to the preparation method of the superfine-denier nylon fibers, the superfine-denier nylon fibers can be prepared, and the finished product ratio can be guaranteed to be 92% or above.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

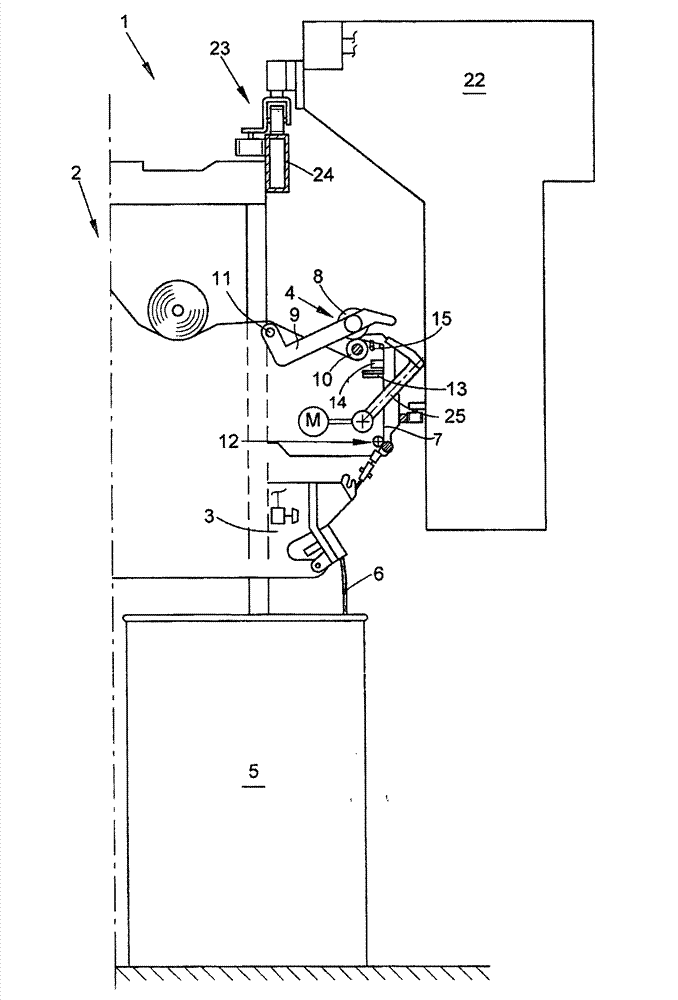

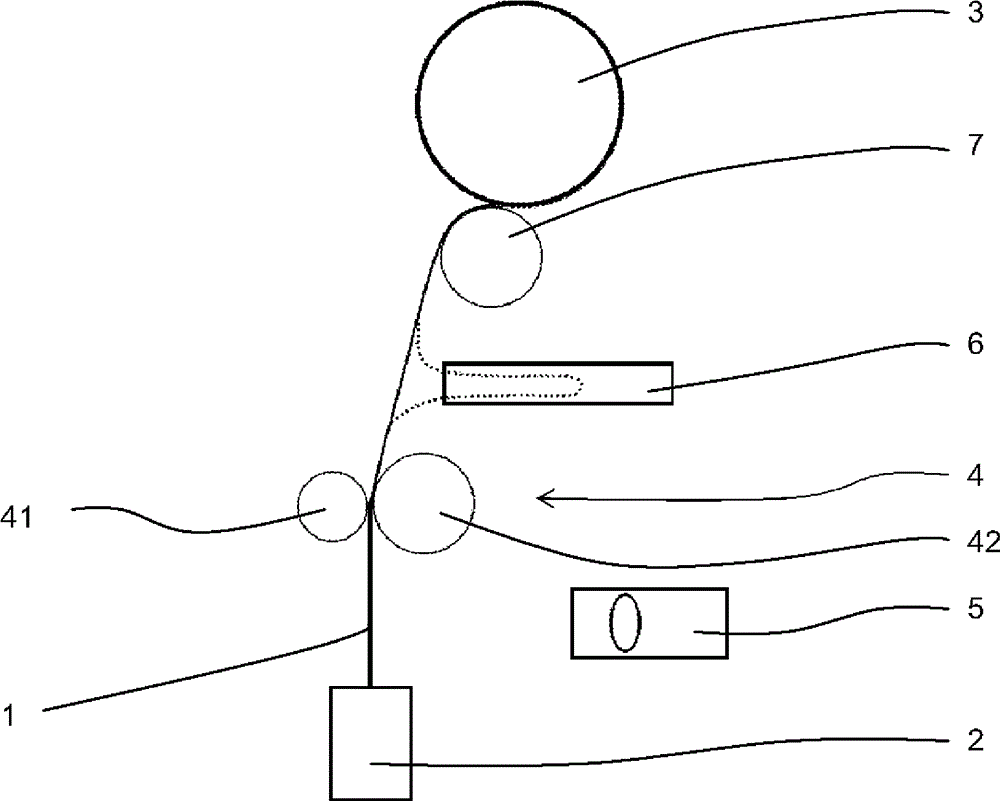

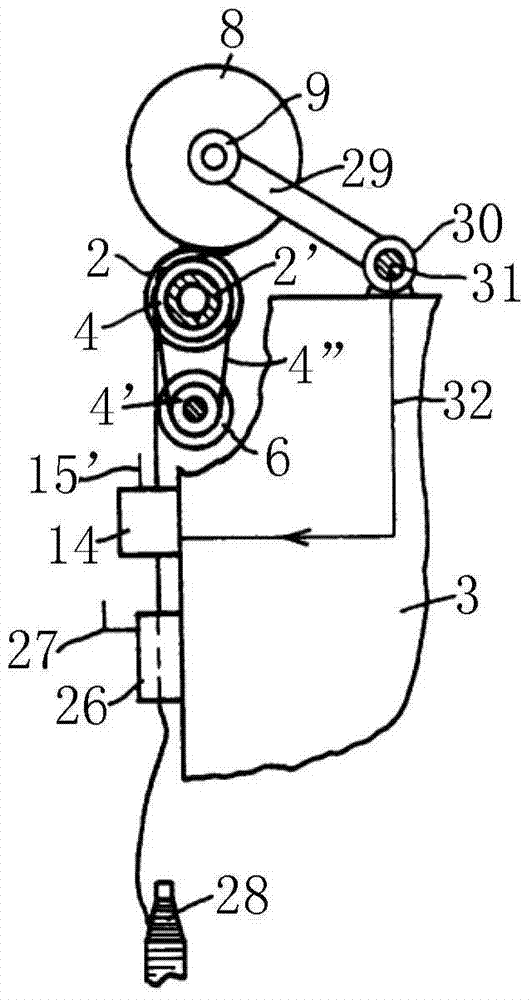

Method for performing single repiecing operation on yarn at work station position of free-end spinning machine

InactiveCN105088440AFast winding speedSlow down the winding speedContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention relates to a method for performing single repiecing operation on a yarn at a work station position of a free-end spinning machine. An electronic control unit (5) enables a lead-out roller (42) to rotate in an opposite direction by means of independent drive of the lead-out roller (42) of a lead-out mechanism (4), thus an end of the yarn (1) is sunken into a gathering tank of a rotary spinning rotor through a lead-out tube of a spinning unit (2), the end of the yarn (1) contacts a fiber belt and is involved. So, after a delay needed and used by the repiecing operation, the control unit (5) enables the lead-out roller (42) of the lead-out mechanism (4) and a winding rolling drum (7) to rotate by means of the independent drive in a direction that the yarn (1) is winded to a yarn cylinder (3), and a joint part and the subsequently spun yarn (1) are drawn out from the spinning rotor of the spinning unit (2) and are winded to the yarn cylinder (3). And a standby part of the yarn (1) or a standby part of the yarn (1) in an undervoltage compensator (6) lengthening the length of the yarn is formed again and then is gradually winded to the yarn cylinder (3).

Owner:RIETER CZ AS

High-temperature-resistant olive modified polyamide fiber and preparing method thereof

InactiveCN111621870ARich functionalityMeet needsMicroballoon preparationArtifical filament manufactureHydroxytyrosolPolymer science

The invention provides a high-temperature-resistant olive modified polyamide fiber. The content of an olive leaf extract in the fiber is 1.0%-5.0%. The preparation method of the polyamide fiber comprises the following steps of 1, preparing olive leaf modified double-layer microcapsules; 2, preparing olive leaf functional modified master batches; 3, conducting mixing and melting; and 4, conductingspinning and post-processing. The olive modified polyamide fiber prepared by the method contains olive leaf extract components, particularly oleuropein and hydroxytyrosol in the olive leaf extract, isa natural additive with natural antibacterial and anti-ultraviolet functions, can provide more functions, and meets the requirements of different consumers.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

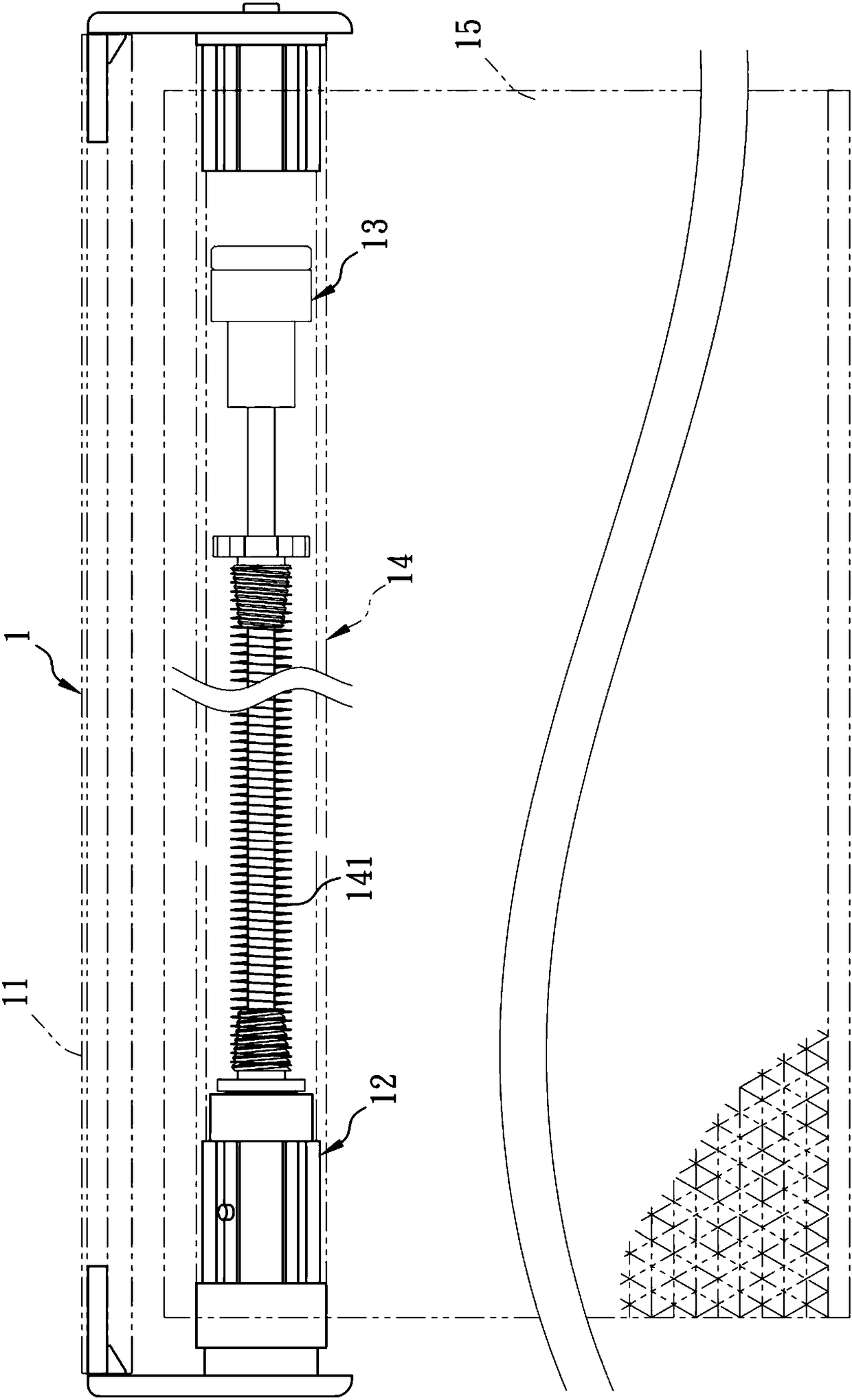

Miniature roller shutter buffer unit

InactiveCN108691501AThe outer diameter of the volume is reducedEasy to useDoor/window protective devicesEngineeringMechanical engineering

