Material strap winding device

A technology of coiling device and material tape, which is applied in the directions of coiling strips, thin material processing, transportation and packaging, etc., can solve the problems of low quality and low work efficiency of winding material tape, and achieve the purpose of ensuring winding quality and guaranteeing The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

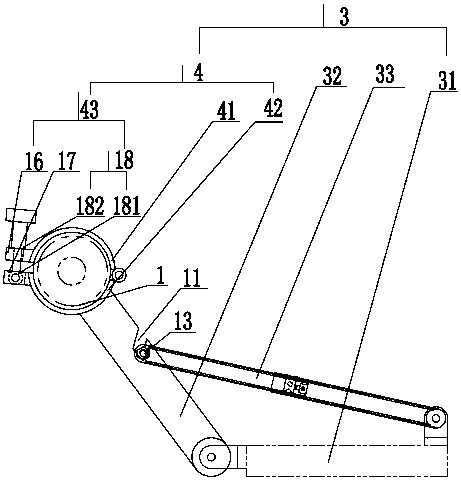

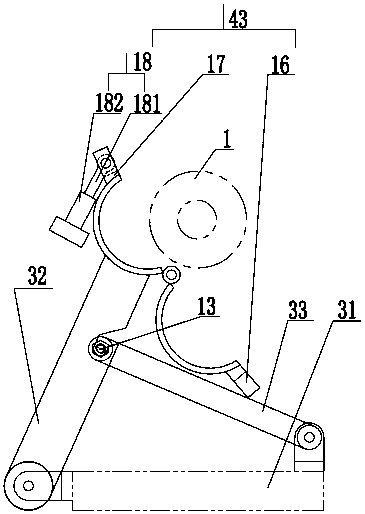

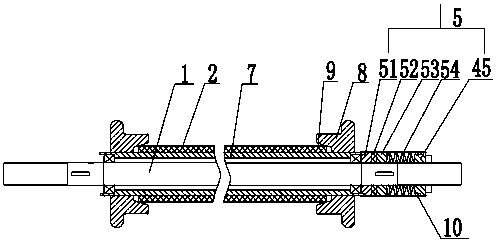

[0025] In the example, such as figure 1 , figure 2 , image 3 As shown, the material tape winding device includes a rewinding shaft 1, and the rewinding shaft 1 is connected with a power device. The rewinding shaft 1 is provided with a reel tube 2 for rewinding the film. The tubes 2 are concentrically matched, and a friction differential device 5 is provided between the rewinding shaft 1 and the coil tube 2. The reel shaft 1 drives the coil tube 2 to rotate through the friction differential device 5, and the reel shaft 1 Equipped with rocker loading and unloading mechanism 3. The friction differential device 5 drives the coil material tube 2 to rotate to coil the material. When the coil material tube 2 is wound with a thicker material, the tightening force of the coil material tube 2 becomes larger. The friction differential device 5 and the coil material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com