Inductor winding mechanism and automatic inductor winding equipment

A winding mechanism and inductor technology, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve problems such as low work efficiency, achieve high work efficiency, improve the degree of automation, and ensure the effect of winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] Example 1

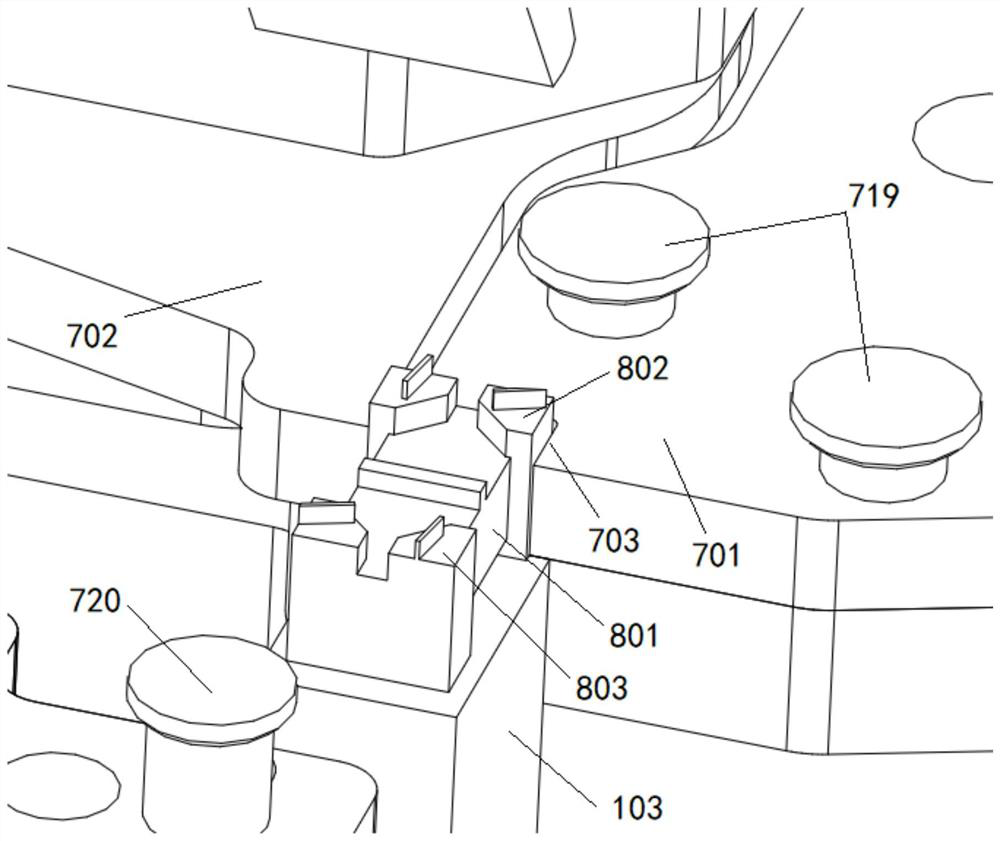

[0040] This embodiment provides an inductor winding mechanism, such as image 3 As shown, the inductor 800 includes a magnetic core 801. The two ends of the magnetic core 801 are respectively provided with a first solder pin 802 and a second solder pin 803. The first solder pin 802 and the second solder pin 803 are provided with wires for positioning the wires. Slot, the wire is passed through the slot and then wound on the magnetic core. The inductor winding mechanism mainly includes a clamp, a wire crimping seat, a crimping thimble and a needle nozzle.

