Method for rewinding dye bobbins to cross-wound bobbins

A technology for cross-winding bobbins and bobbins, which is applied in the field of textile machines for producing cross-winding bobbins. It can solve the problems of expensive control and operation of textile machines, and the decline in cost and productivity, and achieve the effects of increasing productivity, improving productivity, and quickly adjusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

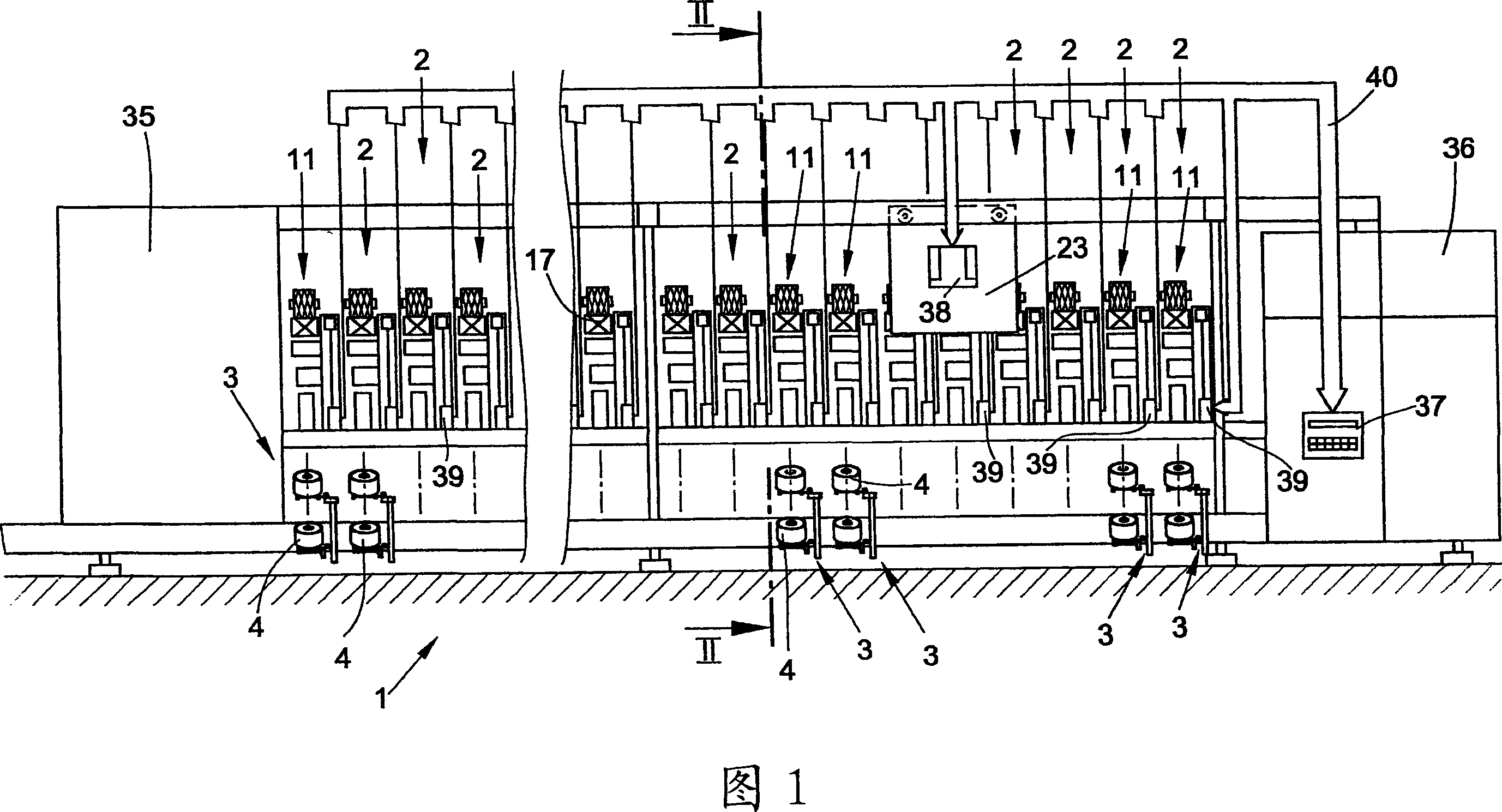

[0022] Fig. 1 schematically shows a front view of a textile machine that produces cross-wound bobbins, that is, an automatic cross-wound machine in this embodiment, which is denoted by reference numeral 1 as a whole. The automatic cross-winding machine 1 has a large number of workstations between its end frames 35, 36, so-called winding heads 2.