A miniature roller shutter buffer unit comprises a housing, a sleeve arranged in the housing on one end, an oil seal sleeved on the sleeve rim so as to form a sealed space in the housing, an outer sleeve fixedly jointed with one end top of the housing in one piece, a spring facing away from the housing and winding on the sleeve rim of the outer sleeve, a rotary body that allows the sleeve winded by the spring to joint and engage so as to realize embedment and rotation between the spring and the sleeve, a seal cover sleeved on the sleeve rim and synchronically rotates, and a fixed member facingaway from the end of the housing and fixed with the seal cover and the sleeve. The buffer unit is small in size, suitable for a window roller shutter and a miniature roller shutter in a vehicle doorof a limited thickness, so the roller shutter can stretch and contract with a buffer effect.

Owner:王智永

Inner ring type metal fiber infrared radiation combustor for yarn production

The invention relates to the technical fields of textile equipment and metal fiber infrared combustion, and particularly discloses an inner ring type metal fiber infrared radiation combustor for yarn production. The inner ring type metal fiber infrared radiation combustor for yarn production can process yarn in an infrared thermal radiation mode and combust yarn hairness exposed out of the surface of the yarn. The inner ring type metal fiber infrared radiation combustor for yarn production is mainly applied to a production process of the yarn. For yarn finished products prepared through the inner ring type metal fiber infrared radiation combustor, fibers cohere closely, the yarn is smooth, free of the hairness and good in gloss, and textiles are clear in grain and good in wearability.

Owner:新乡市新诚纺织有限公司

Method for rewinding dye bobbins to cross-wound bobbins

This invention relates to a method for rewinding the dyeing bobbin (4) onto a cross winding bobbin (11), wherein at the time of rewinding beginning and / or ending, the yarn (30) to unwrap from the dyeing bobbin (4) is unwrapped a defined length at a winding speed which is less than the winding speed arranged for the yarn (30) to rewind.

Owner:SAURER GERMANY GMBH & CO KG

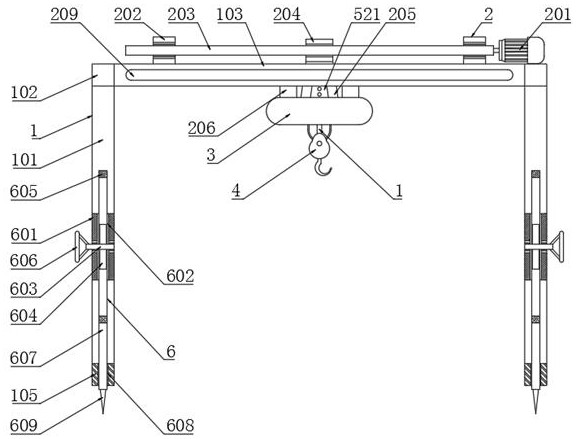

Bridge gantry crane hanging bracket and using method thereof

PendingCN113911906AAvoid shakingReduce shakingBase supporting structuresBraking devices for hoisting equipmentsStructural engineeringControl theory

The invention discloses a bridge gantry crane hanging bracket and a using method thereof. The bridge gantry crane hanging bracket comprises a gantry frame assembly for supporting, an electric hoist used for completing lifting work, a driving mechanism which is arranged at the top of the gantry frame assembly and is used for driving the electric hoist to move left and right, and a self-balancing assembly which is arranged on the surface of the electric hoist and is used for adaptively adjusting and reducing swing of a lifting hook; the lifting hook is movably arranged at the bottom of the electric hoist. One pulling rope can be pulled through shaking of the lifting hook, and the pulling rope drives a mounting plate in the position to be pulled downwards, so that two fixing boxes are not at the same height, an electric contact on the inner wall of one fixing box is completely immersed by mercury liquid, and at the moment, a current loop is formed; and the pulling rope in the lower position is controlled to pull the lifting hook, so that the shaking amplitude of the lifting hook is shortened, the lifting hook is prevented from continuously shaking towards one end, and the situation that a lifted object swings and shakes to cause damage is prevented.