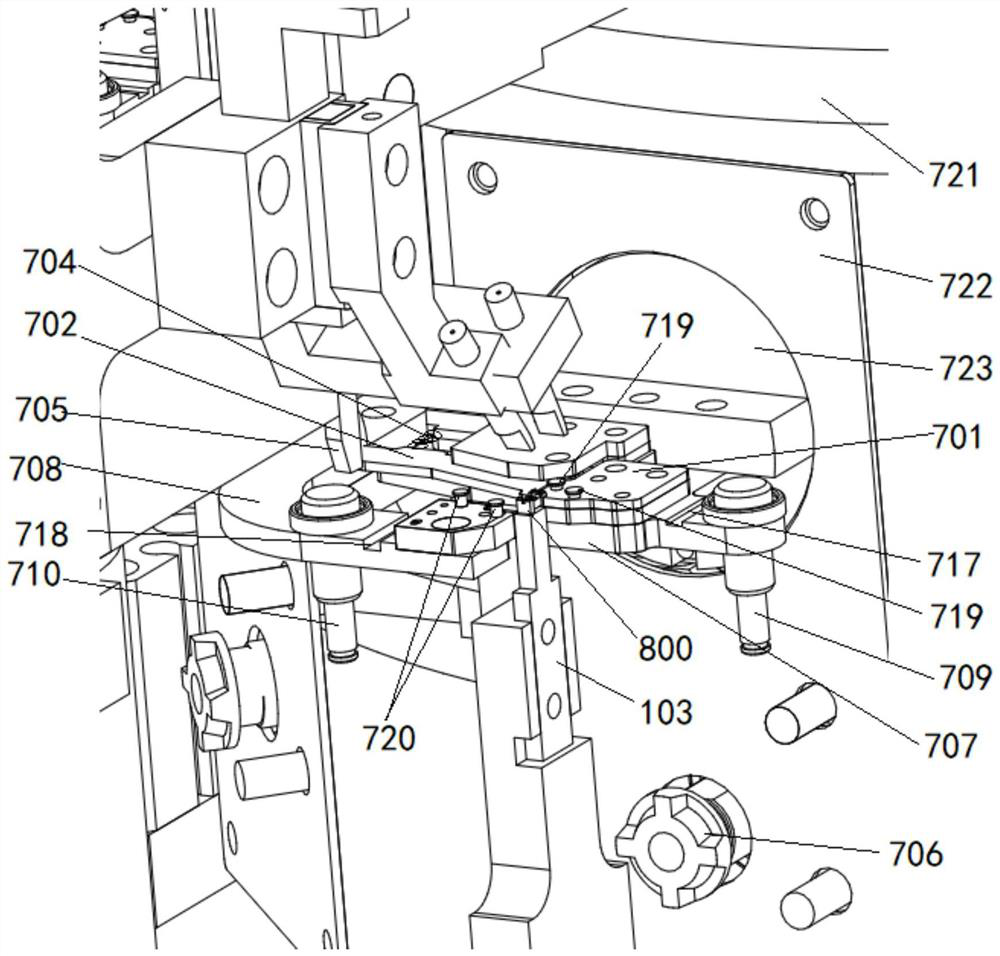

[0041] Please refer to figure 2 and image 3, the clamp is rotatably mounted on the conveying mechanism 700, and the conveying mechanism 700 in this embodiment is described by taking the indexing turntable as an example. The fixture includes a fixed clamping plate 701 and a movable clamping plate 702 that cooperate with each other. The fixed clamping plate 701 is provided with a workpiece slot 703 , a...

Example Embodiment

[0057] Example 2

[0058] In this embodiment, two wires are wound on the magnetic core 801 of the inductor 800 at the same time. The difference between this embodiment and Embodiment 1 is that the first column 719 and the second column 720 are respectively installed on the fixed splint 701 and the second wire pressing seat 708. There is a limit protrusion on the top of the . The wire is pressed by the wire thimble 1 709 and then tensioned on the column 1 719, and then passes through the first welding leg 802; the wire after winding is passed through the second welding leg 803 and then tensioned on the column 2 720, and then by the second welding leg 803. Press the thimble II 710 to press down.

[0059] Please refer to Figure 4 to Figure 6 , in order to realize automatic wire supply, this embodiment also includes two needle nozzles 203 installed in parallel on the fixed sleeve 204 to guide the movement of the wire. After passing through the needle nozzle 203, it should be ...

