Patents

Literature

79results about How to "Avoid yarn breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

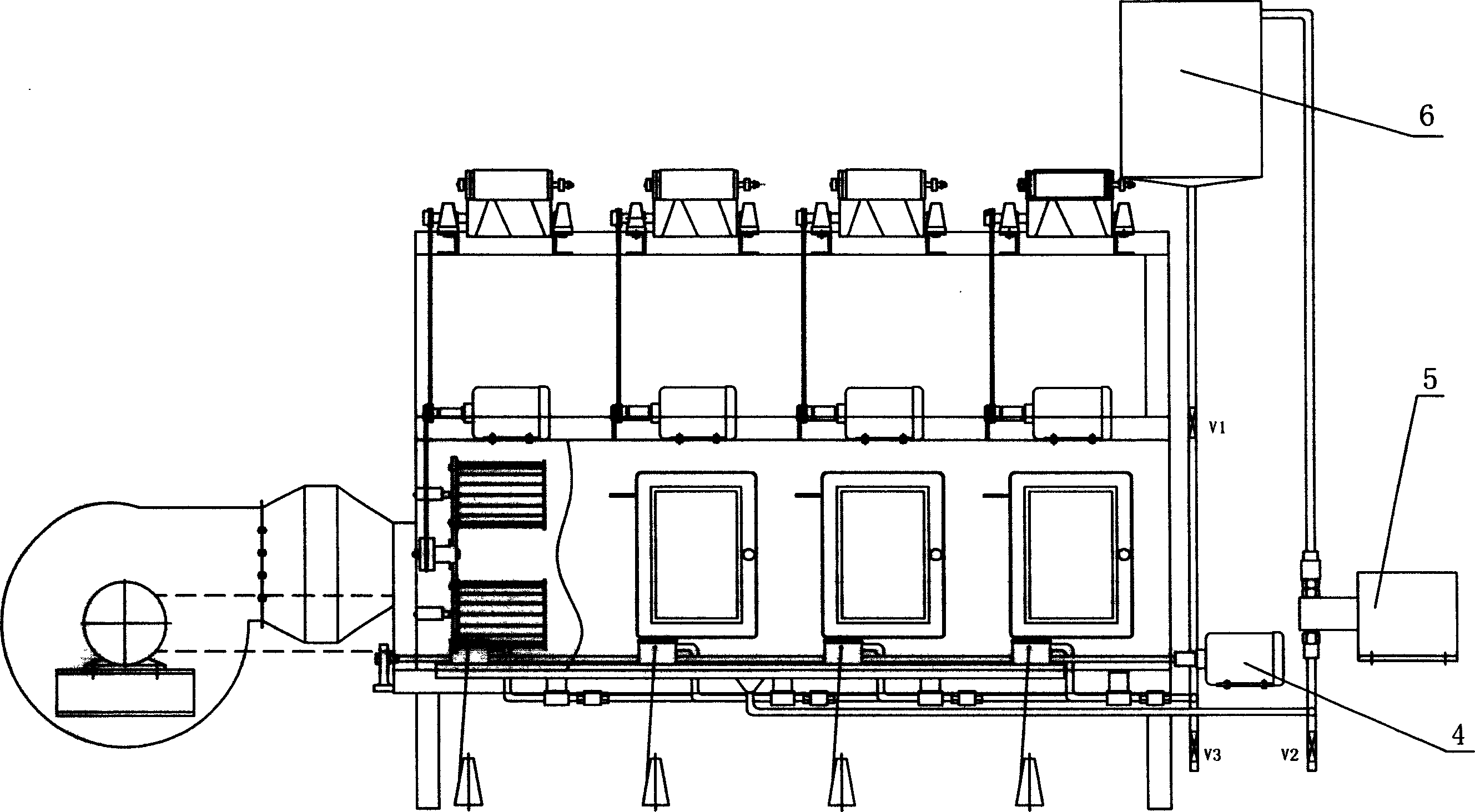

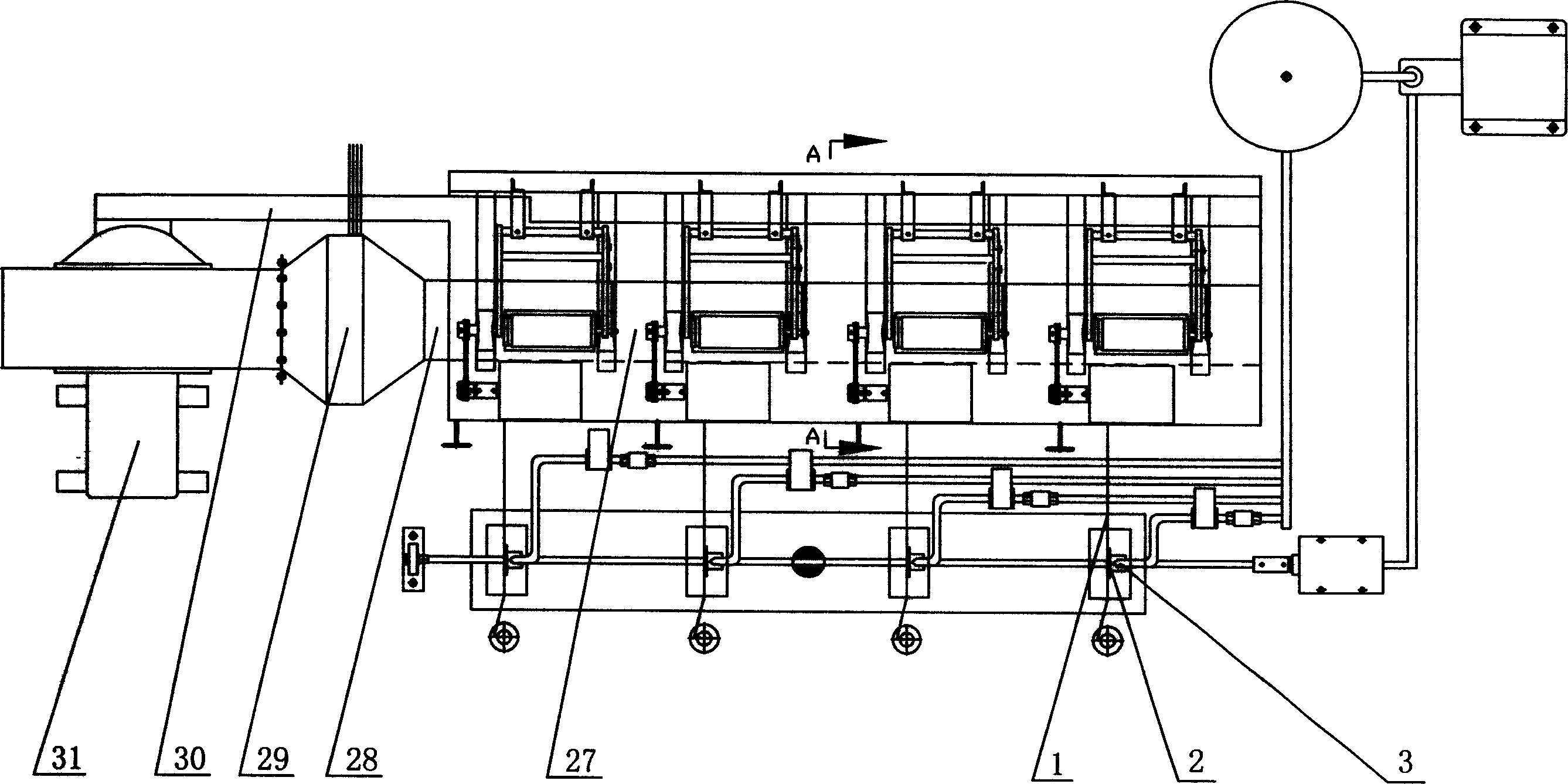

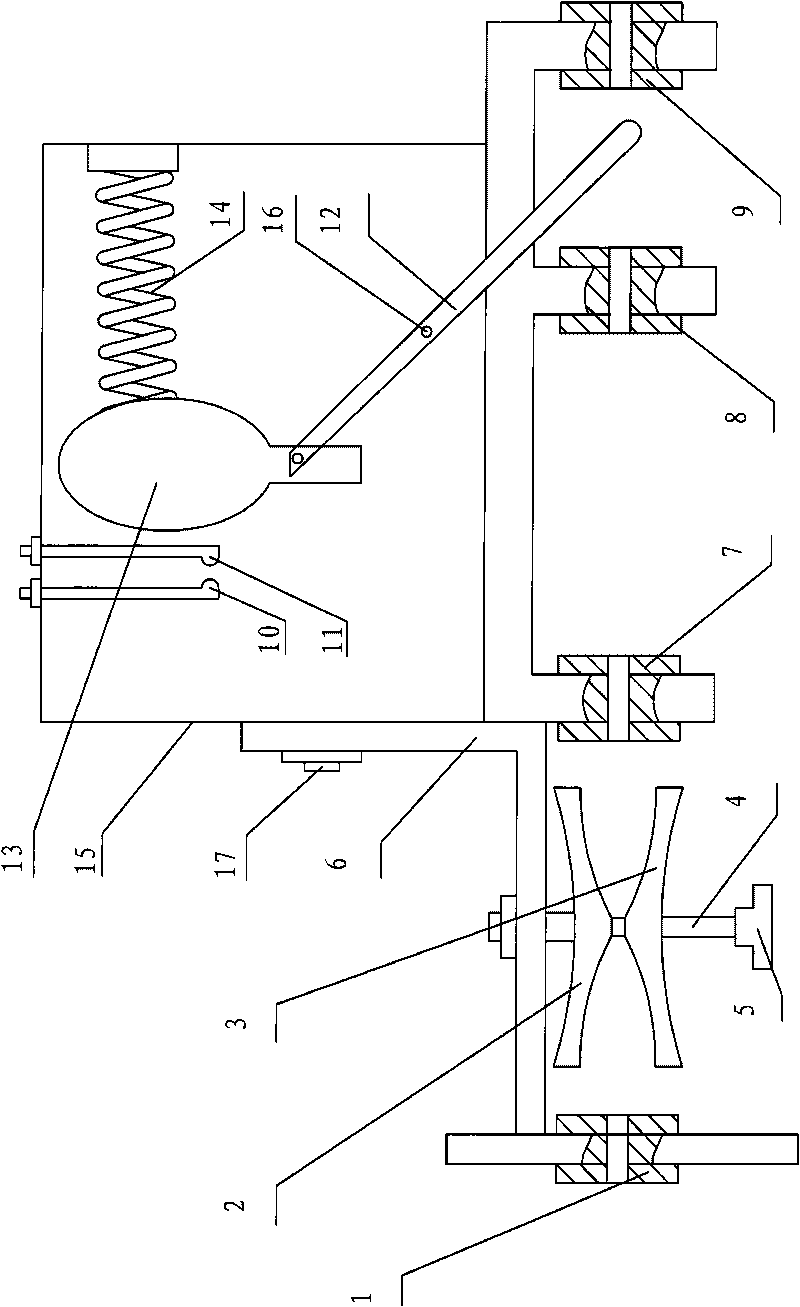

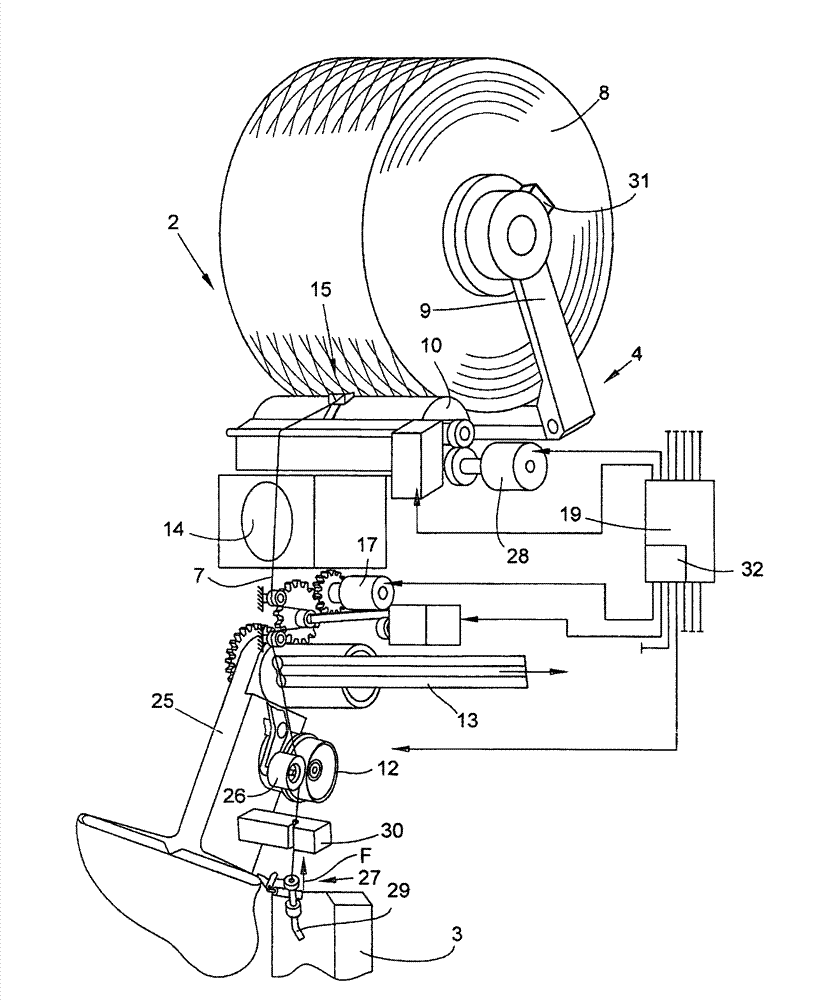

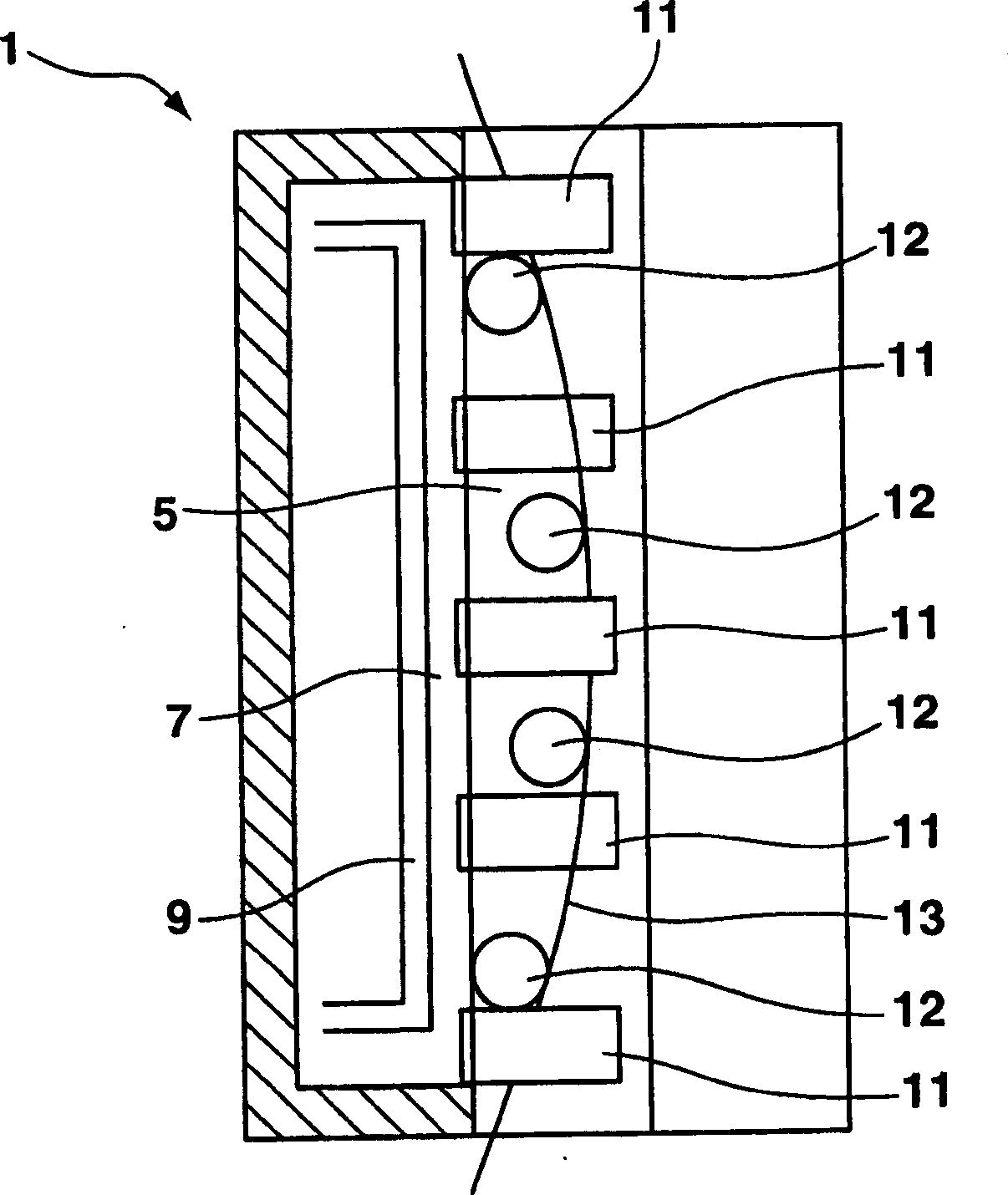

Single yarn dyeing machine

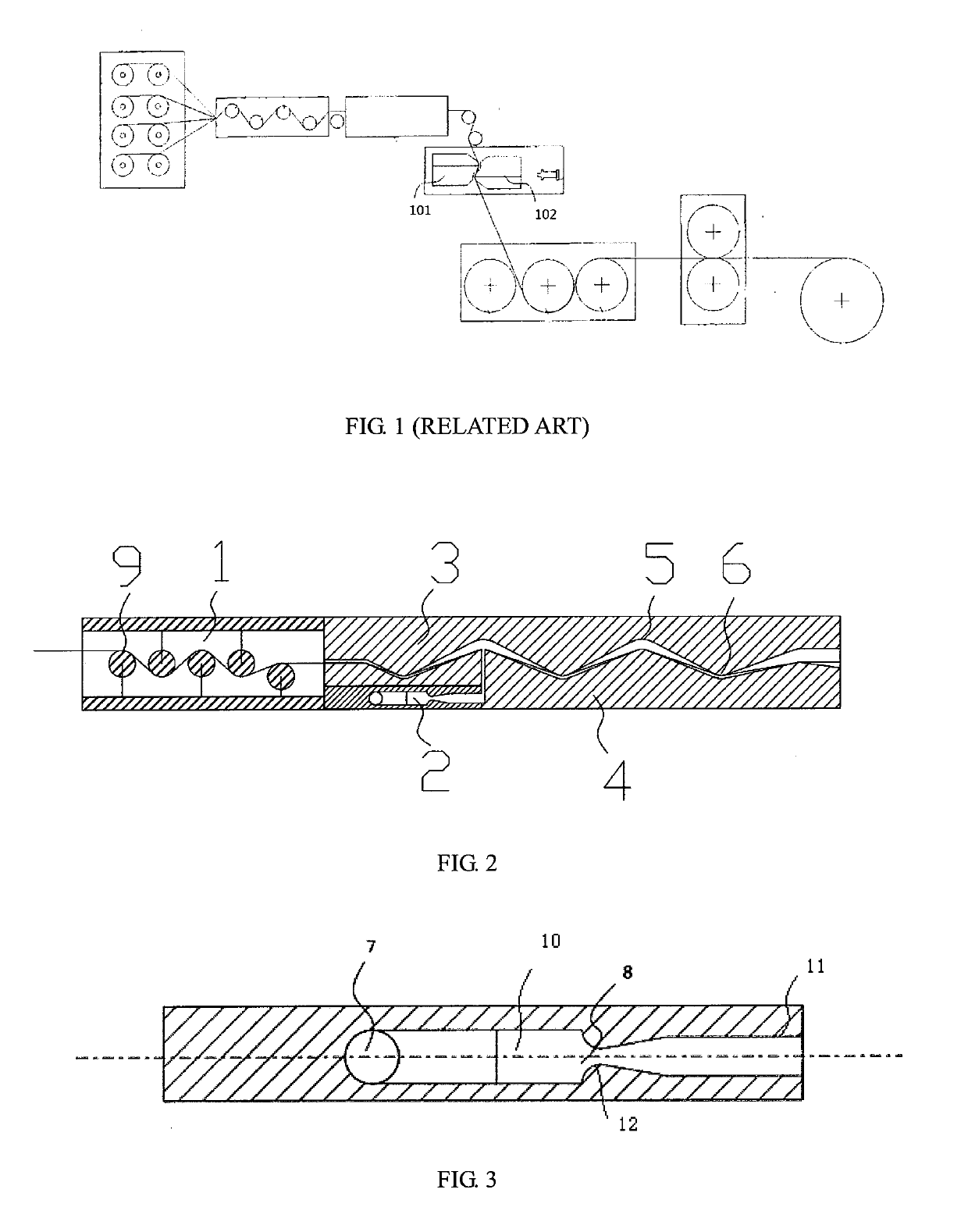

ActiveCN1594706AHigh yarn dyeing efficiencyAvoid yarn breakageLiquid/gas/vapor yarns/filaments treatmentYarnBobbin

The invention relates to a single yarn dyeing machine, which is characterized in that the dye in the dyeing unit locates at a high position which communicates to the nozzles (four in a group) through pipe V1, V2, V3-Vn. The motor controlled by transducer drives the dyeing disc through rotary shaft. The motor shaft of the winding unit sets two belt pulley, in which one of which drives the belt pulley on the groove drum shaft by belt, another drives the belt pulley on the overdrive clutching mechanism through belt. The yarn after dyeing enters the oven and winds uniformly on the rotary spinning drum. The dried yarn winds on the bobbin through groove drum. The invention can regulate the distance of the dyeing yarn, avoids yarn breakage, not only dyes the yarn into homogeneous segment but also heterogeneous segment.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