Owner:李蕾

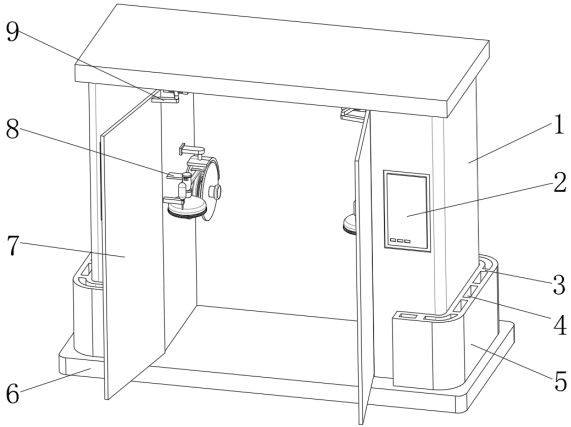

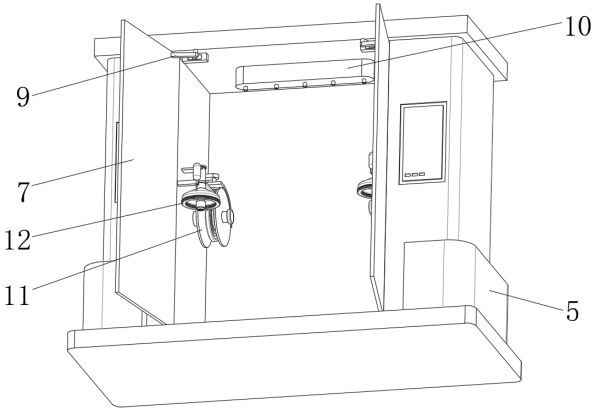

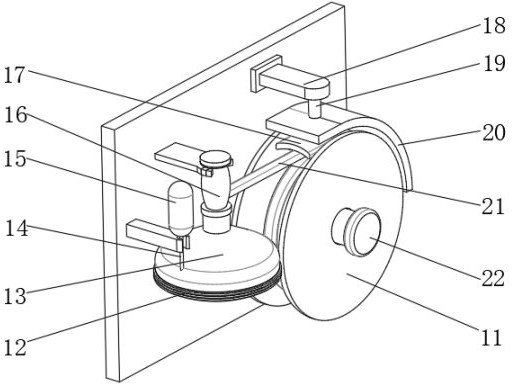

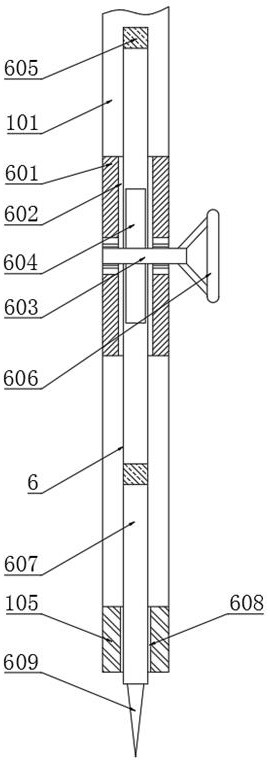

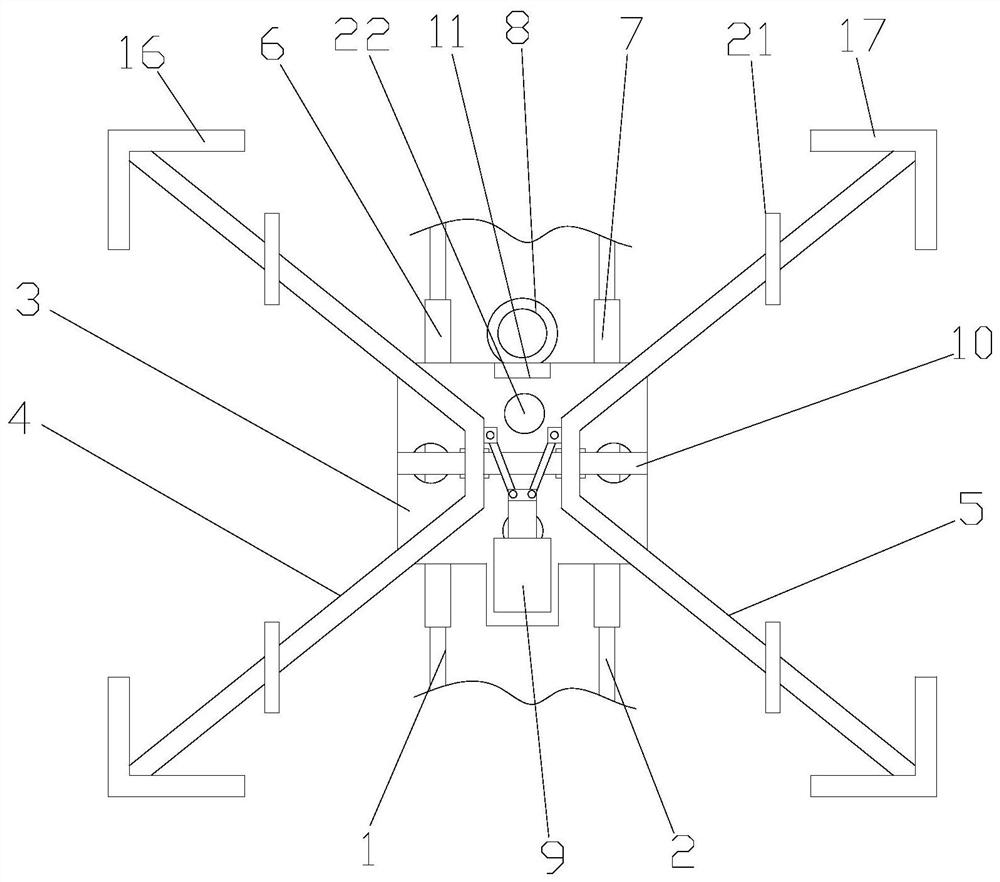

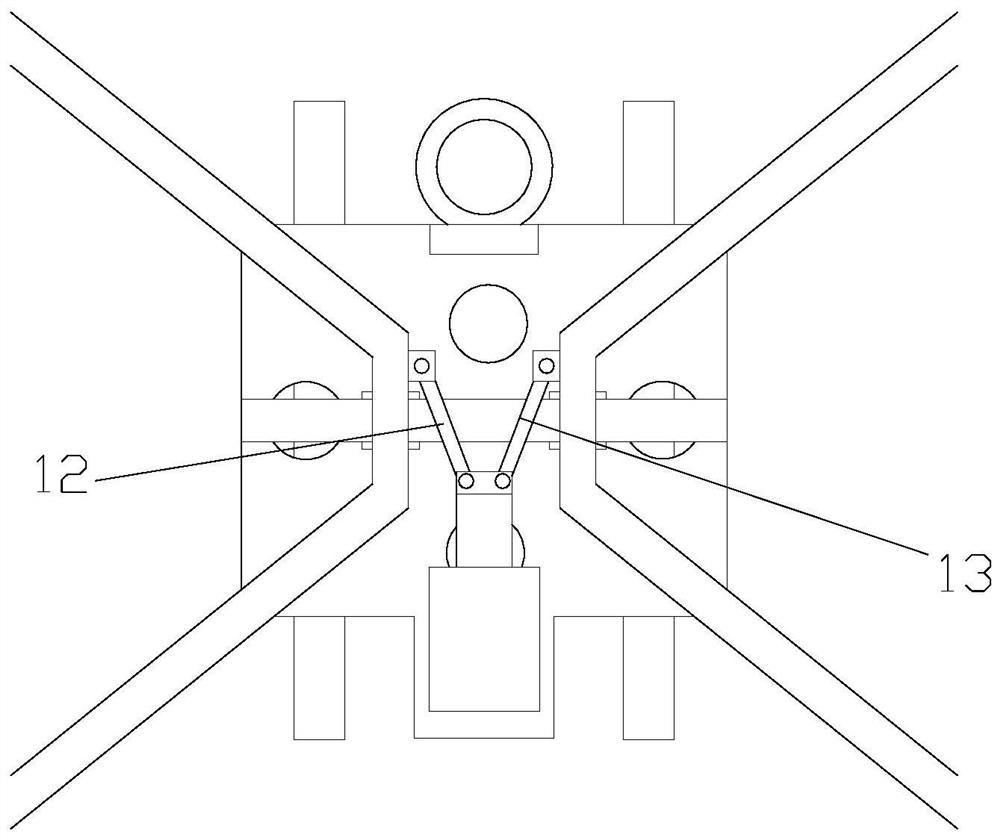

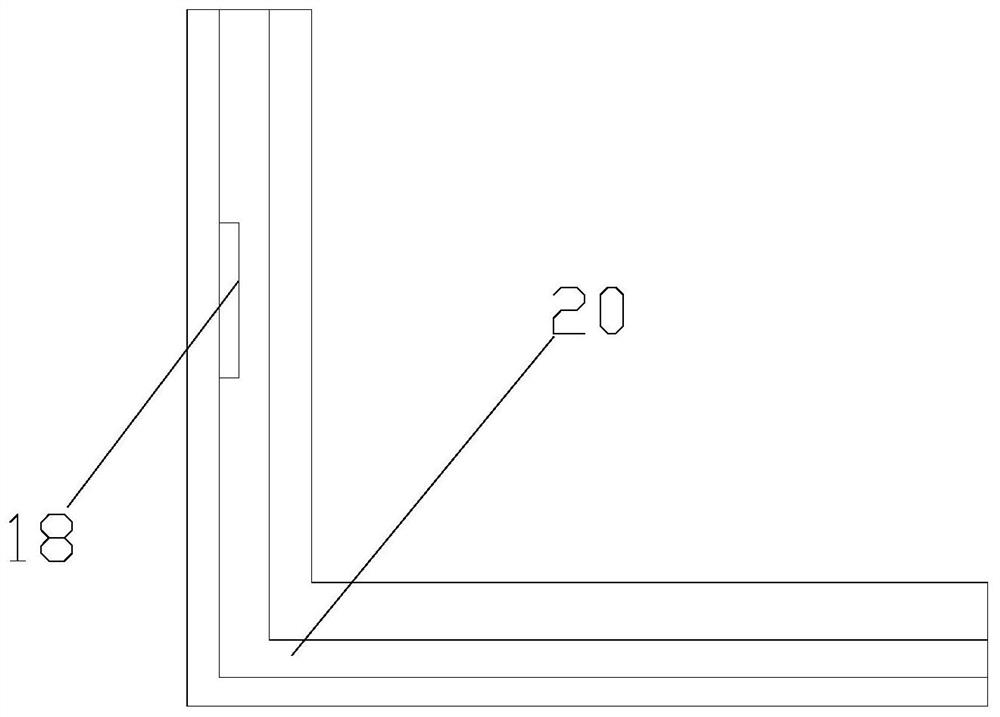

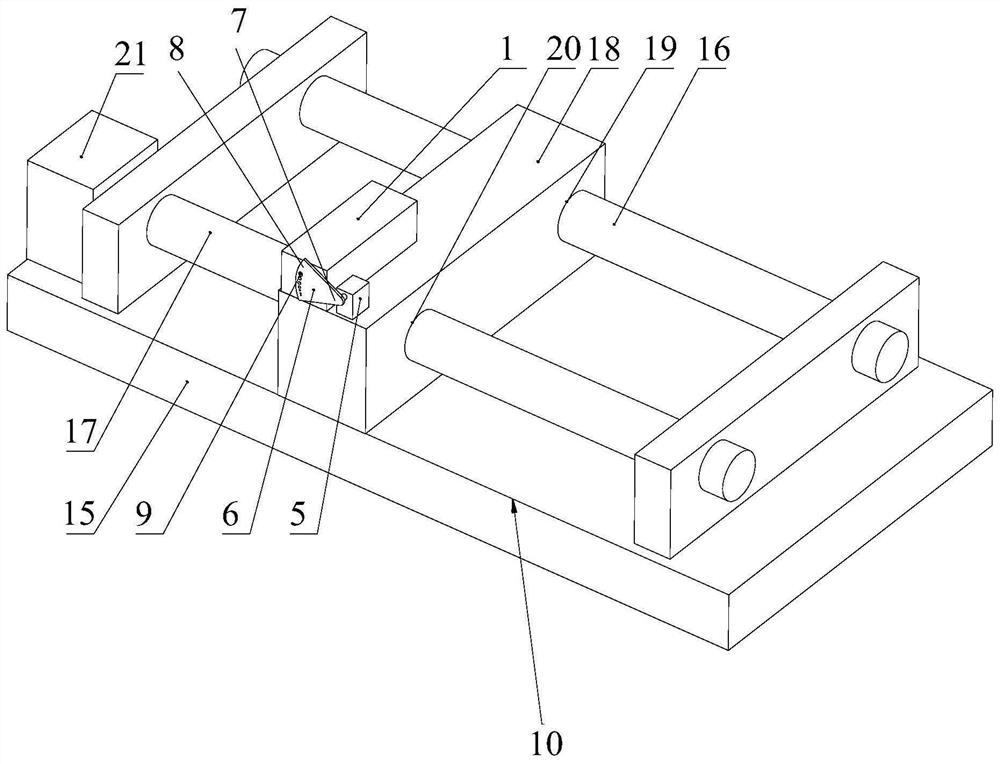

An intelligent hoisting device for building glass curtain walls

ActiveCN110817684BStable deliveryAchieve clampingNon-rotating vibration suppressionLoad-engaging elementsArchitectural glassWinch

The invention discloses intelligent hoisting equipment for a building glass curtain wall. The equipment comprises a winch, a first guide cable, a second guide cable and a glass curtain wall clamp, wherein the glass curtain wall clamp comprises a connecting middle plate, a left V-shaped clamp arm and a right V-shaped clamp arm, a first linear bearing matched with the first guide cable and a secondlinear bearing matched with the second guide cable are arranged on the back surface of the connecting middle plate, a connecting ring bound by a winch rope is arranged on the connecting middle plate,a driving air cylinder, a guiding linear guide rail and a control device are arranged on the front surface of the connecting middle plate, the driving air cylinder is fixedly connected with the connecting middle plate, a first slider and a second slider are arranged on the guiding linear guide rail, and the left V-shaped clamp arm and the right V-shaped clamp arm are fixedly connected with the first slider and the second slider respectively. The intelligent hoisting equipment for the building glass curtain wall can carry out high-speed conveying, and the working efficiency is high.

Owner:江西中一建工集团有限公司

Constant-speed winding device for avoiding winding stall in field of adhesive tape packing tapes

InactiveCN112374233ASlow down the winding speedAvoid interestsWebs handlingAdhesive beltControl theory

The invention relates to the technical field of adhesive tape packing tapes, and discloses a constant-speed winding device for avoiding winding stall in the field of adhesive tape packing tapes. The constant-speed winding device comprises a rotating shaft, wherein a mounting hole 1 is formed in the front surface of the rotating shaft; a mounting hole 2 is formed in the front surface of the rotating shaft; a connecting rod is interactively connected into the mounting hole 1; one end, far from the mounting hole 1, of the connecting rod is fixedly connected with a contact; and the outer side of the connecting rod is movably connected with a sleeve. In the constant-speed winding device for avoiding winding stall in the field of adhesive tape packing tapes, through cooperative use of a variableresistance mechanism and the contact, when the winding speed of a packing tape winder is suddenly accelerated to cause stall, the resistance is automatically increased, so that the winding speed of the winder is decelerated; and when the winding speed of the winder is decelerated, the resistance is automatically reduced, so that the winding speed of the winder is accelerated, the effect of alwayskeeping constant-speed winding is achieved, the working efficiency is improved, the space utilization rate is increased, and the benefit is prevented from being influenced to a certain extent.

