Coil Units and Winding Holders for Low Pole Count Rotors

A coil device and coil winding technology, applied in the direction of winding conductive materials, superconducting magnets/coils, transformers/reactors installation/support/suspension, etc., can solve problems such as high weight, high material consumption, and large space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

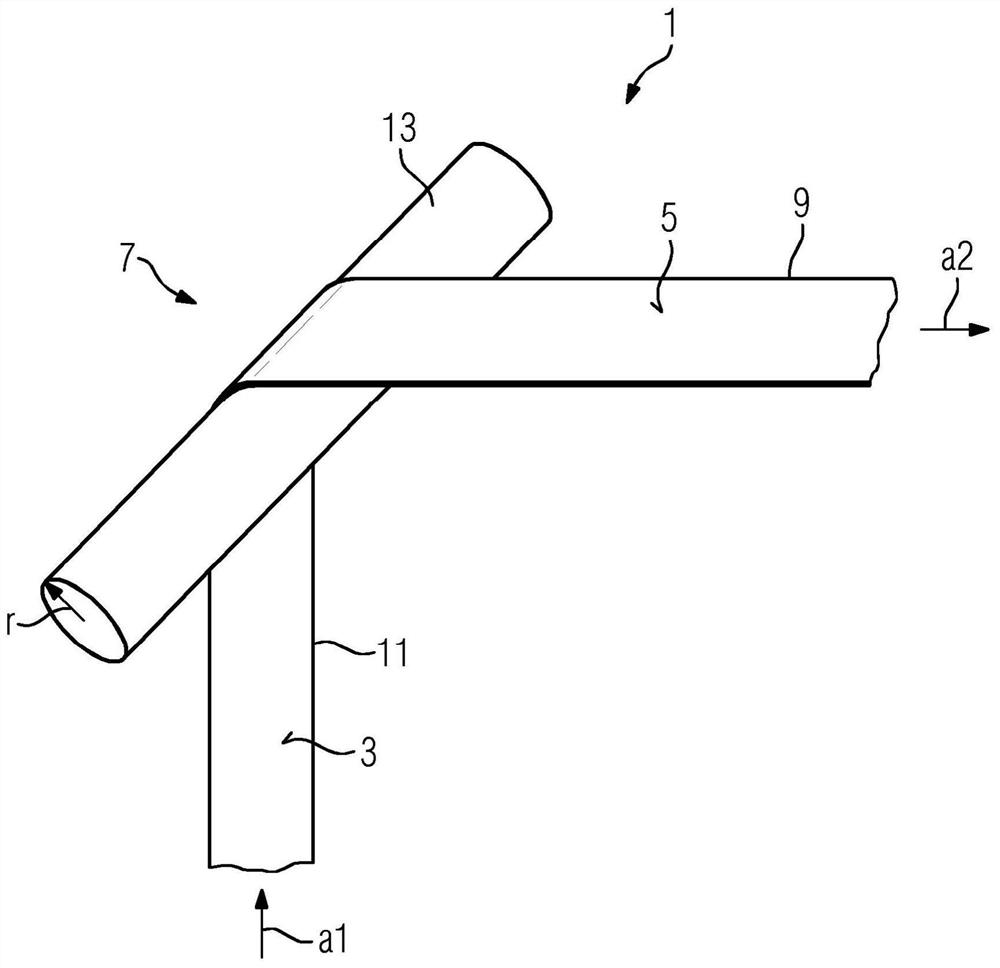

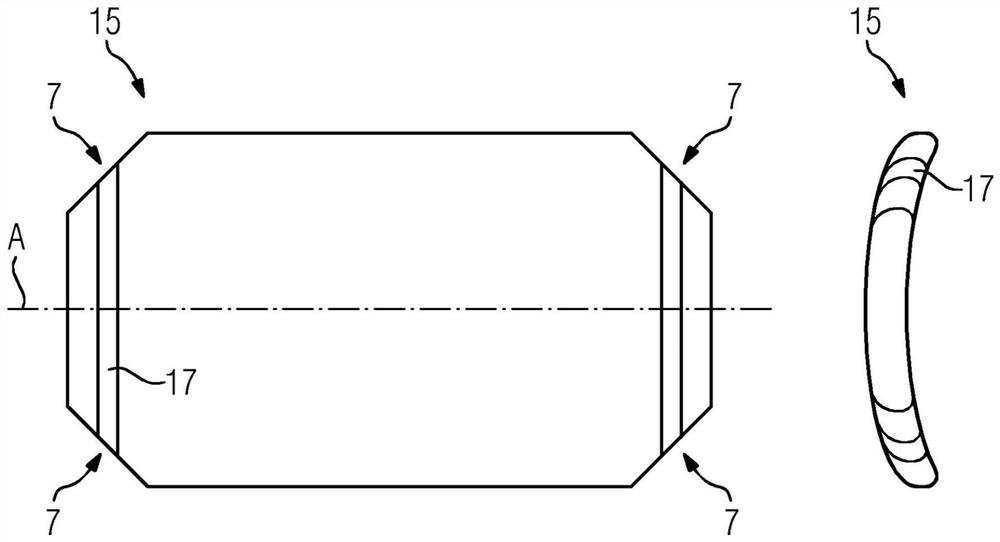

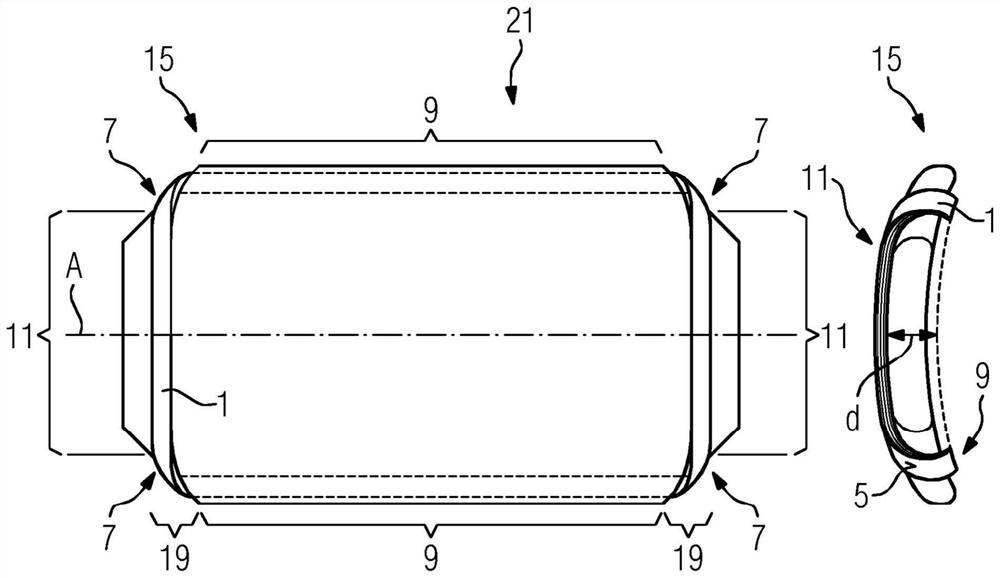

[0054] exist figure 1 A schematic representation of the strip conductor 1 in the inversion region 7 of the coil arrangement according to the invention is shown in FIG. Such an inversion region 7 can in principle occur in any region of the coil winding that is part of such a coil arrangement. It is important in connection with the present invention that the strip conductor 1 achieves a significant change of direction in such an inversion region 7 and at the same time changes the orientation of its two main surfaces. Therefore, the longitudinal direction of the strip conductor 1 is figure 1 In the left-hand region of the drawing, the strip conductors extend vertically in the direction a1 in the shown figure, while in the right-hand part of the drawing, the strip conductors are horizontally in the drawing in the direction a2 after passing the inversion region 7 . That is, the longitudinal direction of the strip conductor 1 is changed by about 90° here. On the left, the strip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com