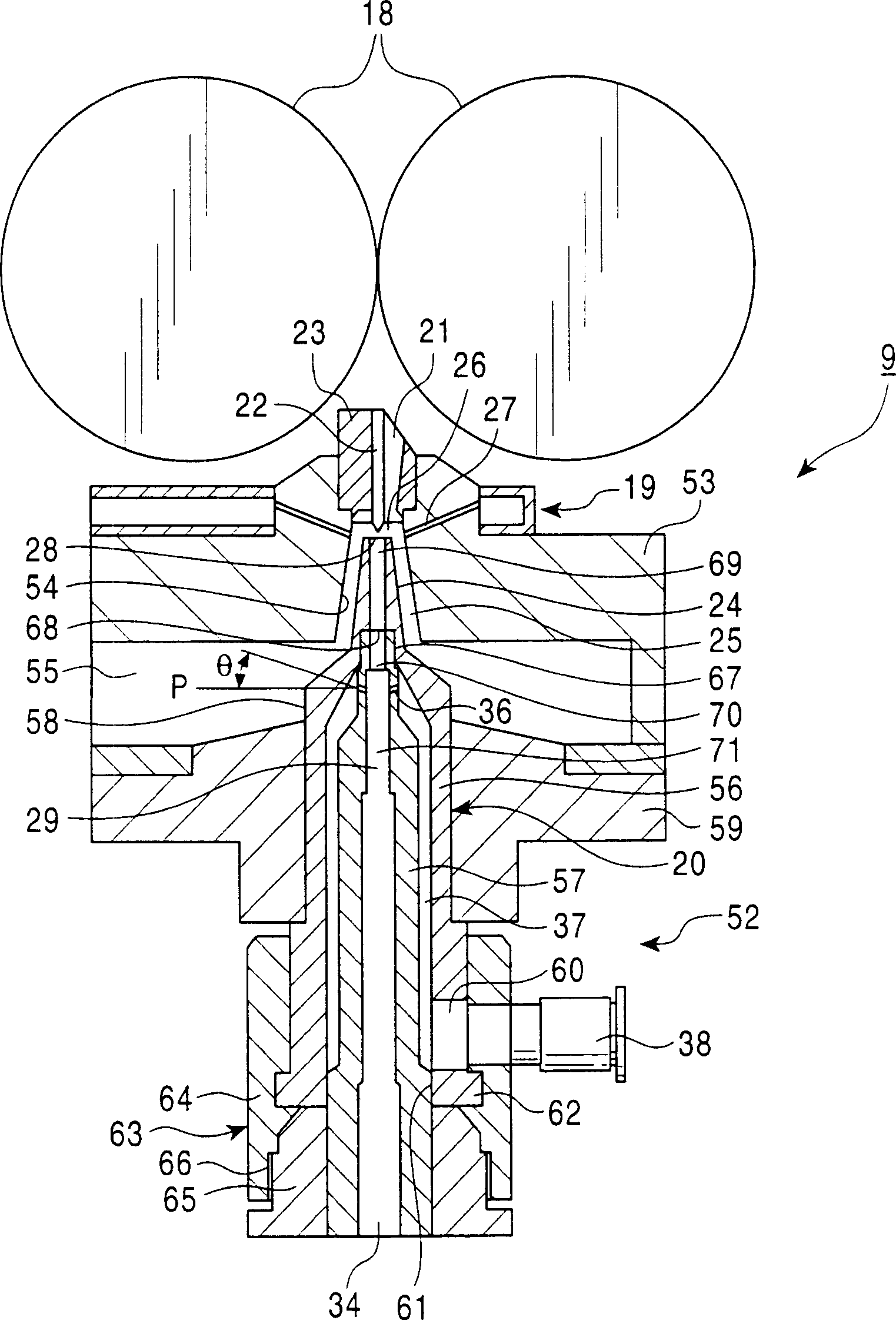

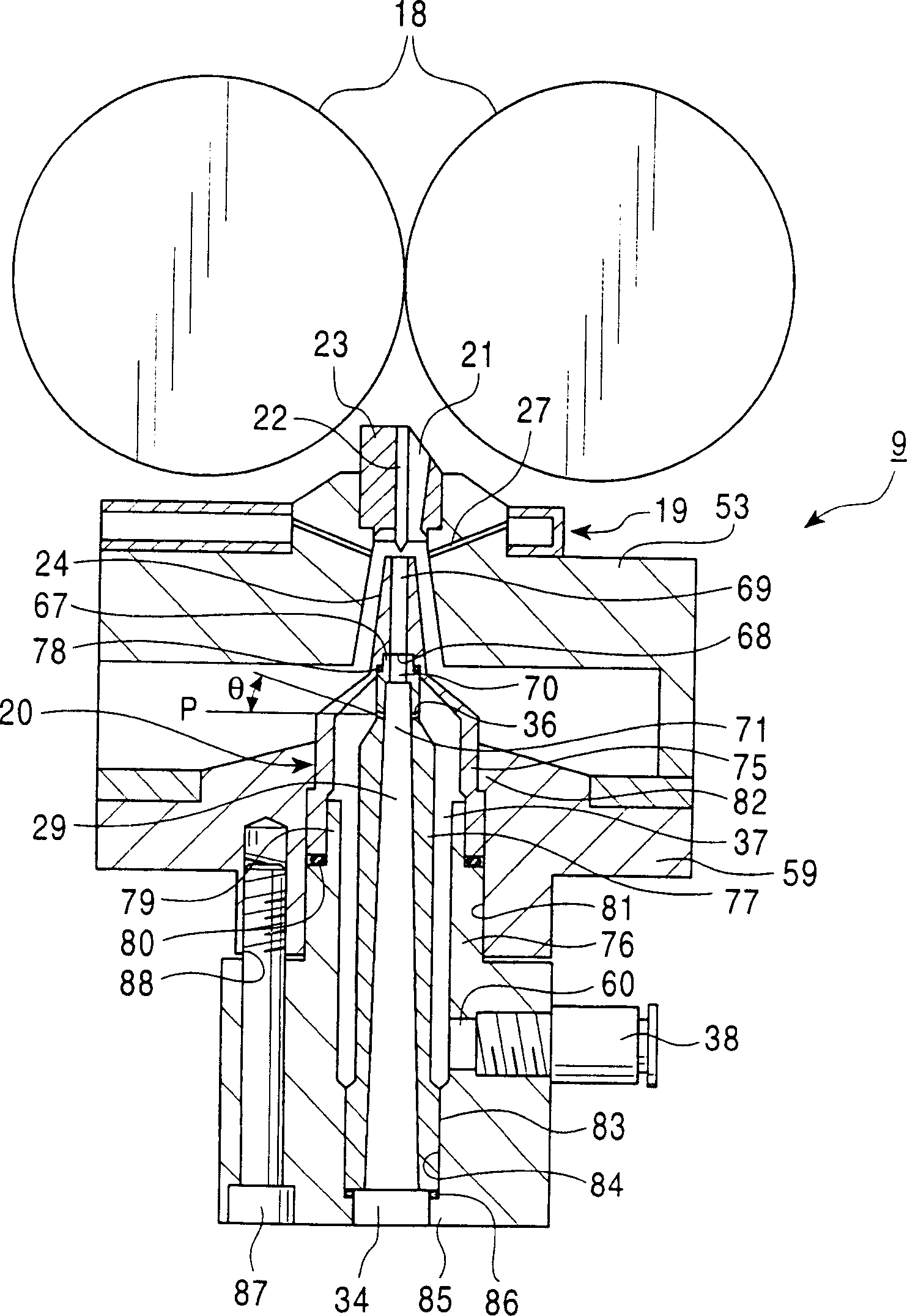

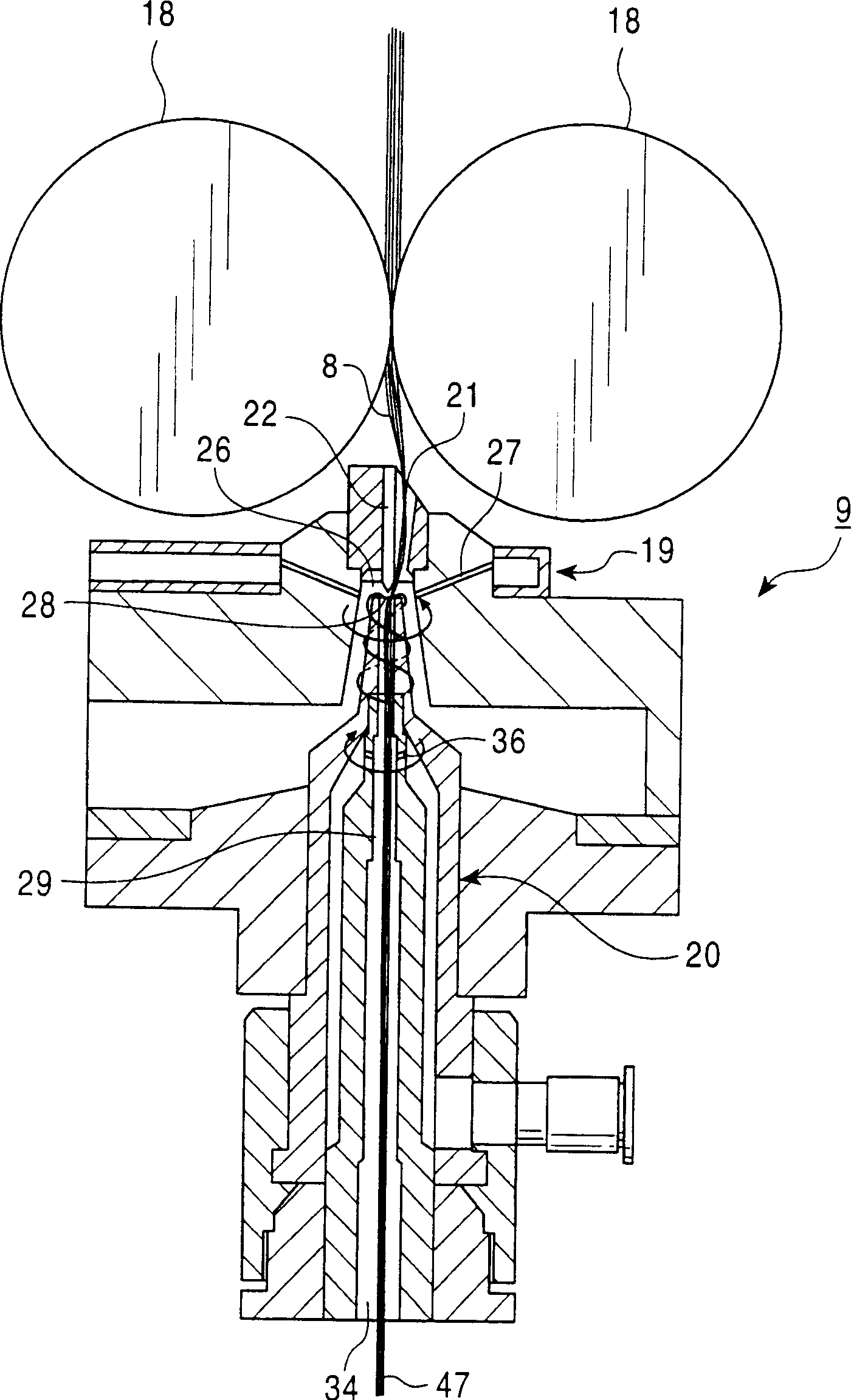

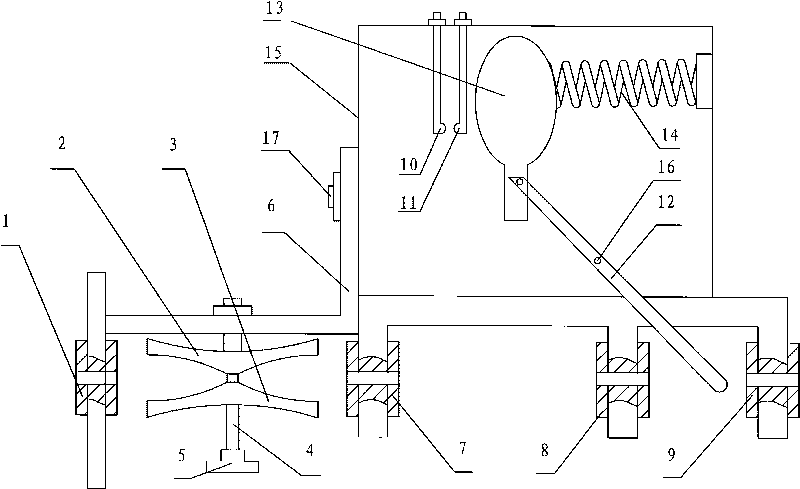

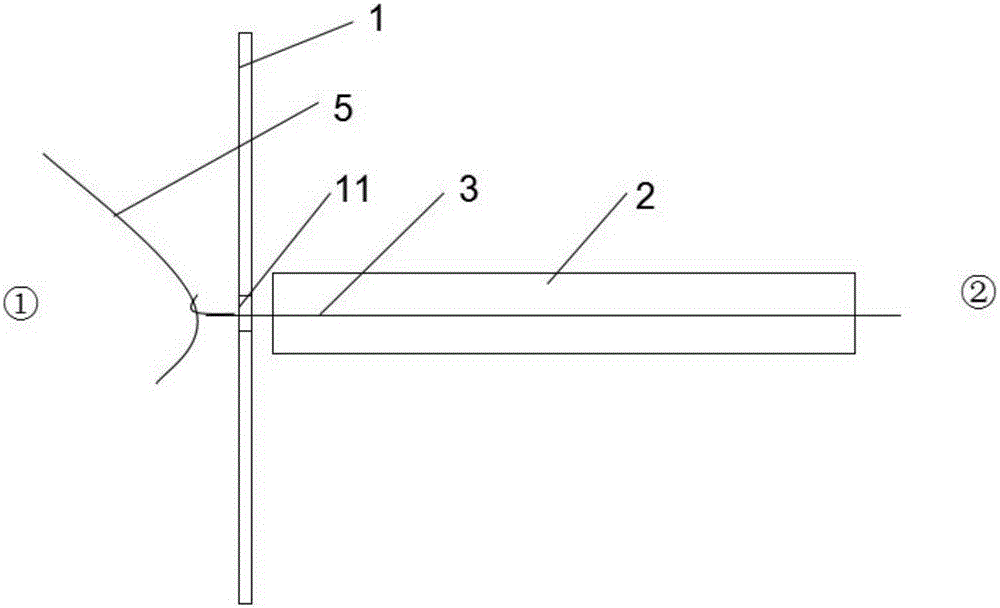

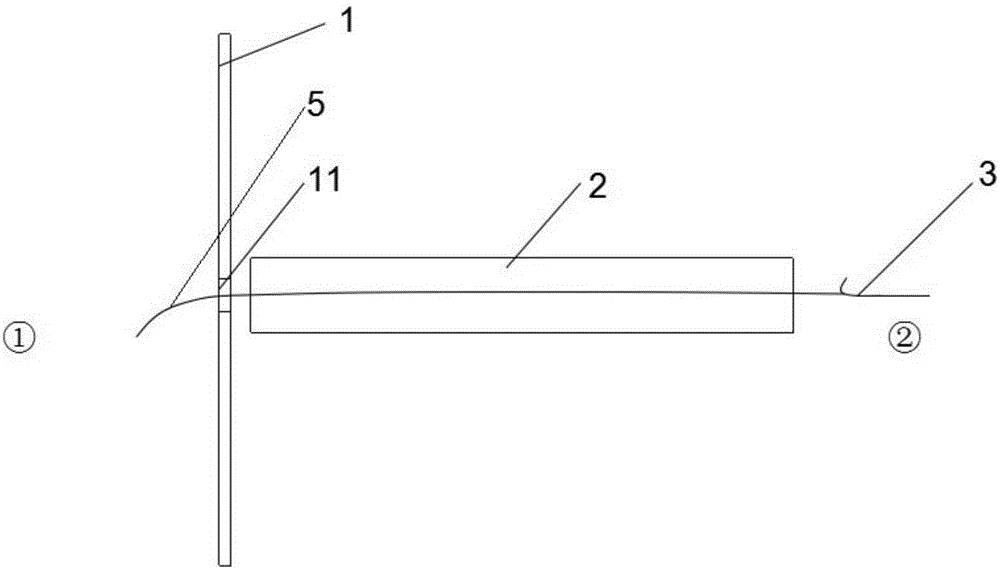

Spinning devices

InactiveCN1407153AAvoid yarn breakageIncrease success ratePiercing arrangementsContinuous wound-up machinesEngineeringYarn strength

The invention provides a high-speed spinning by increasing success rates of the taking-out of a yarn and the piecing of the yarn. This spinning frame has a pneumatic spinning nozzle 27 for generating a rotational gas flow at the vicinity of a tip part 24 of a hollow guide shaft 20 and an assistant nozzle 36 for generating the rotational gas flow in a yarn passage 29 in a hollow guide shaft 20. The assistant nozzle 36 is tilted so as to be directed to the downstream side based on the plane P orthogonal to the yarn passage 29. The tilting angle of the assistant nozzle 36 is preferably 10-35 degrees, more preferably 20 degrees. As a result, the component of the flow directed to the downstream side, and accompanied by the rotational gas flow generated by the assistant nozzle is enlarged, and the sucking power into the yarn passage is enhanced. The balance between the components in the downstream direction and the rotational direction is corrected and the yarn strength of a bound yarn to be discharged is increased to prevent the yarn break or the like.

Owner:MURATA MASCH LTD

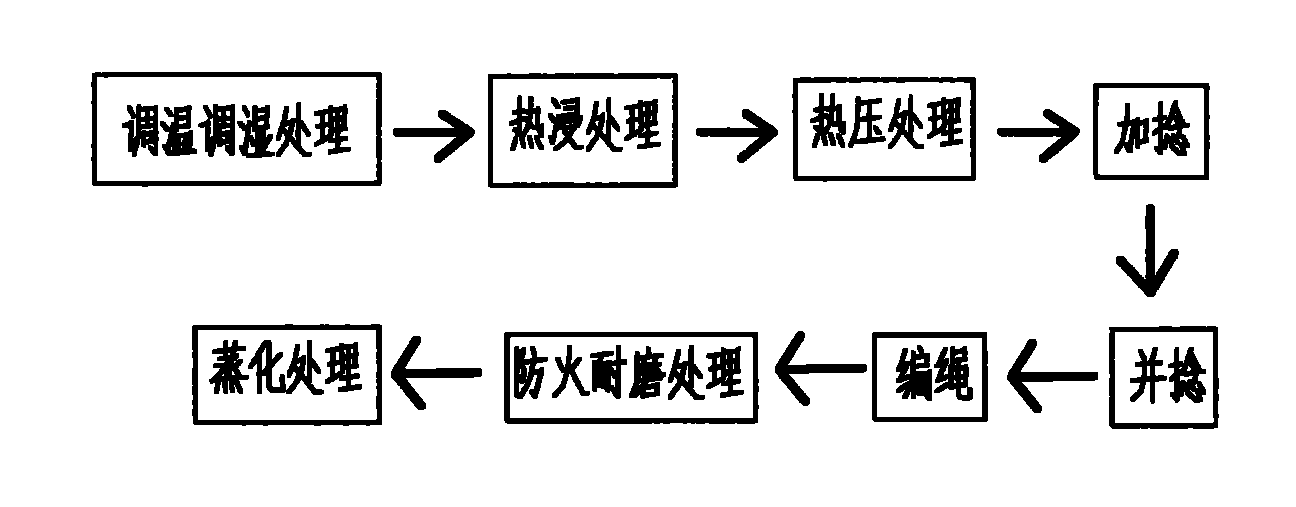

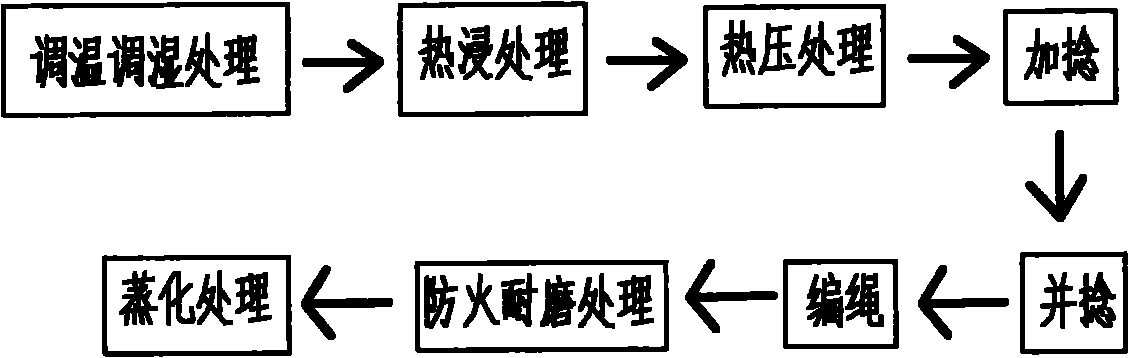

Method for producing basalt fiber rope net

ActiveCN101838885AImprove the finishHigh tensile strengthLiquid/gas/vapor removal by squeezing rollersBraidPolymer scienceActive agent

The invention discloses a method for producing basalt fiber rope nets, which comprises the following processes of: heat soaking treatment, hot-pressing treatment, weaving ropes, fireproof and wear-resistant treatment, steaming treatment, and the like. The heat soaking treatment solution contains an anionic surfactant, sodium alga acid and other aids; a tension regulation device is arranged on a high-speed braiding machine; and the fireproof and wear-resistant treatment solution contains PTFE, neutral salts, and other active agents. The method has reasonable process and advanced treatment technology and method, and the produced rope nets have the advantages of high temperature resistance, corrosion resistance, high intensity, high safety, and high cost performance.

Owner:TAIAN ROPE NET PLASTIC

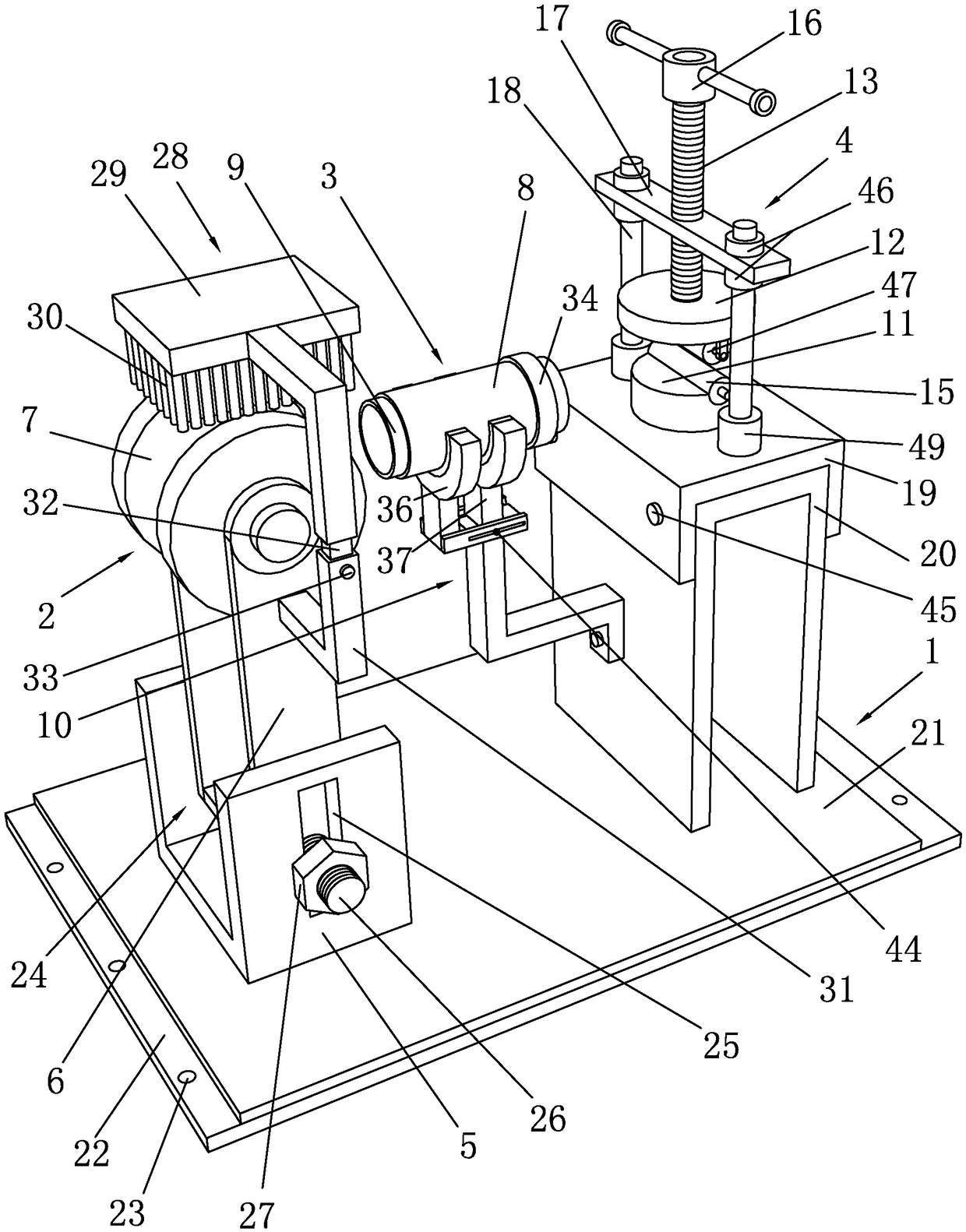

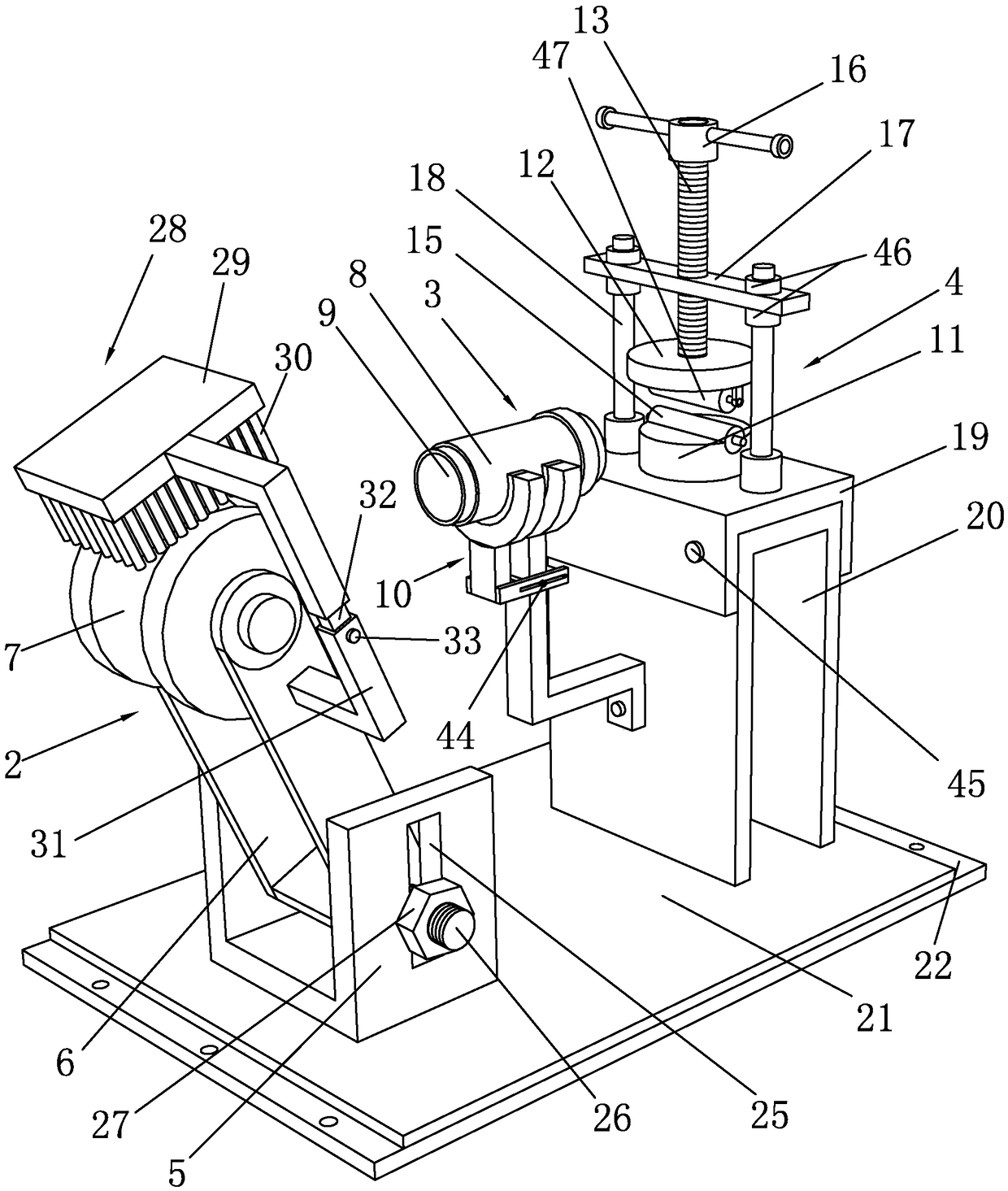

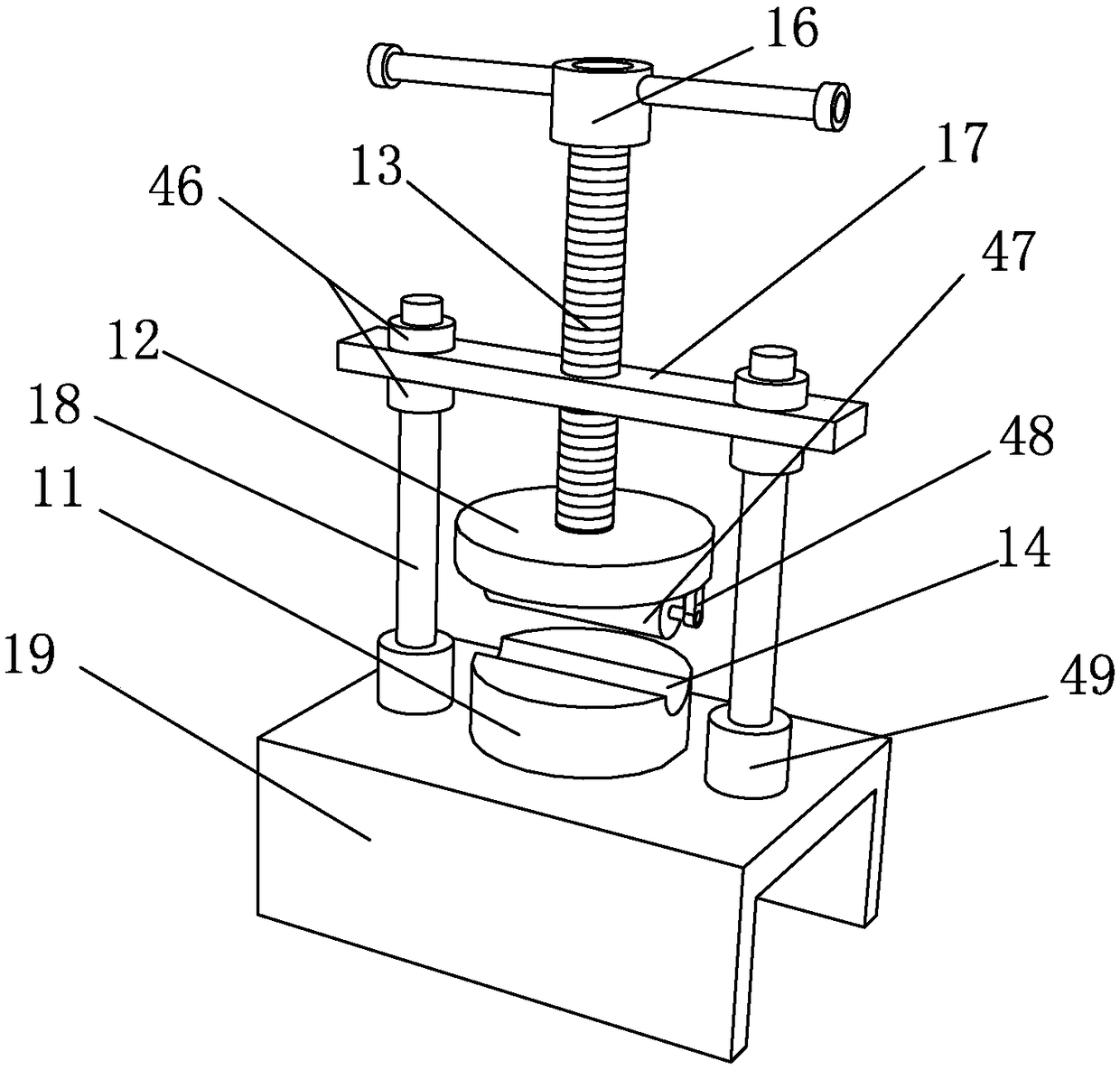

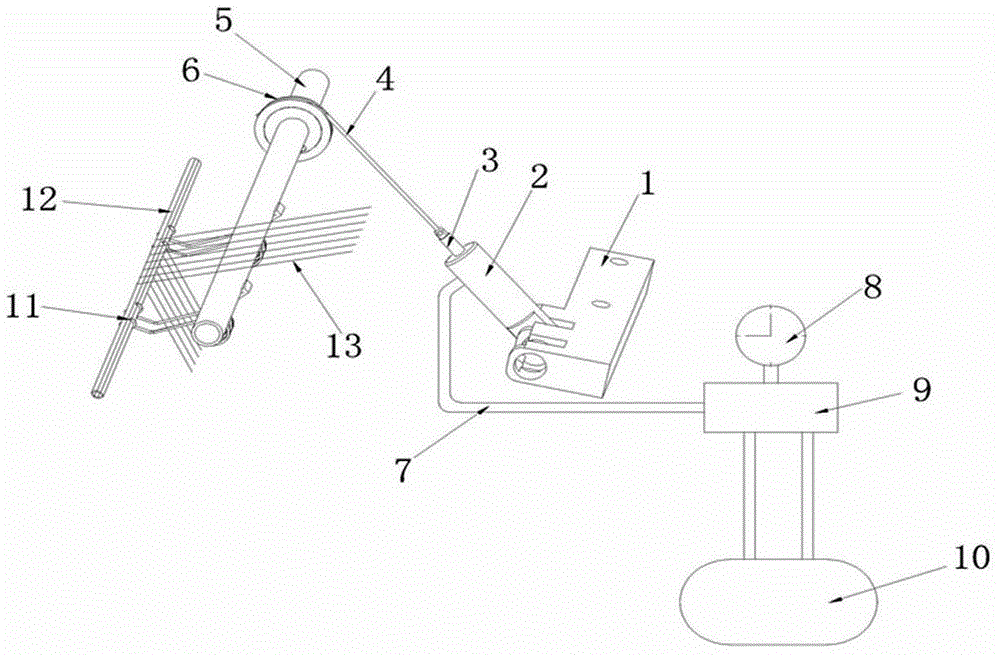

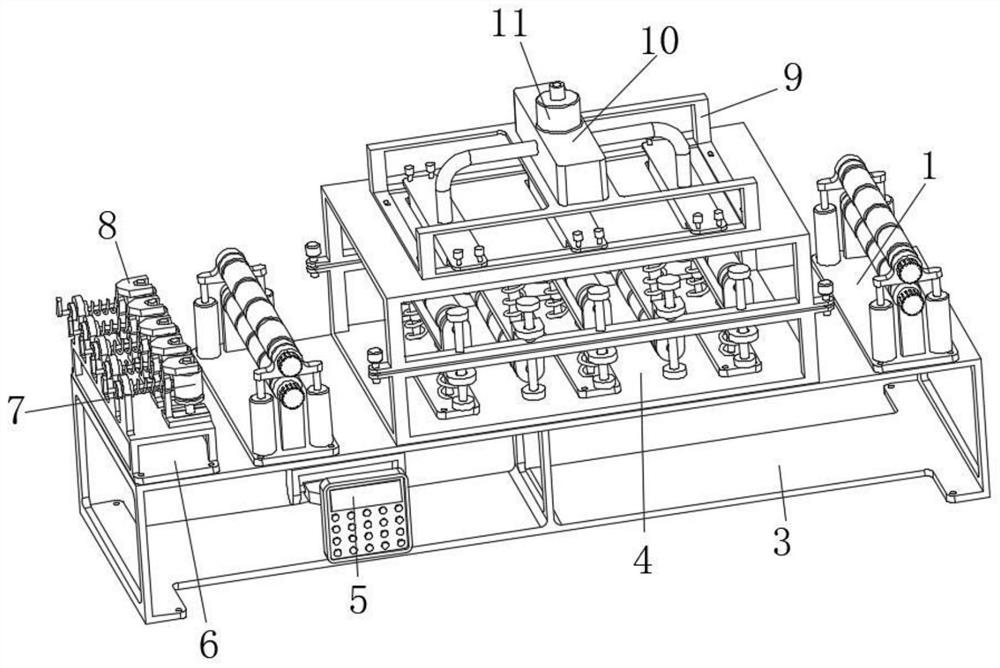

Yarn guiding device for textile product production

InactiveCN109281021AReduce mechanical vibrationEasy to assemble and disassembleYarnYarnPulp and paper industry

The invention discloses a yarn guiding device for textile product production. The device comprises a fixing bottom plate, a guiding assembly, a burr removing assembly and an adjusting assembly, the burr removing assembly comprises a guiding tube, a heating sleeve tube and a supporting frame, the heating sleeve tube is sleeved with the guiding wire, a heating wire is arranged in the heating tube, the adjusting assembly comprises a fixing plate, an adjusting plate and a pressurizing screw rod, the fixing plate is located on the limiting frame, a tensioning roller is arranged below the bottom ofthe adjusting plate, and the pressurizing screw rod is sleeved with the limiting plate. According to the yarn guiding device, yarns can be welled guided to prevent the yarns from breaking in the conveying process, the adjustment of the angle of the yarns can be conducted according to the conveying angle of the yarns, the using range of the guiding device is expanded, burrs, impurities and the likeon the yarns are removed through the burr removing mechanism to improve the quality of the yarns, and tensioning force in the yarn conveying process can be conducted by the adjusting assembly according to the conveying demands of the yarns to help the conveying of the yarns.

