Method and device for determining the necessary speed of rotation of a coil drive roller

A technology for driving rollers and bobbins, which is used in transportation and packaging, thin material handling, and transportation of filamentous materials, etc., and can solve problems such as quality problems and negative effects of subsequent processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

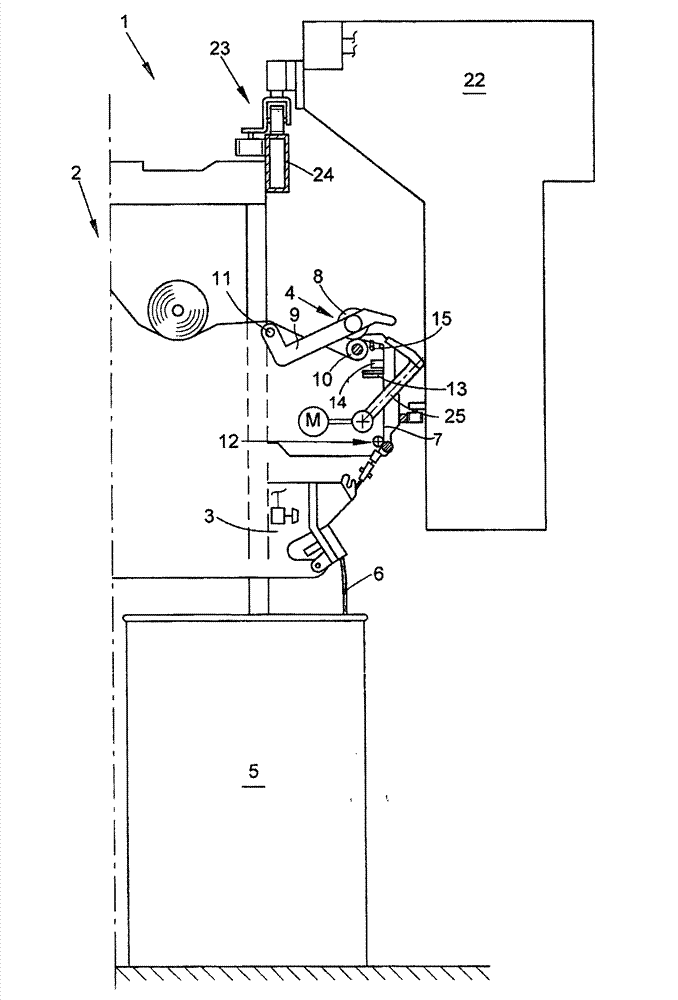

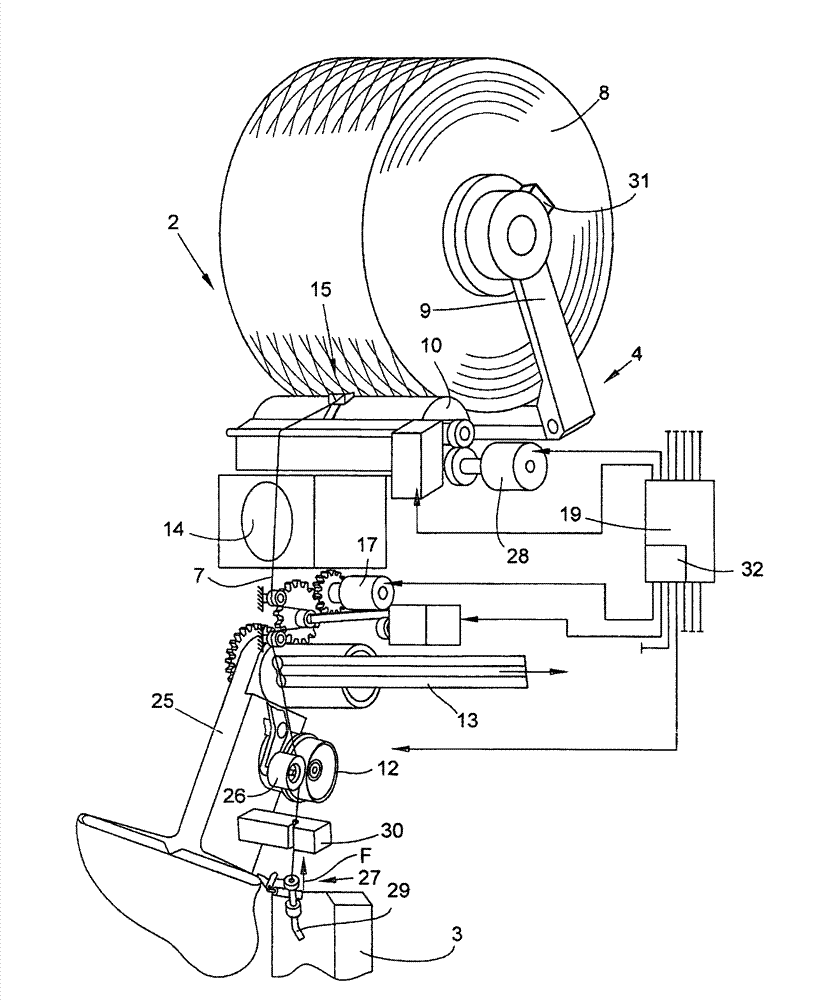

[0021] figure 1 A side view of the station 2 of the open-end rotor spinning machine 1 is shown. Such an open-end rotor spinning machine 1 has a plurality of such workstations 2 arranged side by side in each case on its two machine longitudinal sides. Here, the structure and working principle of the stations 2 are the same, so only one station 2 will be used for description.

[0022] figure 1 with figure 2 Shown is a station 2 with an open-end spinning device 3 and a winding device 4 including a suction nozzle 25 . As is known, a fiber sliver 6 stored in a spinning barrel 5 is spun into a yarn 7 in an open-end spinning device 3 . The yarn 7 is then wound onto a cross-wound bobbin 8 in the winding device 4 . The cross-wound bobbin 8 is held in the winding device 4 on the creel 9 during the spinning / winding process, where it is driven by a bobbin drive roller 10 with a friction fit. The creel 9 is pivotably mounted about a pivot axis 11 .

[0023] The yarn 7 is drawn out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com