One-time molding mechanism of brake shoe panel

A forming mechanism and brake shoe technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low flatness of bosses on the panel, waste of raw materials, low production efficiency, etc., to avoid unqualified products , Reduce production costs and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

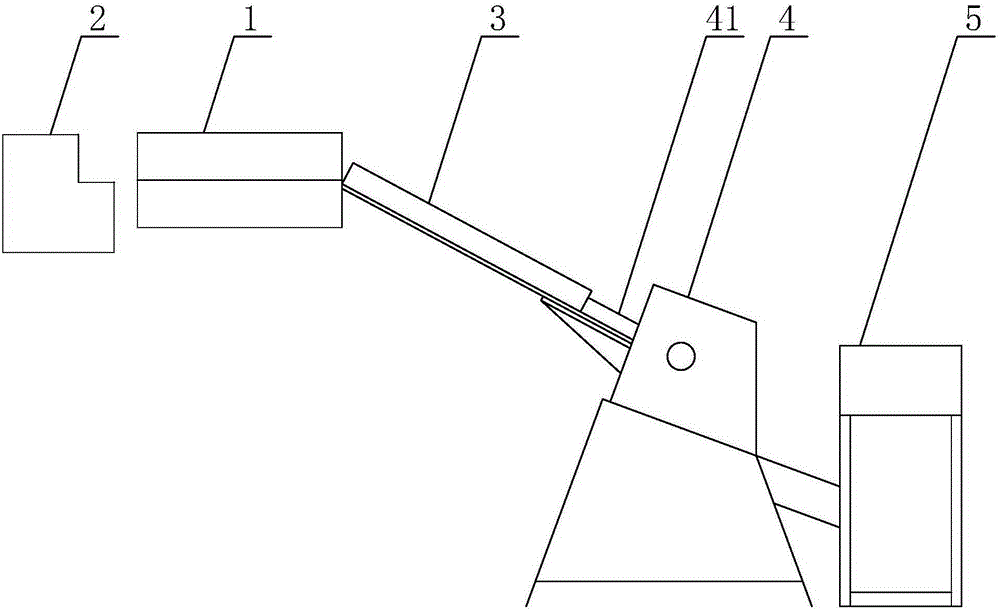

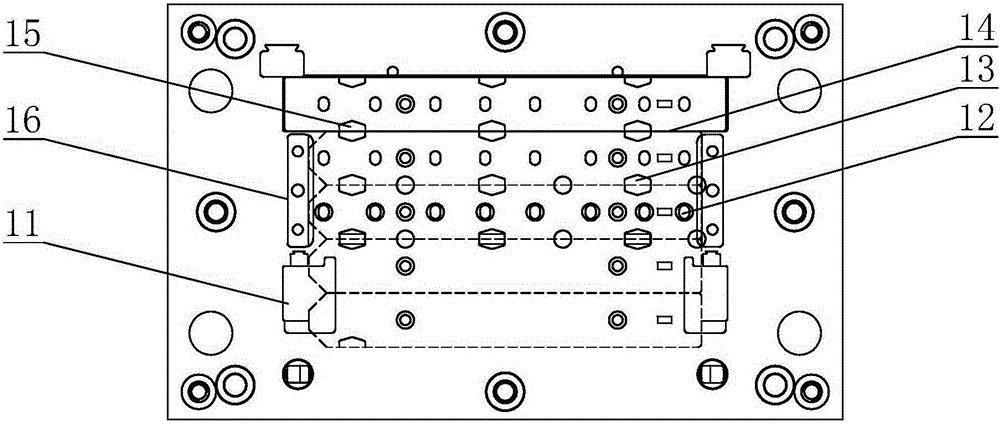

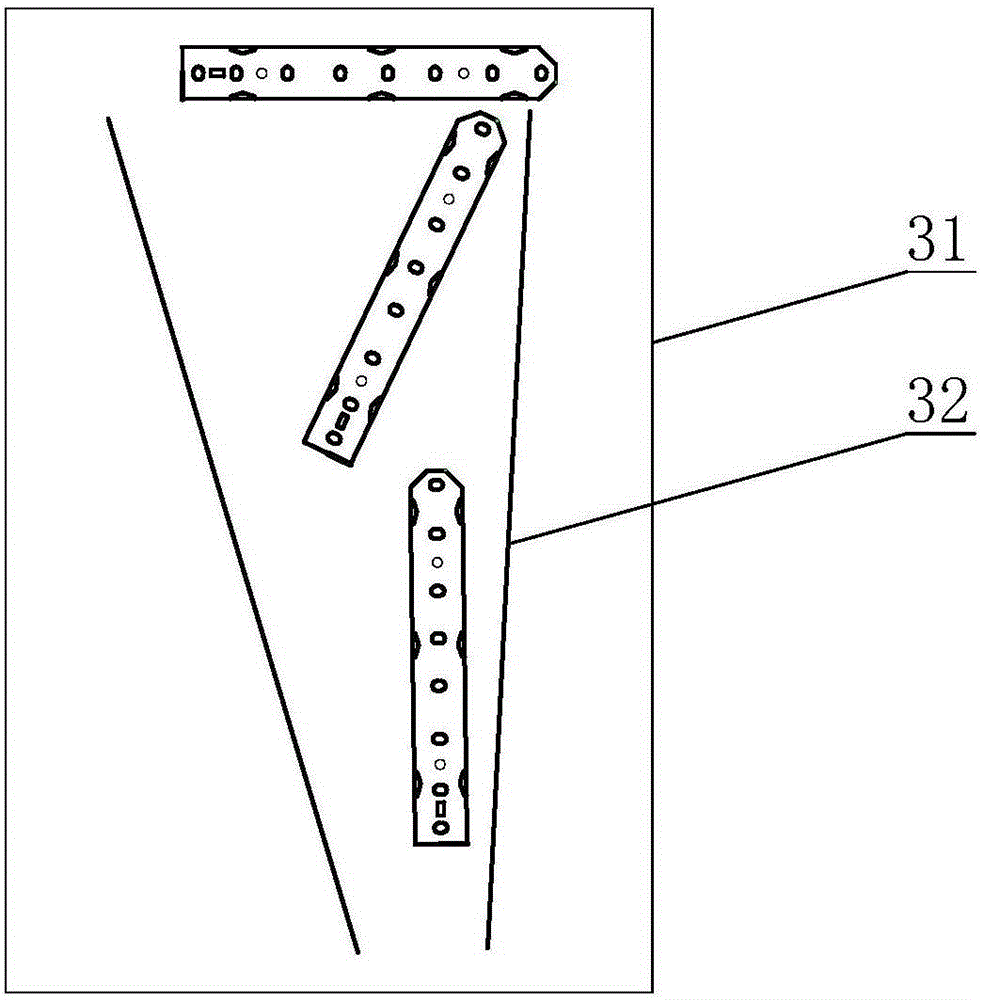

[0037]Embodiment 1: The present invention is a one-time forming mechanism of a brake shoe panel, which includes a progressive die, and the progressive die is installed on a punch press, and the punches are sequentially arranged in the progressive die along the moving direction of the blank. The bump station, the boss station and the cut-off station composed of the head and the insert block, the stamping structure of the bump station, the boss station and the cut-off station in the progressive die are the same as those of the ordinary single-station stamping die The stamping structure is the same. The bump processing of the panel can be completed on the bump station, the boss processing of the panel can be completed on the boss station, and the shape blanking of the panel can be completed on the cutting station, which can reduce the occupation of manpower, equipment and space , can improve production efficiency. The cutting station is equipped with an insert suitable for the b...

Embodiment 2

[0038] Embodiment 2: The present invention is a one-time forming mechanism of a brake shoe panel, including a progressive die, the progressive die is installed on a punching machine, and the punching dies are sequentially arranged in the progressive die along the moving direction of the blank. The trimming station, bump station, boss station and cutting station composed of head and insert, the trimming station, bump station, boss station and cutting station in the progressive die The stamping structure is the same as that of ordinary single-station stamping dies. The edge trimming of the panel end can be completed at the trimming station, the punching of the length of the panel can be completed, the workload on the cutting station can be reduced, the service life of the mold can be improved, and the bumps of the panel can be completed at the bump station Processing, the boss processing of the panel can be completed at the boss station, and the cutting and blanking of the panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com