Owner:SHENGZHOU WENDA TEXTILE CO LTD

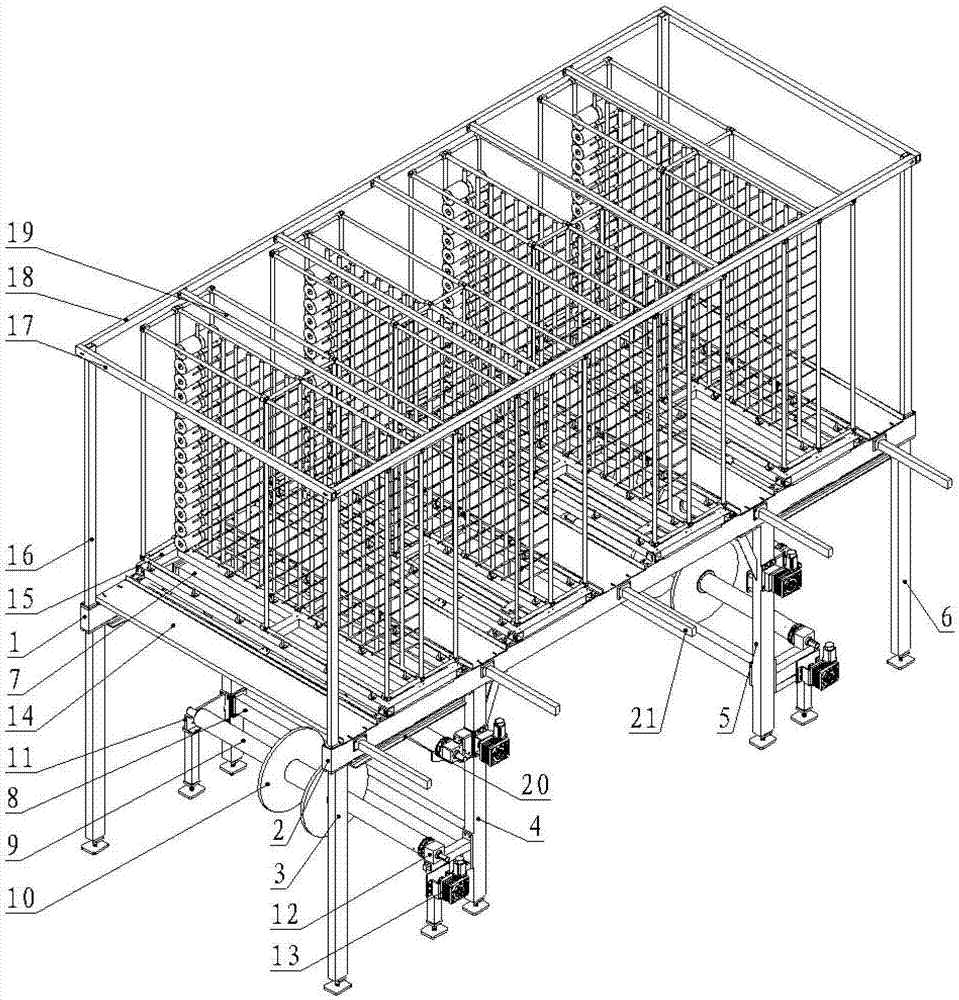

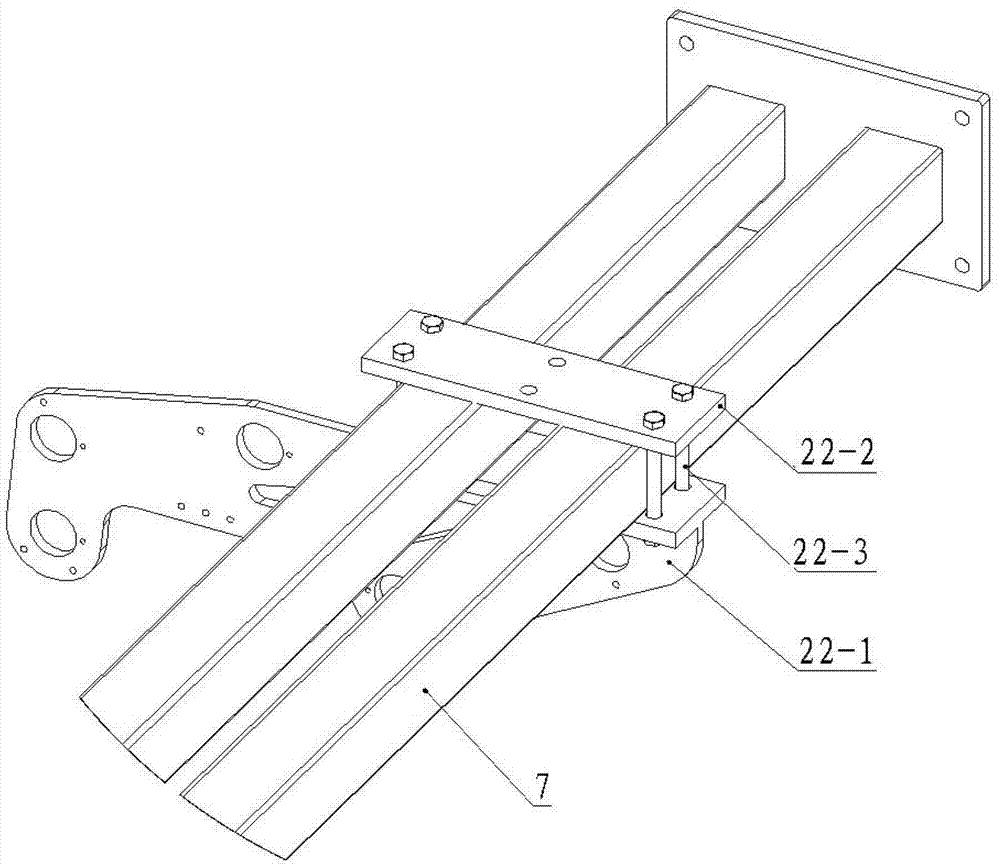

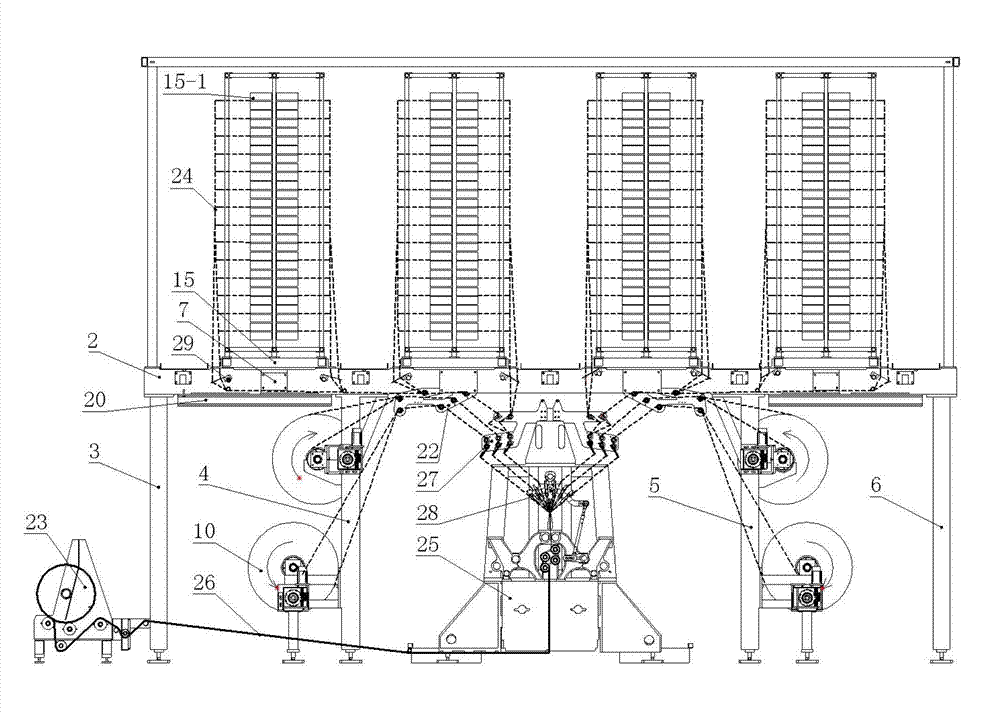

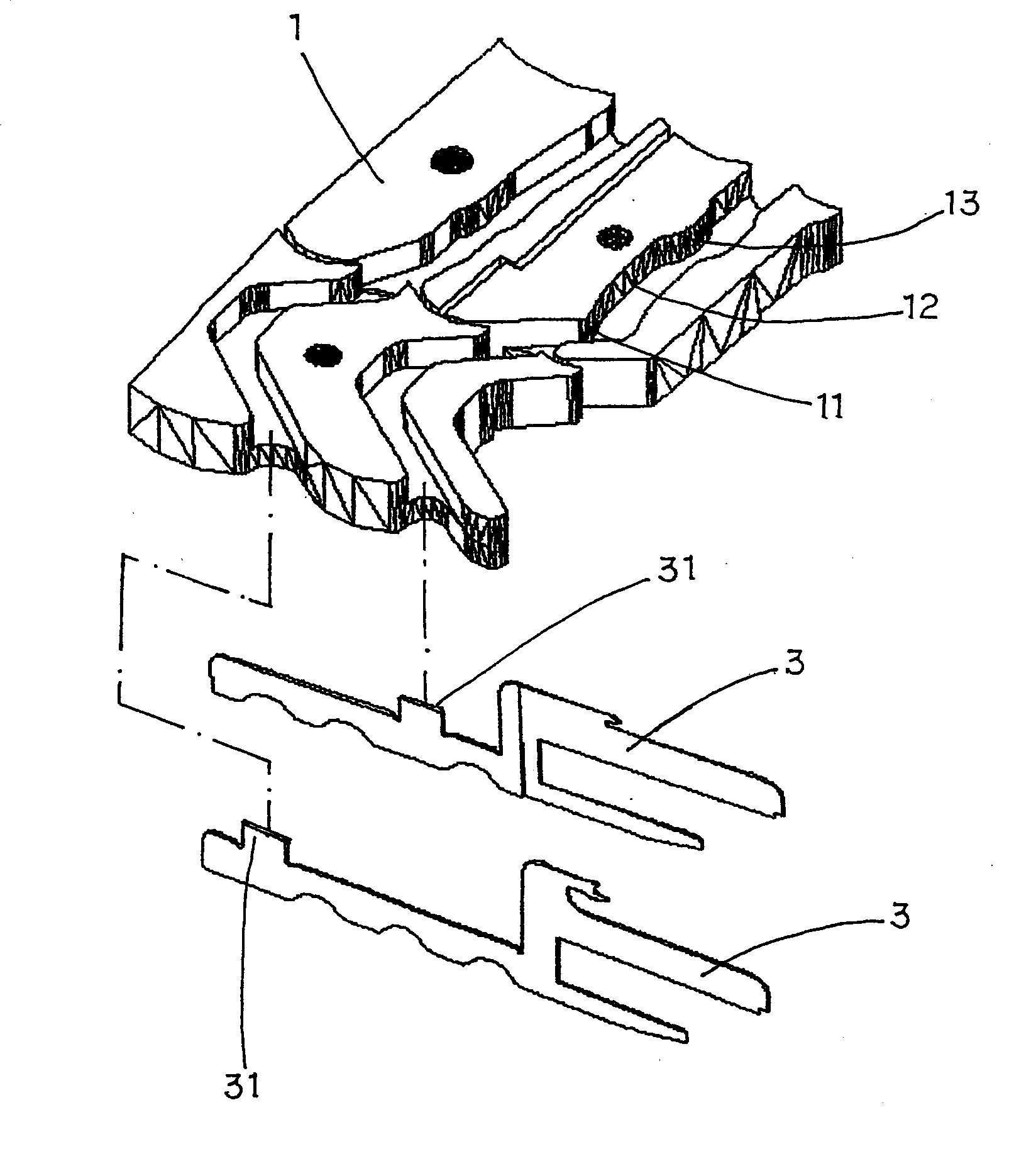

Let-off device of warp knitting machine

InactiveCN103243474AMeet weaving requirementsTake advantage ofWarp knittingTextile manufacturingBobbin

The invention relates to a textile manufacturing machine, in particular to a let-off device of a warp knitting machine. The let-off device comprises a creel let-off unit and a beam creel let-off unit. The creel let-off unit is located above the beam creel let-off unit. A top support of the beam creel let-off unit is supported on a mounting face through side supports. A beam is mounted on the side supports through a beam mounting component. A guide rod component is mounted on the top support. The creel let-off unit comprises at least one creel set mounted on the top support of the beam creel let-off unit. A pan head on the beam and a bobbin on the creel device are let off yarns to the warp knitting machine through the guide rod component. The let-off device has the advantages that the different requirements on let-off amount and tension are met, the whole warp knitting machine is compact in structure, space is fully utilized, plane area is reduced, let-off length is shortened, and yarn breakage caused by the fact that the excessive let-off length makes tension difficult to control is avoided effectively.

Owner:CHANGZHOU WUJIN WUYANG TEXTILE MACHINERY

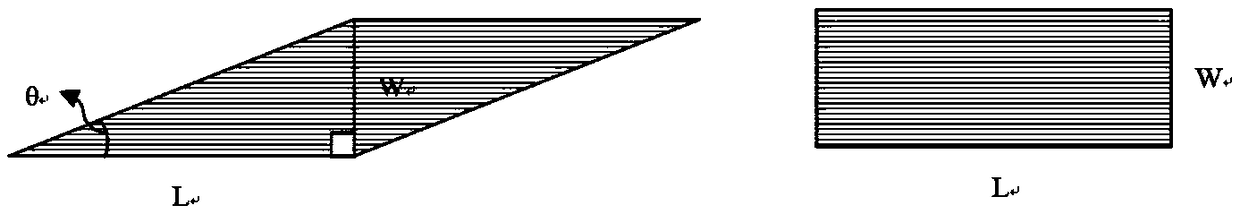

Discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and preparation method thereof

The invention provides a discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and a preparation method thereof. The mold pressing precast body comprises slices formed by slitting / cutting of continuous fiber reinforced thermoplastic composite material preimpregnated sheets / preimpregnated yarns, wherein the length L range of the slices is 5-200 mm, the width W range of the slices is 2-30 mm, and the weight percentage content of fibers in the slices is 20-90 wt%; and high-strength isotropous complicated parts with high size stability can be prepared through secondary mold pressing of the precast body, so that the defects of easy warpup, fiber length loss, weaker part performances, anisotropic mechanical performances of continuous fiber reinforced composite materials and difficult machining of different-thickness complicated parts after mold pressing injection molding of short-fiber and long-fiber particles are made up.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