Owner:杭州品胜胶带厂

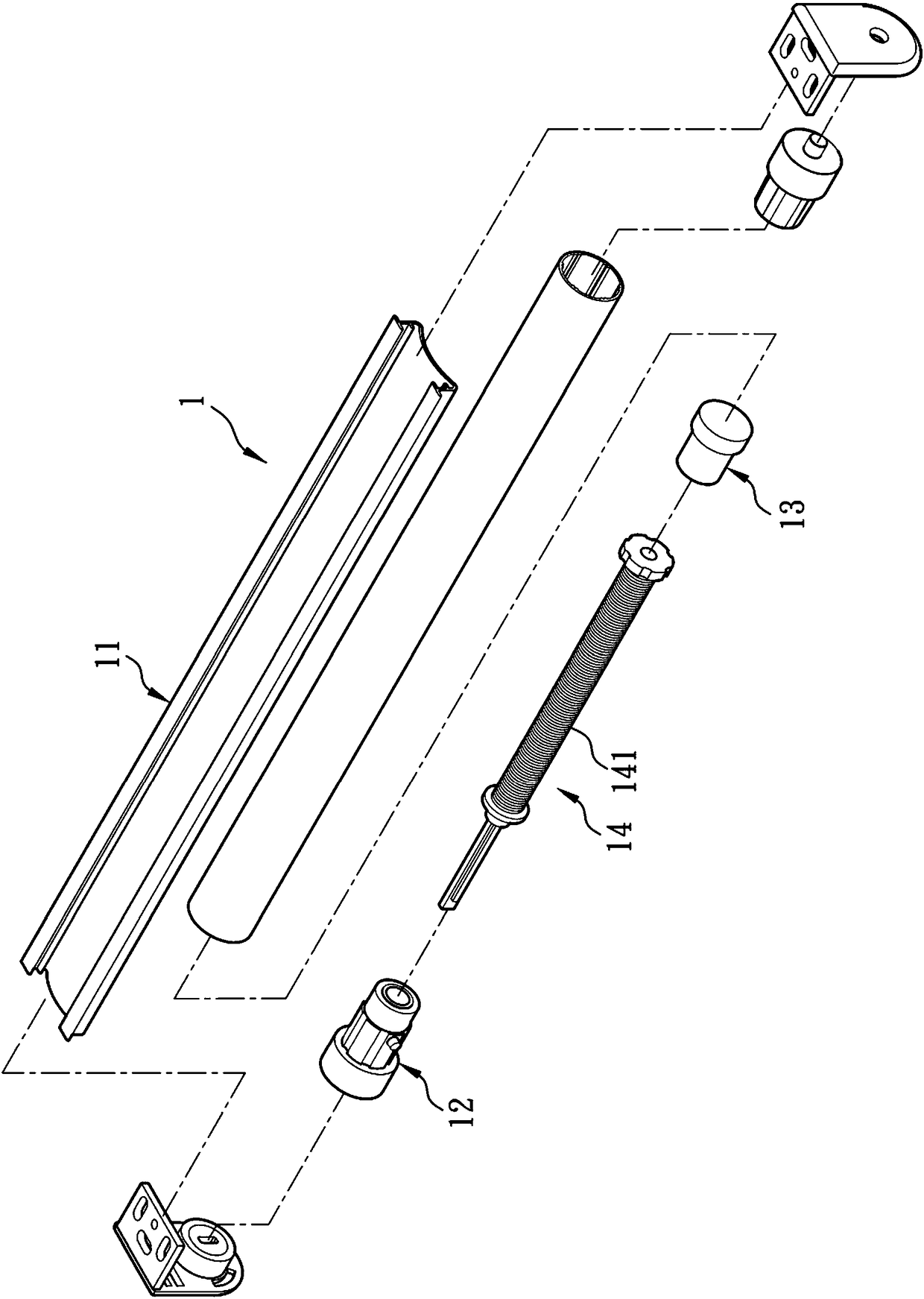

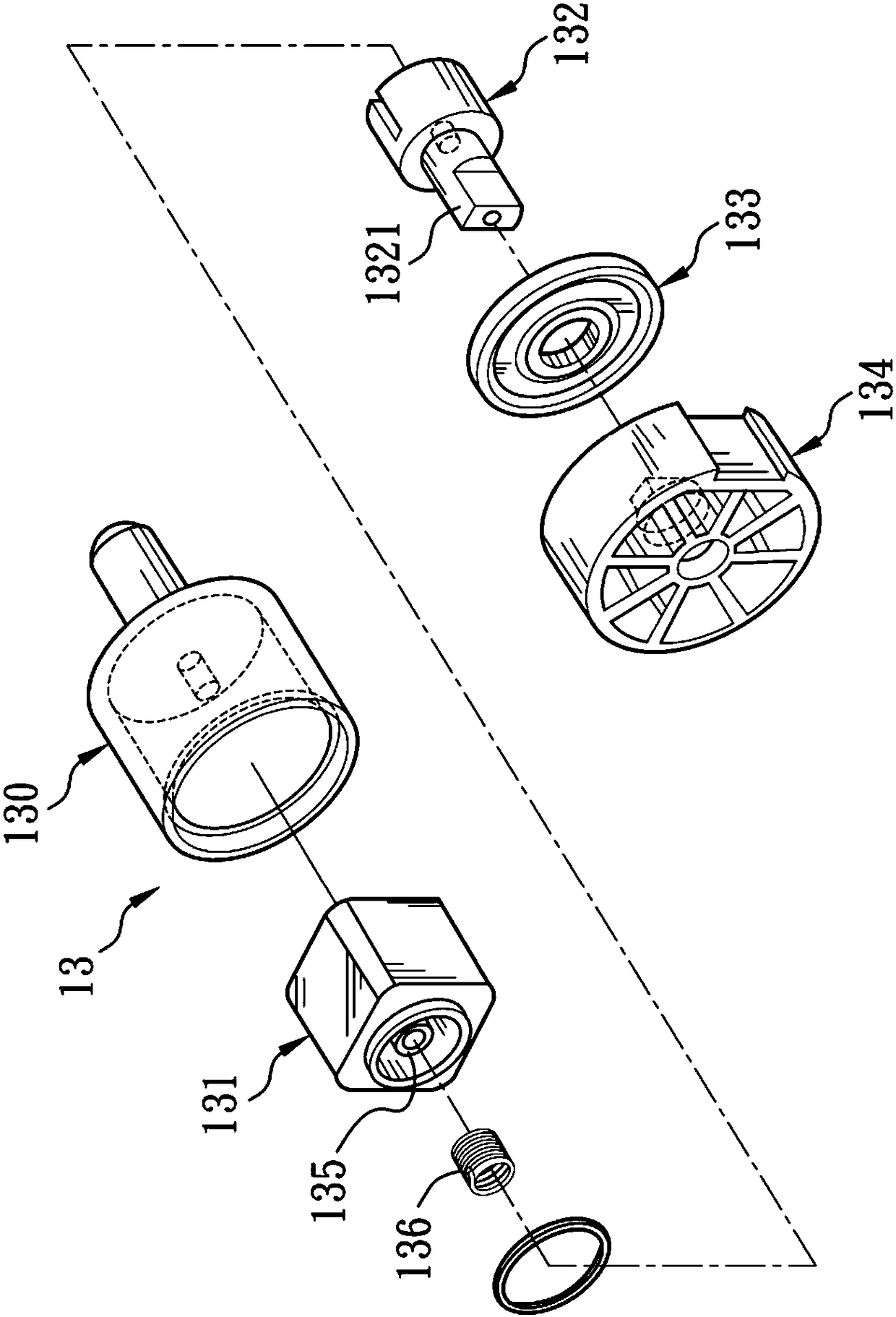

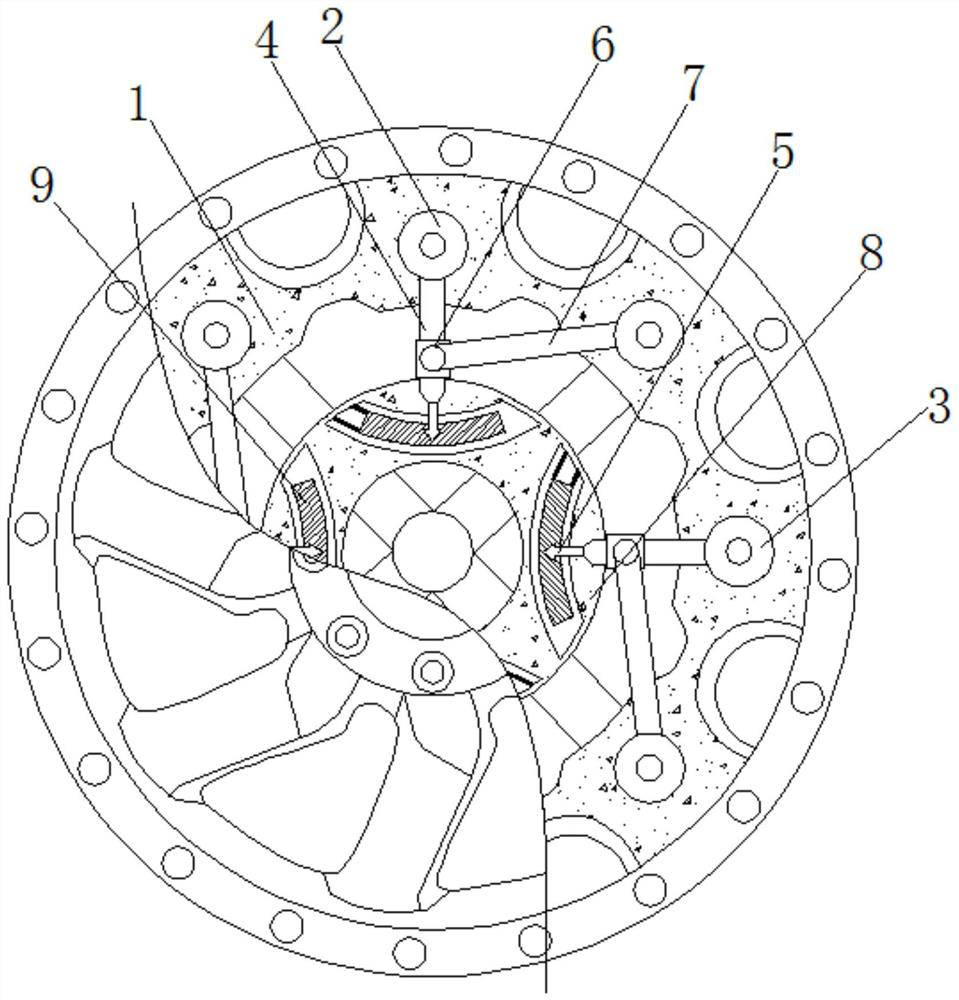

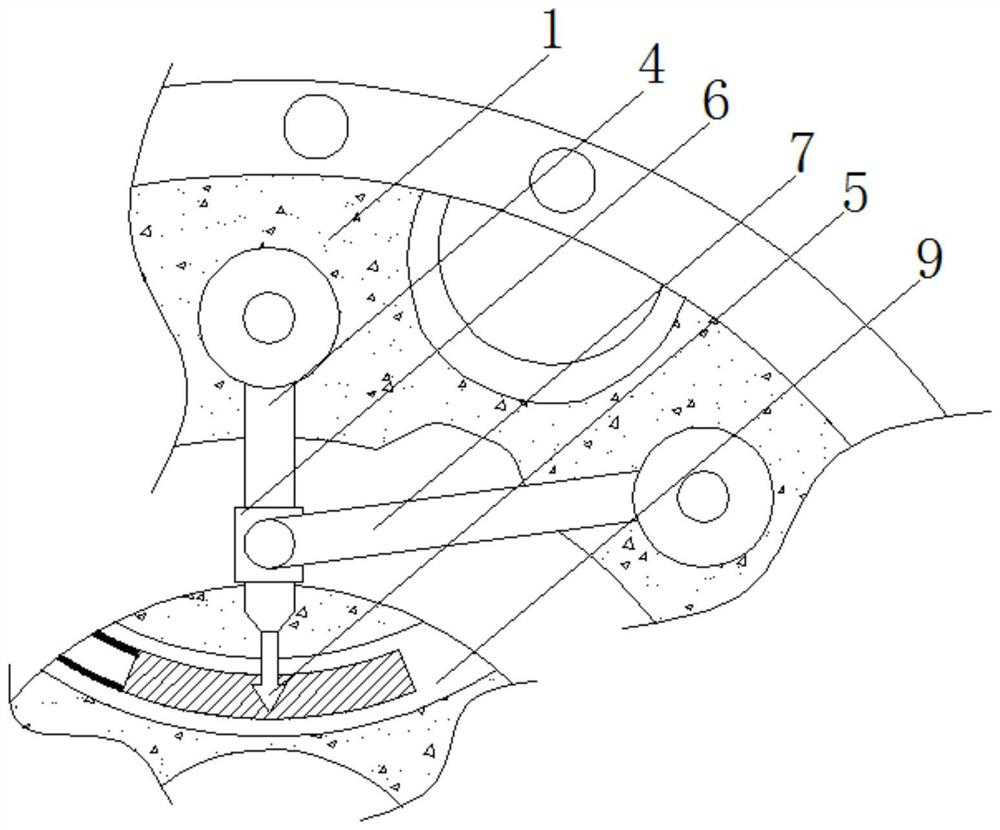

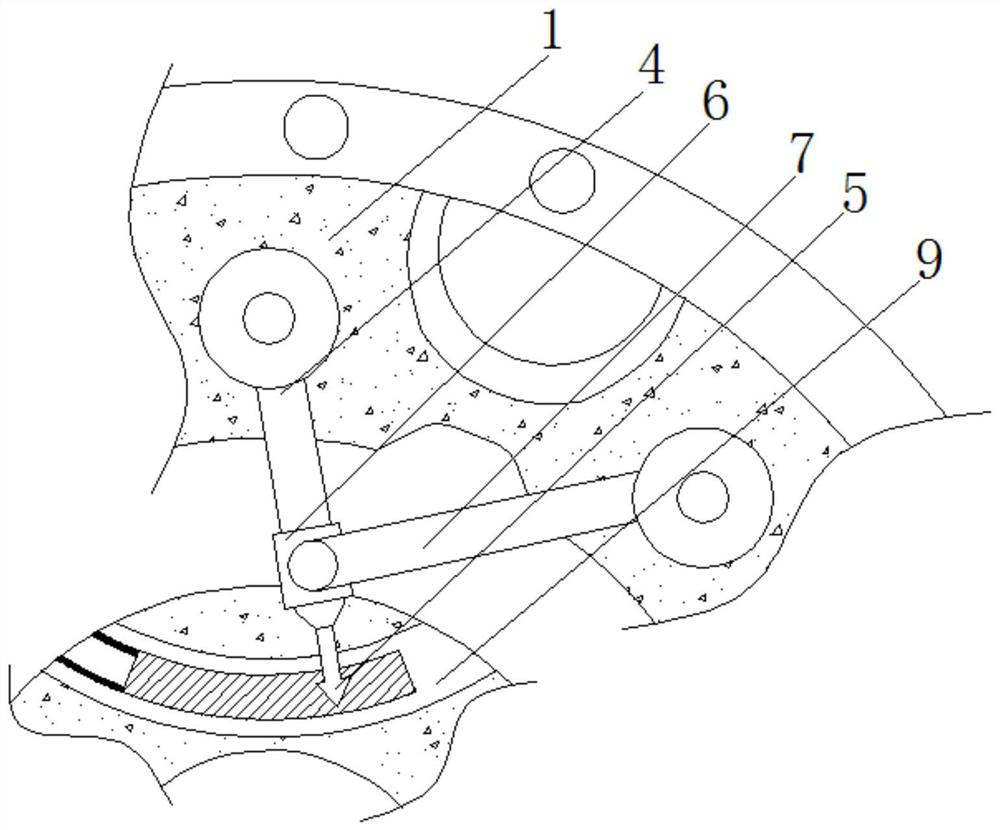

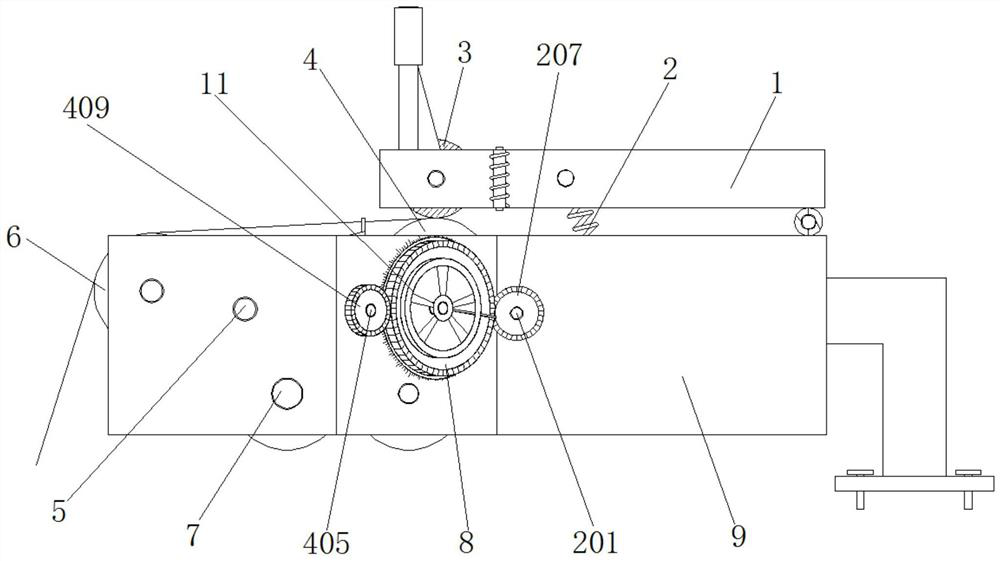

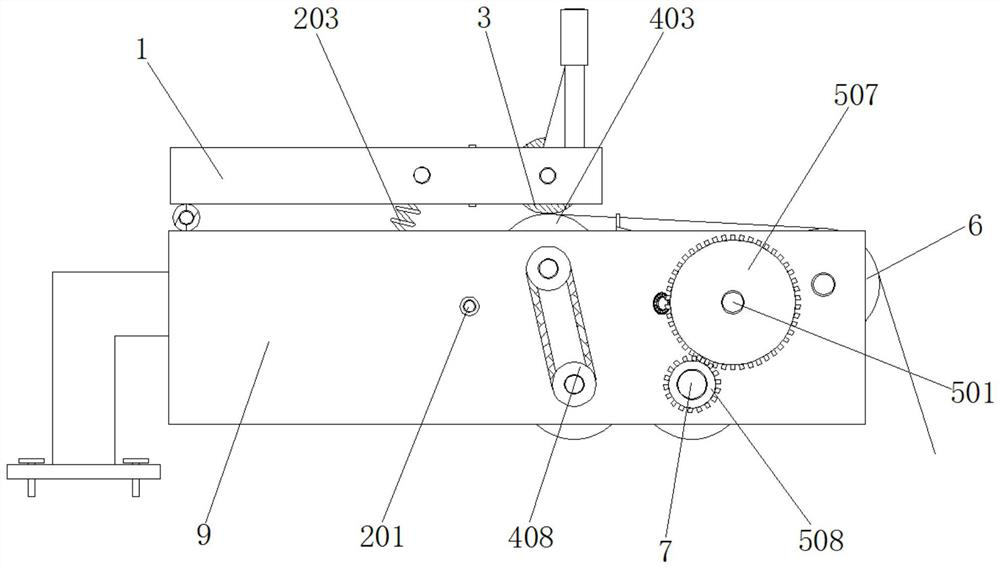

Roller reducer for curtains

ActiveCN106150328BImprove the ease of assemblySlow down the winding speedDoor/window protective devicesReduction driveReducer

A curtain rolling reducer, comprising: a rotating unit that can rotate with a reel of the curtain, a fixed unit that is sleeved with the rotating unit, a clutch unit installed in the rotating unit, and a can A resistance unit that increases resistance when the rotating unit rotates, the resistance unit is connected to the rotating unit and the fixed unit. In addition to slowing down the reeling speed of the reel, the present invention can also make the rewinding reducer suitable for modular production, and improve the ability of the curtain to change the rewinding speed. Ease of assembly when resisting.

Owner:林雅莹

Energy-saving spherical friction rotating speed adjusting type winding equipment for two-for-one twisting yarn production

The energy-saving spherical friction rotating speed adjusting type winding equipment for two-for-one twisting yarn production comprises a U-shaped bin, a U-shaped mounting frame is hinged to one side of the top of the U-shaped bin, a winding roller is arranged on the side, away from the hinged position of the U-shaped mounting frame, of the interior of the U-shaped mounting frame, and a partition plate is mounted in the middle of the interior of the U-shaped bin; and a wire guide wheel is arranged at the top of one side in the U-shaped bin. A hand wheel is rotated clockwise, threads force a U-shaped movable frame to move from one end of the outer side of a first threaded rod to the other end, when a transmission rolling ball moves to the small-diameter end of a driving conical roller, the transmission rolling ball is also located at the large-diameter end of a driven conical roller, in the process, the yarn winding speed of a winding roller is reduced, and on the contrary, the yarn winding speed is reduced. In this way, the yarn winding speed of the yarn winding device can be freely adjusted by adjusting the position of the transmission rolling ball, and the two-for-one twister using the yarn winding device can conduct yarn winding and winding on different types of yarn at the same time.