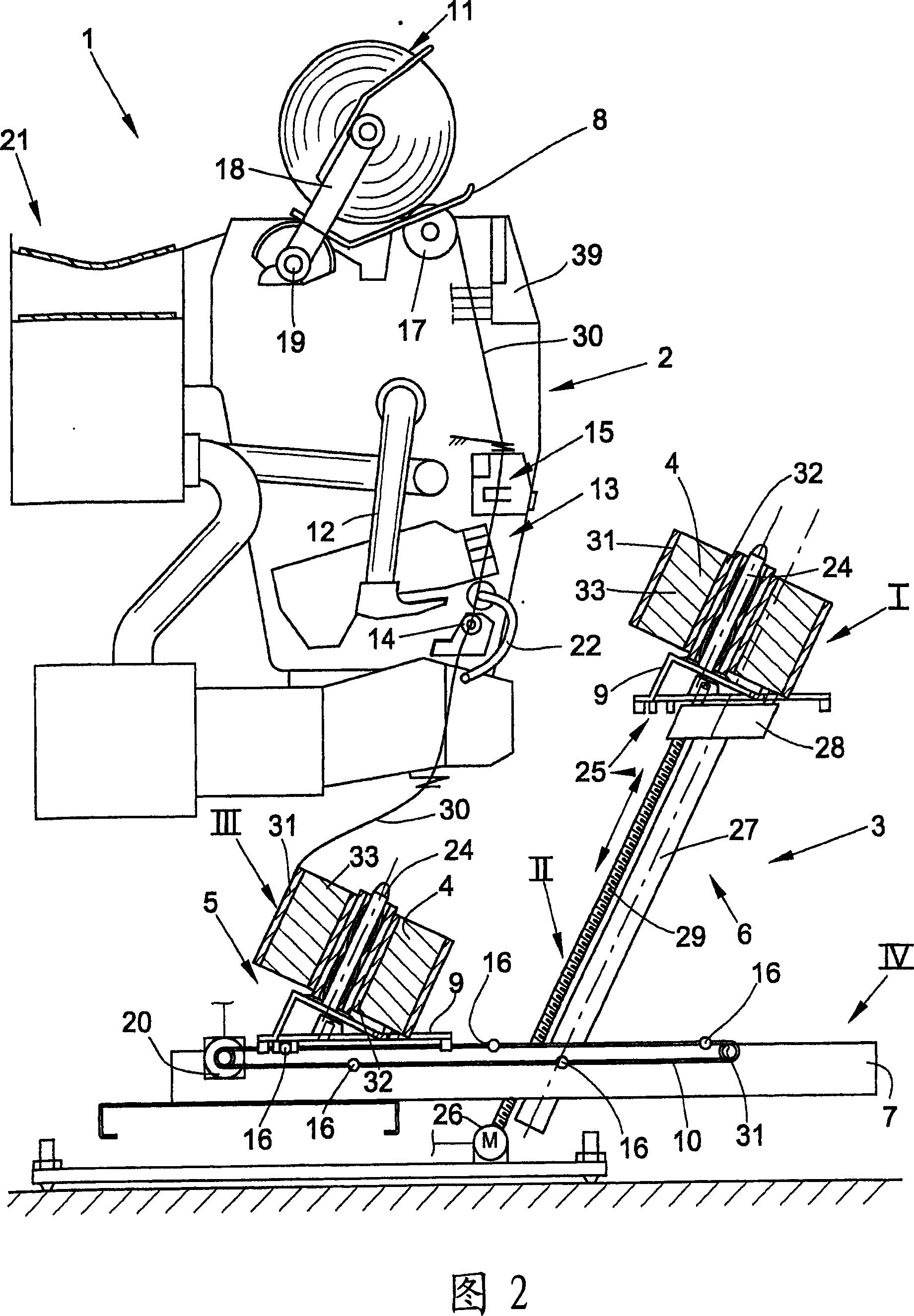

[0023] As can be specifically seen from FIG. 2, the dyeing bobbin 4 is rewinded on the winding head 2 to form a cross-winding bobbin 11. The completed dyeing bobbin 4 newly rewinded to form the cross-wound bobbin 11 is transported to the conveying device 21 by the automatic operation service unit, for example, by the cross-wound bobbin changer 23, which transfers the cross-wound bobbin 11 Transport to a bobbin loading station (not shown) etc. arranged at the end of the machine.

[0024] Such an automatic cross-winding machine 1 generally also has a central control unit 37, which is connected to each winding head computer 39 of the windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com