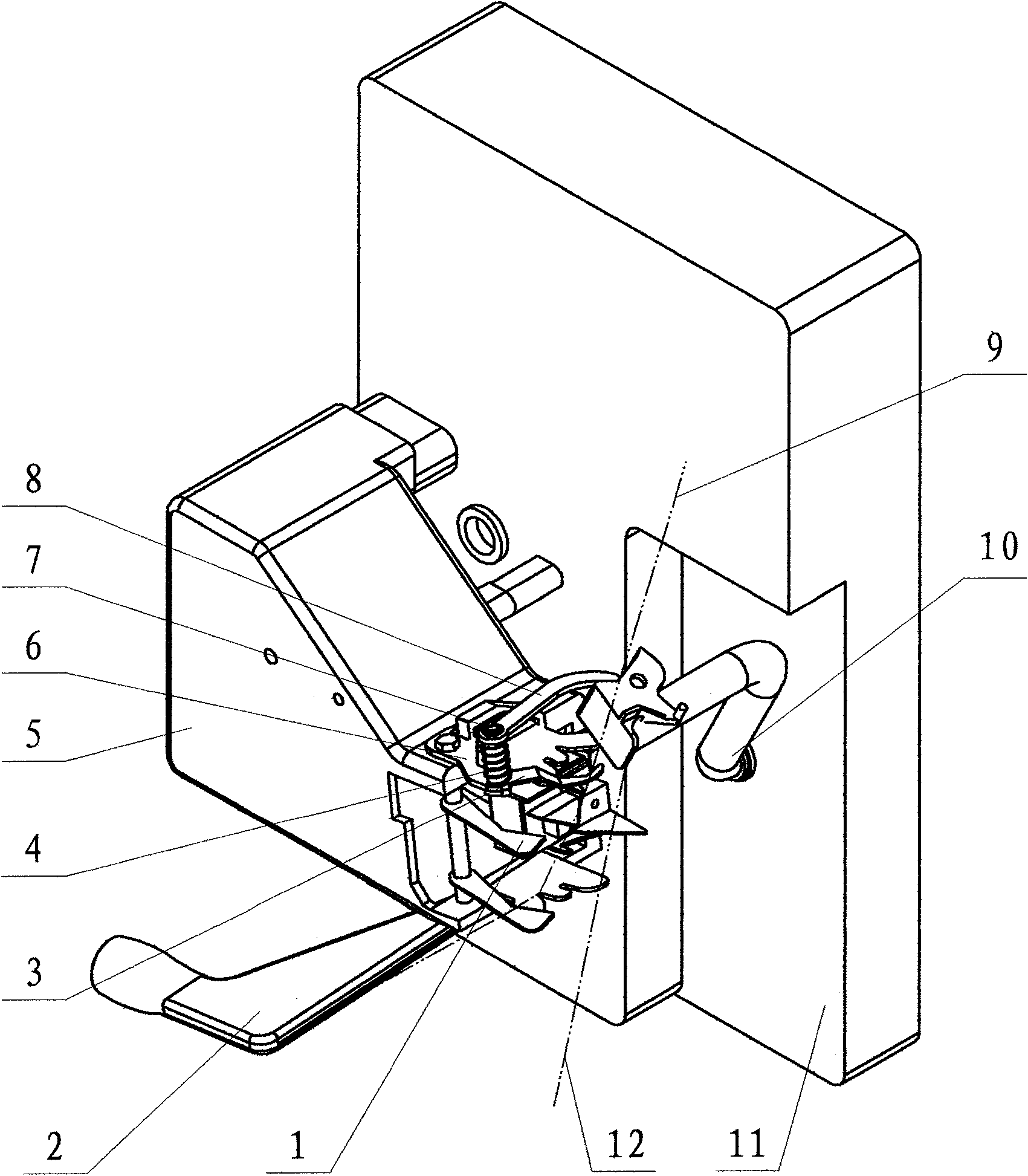

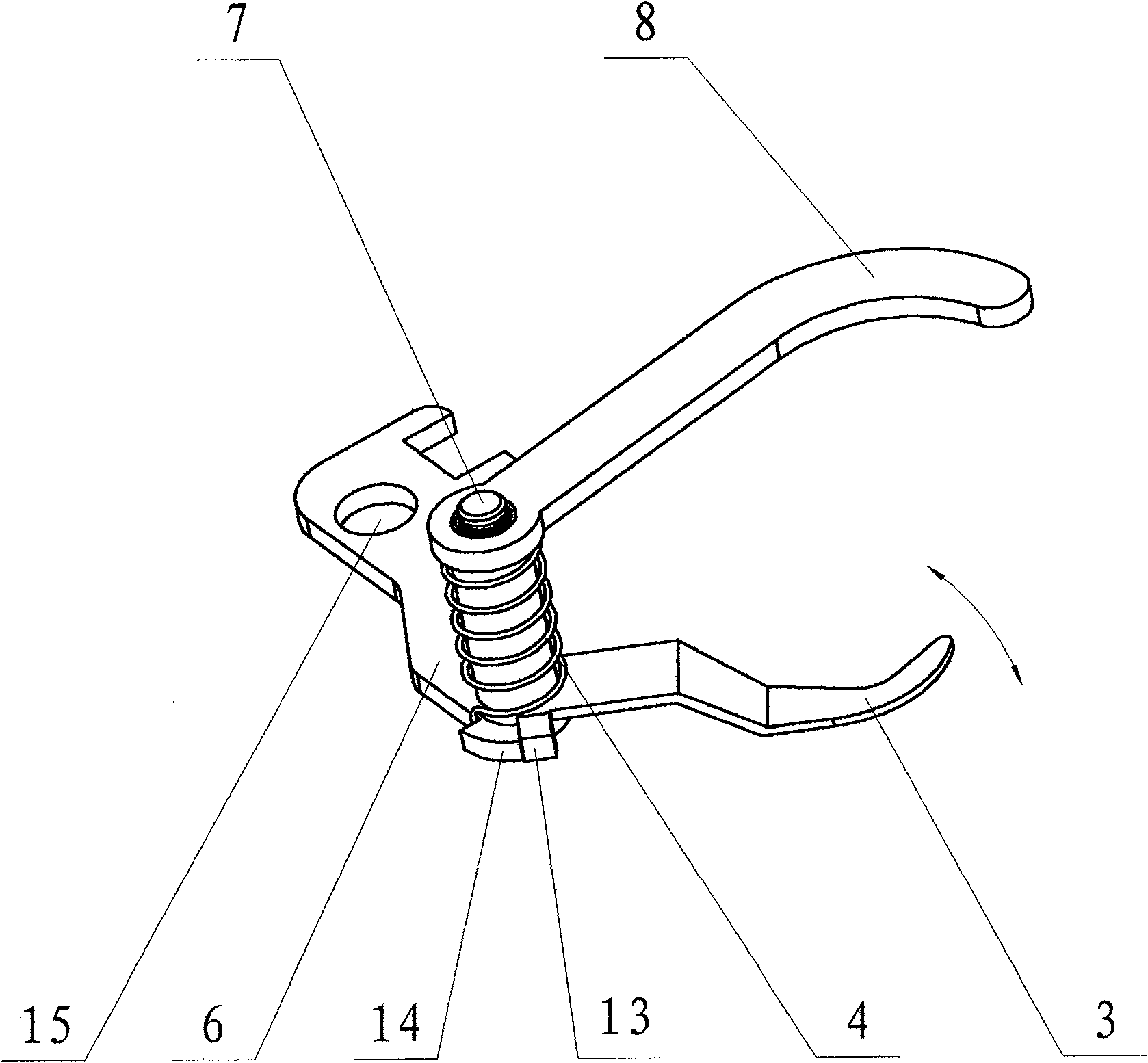

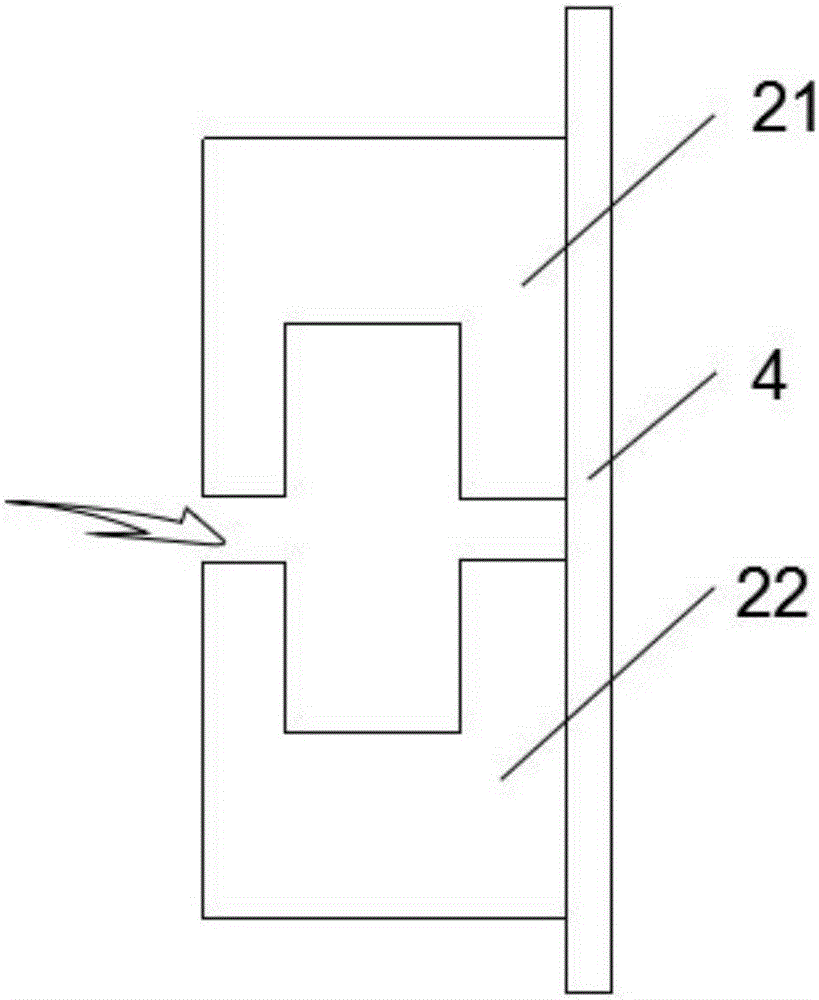

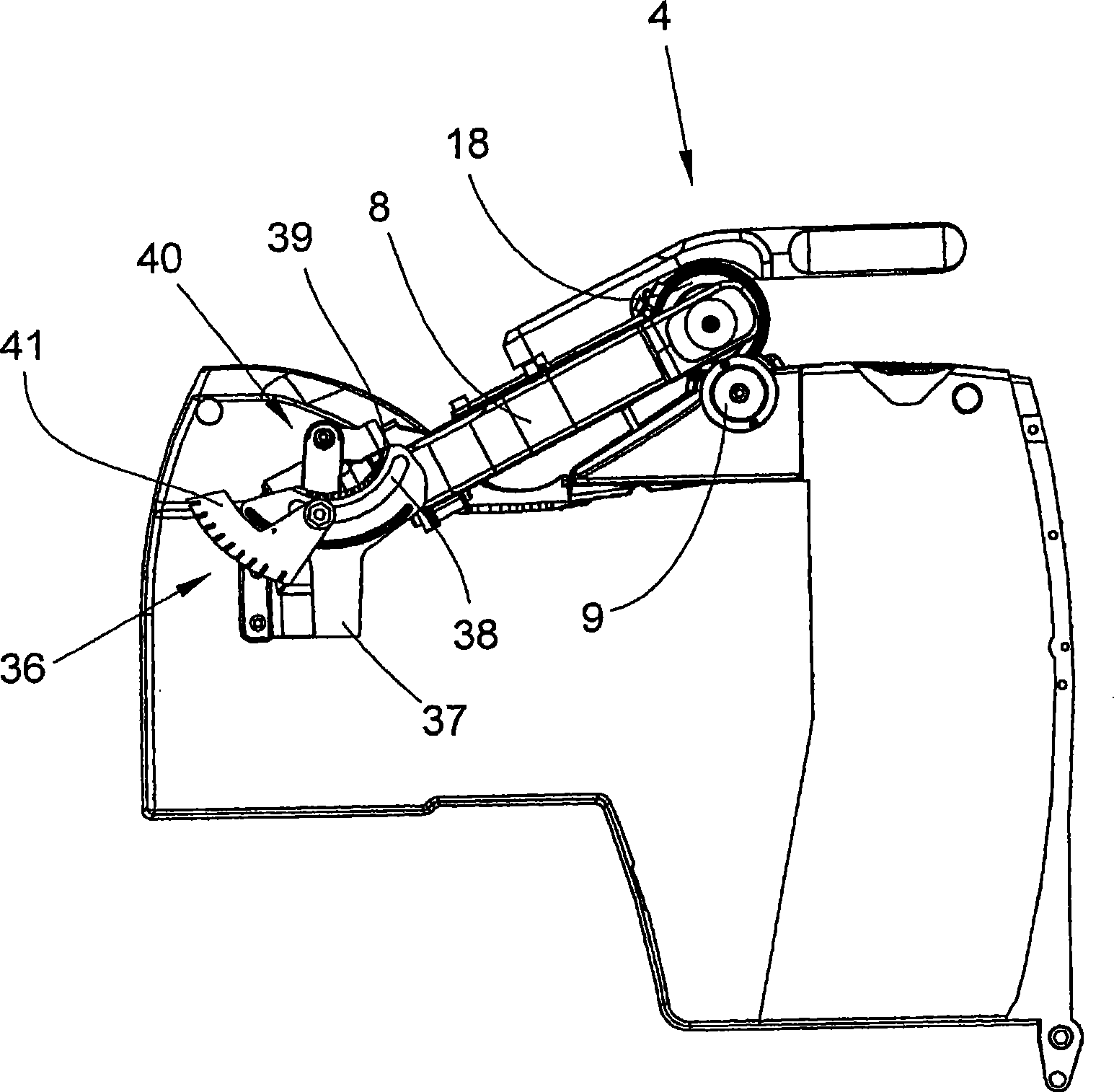

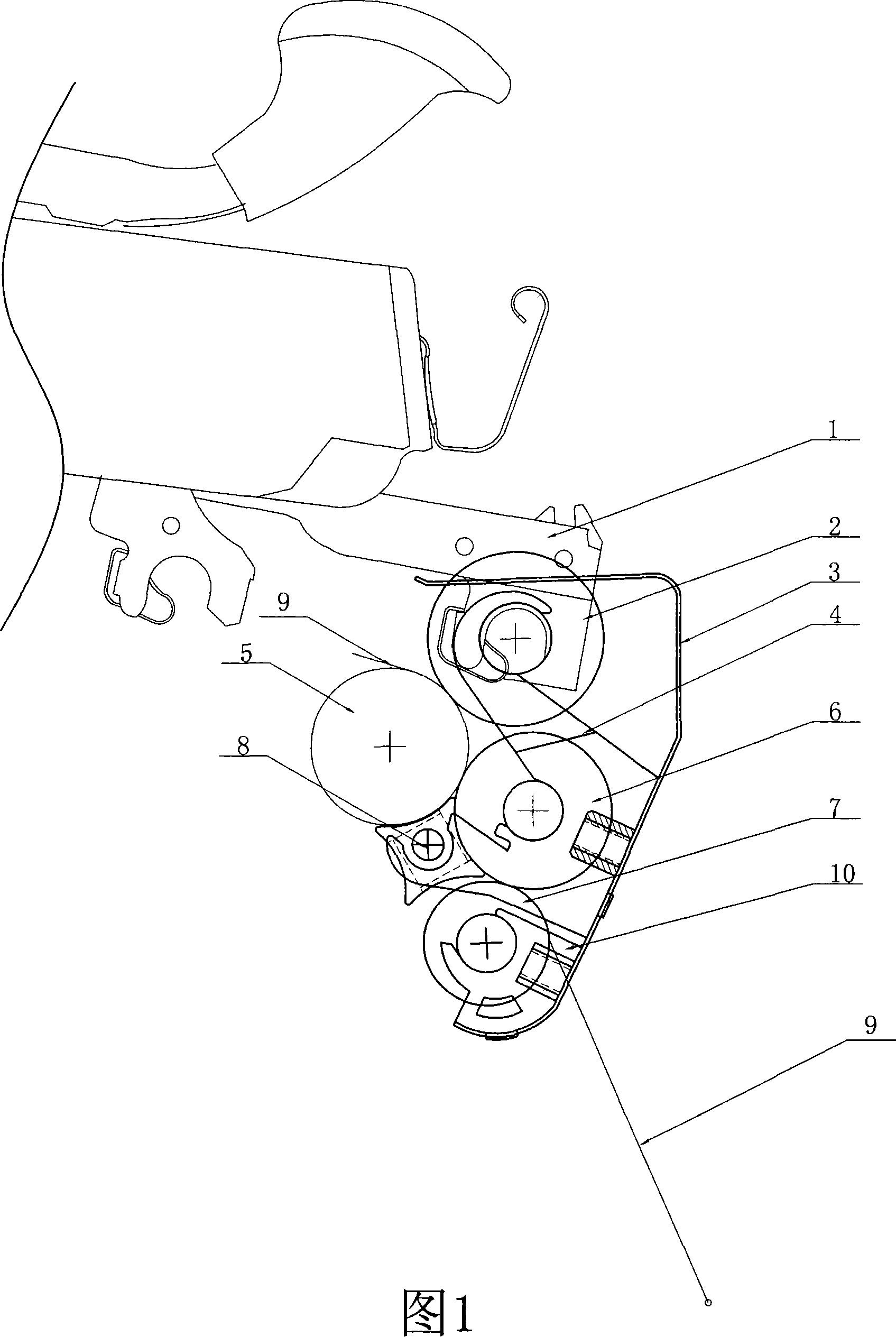

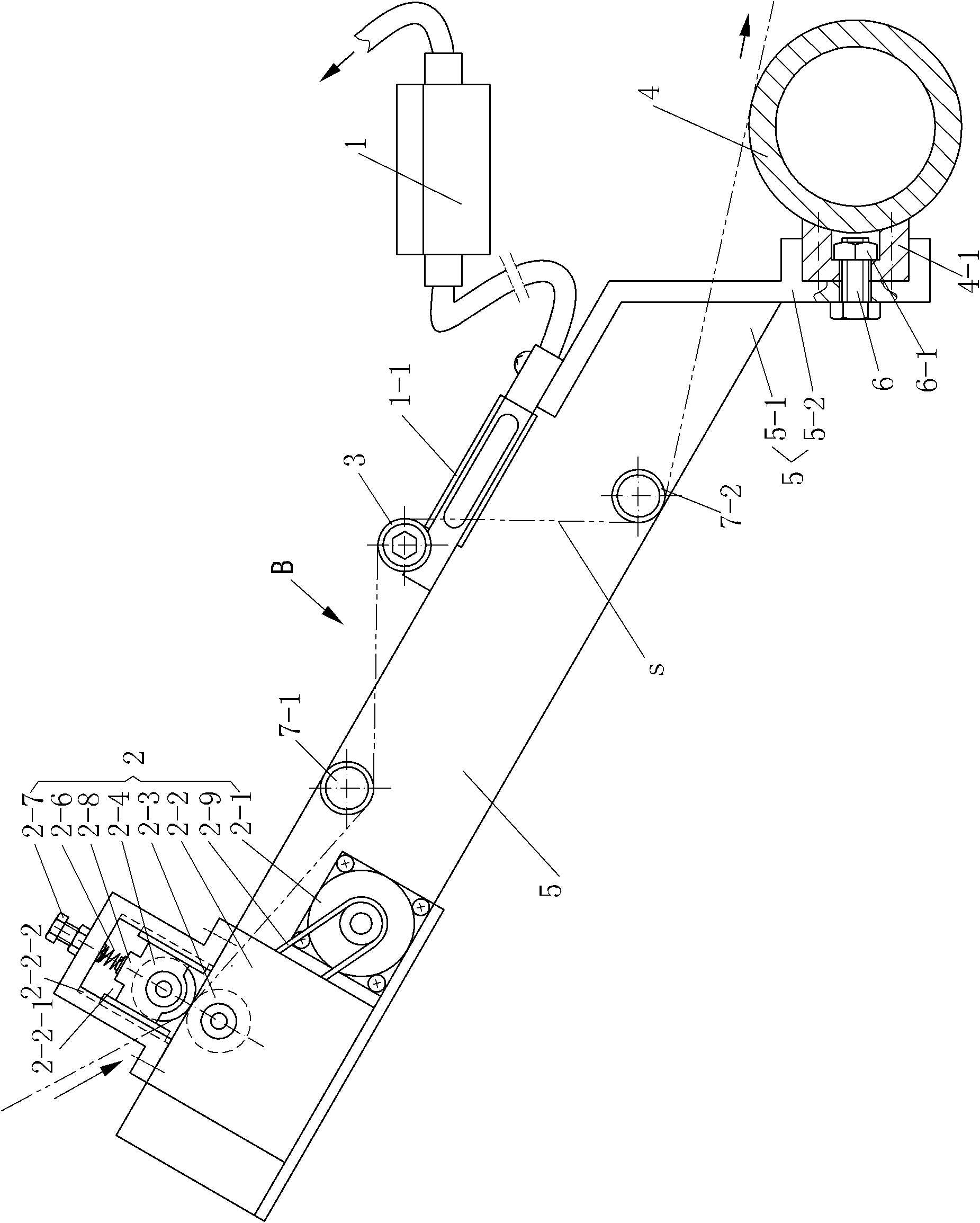

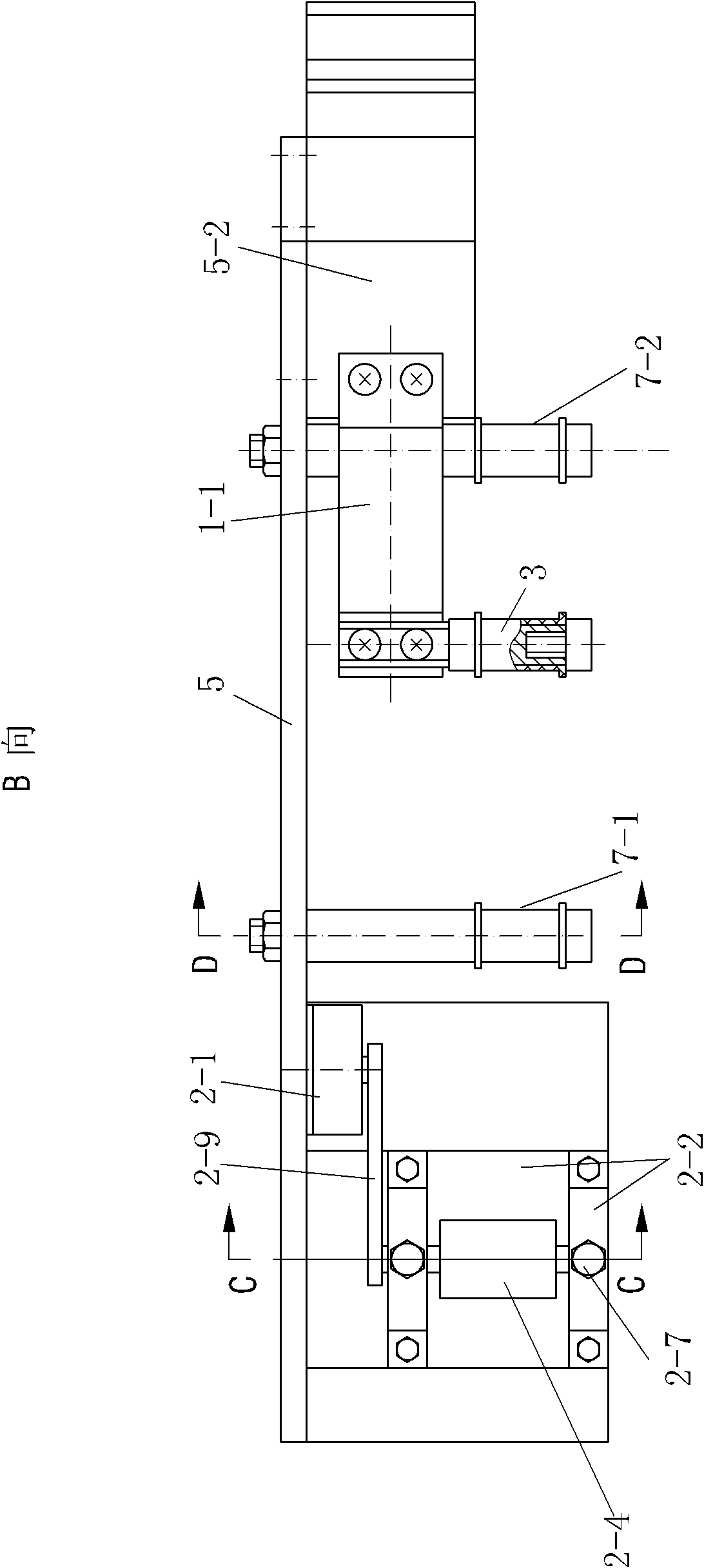

Yarn splicing guide device of automatic bobbin winder

InactiveCN101580195AEliminate the phenomenon of deviation from the splicing channelImprove qualityFilament handlingYarnFixed position

The invention discloses a yarn splicing guide device of an automatic bobbin winder. The device comprises a splicer and a guide bracket, wherein the splicer is used for grabbing a large suction nozzle at the upper yarn end and grabbing a small suction nozzle at the lower yarn end, and the guide bracket keeps a fixed position with the splicer; the guide bracket supports a yarn guide hook in a swing mode, and the yarn guide hook is mutually and fixedly connected with a guide swing arm; the yarn guide hook and an upper yarn passage form space intersection, and an arm end part of the guide swing arm is positioned on a rotary track of the small suction nozzle; and the guide bracket is also provided with an offsetting spring for rotating and offsetting the yarn guide hook. The yarn guide hook is mutually and fixedly connected with the guide swing arm through a connecting sleeve which is sleeved on a yarn guide hook support shaft in a swing mode; the yarn guide hook support shaft is vertically and fixedly arranged on the guide bracket; and the yarn guide hook and the guide swing arm are crossed and staggered in space. The yarn splicing guide device has the advantages of simple structure, accurate yarn guide and good splicing quality, and is widely applied to various automatic bobbin winders.

Owner:马佐里(东台)纺机有限公司

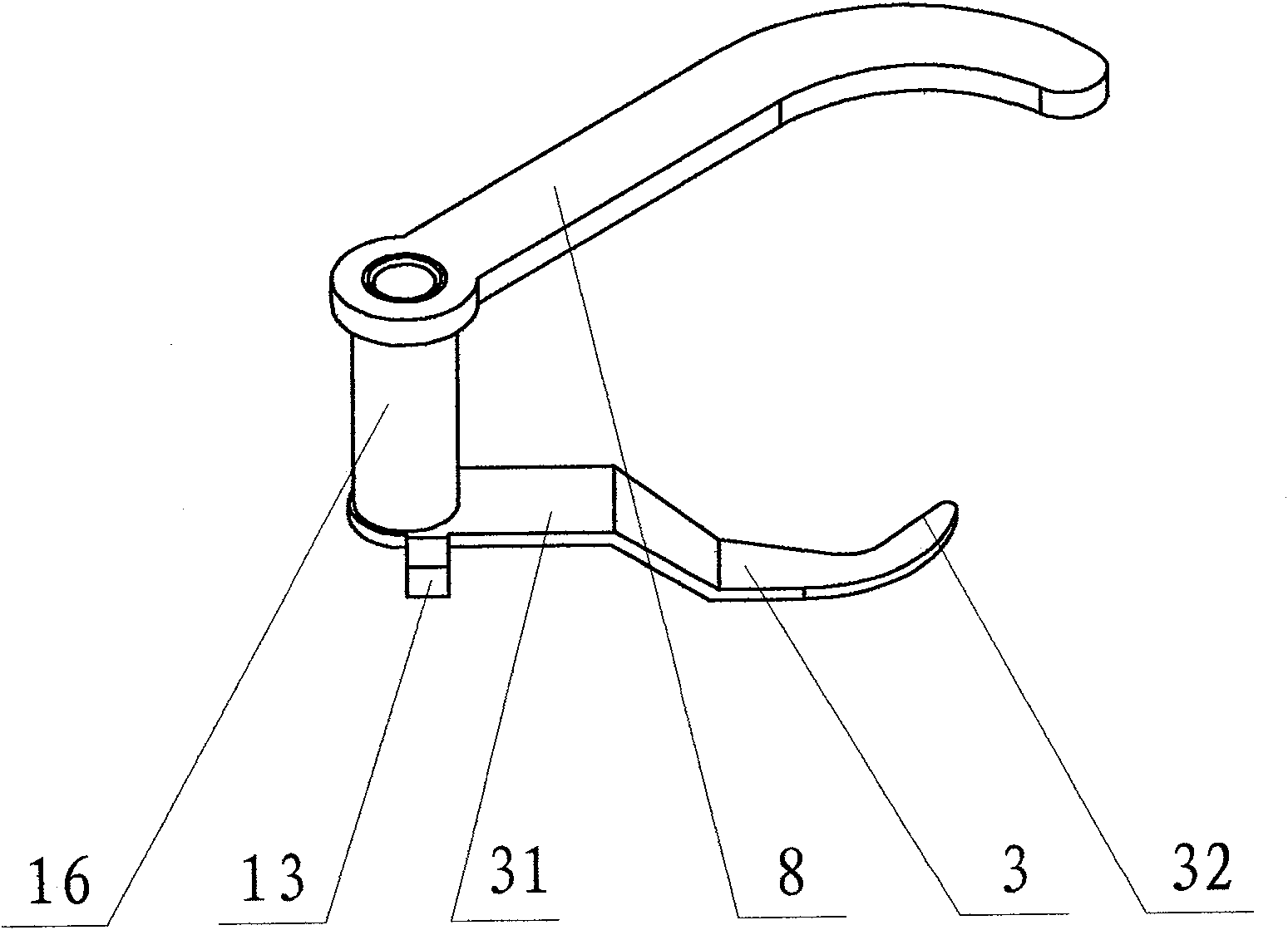

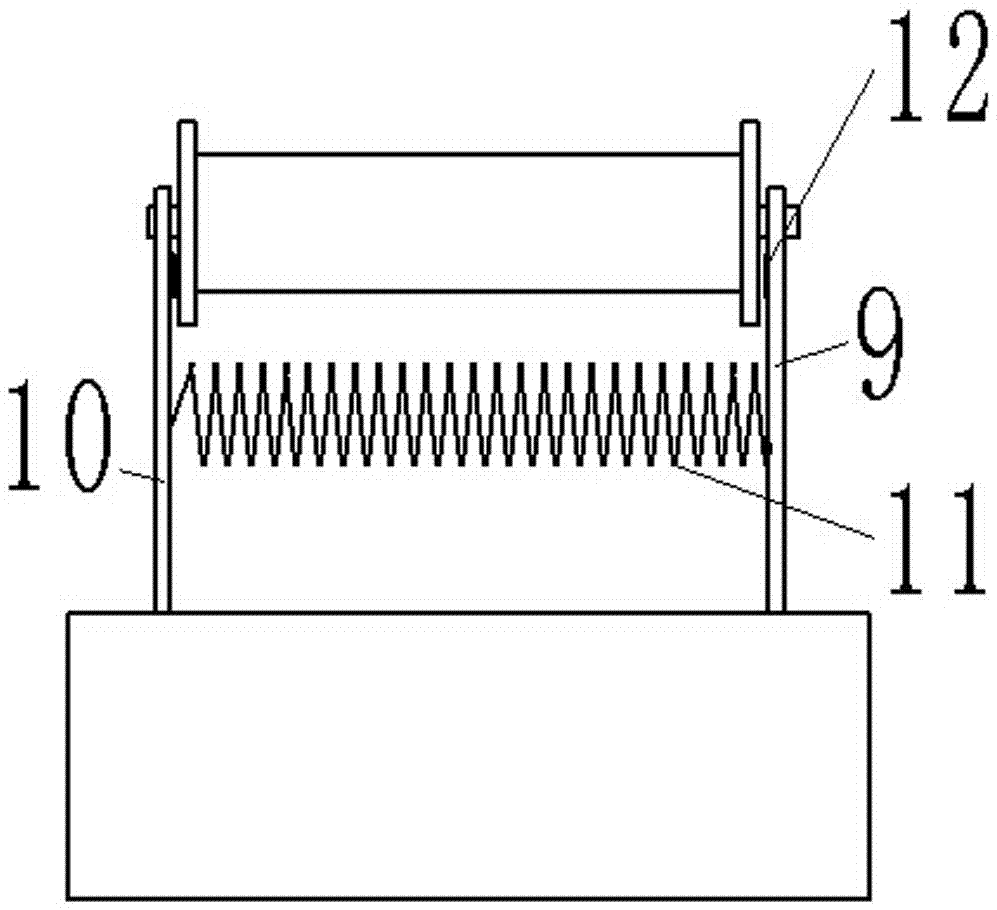

Broken yarn self-stop device

InactiveCN101760820AAdjustable tightnessImprove tensile propertiesTextiles and paperYarnMaintainability

A broken yarn self-stop device comprises a test device and an execution device, and is characterized in that the execution device is provided with a regulating part for regulating tension of yarns and the regulating part comprises a fixing plate, a regulating plate, a regulating bar and a regulating handle, the fixing plate and the regulating bar are fixedly connected, the regulating plate and the regulating bar are in thread connection, the regulating handle is rotated to regulate the gap between the fixing plate and the regulating bar, thus regulating tightness of yarns, greatly enhancing tensile capacity of yarns, avoiding yarn breakage due to unstable tension of yarn looping machine. The test device in the invention is extremely simple in comparison with the prior art, and the running stability and maintainability of the test device are improved.

Owner:WUJIANG CITY HAICHENG TEXTILE

Yarn tension device for warp knitting machine

The invention discloses a yarn tension device for a warp knitting machine. The yarn tension device comprises a cylinder fixation seat, a cylinder, a cylinder pull head, a steel rope, a yarn through rod, rotary wheels, an air supply tube, a pressure gauge, a valve, an air storage tank, a tension spring, a yarn guide cap, a yarn and the like, wherein the rotary wheels are installed at the both ends of the yarn through rod, the tension spring is uniformly installed at the middle, and the yarn guide cap is clamped at the tail end of the tension spring; the yarn is woven by a machine table round the yarn guide cap; one end of the cylinder is located on the fixation seat, and the cylinder pull head at the other end is provided with the steel rope; the other end of the steel rope is fixed on the rotary wheel; in this way, the yarn through rod is tensioned as long as the cylinder works, thus tensioning the yarn guide cap; the air storage tank is installed on the machine table of the warp knitting machine, and an air compressor in a workshop is used for supplying air to the air storage tank; air in the air storage tank enters the cylinder through the air supply tube; a pressure in the cylinder is adjusted by a pressure adjusting valve, and the pressure is adjusted according to the tension of the yarn; the pressure display gauge is capable of displaying the air pressure during the working of the cylinder, thus facilitating operation.

Owner:FUJIAN XIN GANG TEXTILE MACHINERY

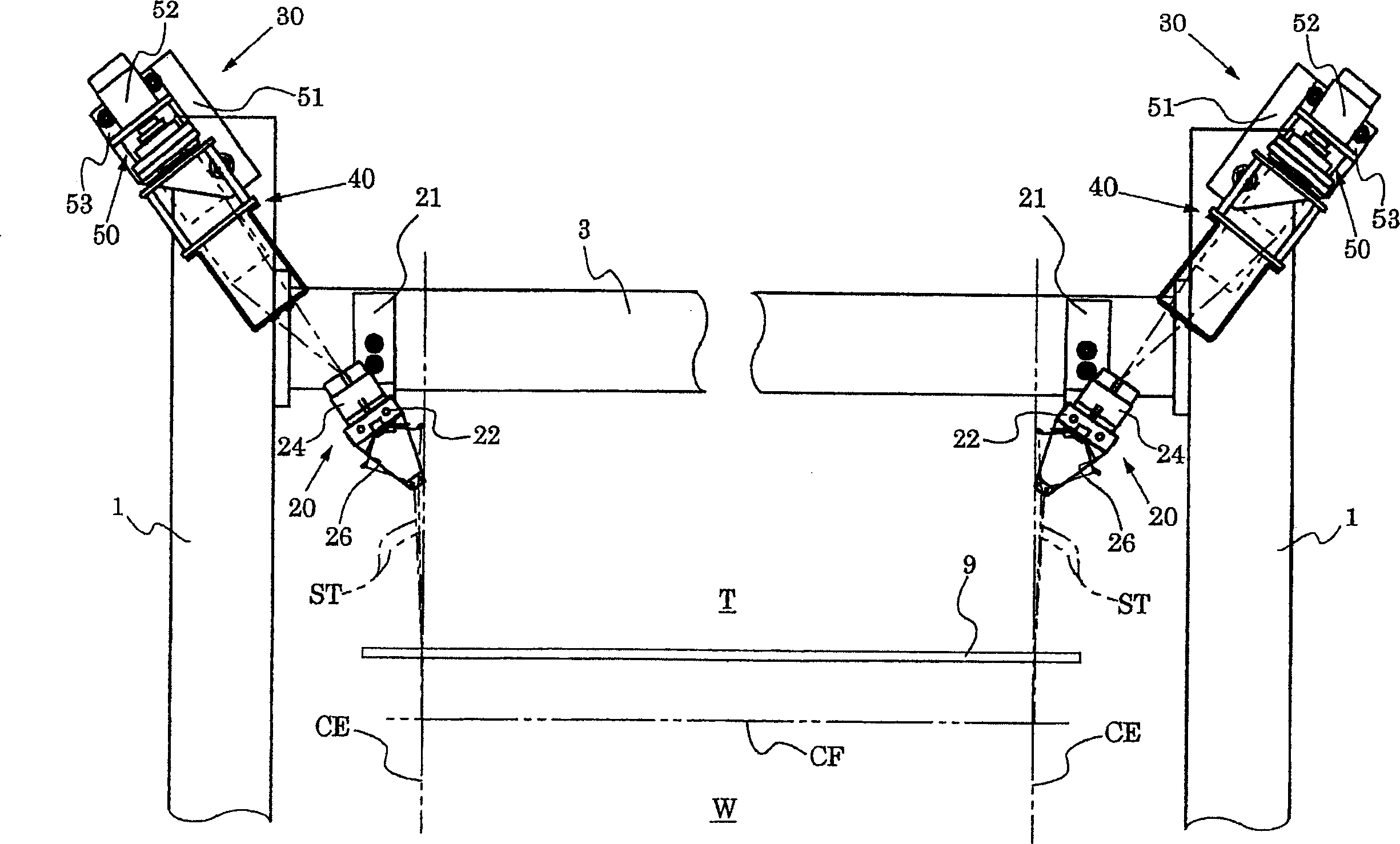

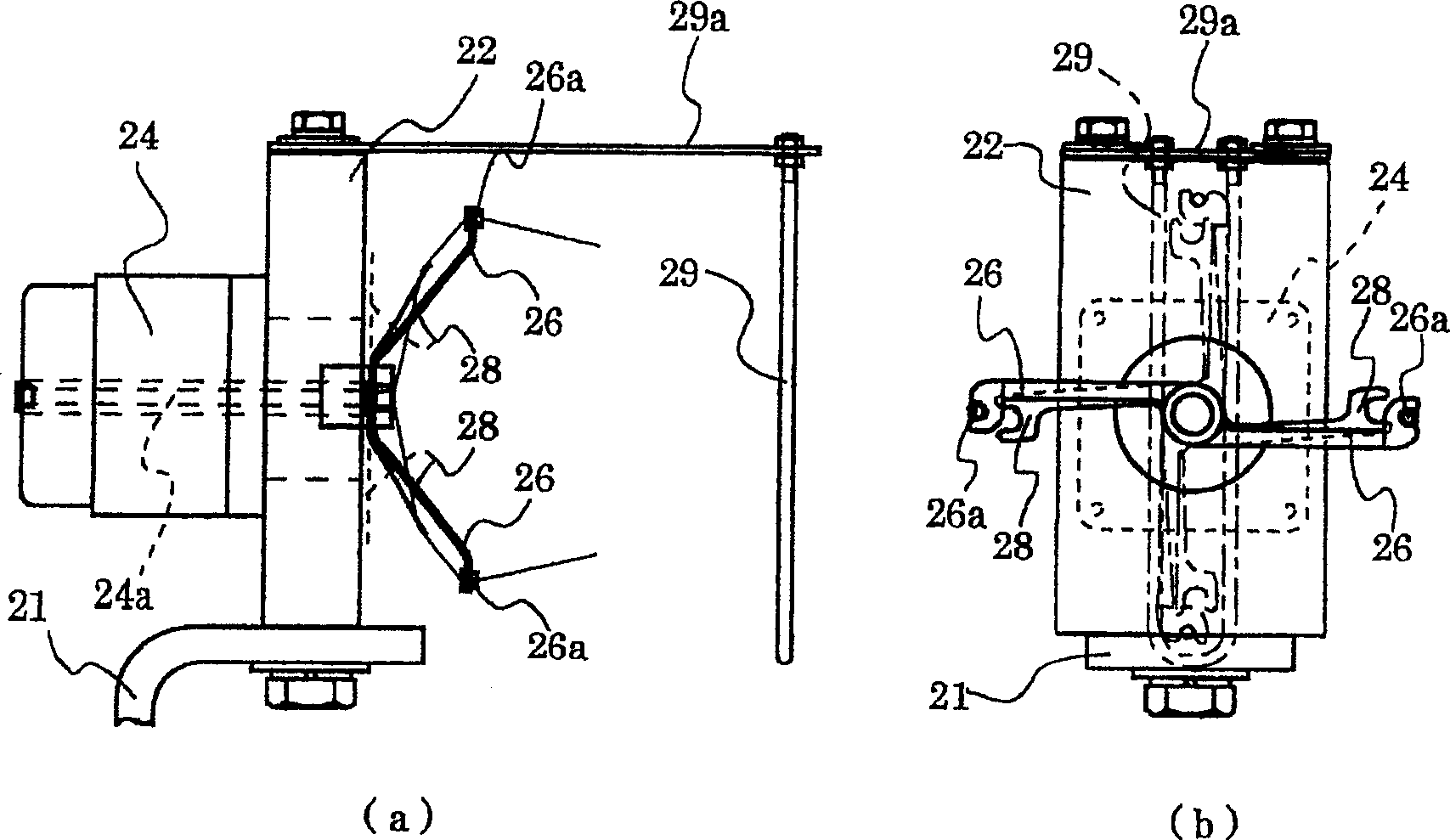

Selvage device in loom

A selvage device in a loom has a rotary member provided with guides for guiding selvage yarns, and rotates the rotary member to move the selvage yarns in a shedding motion. The selvage device includes a selvage shedding mechanism having the rotary member and a designated driving motor that rotates the rotary member unidirectionally in an intermittent fashion; and a selvage feeding mechanism disposed upstream of the selvage shedding mechanism in a traveling direction of the selvage yarns. The selvage feeding mechanism includes a guide unit having a pair of guide portions for guiding the selvage yarns respectively fed from a pair of yarn feeders; and a rotating unit supporting the guide unit and rotated continuously in the same rotational direction as the rotary member. The guide portions revolve in response to the rotation of the rotating unit, such that sections of the selvage yarns extending from the yarn feeders to the corresponding guide portions revolve without intercrossing each other.