Owner:JIANGSU DESHUN TEXTILES

Winding method and device for winding bobbins

The invention relates to a method and a device for winding a crosswound bobbin. The method is characterized in that winding operation is performed at the starting phase of a bobbin stroke at target value of winding speed; and the target value decreases relative to that of winding speed after the starting phase. The invention further relates to the device used for applying the method.

Owner:RIETER AUTOMATIC WINDER GMBH

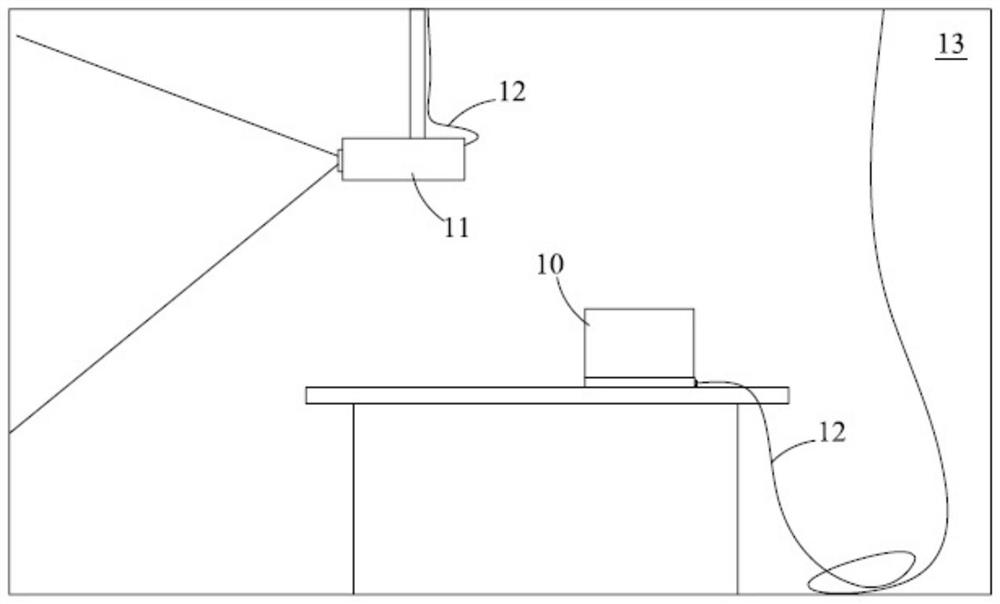

Optical fiber processing method

ActiveCN113620593AReduce tensionAvoid breakingGlass making apparatusGlass productionLaser transmitterLaser beams

The invention discloses an optical fiber processing method, which comprises a gas line detection process, wherein the gas line detection process comprises the following steps: 1) transmitting a laser beam perpendicular to an optical fiber to the optical fiber through a laser transmitter, and receiving the laser beam through a laser receiver; 2) when the intensity of the signal received by the laser receiver changes suddenly, judging that the optical fiber has a gas line, recording the initial position of the gas line, and controlling winding equipment to reduce a winding speed; and 3) when the intensity of the signal received by the laser receiver is recovered, judging that the optical fiber has no gas line, recording the end position of the gas line, and recovering the winding speed of the winding equipment after the gas line section of the optical fiber is completely wound on a winding disc. According to the optical fiber processing method, by setting the additional gas line detection process, the appearance position and the end position of the gas line can be detected online, so that the gas line section can be conveniently processed in the later period, the winding speed of the winding equipment can be controlled to be reduced when the gas line is detected, the tension of the optical fiber is reduced, and the optical fiber is prevented from being broken due to the gas line.

