Winding method and device for winding bobbins

A winding device and bobbin technology, applied in the direction of transportation and packaging, thin material handling, and delivery of filamentous materials, etc., can solve the problems of damage to yarn quality, yarn quality reduction, yarn breakage, etc., and increase energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

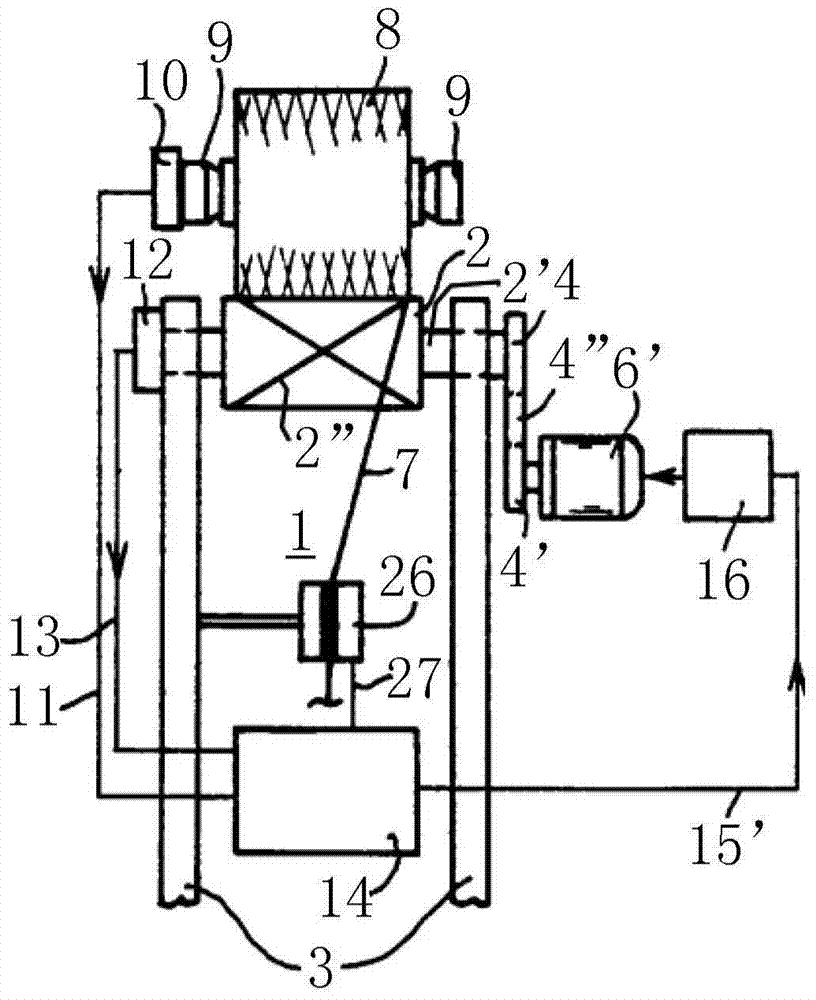

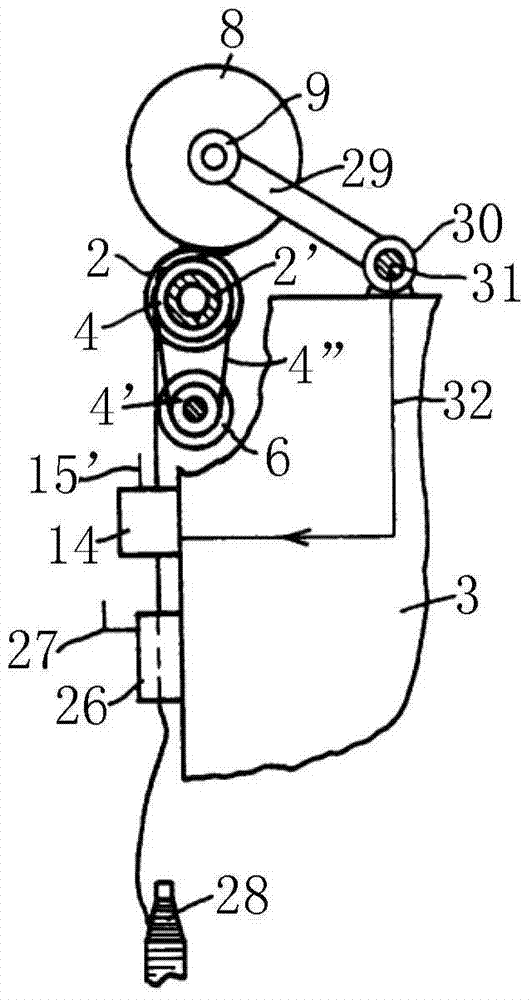

[0038] Basically quoted from EP 0399 243 B1 (wherein figure 2 and Figure 5 shown) figure 1 and figure 2 The winding station 1 of the winding machine provided according to the invention is schematically shown in simplified front and side views.

[0039] At the winding station 1 , the winding bobbin 8 mounted in the bobbin holder 9 is frictionally driven by the drive drum 2 , which is wound by the winding station 1 in the form of a cross-winding bobbin 8 . The thread 7 drawn therein from the bobbin 28 is wound onto a cross-winding bobbin 8 . The wire 7 is arranged parallel to the axis of the cross-wound bobbin 8 by means of the helical groove 2" of the drive drum 2. The desired cross-wind is thereby produced.

[0040] The drive drum 2 is mounted on the frame 3 of the winder via a drum shaft 2'. The drive of the drum shaft 2' is achieved via belt pulleys 4 and 4' connected by a V-belt 4", wherein the belt pulley 4' is driven by an electric motor 6'. Instead of belt d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com