Owner:TSUDAKOMA KOGYO KK

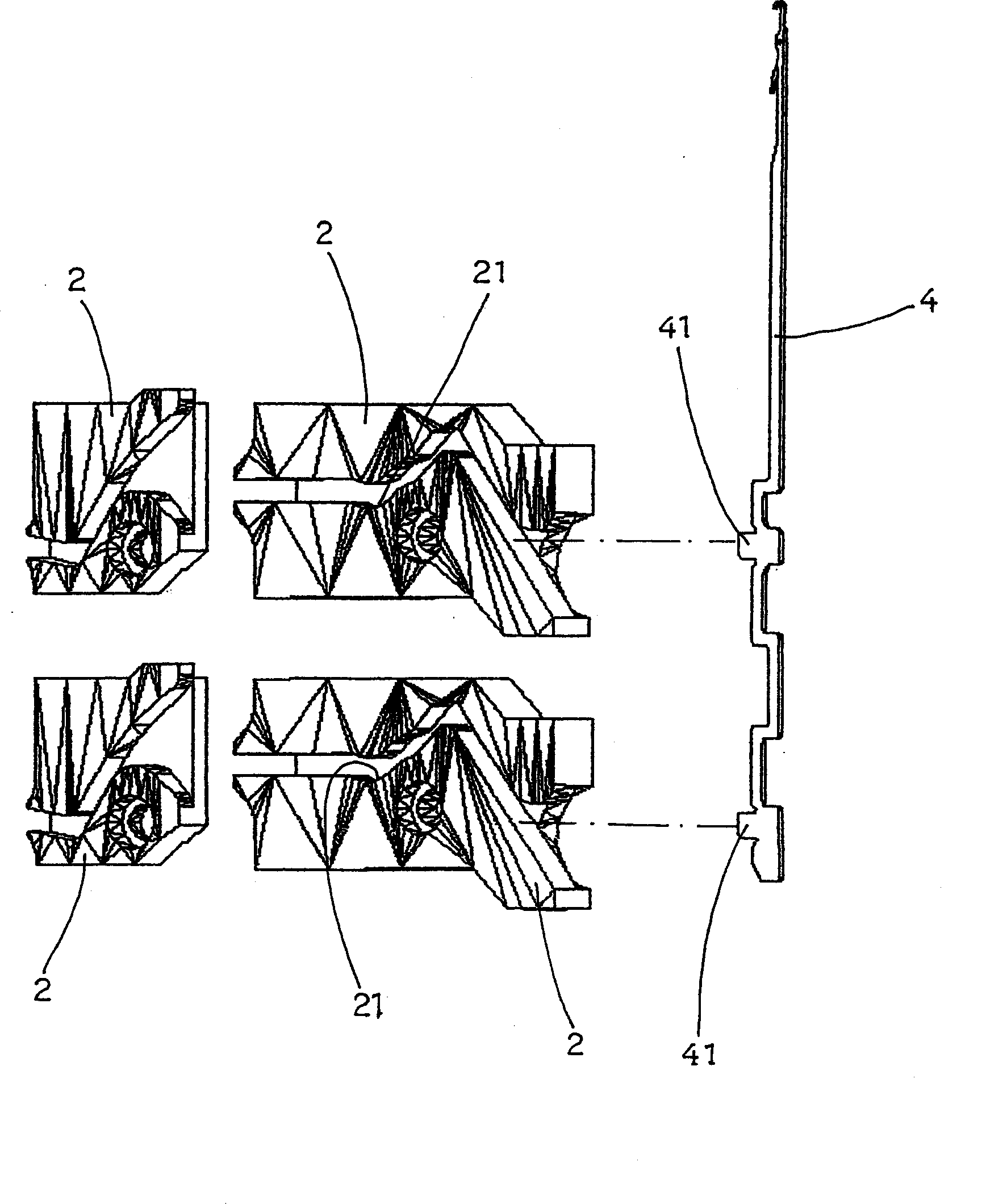

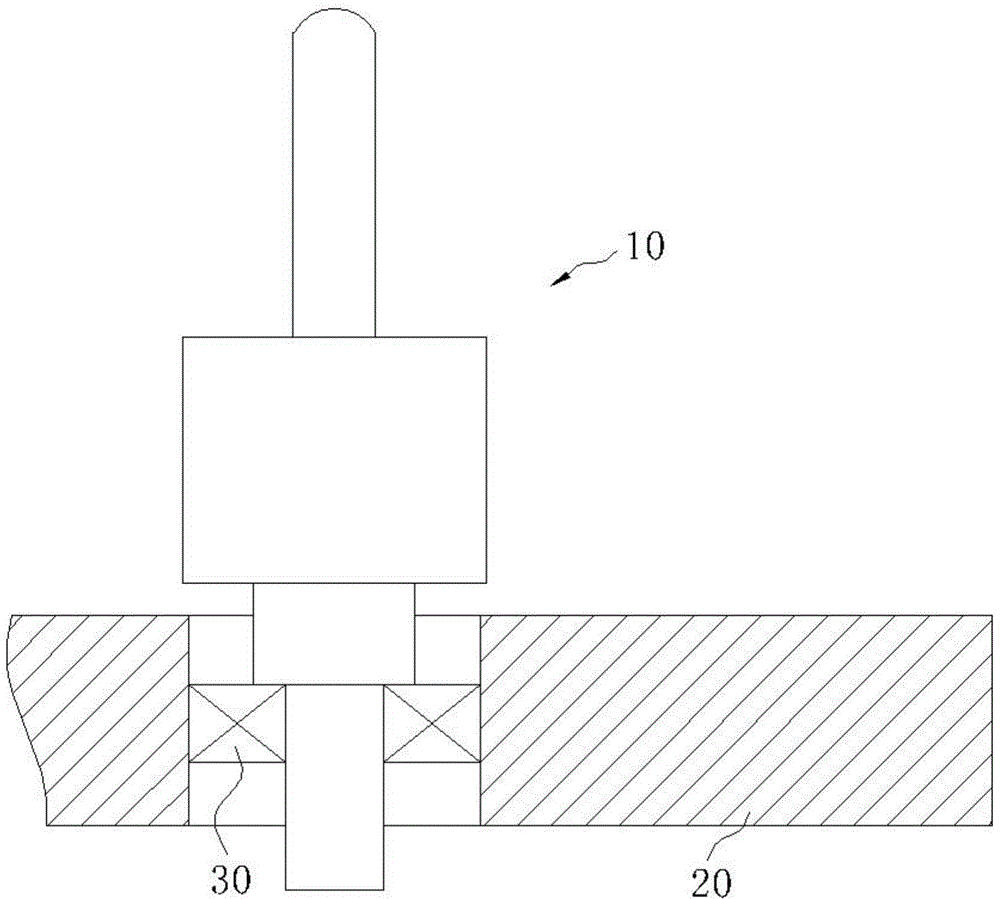

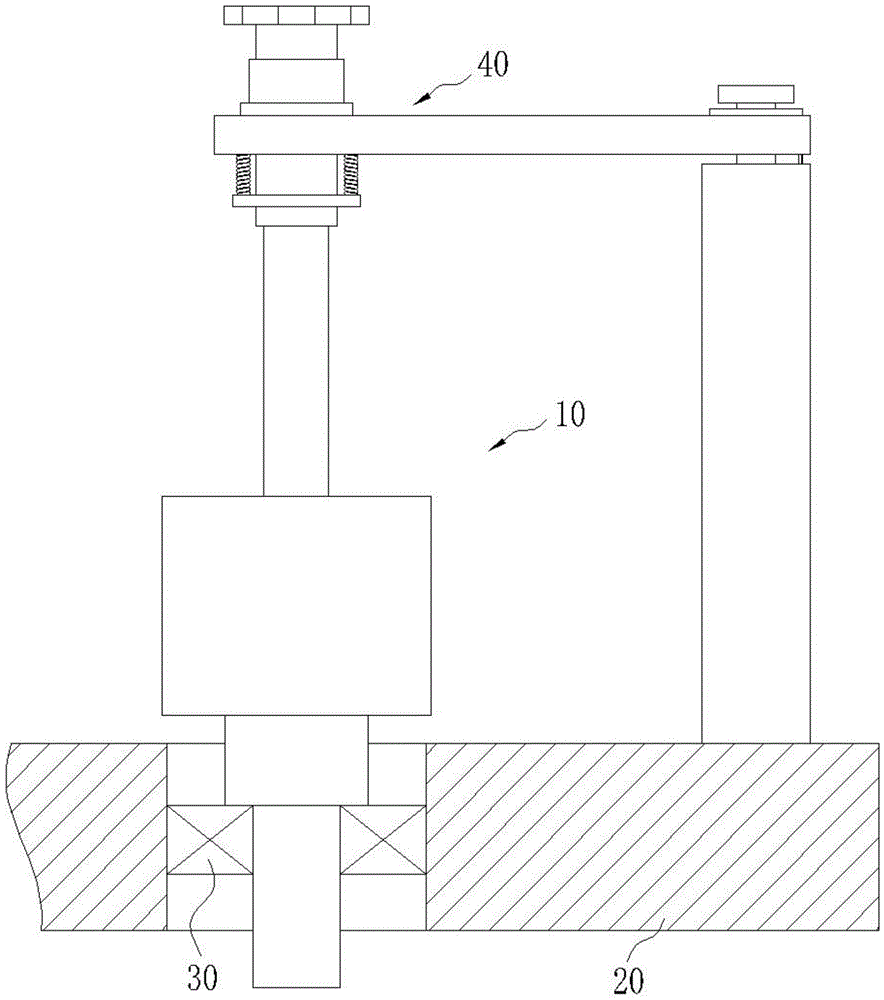

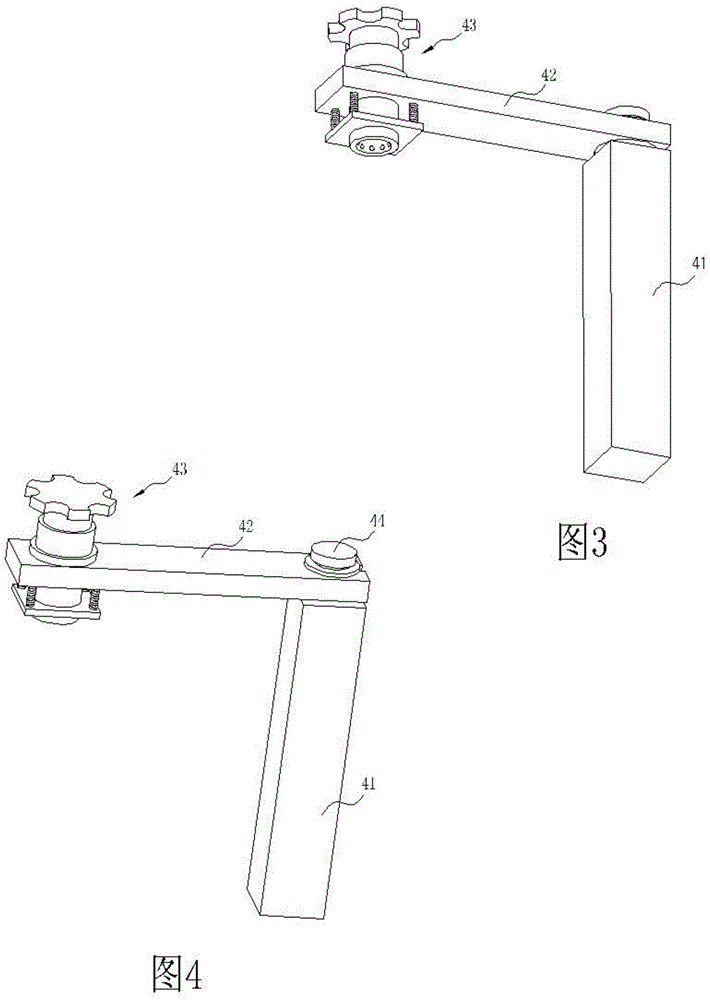

Spindle mechanism capable of reducing vibration amplitude

InactiveCN104118766AImprove fluencyReduce vibration amplitudeFilament handlingVibration amplitudeYarn

The invention discloses a spindle mechanism capable of reducing vibration amplitude. The spindle mechanism capable of reducing vibration amplitude comprises a spindle (10), a spindle base (20), a bearing (30) and a core fixing device (40) installed on the spindle base (20), wherein the core fixing device (40) comprises a fastening component (43) located above the spindle (10), a groove (431) is formed in the bottom end of the fastening component (43), the groove (431) can cover the top end of the spindle (10), and therefore when the spindle rotates, the vibration amplitude of the spindle is limited by the groove. According to the technical scheme, the core fixing device is additionally arranged on the spindle, the original structure of the spindle does not need to be changed, installation is convenient, broken yarn caused by large vibration amplitude when the spindle rotates can be avoided, and winding smoothness is improved.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

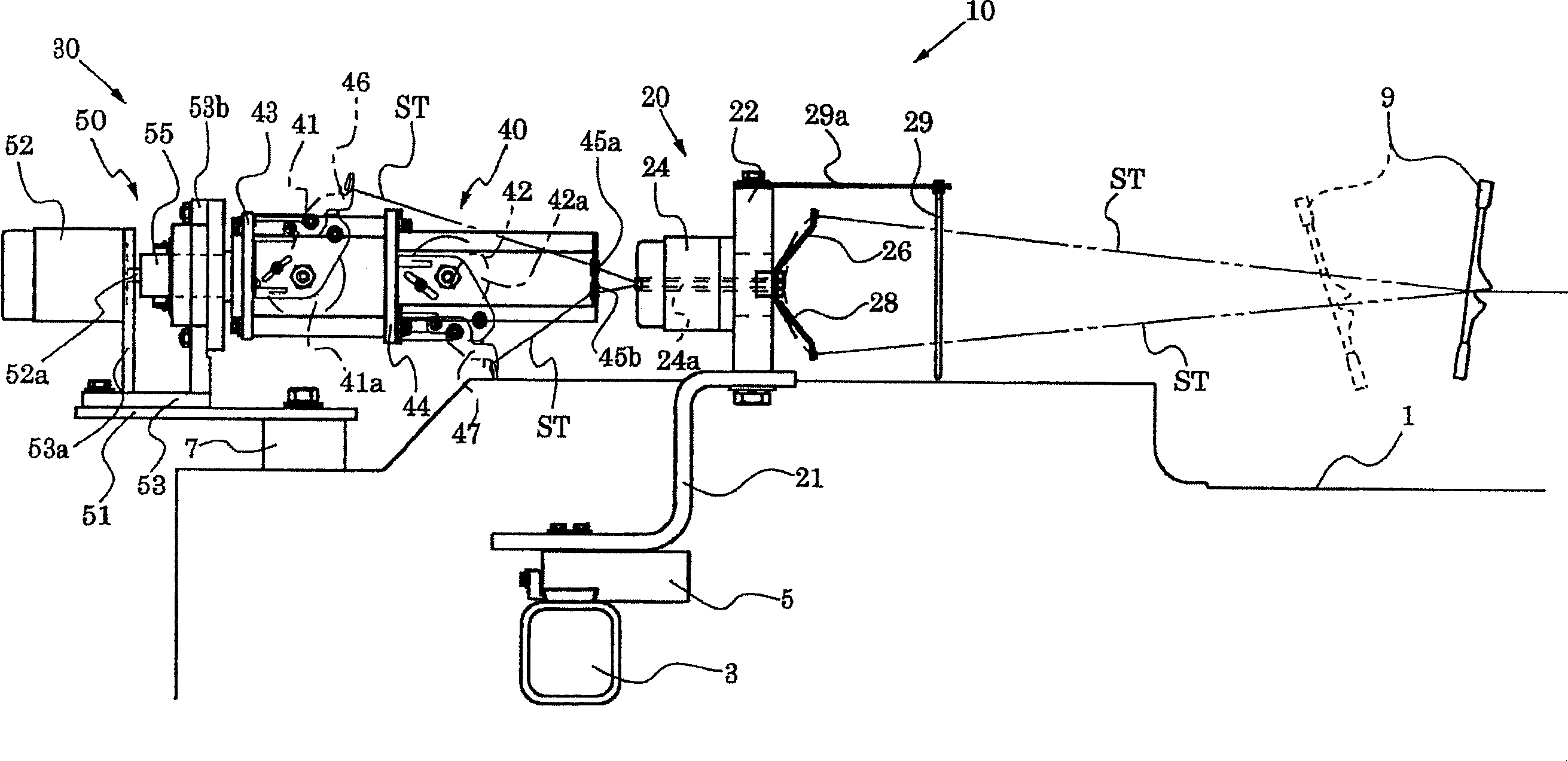

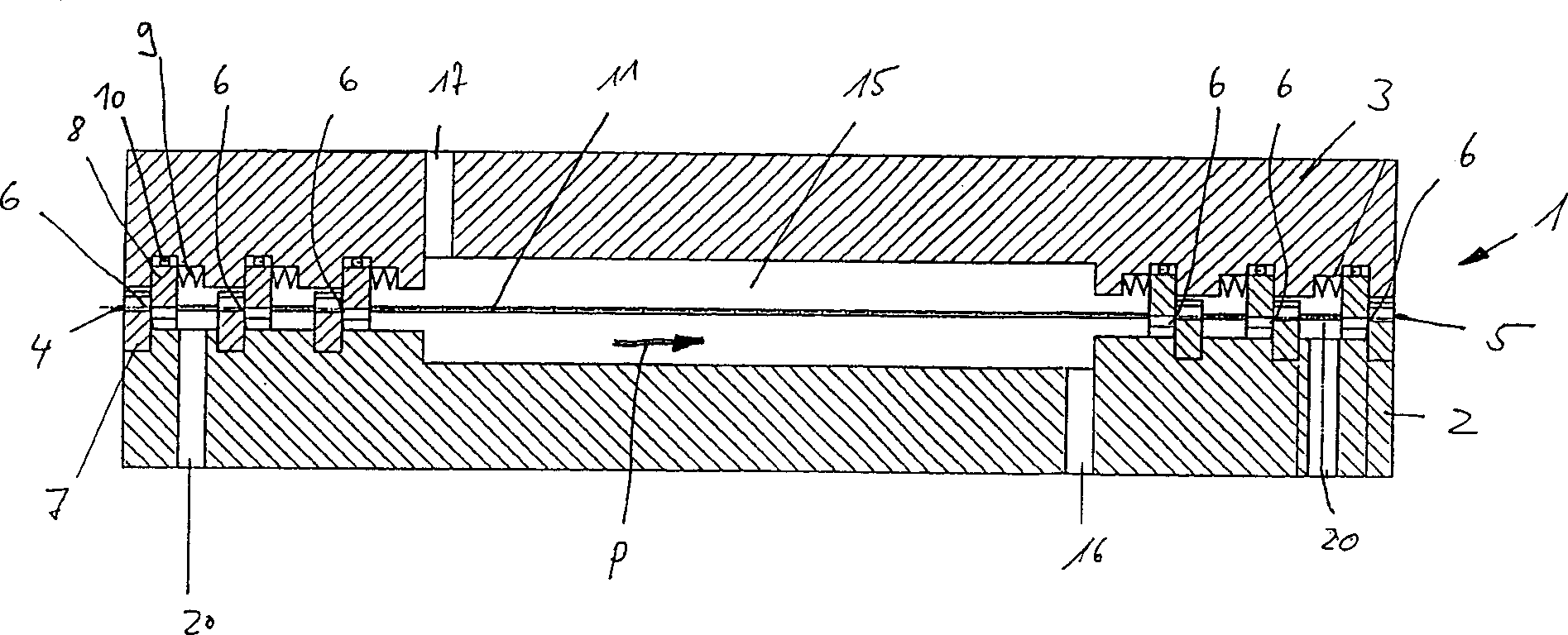

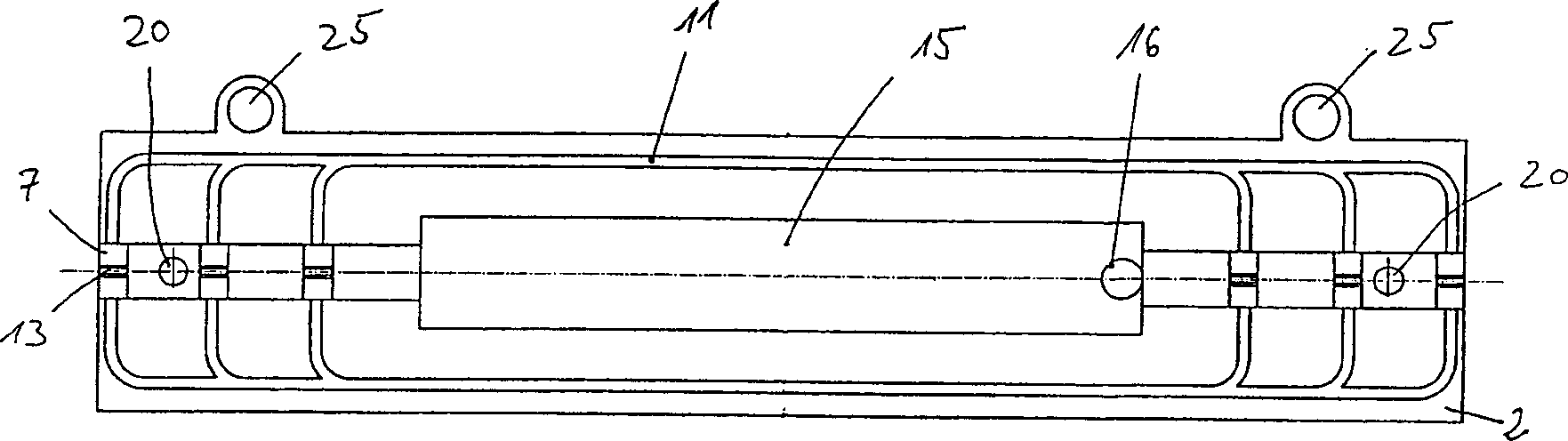

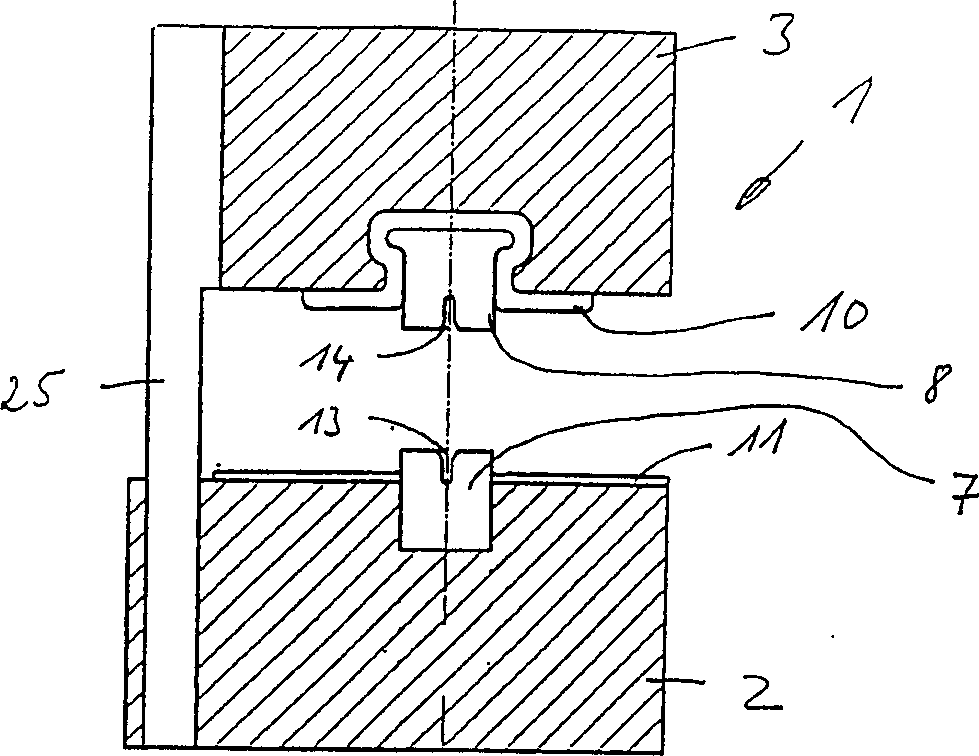

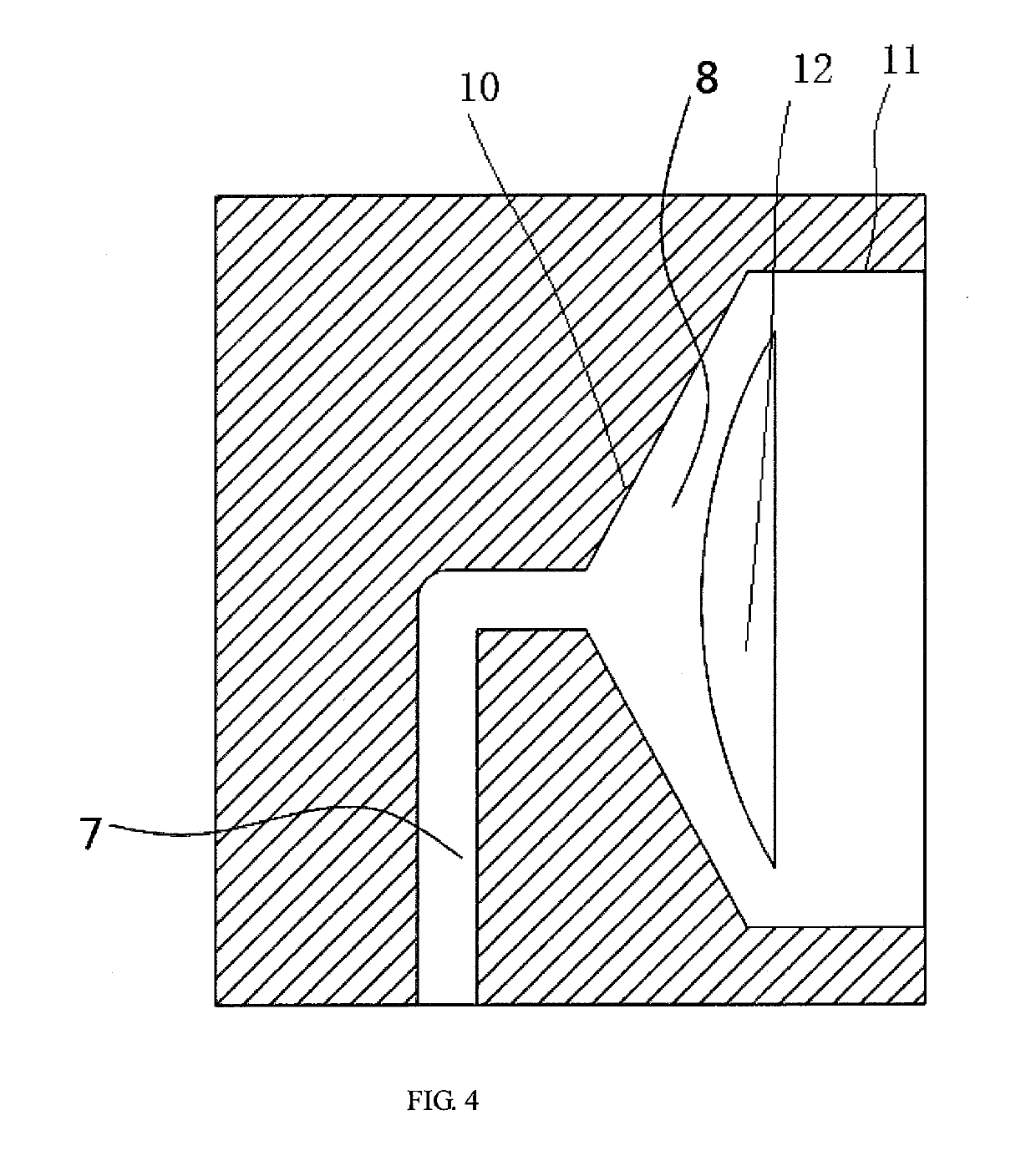

Method for feeding in and starting a thread and false twist texturing device

InactiveCN1340114AAvoid yarn breakageEasy to put inTextile treatment containersFilament handlingInjector nozzleAirflow

The invention relates to a method for feeding in and starting a thread in a false twist texturing device. Said device has a heat exchanger (1) containing a fluid. Said heat exchanger has at least two yarn passages (4, 5, 6) which are provided for guiding the yarn through and for sealing the heat exchanger (1). Said yarn passages (4, 5, 6) are enlarged for introducing the yarn. Alternatively, the yarn is drawn through the yarn passages (4, 5, 6) by suction and / or blown through by means of an auxiliary airflow or pulled through by means of an awl. The heat exchanger (1) in the false twist texturing device pertaining to this method is divided along the direction of passage of the yarn and the parts (2, 3) for introducing the yarn into the heat exchanger can be removed from each other. Alternatively, an injector nozzle (37) is arranged before and / or after the individual yarn passages (4, 5, 6) on the yarn inlet (4) and / or on the yarn outlet (5) for guiding the yarn through the yarn passage.

Owner:天科纺织机械部件有限公司

Automatic drafting machine and drafting method thereof

The invention discloses an automatic drafting machine and a drafting method thereof. The machine comprises a heddle, a rail, a crochet hook and a wallboard. The rail is half-enclosed, is composed of an upper concave block and a lower concave block which are oppositely arranged, and one side of the rail is fixed to the wallboard. The heddle is arranged on one side of the rail. A heddle eye is arranged at the position, corresponding to the position of the rail, of the heddle. After the crochet hook hooks a warp yarn, the crochet hook passes through the heddle eye and the rail, and then the drafting is completed. Nozzles are uniformly distributed in the length direction of the rail. The beneficial effects of the machine are that the nozzles are uniformly mounted in the rail through which the crochet hook passes; the nozzles are connected to an external air compression device, and the nozzles inject air in the rail; and when the crochet hook normally hooks the yarn and passes through the rail, the yarn which is attached on the surface of the rail as static electricity is generated due to friction can be blown out of the rail, so that mistakes can be reduced.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Triangular track structure of two-sided terry circular knitting machine

InactiveCN101481846ALabor-saving movement strokeSmooth strokeCircular knitting machinesYarnEngineering

The invention discloses a triangle track structure of a double-side terry circular knitting machine. The structure comprises a sinker and a knitting needle which are arranged in a needle cylinder sinker slot and a knitting slot, an upper triangle track and a lower triangle track which drive the sinker and the knitting needle to act, the front section of a yarn taking section of the upper triangle track which drives the sinker to act is a convex slot area which causes the sinker to extend slightly forward, a concave slot area capable of causing the sinker to slightly retract is connected at the rear section of the yarn taking section, and the convex slot area capable of causing the sinker to extend a bit forwards is connected at the rear section of the yarn taking section; and the front end of a half needle section of the lower triangle track which drives the kitting needle to act is provided with the concave slot area which causes the knitting needle to slightly decline and recover. The triangle track structure causes the terry at the face side of knitted fabrics to have the same length and be neat, prevents broken yarn and blow holes, and can cause the knitting to be labor saving and smooth while acting.