Owner:HANGZHOU FUTONG COMM TECH CO LTD +1

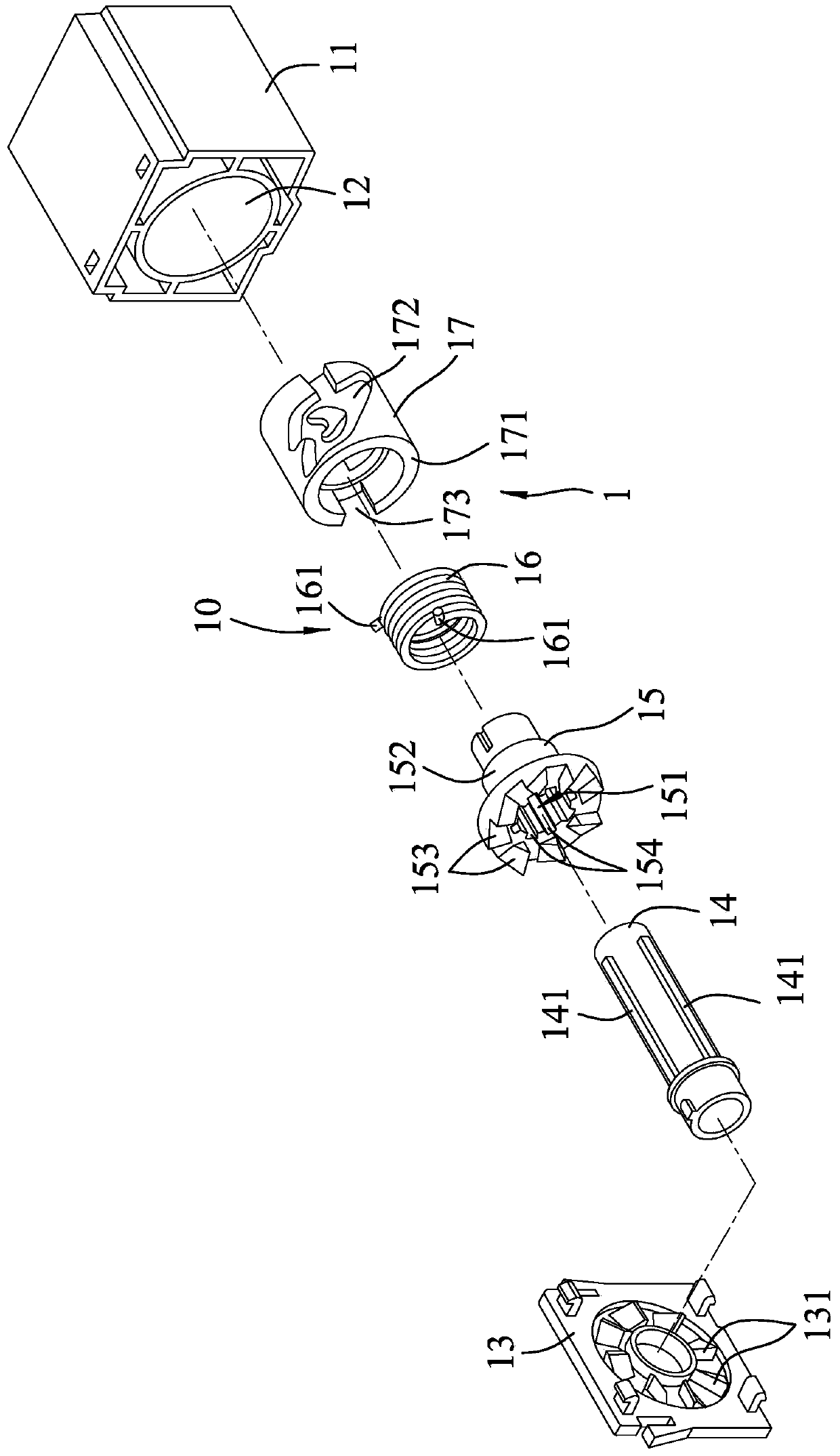

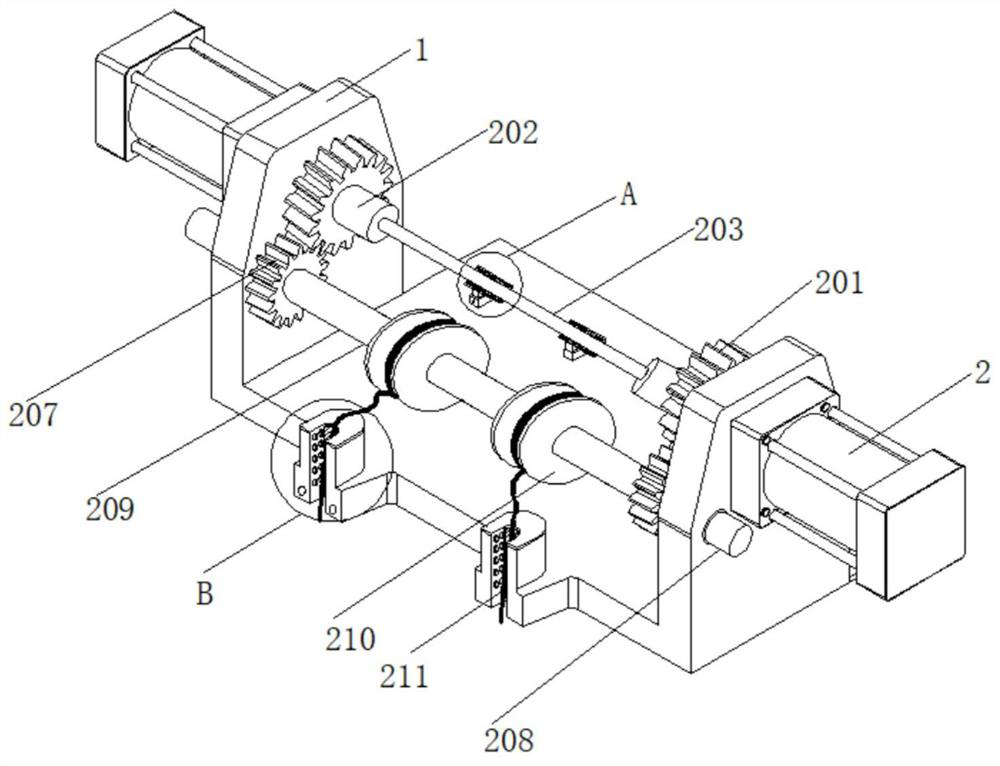

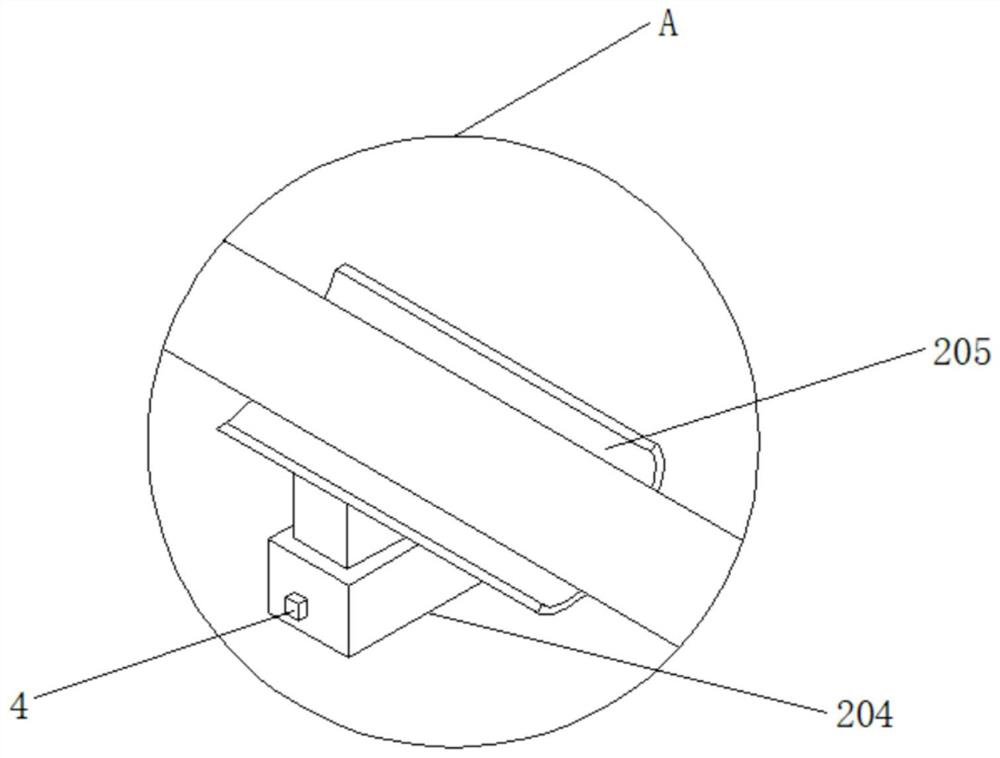

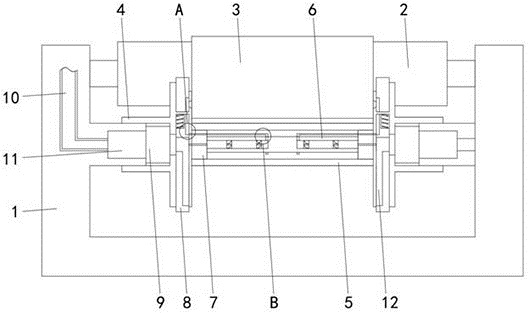

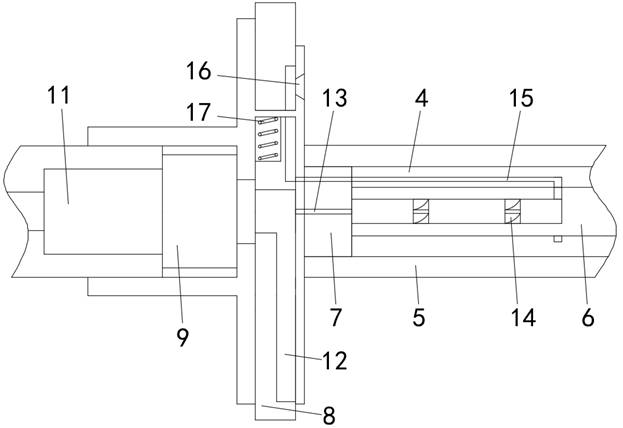

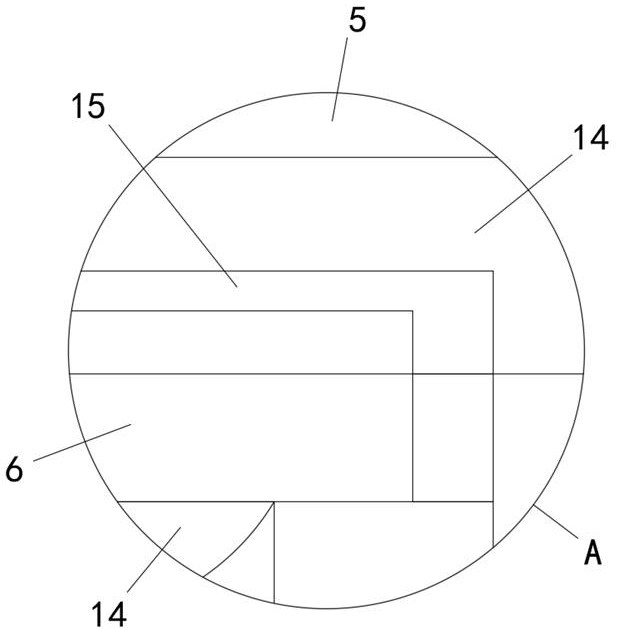

Speed reducing mechanism and winding device thereof

The invention provides a speed reducing mechanism. The speed reducing mechanism comprises a shell, a moving part, a rotating piece and a damping piece; wherein the movable piece is movably arranged ona spiral track on the first surface of the shell. The rotating piece is rotatably coupled to the shell, the rotating piece is provided with a second surface opposite to the first surface, the rotating piece comprises an actuating part which is arranged on the second surface and abuts against the moving piece, and when the rotating piece rotates relative to the shell, the actuating part drives themoving piece to move in the spiral track. The damping part is selectively arranged on the rotating piece and corresponds to the speed reduction section of the spiral track, and when the moving pieceenters the speed reduction section, the damping part abuts against the moving piece so as to reduce the rotating speed of the rotating piece relative to the shell. In one embodiment, the speed reducing mechanism is combined with the winding device to form the winding device with a speed reducing function, so that the speed can be properly reduced when the take-up end part is close to the shell.

