Inner ring type metal fiber infrared radiation combustor for yarn production

A technology of metal fiber and infrared radiation, which is applied in the direction of burners, gas fuel burners, and combustion methods, can solve the problems of loose fiber cohesion, fiber damage on the surface of the yarn, and yellowing of the fiber on the surface of the yarn. The effect of uniform air permeability, complete combustion and low emission concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

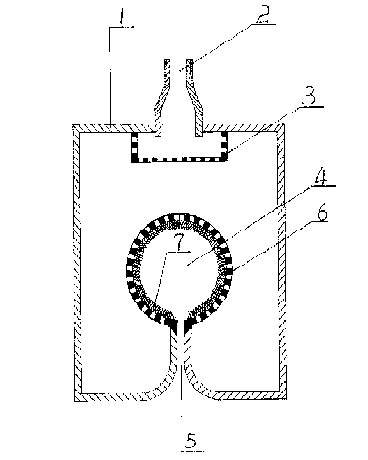

[0014] The embodiments are described in detail with reference to the accompanying drawings. An inner ring metal fiber infrared radiation burner for yarn production is mainly composed of a gas supply housing 1, a gas interface 2, a gas distribution plate 3, a gas injection plate 6 and a metal combustion mesh felt 7. The gas supply housing One side of 1 is provided with a gas port 2. When the burner is working, fully premixed combustible gas enters from this gas port 2. A gas distribution plate 3 is installed in the gas supply shell 1 around the gas port 2. The working surface of the gas distribution plate 3 is machined with a number of transparent nozzle holes, which play the role of first-level distribution of the gas. The gas is distributed through the distribution of the gas distribution plate 3, and the pressure is balanced and mixed evenly distributed in the gas supply shell 1. In the cavity, there is a combustion channel 4 running up and down in the central area of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com