Owner:洪荣豪

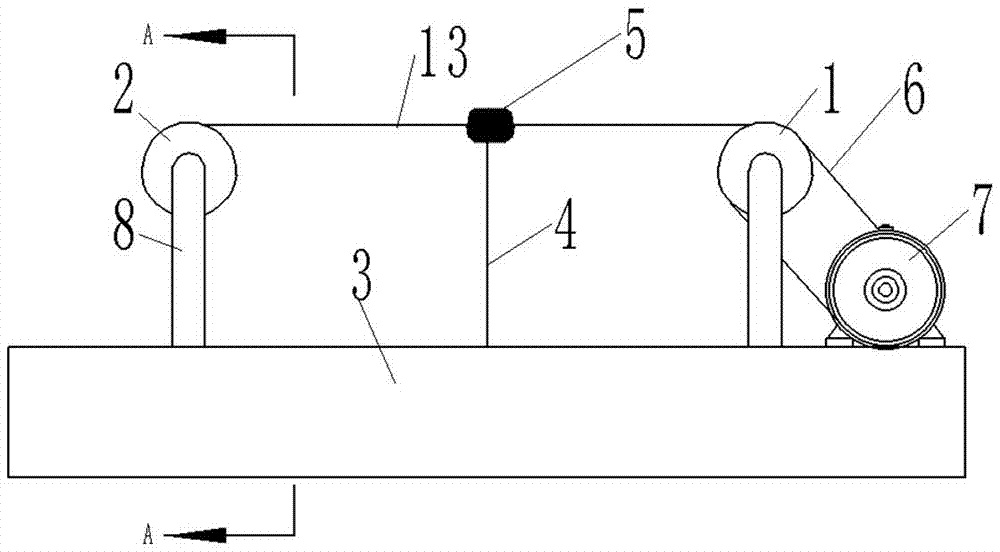

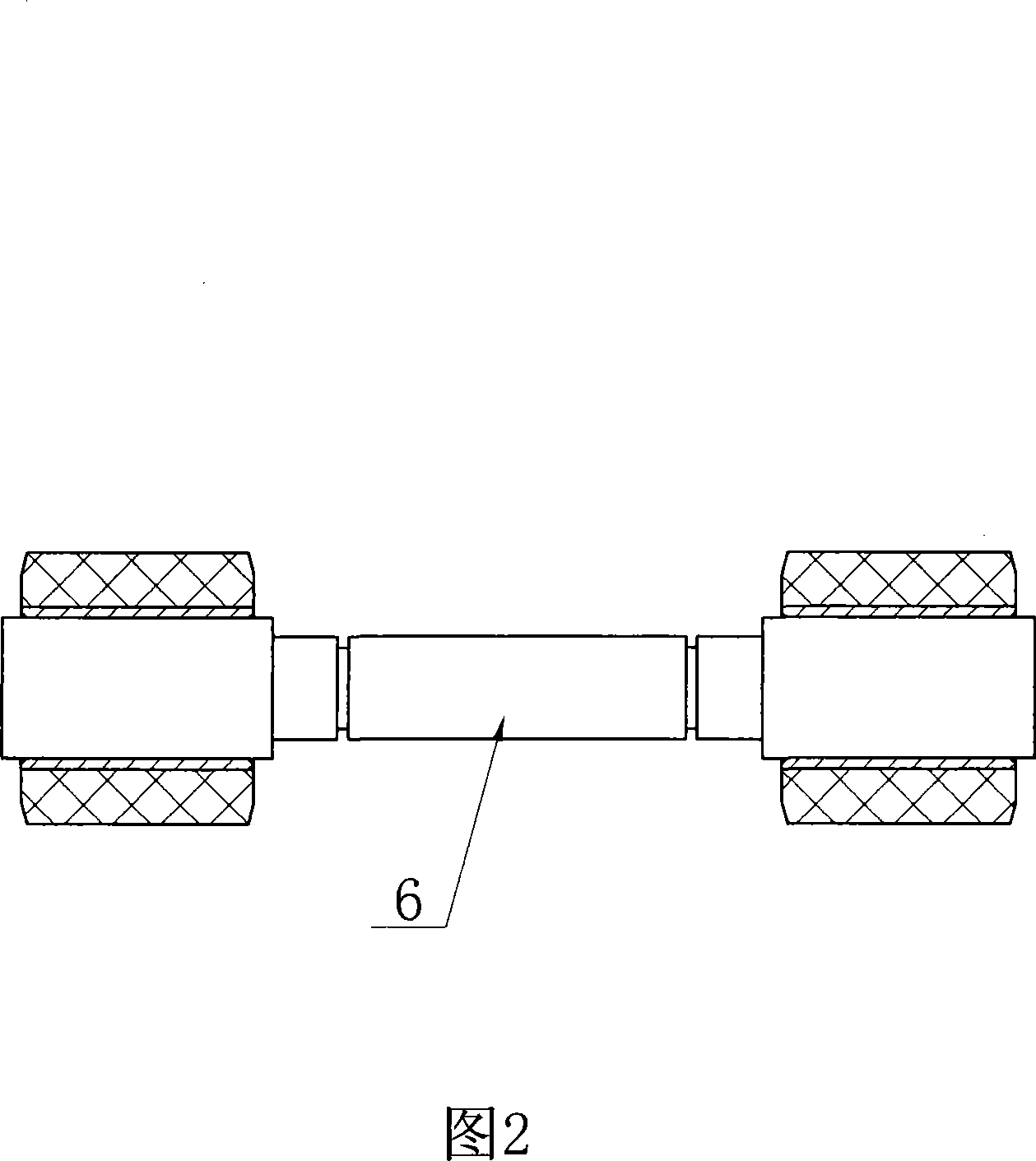

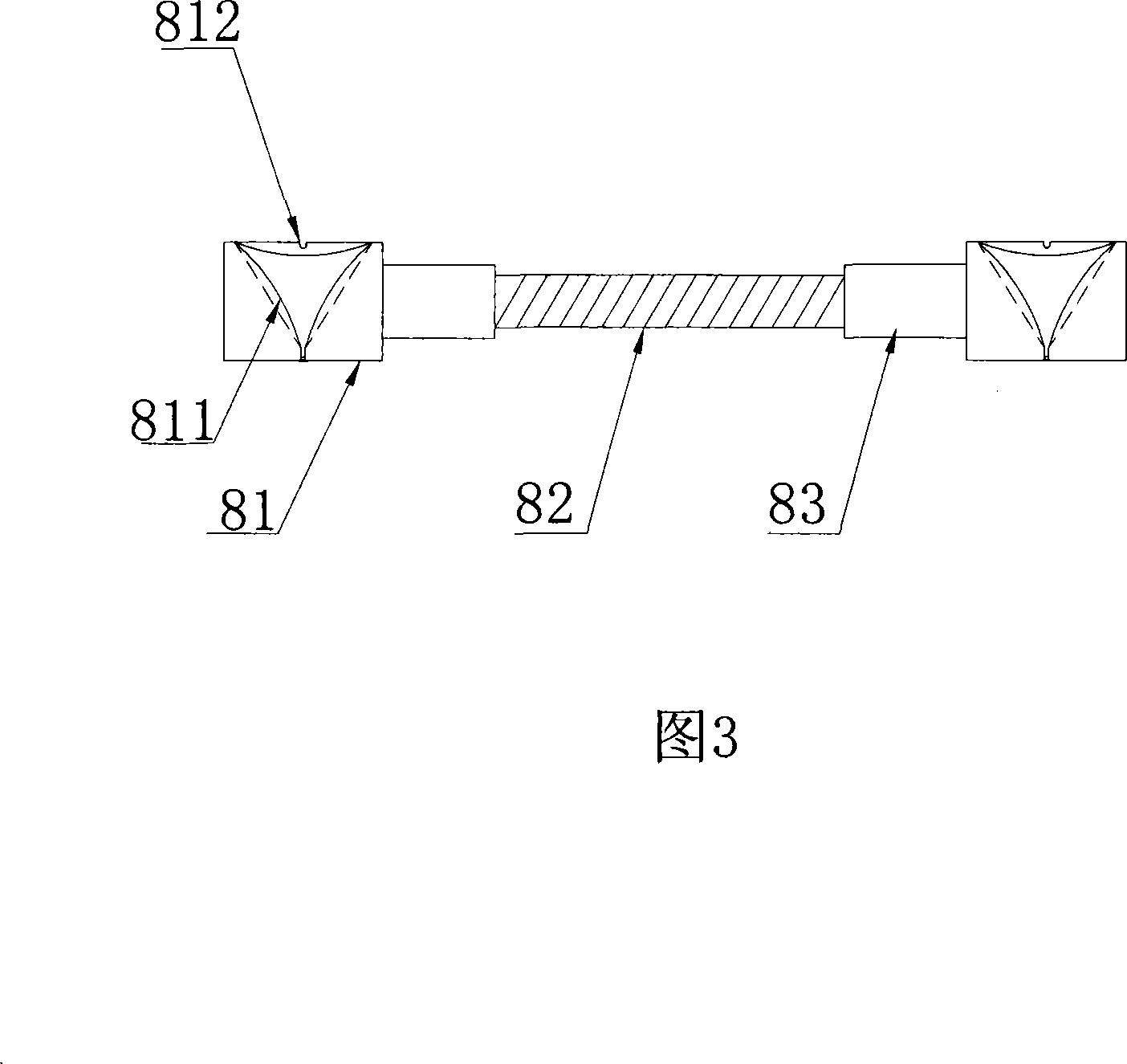

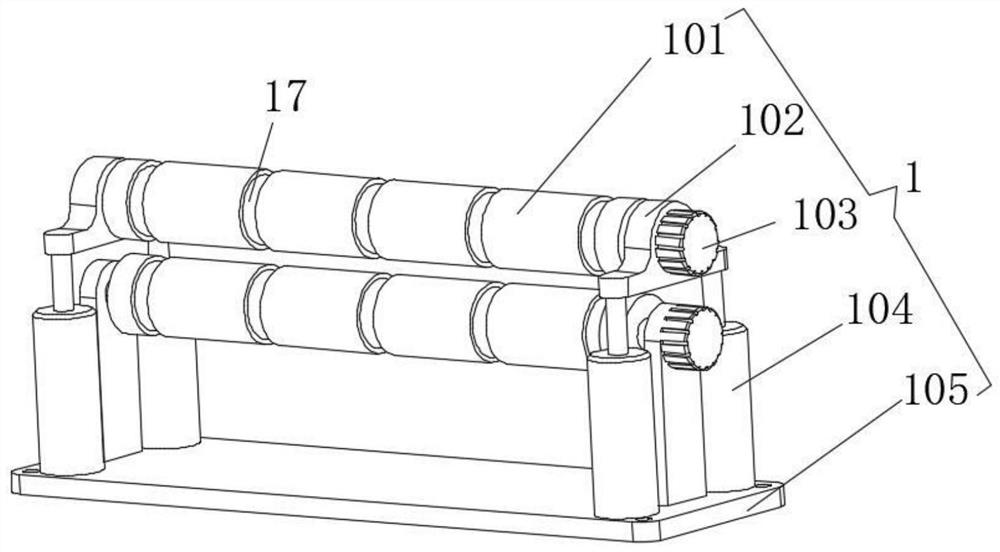

Heating remover for short piles on yarns

The invention relates to a heating remover for short piles on yarns; the heating remover is characterized by comprising a driving bobbin, a driven bobbin, a base, a vertical rod, and an electric heating ring; the driving bobbin is movably connected with a first connection frame, the first connection frame is fixedly connected with the base, the driving bobbin is connected with a motor through a transmission mechanism, and the motor is mounted on the base. The heating remover has the advantages that the heating remover can remove short piles on the surface of yarns, breakage of yarns is avoided during removal of the short piles on the yarns, one-off removal of short piles is achieved, and repeated removal by carding is not required.

Owner:NANTONG JINSHAN TEXTILE

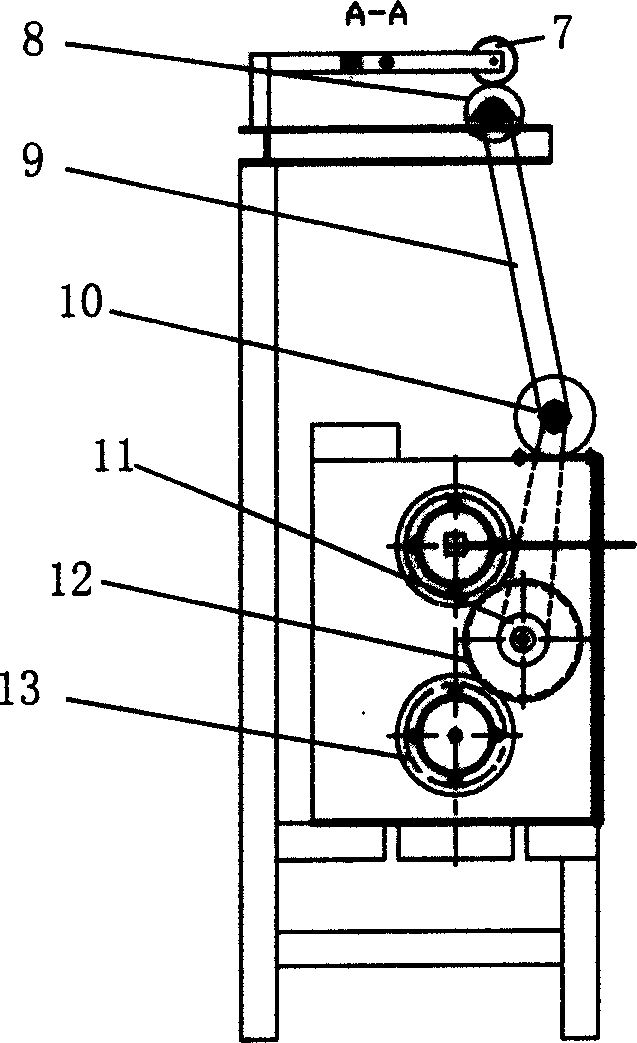

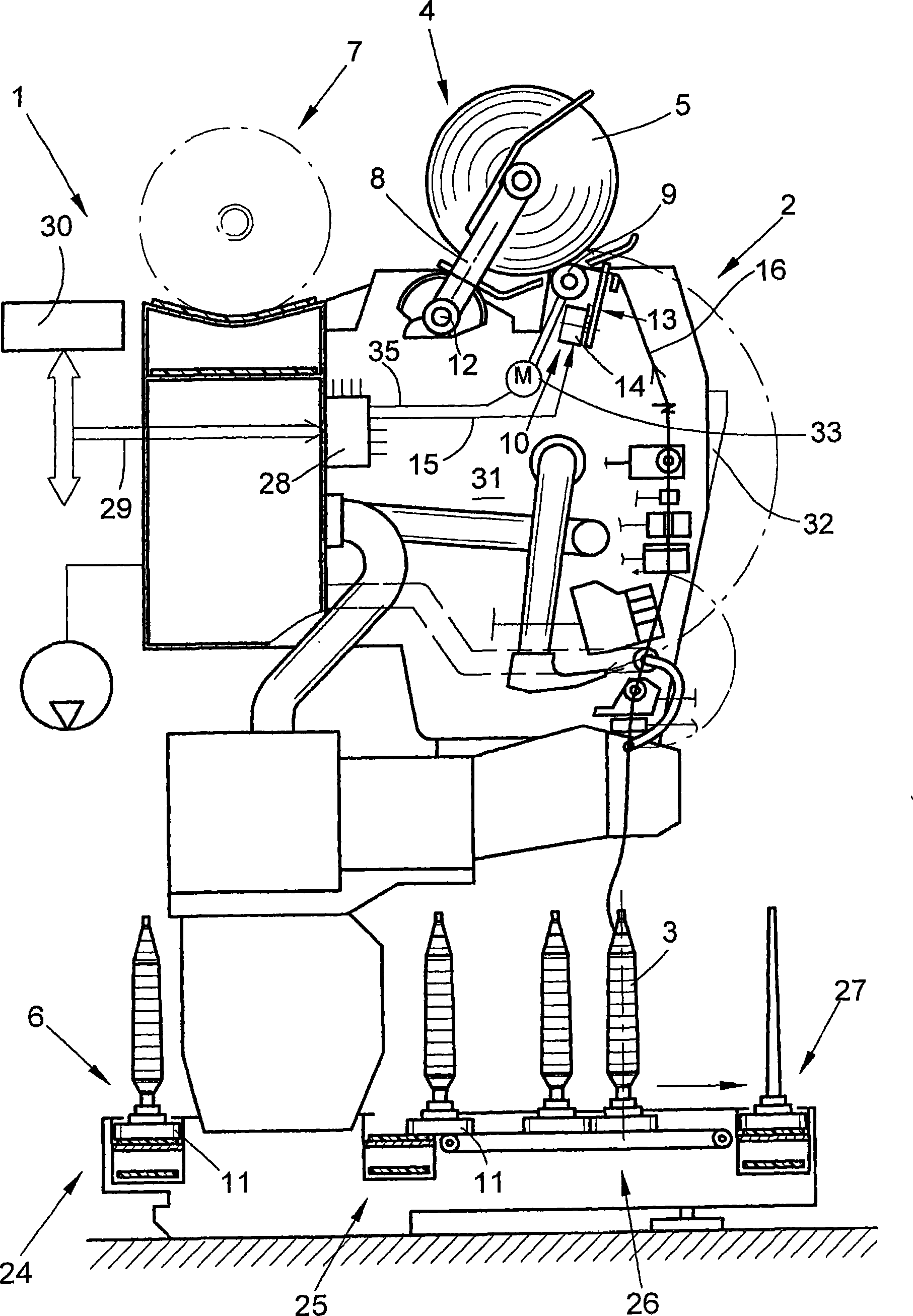

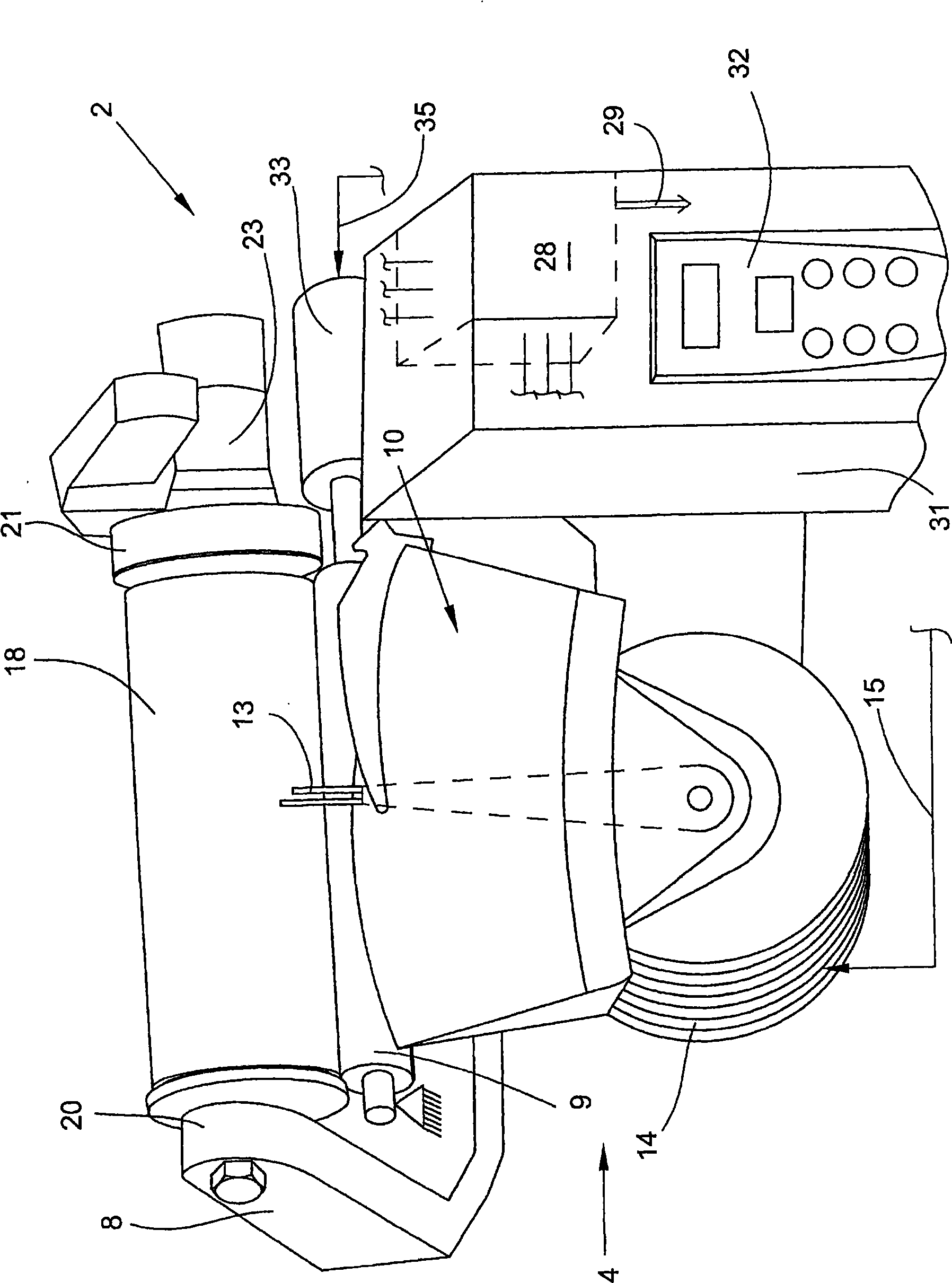

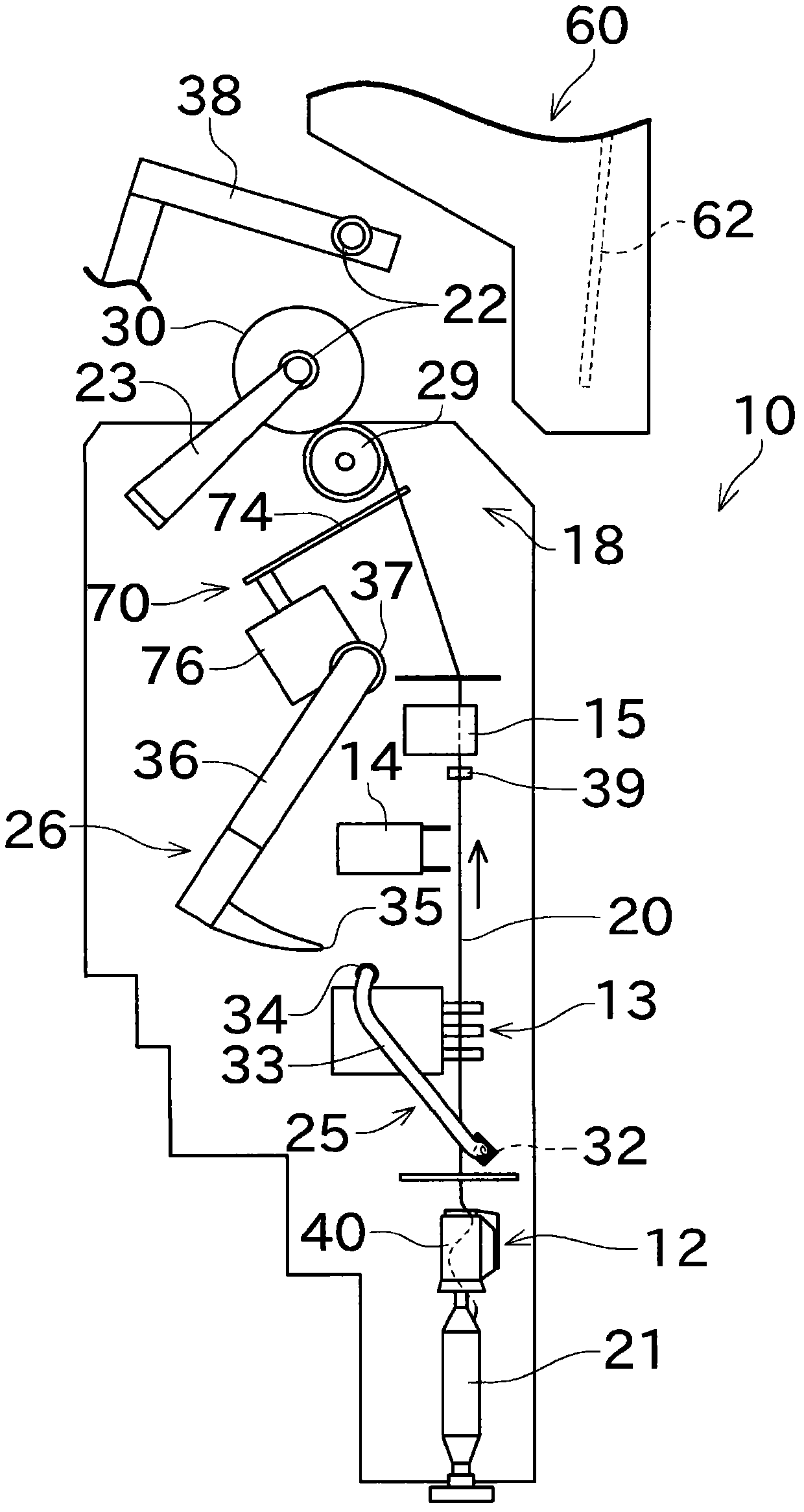

Method for winding yarn on bobbin to form intersected coiled bobbin

The invention relates to a method for winding yarn (16) on a bobbin (18) to form an intersected coiled bobbin (5). The bobbin held in a bobbin creel (8) can be driven by a device (9) driven by a individual motor, and the yarn is moved on the intersected coiled bobbin (5) by using a traversing gear (10) driven by the individual motor, finally bobbin is formed gradually, wherein the taper coefficient is adopted to actuate the single motor drive unit (14) of the traversing gear (10). The taper coefficient represents the ratio of the movement rate of the yarn at the end face of the intersected coiled bobbin (5). On the cylindrical bobbin, when the intersected coiled bobbin runs, the taper coefficient is increased or reduced from 1 in yarn twisting direction. The taper is appended on the bobbin creel (8) to make the bobbin lean towards the horizontal line. The appended taper is in accordance with the asymmetrical yarn because of the change of taper coefficient at least in the direction.

Owner:SAURER GERMANY GMBH & CO KG

Method and device for determining the necessary speed of rotation of a coil drive roller

ActiveCN103241588AIncreased winding tensionSlow down the winding speedFilament handlingYarnEngineering

The present invention relates to a method and a device for determining the necessary speed of rotation of a coil drive roller, which particularly reduces rotation speed fluctuation of crossly wound coils (8) when a winding stroke is started. In a station (2) of a spinning machine (1), besides cylindrical crossly wound coils (8), conical crossly wound coils are manufactured in a so-called twisting winder (4). For the uniform roller structure, feeding of a constant winding tension to the yarn (7) is very important. Winding tension fluctuation can cause yarn fracture besides yarn layer loosening, and affects continuous spinning and winding processes. For preventing this effect, the invention prescribes that: angular momentum of the crossly wound coils (8) is detected through the sensor and calculated according to time sequence of a corresponding driving diameter before paving or splicing, so as to select the rotation speed of the coil drive roller (10) before the winding stroke.

Owner:SAURER GERMANY GMBH & CO KG

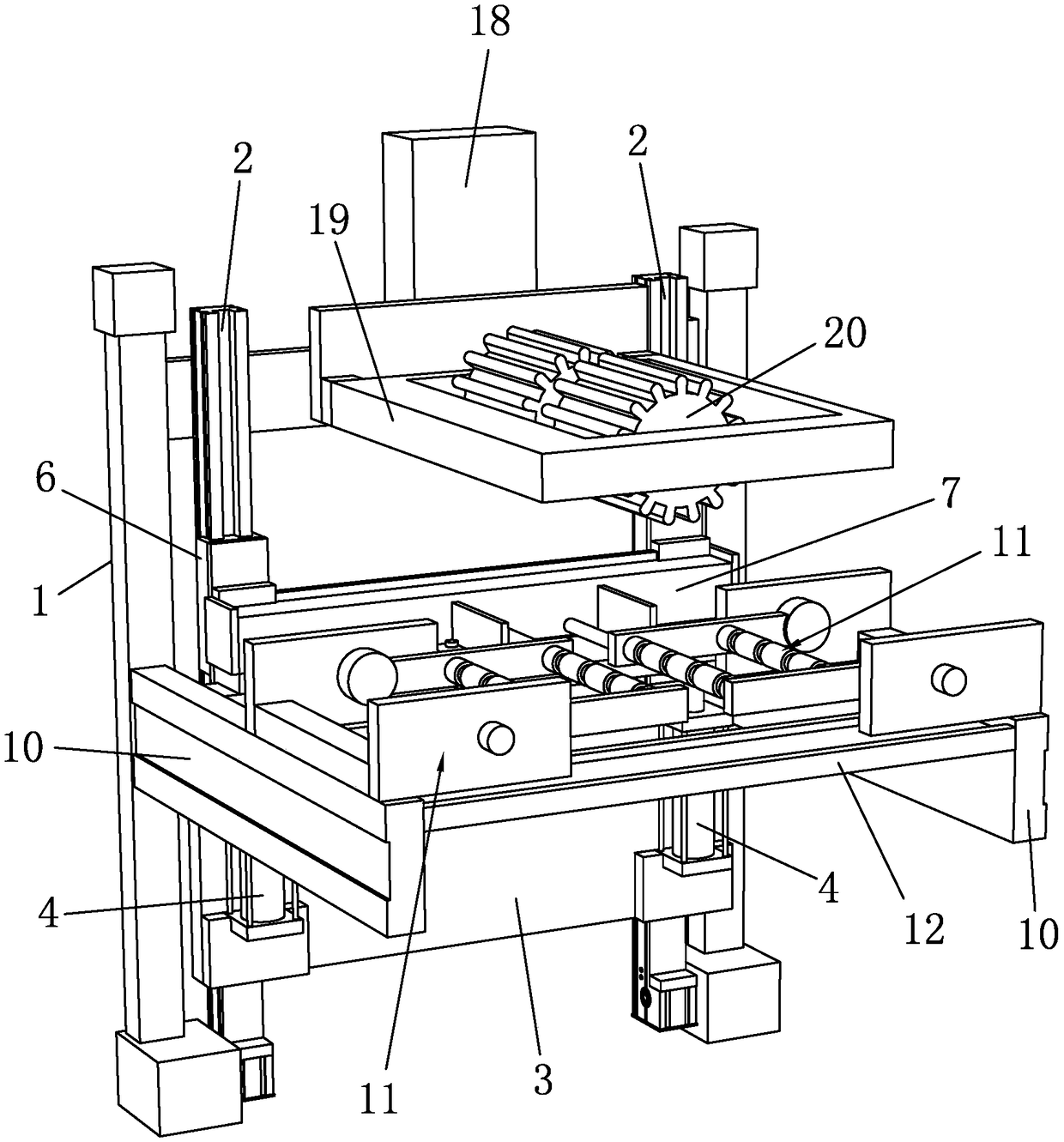

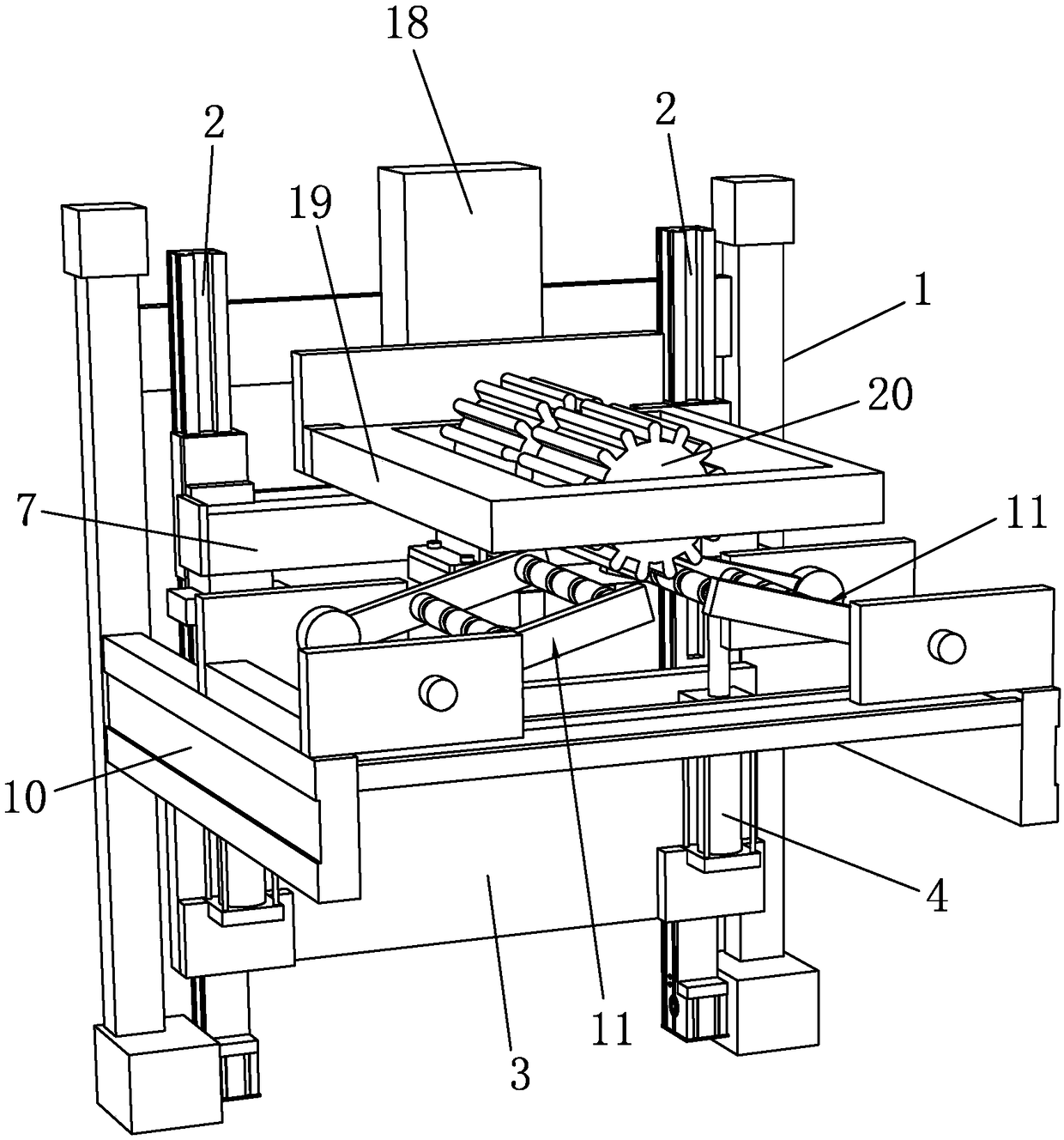

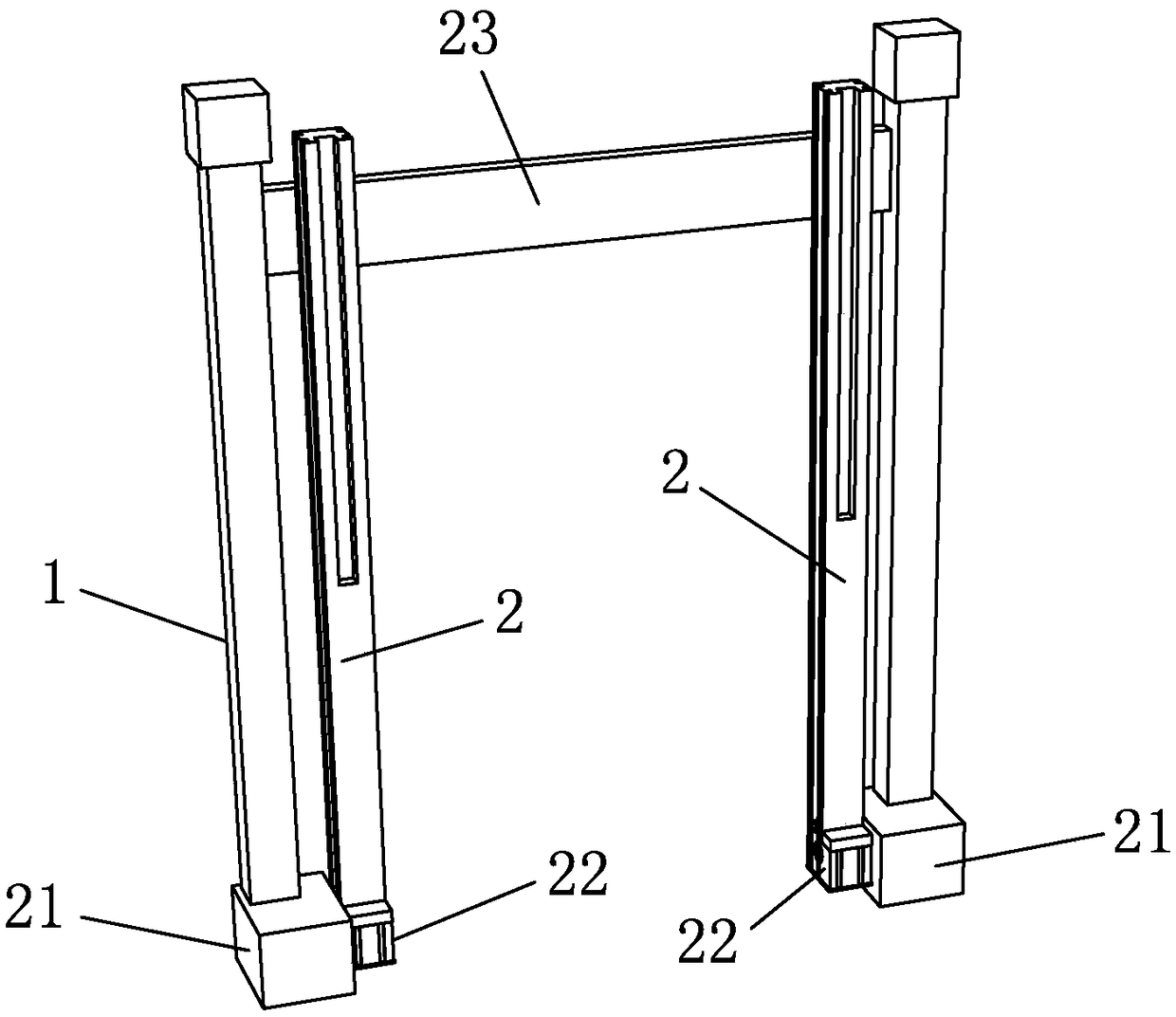

Yarn positioning electrostatic treatment device

InactiveCN109287057AImprove installation accuracyAvoid yarn breakageElectrostatic chargesAutomatic controlYarn