Owner:ATEN INT CO

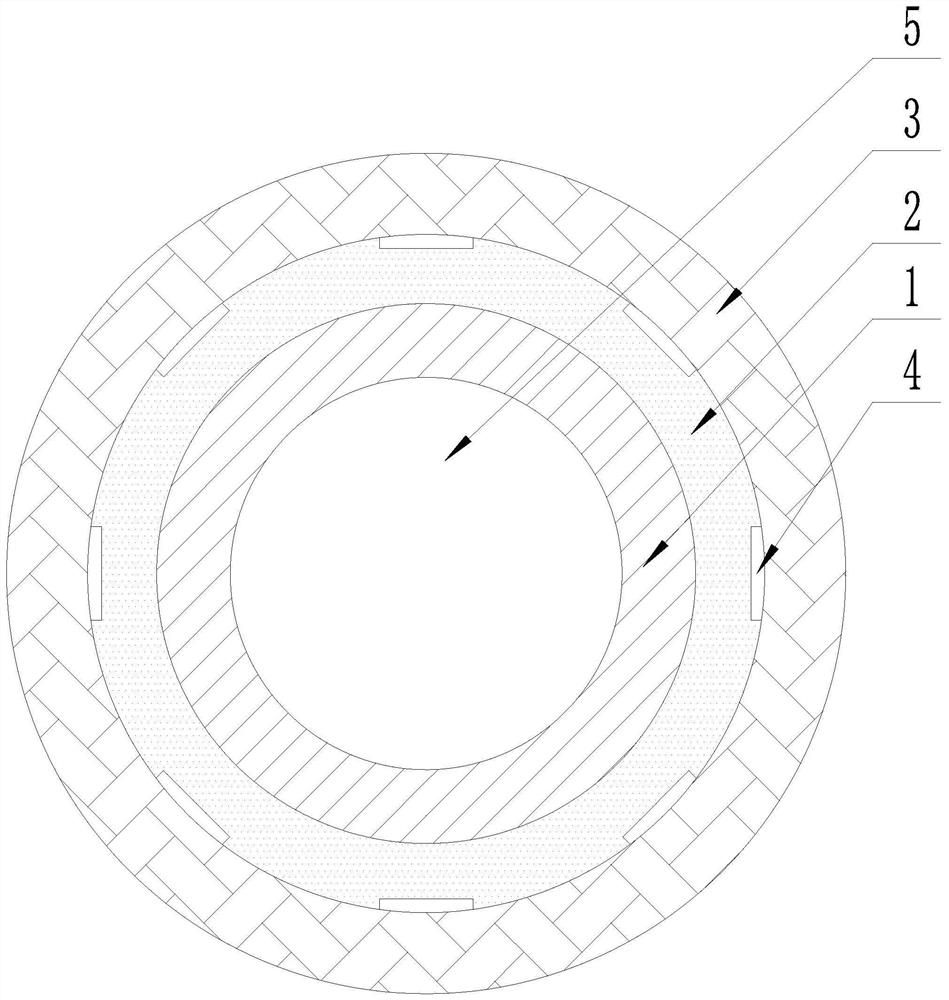

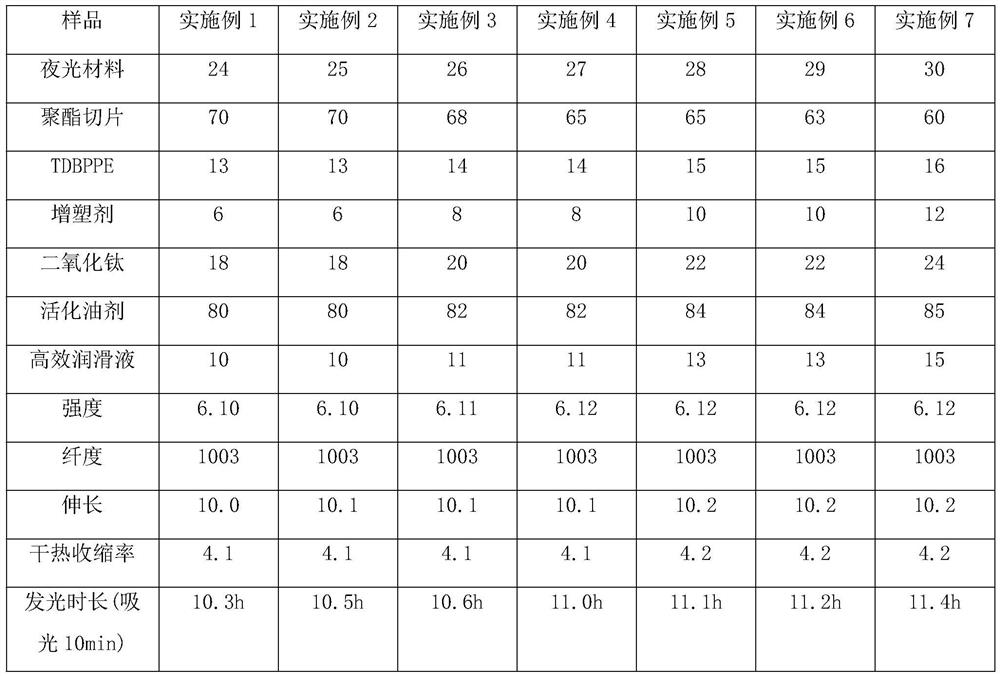

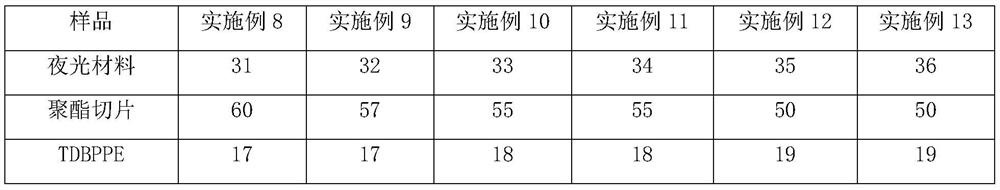

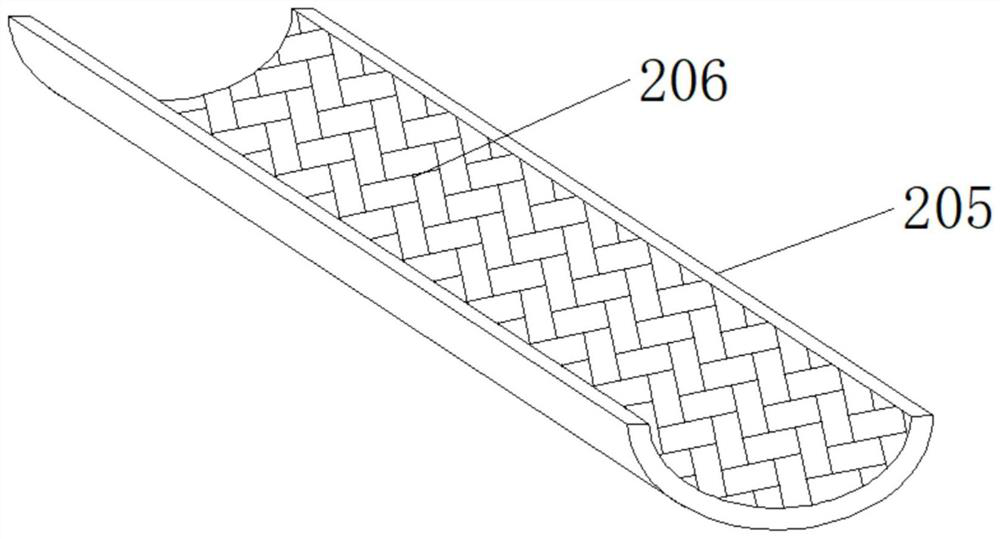

Noctilucent polyester, braided layer with polyester and fire hose with braided layer

PendingCN111826738AImprove luminosityLow viscositySynthetic resin layered productsFlexible pipesPolyesterPolymer science

The invention relates to a noctilucent polyester, a braided layer with the polyester and a fire hose with the braided layer, and aims at solving the technical problem that polyesters and fire hoses inthe prior art have no noctilucence. Raw materials of the noctilucent polyester comprise polyester chips, a noctilucent material, a flame retardant, a plasticizer and titanium dioxide, the obtained polyester has good flame retardance and corrosion resistance and also has a good noctilucent effect, and the braided layer made of the polyester and the fire hose with the braided layer also have good noctilucence.

Owner:SUZHOU LONGJIE SPECIAL FIBER

Method for rewinding dye bobbins to cross-wound bobbins

This invention relates to a method for rewinding the dyeing bobbin (4) onto a cross winding bobbin (11), wherein at the time of rewinding beginning and / or ending, the yarn (30) to unwrap from the dyeing bobbin (4) is unwrapped a defined length at a winding speed which is less than the winding speed arranged for the yarn (30) to rewind.