Example Embodiment

[0065] Example 3

[0066] This embodiment provides an inductance automatic winding device including the winding mechanism described in Embodiment 1 or Embodiment 2.

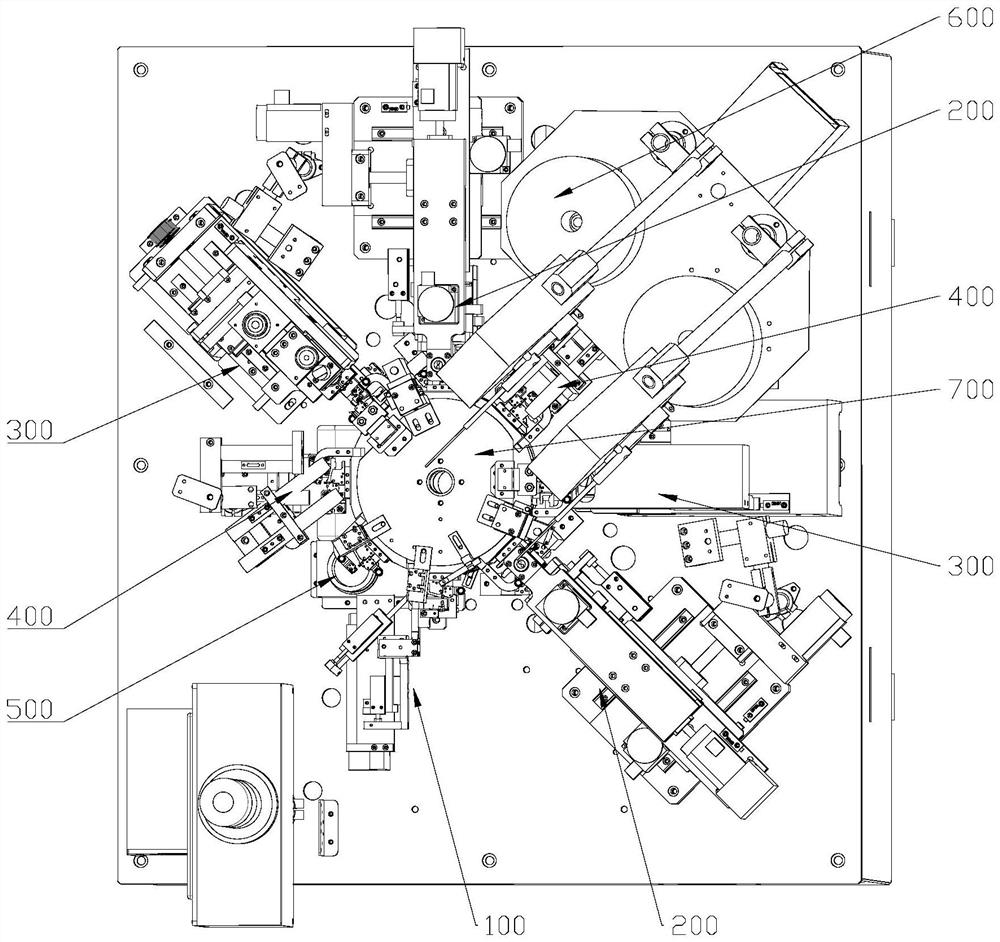

[0067] like figure 1 As shown, the conveying mechanism 700 is an indexing turntable 722. Multiple sets of clamps and wire crimping seats are installed on the indexing turntable 722 at equal intervals. The conveying mechanism 700 sequentially sends each group of clamps and wire crimping bases to the feeding station 100, the wire winding Station 200 , welding station 300 , waste discharge station 400 and blanking station 500 . When two layers of wires need to be wound, two rounds of the above-mentioned stations can be repeatedly set on the periphery of the indexing turntable 722, so that two layers of wires are repeatedly wound.

[0068]Among them, the push rod 705 is located on the feeding station 100 and the unloading station 500, the support block 103 and the cylinder 5 are located on the feeding station 100, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com