The invention discloses a yarn positioning electrostatic treatment device. The yarn positioning electrostatic treatment device comprises a rack and an automatic control system. The rack is provided with a linear guide rail, the linear guide plate is provided with a mounting plate, a hydraulic oil cylinder is arranged on the side face of the mounting plate and provided with a piston rod, a single section of the linear guide rail is provided with a sliding block, the piston rod drives the sliding block, a movable plate is arranged at the bottom of a positioning table, the rack is provided with ahorizontal supporting plate, and a positioning and collating device is arranged on the top face of the horizontal supporting plate. The positioning and collating device comprises a positioning support rotationally connected with rotary arms, a roller is arranged between the rotary arms, the roller is provided with a positioning groove, handles are arranged on the side faces of the rotary arms, the handles are arranged on the movable plate, the automatic control system is in drive connection with a lifting rod, and the lifting rod drives an ion stick. Yarn is positioned and collated, the yarnis conveyed along a certain path, the tension of the yarn in the conveying process is adjusted, meanwhile, the ion stick is adopted for electrostatic neutralizing treatment, and the yarn breakage phenomenon of the yarn is avoided.

Owner:SHENGZHOU WENDA TEXTILE CO LTD

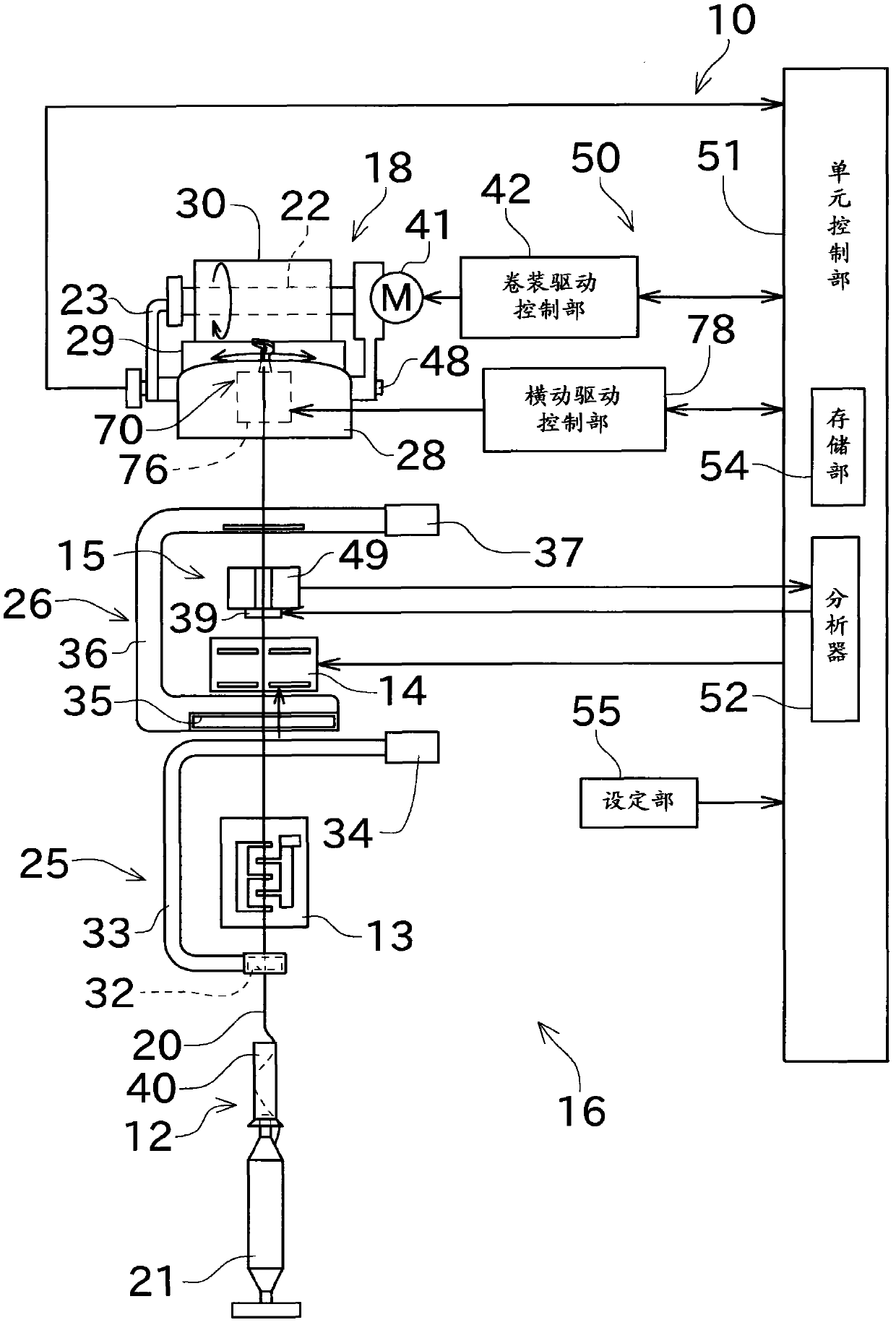

Yarn winding unit and yarn winding machine

A yarn winding unit includes a winding section that winds a yarn around a winding tube to form a package, and a control section that controls the winding section. The winding section includes a winding tube supporting section that supports the winding tube, a contact roller that rotates in contact with the winding tube or the package, and a traversing device that is arranged independently of the contact roller and that traverses the yarn that is to be wound around the winding tube. The control section controls the winding section such that the traversing speed of the traversing device is maintained equal to or below a predetermined speed when the winding of the yarn is started.

Owner:MURATA MASCH LTD

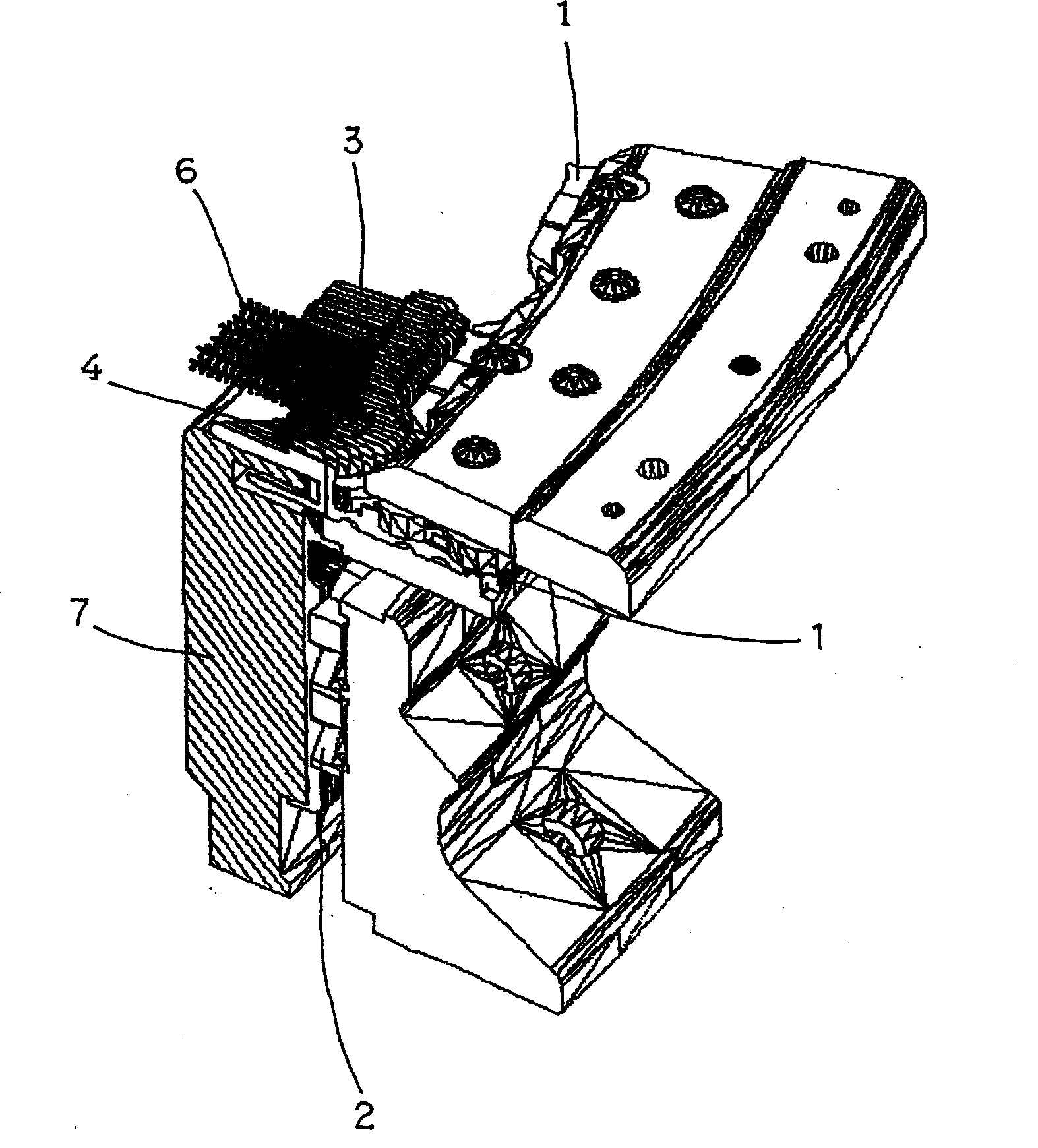

Resilient disc sheet type solid compact spinning apparatus

The invention discloses an elastic disc type three-dimensional compact spinning device that belongs to the technical field of textile machines. The device comprises a rocking shelf mounted on the spinning machine; the rocking shelf is arranged with a lower leather-covered roll; the lower roller is positioned below the rocking shelf; the rocking shelf is fixed with a spring plate; the spring plate is arranged with a central leather-covered roll and a supper-low leather-covered roll; the central leather-covered roll is mounted below the lower leather-covered roll, and tightly pressed on the lower roller; the super-low leather-covered roll is tightly pressed on the central leather-covered roll; between the central leather-covered roll and the lower roller, an elastic disc is provided; the elastic disc comprises a bundling disc and an elastic bar; one side of the bundling disc is pressed on the lower roller through the elastic bar; the other side tightly leans against the central leather-covered roll; on one side where the bundling disc tightly leans against the central leather-covered roll, an arc-shaped slot is opened with a horn-shaped breach in width that gradually becomes smaller. The invention is characterized by perfect bundling effects and convenient installation and utilization.

Owner:朱爱萍

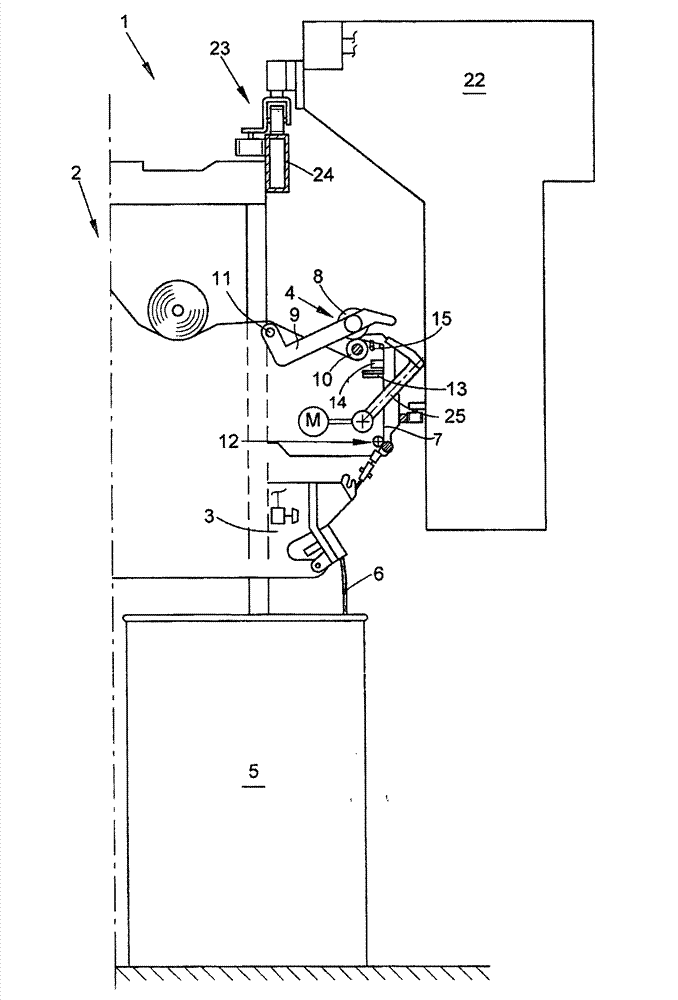

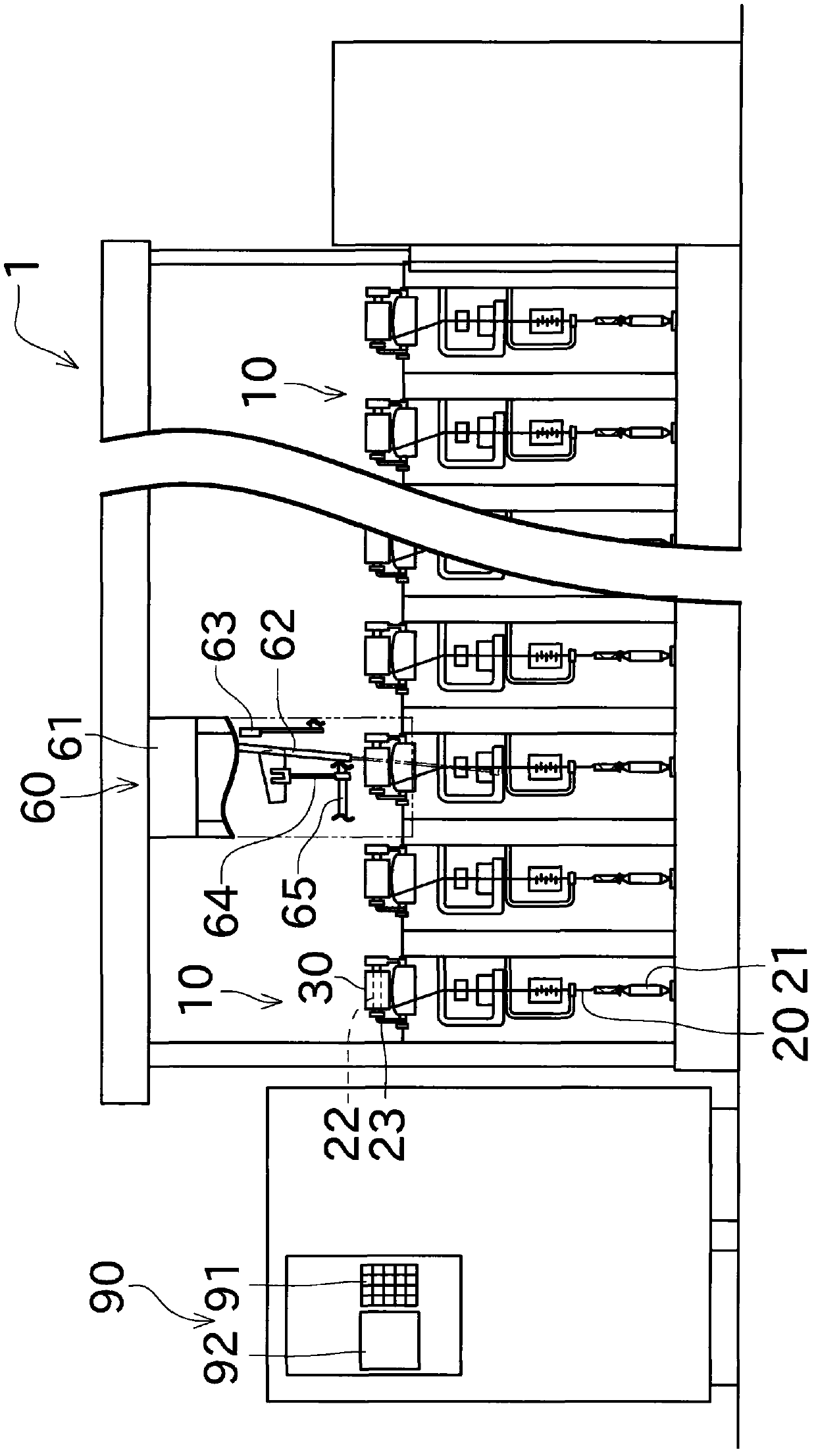

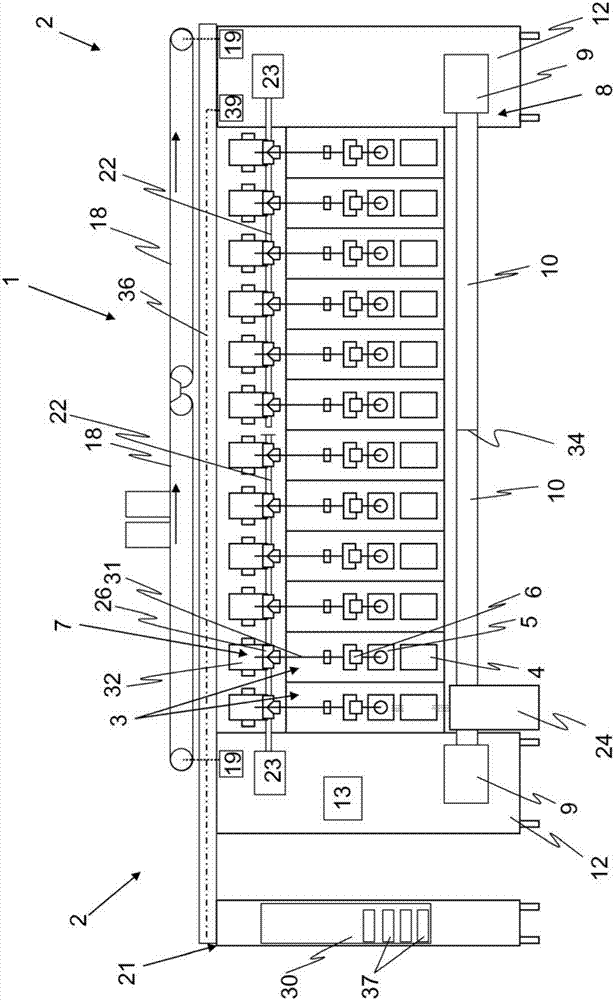

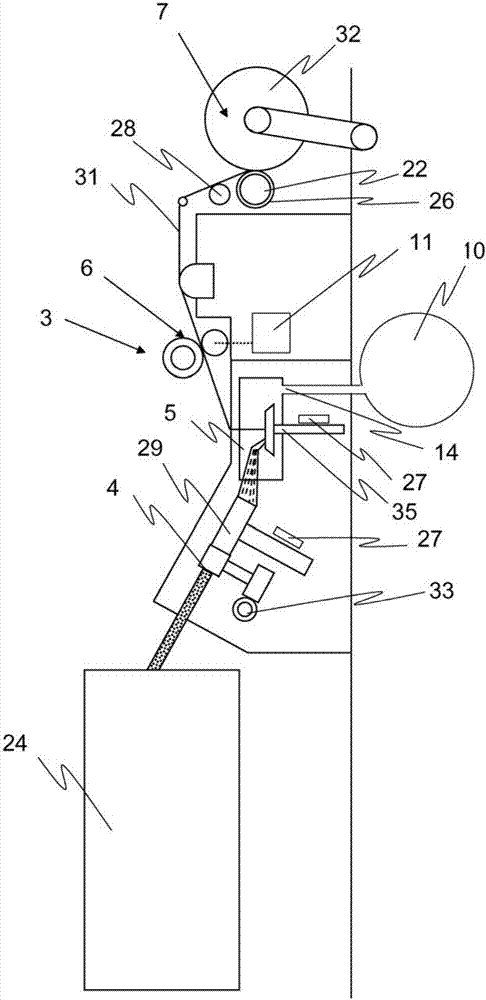

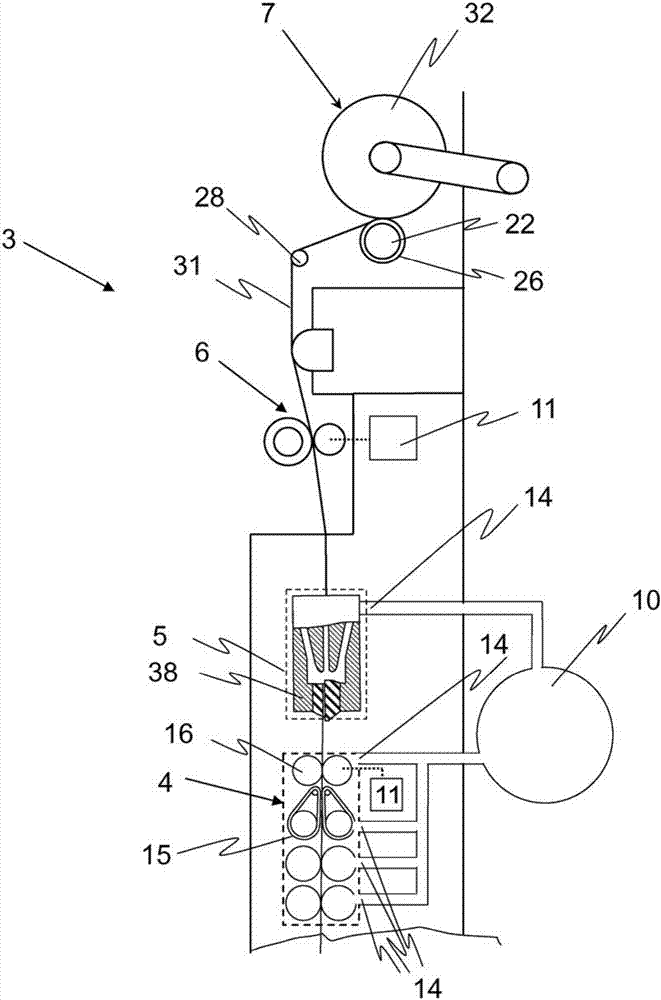

Spinning machine comprising a plurality of workplaces and a suction appliance

ActiveCN107447303AAvoid formingAvoid cloggingFilament handlingContinuous wound-up machinesYarnElectric drive

A spinning machine (1) features a multiple number of work stations (3) arranged side by side between two front-side ends (2) of the spinning machine (1) on at least one longitudinal side of the spinning machine (1), each of which features a multiple number of work elements for the production and winding of a yarn (31), whereas the work elements comprise at least one feed device (4), one spinning chamber (5), one draw-off device (6) and one winding device (7). The spinning machine (1) features drives for driving the work elements and a suction device (8) for generating negative pressure at the work stations (3). The suction device (8) includes at least one negative pressure source (9) and at least two negative pressure channels (10), which extends in the longitudinal direction of the spinning machine (1) only over one part of the work stations (3). Thereby, each work station (3) features an individual drive (11), in particular an individual electrical drive (11), for the draw-off device (6).