Owner:RIETER AUTOMATIC WINDER GMBH

Winding device for engineering machinery

ActiveCN113148886ASlow down the winding speedIncrease in sizeWinding mechanismsCleaning using liquidsGear driveGear wheel

The invention relates to the technical field of mechanical engineering, in particular to a winding device for engineering machinery. The device comprises a winding frame, a winding mechanism is arranged at the top of the winding frame, a rust removal mechanism is arranged at one side of the winding frame, and the winding mechanism comprises a rotating motor located on the outer wall of the winding frame. The output end of the rotating motor penetrates through the winding frame and extends to the inner side of the winding frame, the output end of the rotating motor is connected with a driving gear, and one side of the driving gear is fixedly connected with a rotating cylinder. The winding device has the beneficial effects that the driving gear drives a driven gear to rotate, a rotating shaft is beneficial to providing of supporting force for the driven gear during rotation, the driven gear can drive a connecting column and a winding cylinder to rotate, the winding cylinder drives a steel wire rope to wind, when the winding speed needs to be changed, a starting switch is turned on, a lifting column drives an arc-shaped plate to ascend, a friction layer in the arc-shaped plate makes contact with a speed reduction rod, and the rotating speed of the speed reduction rod is reduced under the friction effect.

Owner:湖北恒子工程技术有限公司

A kind of preparation method of ultrafine denier nylon fiber, ultralight fabric and ultralight coat

ActiveCN112301441BStrongHigh strengthElectroconductive/antistatic filament manufactureOvergarmentsMasterbatchPolymer science

The invention discloses a preparation method of ultrafine denier nylon fiber, comprising the following steps: 1) Weighing the following components by weight: 96-99 parts of nylon 66 slices, TiO 2 0.35-2 parts of matting masterbatch, 0.05-1 part of phosphite antioxidant, 0.05-0.5 part of fatty alcohol phosphate and 0.05-0.5 part of polyethylene glycol antistatic agent, the model of nylon 66 slice is CM3006, and the relative molecular weight is 25000 ‑30000, the viscosity is 2.8‑2.9; 2) the raw material weighed in step 1 is prepared through the melt spinning method to obtain a nylon fiber with a monofilament fineness of 0.3‑0.5dtex, wherein in the melt spinning process, the melting temperature is 260‑ 290°C, the number of holes in the spinneret is 5-30, the hole diameter is 0.1-0.2mm, the winding speed is 300-500 m / min, the winding temperature is 18-19°C; the yield rate is over 92%. The invention also provides a preparation method of an ultra-light fabric and an ultra-light coat. The preparation method of the superfine-denier nylon fiber of the present invention can prepare the superfine-denier nylon fiber, and can ensure that the finished product rate is above 92%.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

Improvement method for finishing and trimming of double-zero foil material

PendingCN113896026AAvoid sticking phenomenonNo stickyArticle deliveryWebs handlingCircular discVertical edge

The invention discloses an improvement method of finishing and trimming of a double-zero foil material. According to the improvement method, the shearing overlapping amount of a cutting disc and the winding speed and the winding tension of a winding sleeve are adjusted according to the plate type condition of a material roll, when the measurement result is within the range of a standard plate type, it can be guaranteed that the winding sleeve conducts winding evenly, cutting of the cutting disc is free of vertical edges, and the material roll is wound normally without sticking damage; and when the measurement result exceeds the range of the standard plate type, vertical edges at the edge part of the material roll are reduced by reducing the shearing overlapping amount and reducing the rolling speed and the rolling tension of the rolling sleeve, and the phenomenon of adhesion between adjacent material roll layers due to vertical edge accumulation is improved.

Owner:INNER MONGOLIA LIANSHENG NEW ENERGY MATERIALS CO LTD

Garlic straw natural fiber antibacterial gauze preparation device and preparation method thereof

ActiveCN114000247ASlow down the winding speedAvoid plastic deformationLoomsAuxillary apparatusWinding machineNatural fiber

The invention relates to the technical field of machining, and discloses a garlic straw natural fiber antibacterial gauze preparation device and a preparation method thereof. The garlic straw natural fiber antibacterial gauze preparation device comprises a machine body, an auxiliary wheel is movably installed in the middle of the machine body, gauze is movably connected to the surface of the auxiliary wheel, and a winding wheel is movably installed at one end of the middle of the machine body and is in an I shape. By arranging a deviation return mechanism, when a gauze winding machine works normally and gauze deviates, the lower end of an adjusting cavity is opened by a staggered and closed opening under the action that the gauze exerts downward pressure on the deviation side of an adjusting disc, gas in a gas storage cavity can be discharged outwards through magnetic repulsion when the pressure is gradually increased, and under the action of counter-acting force, the winding wheel drives a winding drum to move towards the deviating side, so that the gauze is reset in a winding drum moving mode, and the situation that a traditional gauze winding machine needs to be shut down for resetting when the gauze deviates is avoided.

Owner:YANTAI VOCATIONAL COLLEGE

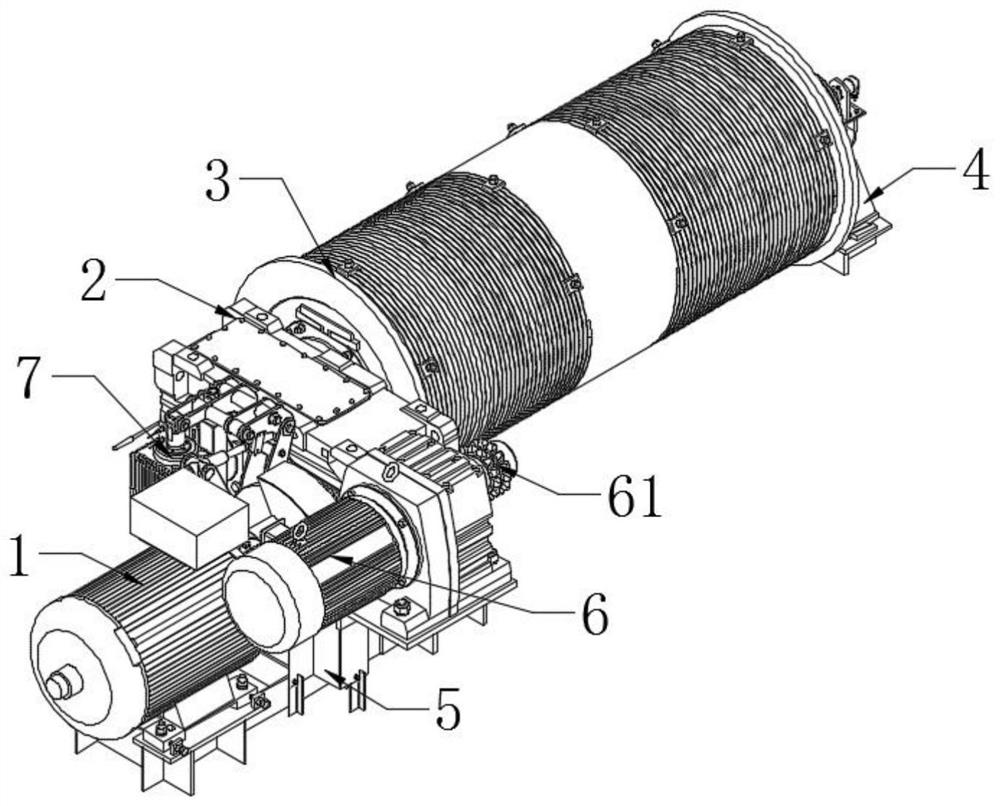

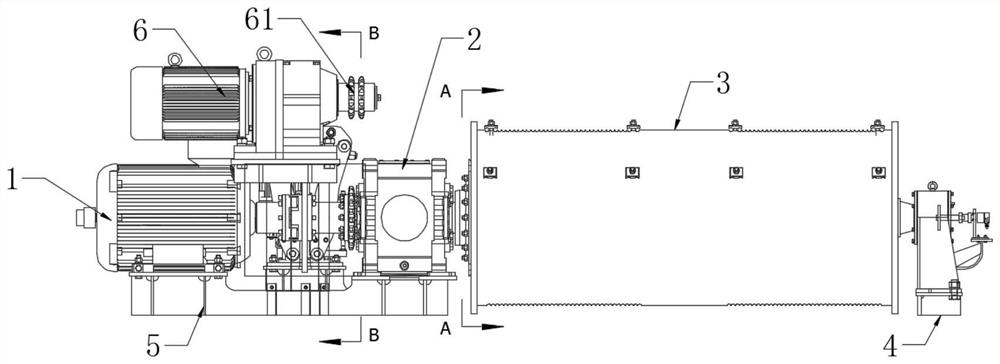

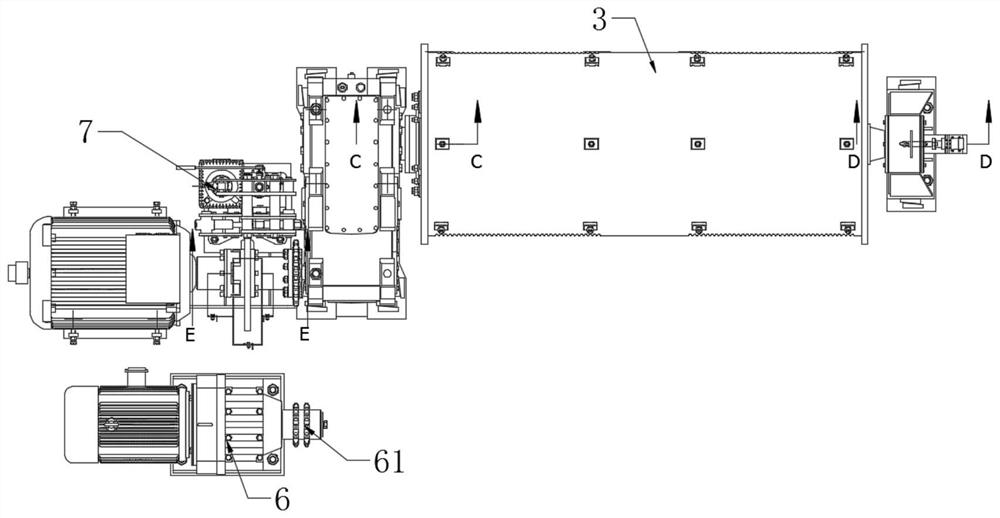

Trolley running mechanism for quayside container crane and using method of trolley running mechanism

PendingCN113879969AReduce speedSlow down the winding speedBearing componentsWinding mechanismsCouplingContainer crane

The invention provides a trolley running mechanism for a quayside container crane and a using method of the trolley running mechanism. The trolley running mechanism comprises a base and a connecting shaft, a driving motor and a reduction gearbox are sequentially installed on the base, a brake disc coupler is arranged on an output shaft of the driving motor, the brake disc coupler is connected with an input shaft of the reduction gearbox, a winding reel coupler is arranged on an output shaft of the reduction gearbox, a winding drum is arranged on the winding reel coupling, a supporting seat is installed at the other end of the winding drum through a connecting shaft, a bearing seat is arranged between the supporting seat and the connecting shaft, and a disc brake used for carrying out speed reduction on the brake disc coupler is installed on the base. The trolley running mechanism is reasonable in structure, convenient to combine and install, high in conveying stability, good in braking effect and high in safety.

Owner:JIANGSU DINSON HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com