Owner:RIETER INGOLSTADT GMBH

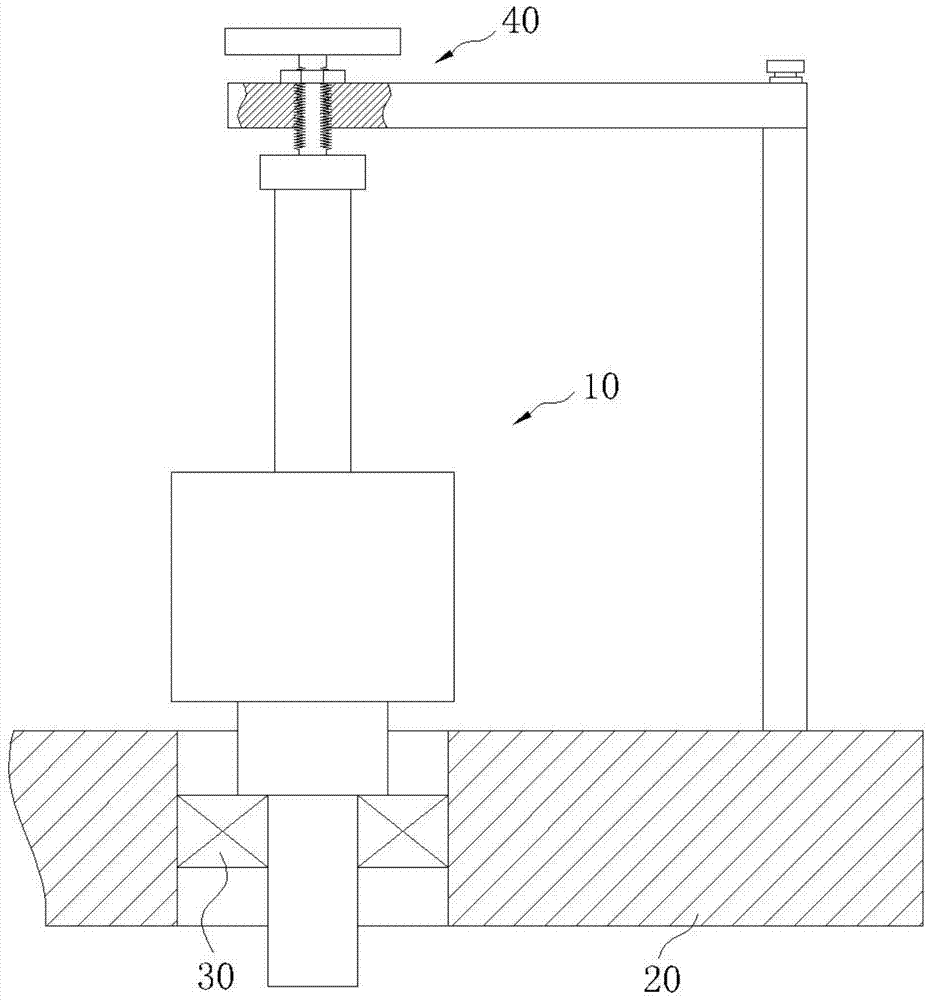

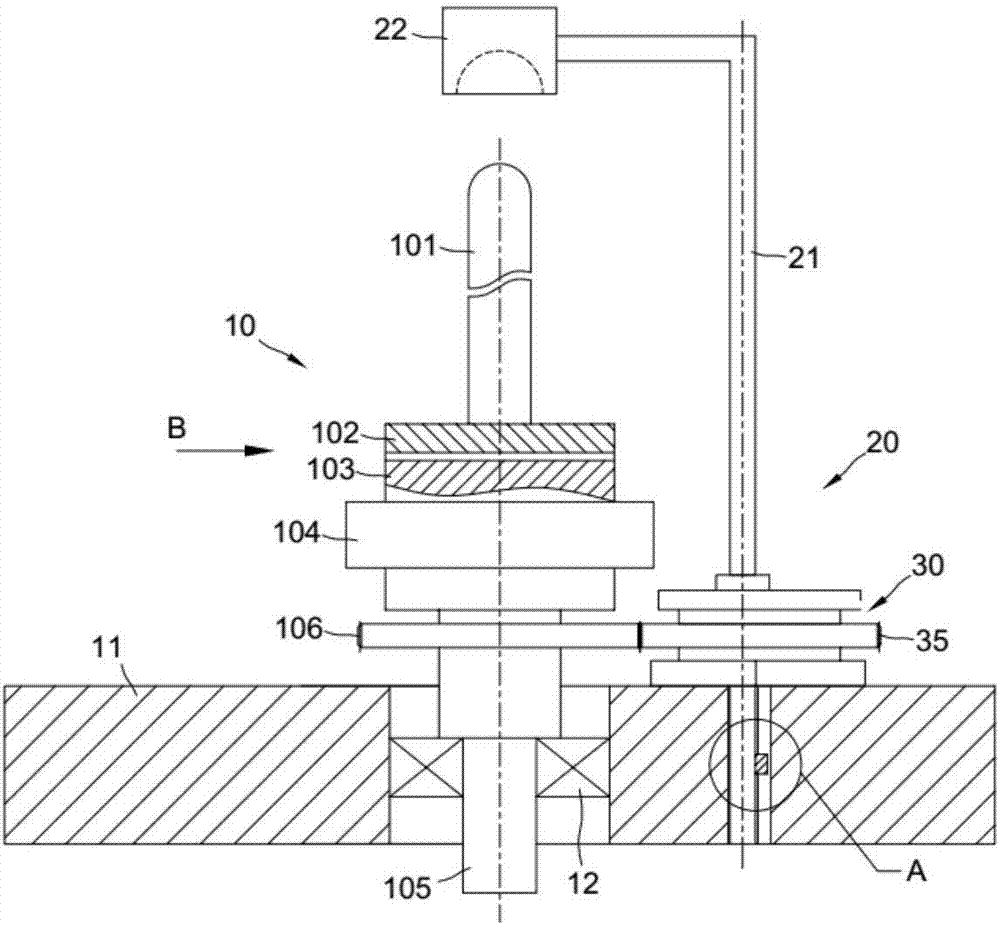

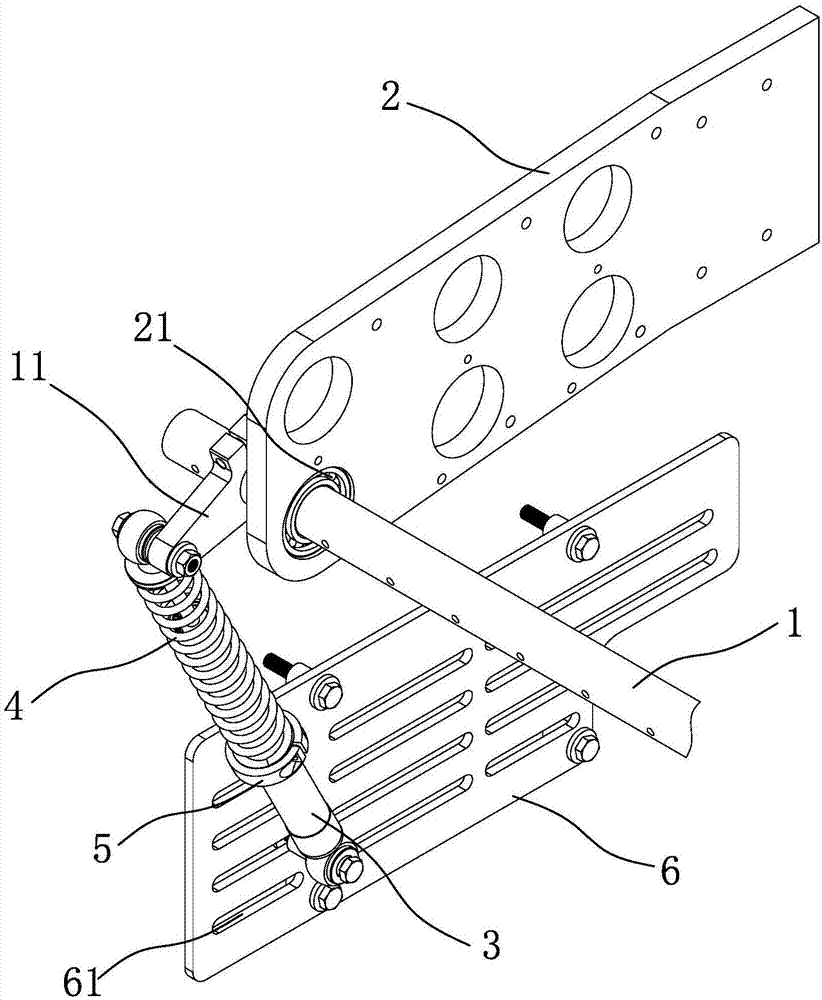

Spindle device for reducing vibration amplitude

The invention discloses a spindle device for reducing the vibration amplitude. The spindle device comprises a spindle and a spindle base, and the spindle is installed on the spindle base through a bearing; the spindle comprises a spindle rod, a spindle rod sliding block arranged at the bottom of the spindle rod, a spindle rod base matched with a spindle rod sliding block and a belt wheel installed on the spindle rod base; and a fixed core mechanism is arranged on the spindle base and comprises a lifting rod, a lifting driving mechanism for driving the lifting rod to ascend and descend and a positioning block installed at the top of the lifting rod, and the bottom of the positioning block is provided with a hemispheric groove matched with the top end of the spindle. In operation, the spindle rod sliding block drives the spindle rod to transversely move, a spinning barrel is installed on the spinning rod in a sleeving manner, the spinning rod sliding block resets, the lifting rod descends, and the hemispheric groove of the positioning block is arranged at the top end of the spindle rod in a sleeving manner. When the spindle rotates, the vibration amplitude of the spindle is limited by the groove, and the vibration amplitude of the spindle in the wire winding process is reduced.

Owner:连云港中鸿包装有限公司

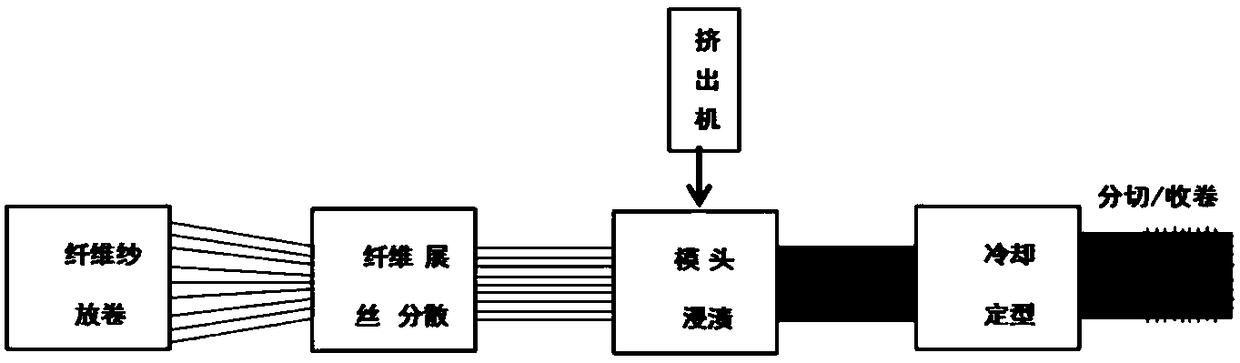

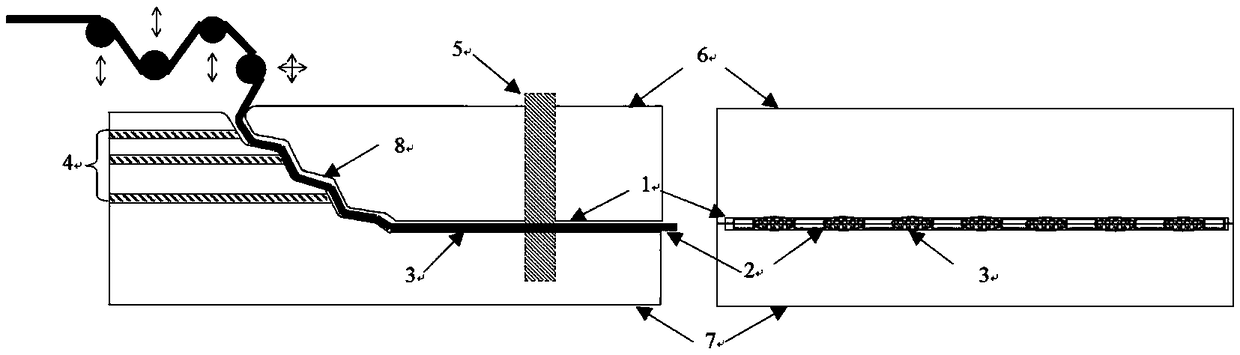

Melt impregnation device and melt impregnation method

The present invention discloses a melt impregnation device and a melt impregnation method. Through an impregnation chamber with a corrugated shape, when a resin melt-distributing runner is connected with a peak position of the impregnation chamber, a chamber vertical height of the peak position of the impregnation chamber is larger than a chamber vertical height of a trough position of the impregnation chamber, and when the resin melt-distributing runner is connected with the trough position of the impregnation chamber, the chamber vertical height of the trough position of the impregnation chamber is larger than the chamber vertical height of the peak position of the impregnation chamber. The present invention can balance an impregnating effect of a continuous fiber band, can carry a broken fiber hairiness which is generated during the impregnation out of an impregnation area, avoids a broken yarn, and enhances a production stability and a production efficiency.

Owner:KINGFA SCI & TECH CO LTD

Single-yarn control device of computer type Jacquard warp-knitting machine

The invention relates to a single-yarn control device of a computer type Jacquard warp knitting machine, which comprises an upper yarn guide rod, a weight transmitter, an adjuster and a sliding seat, wherein the sliding seat can move on the upper yarn guide rod; a locking screw is arranged between the sliding seat and the upper yarn guide rod; a sensor of the weight transmitter is fixed on the sliding seat; a sensing roller is fixed on the sensor; the adjuster is provided with a servo motor and a roller bracket which are arranged on the sliding seat, a driving rubber roller connected to the roller bracket, and a floating rubber roller pressed on the driving rubber roller; the driving rubber roller is driven by the servo motor to rotate; and the sliding seat is also provided with a front yarn guide roller and a back yarn guide roller. The device better solves the problem that the connection of the front and the back sheets of a seamless forming product has seams because of the over loose of single yarn; the clearness of a hollow flower shape can be simultaneously guaranteed in knitting meshes, in particular the clear flower type with three-dimensional feeling can be knitted on the Jacquard surface layer of interval Jacquard fabrics with double needles, i.e. sandwich Jacquard fabrics..

Owner:DAO QI NEW MATERIAL TECH CO LTD

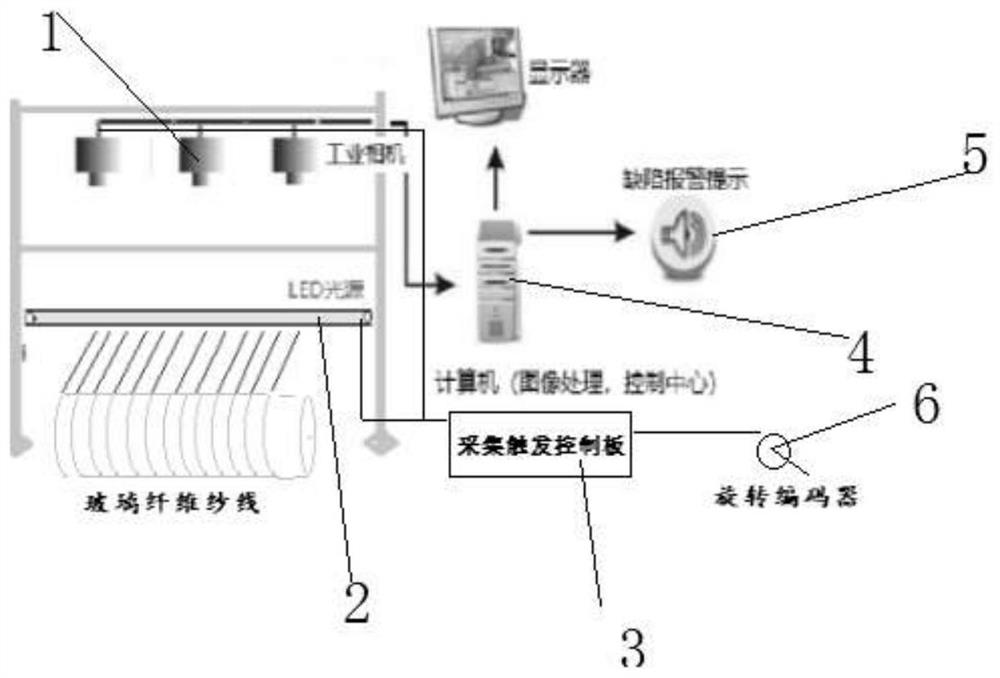

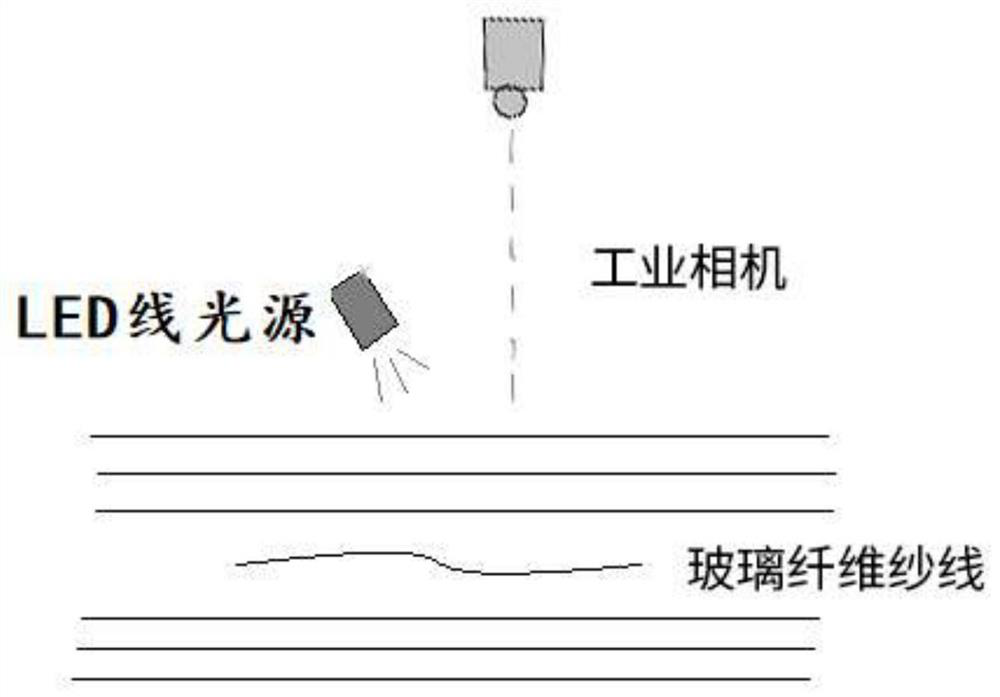

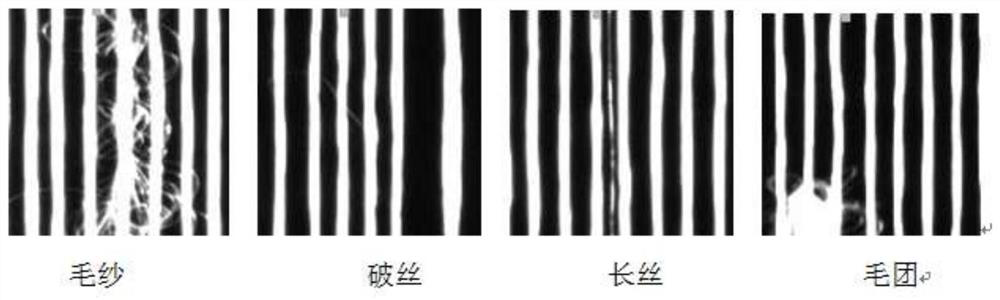

Online detection equipment and method forglass fiber yarn based on machine vision

PendingCN112834524ANo contactNon-destructive testingOptically investigating flaws/contaminationComputer hardwareGlass fiber

The invention discloses online detection equipment forglass fiber yarn based on machine vision, which comprises an LED line light source erected above the glass fiber yarn, wherein an industrial camera is arranged on one side of the LED line light source, the LED line light source and the industrial camera are connected in parallel with an acquisition trigger control panel, the acquisition trigger control panel is also connected with a rotary encoder, the rotary encoder is located on a glass yarn production line, the industrial camera is connected with the input end of the industrial control computer, and the output end of the industrial control computer is connected with a defect alarm prompter. The invention further discloses a detection method of the online detection equipment for the glass fiber yarn based on machine vision, the machine vision technology is adopted, non-contact and non-damage detection of the glass fiber yarn is achieved, and the problem of non-hair detection in the prior art is solved.

Owner:XIAN HUODE IMAGE TECH CO LTD

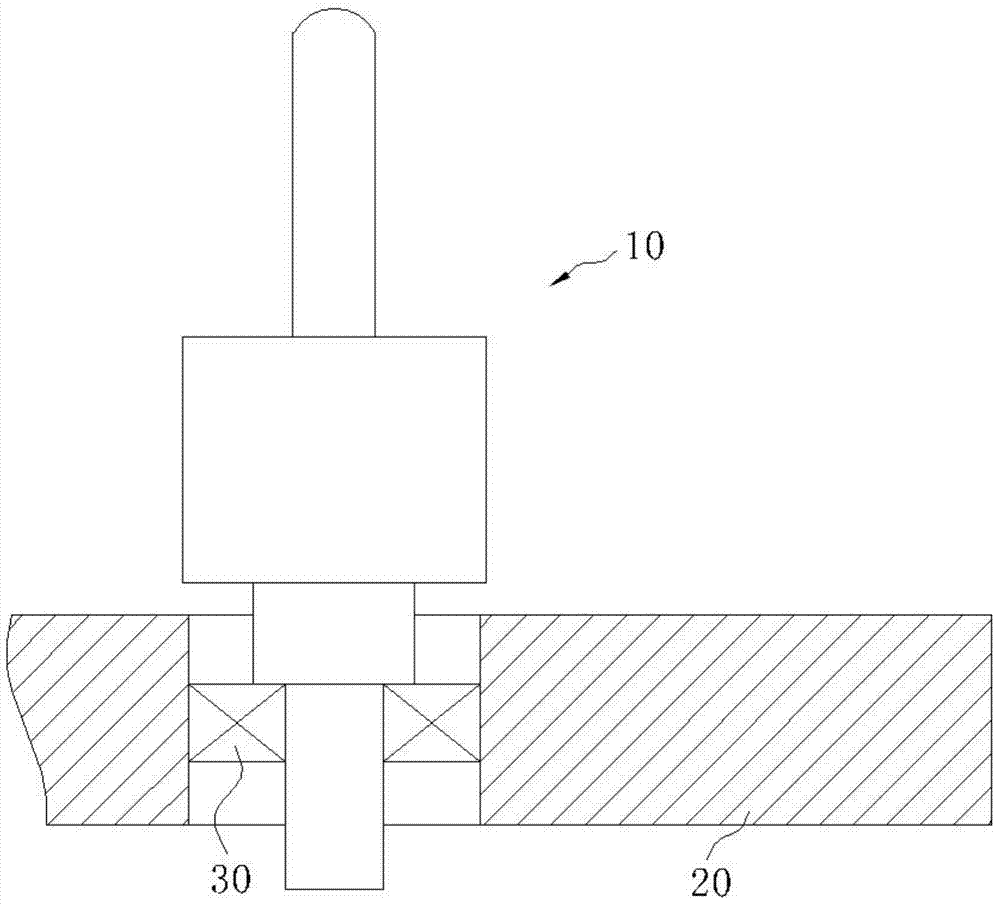

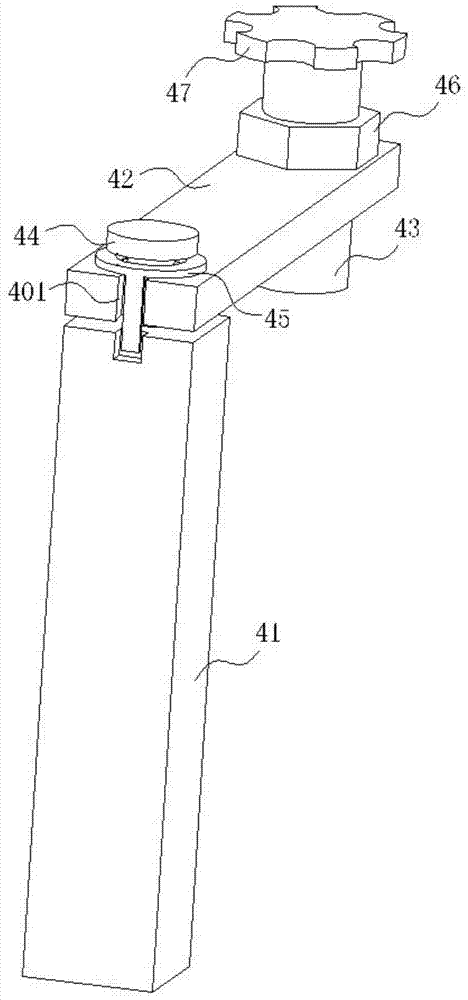

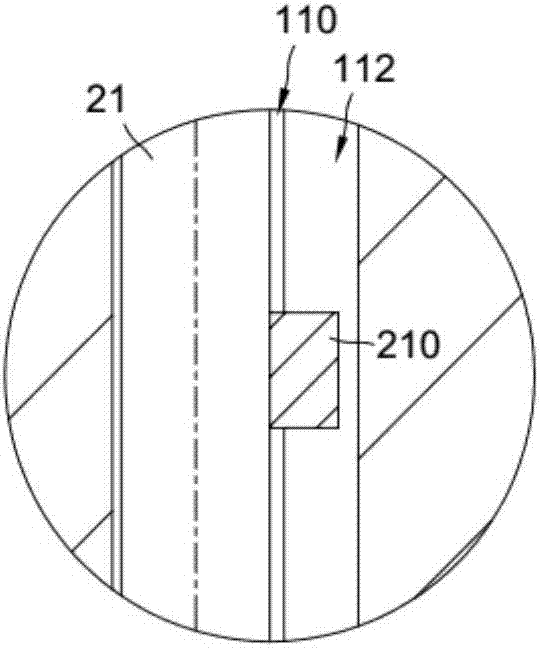

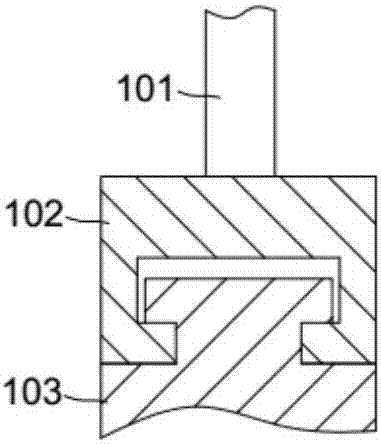

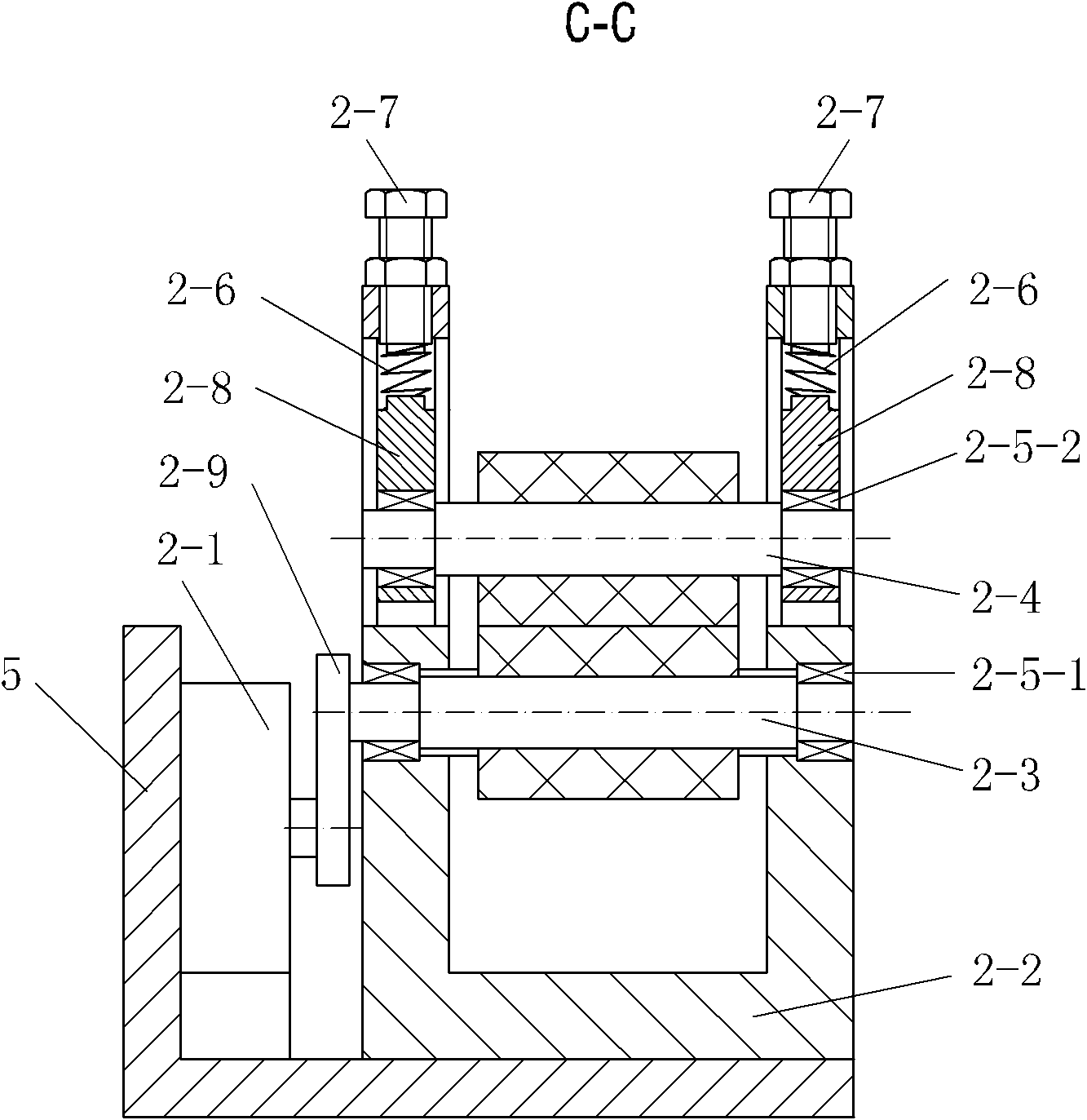

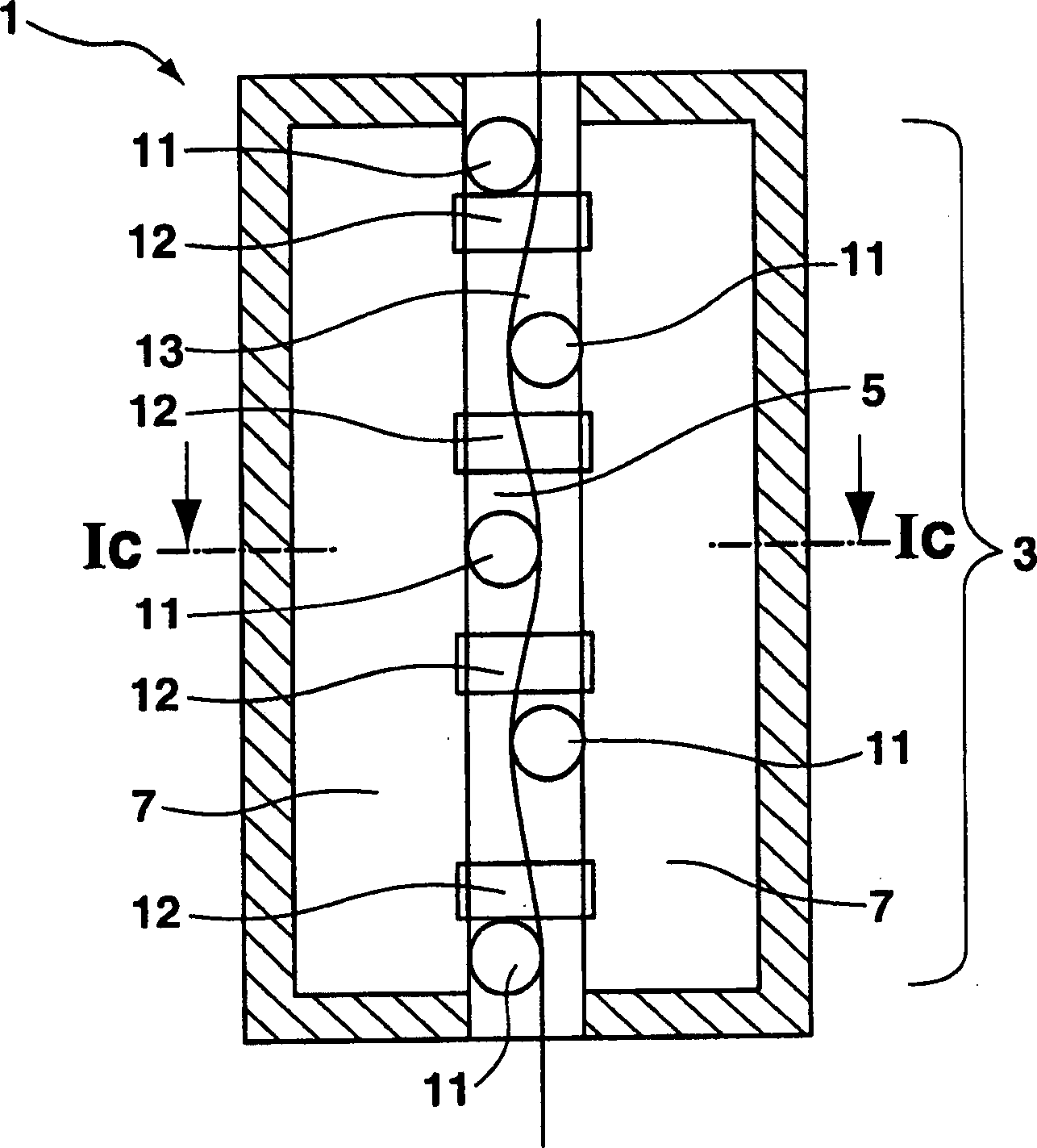

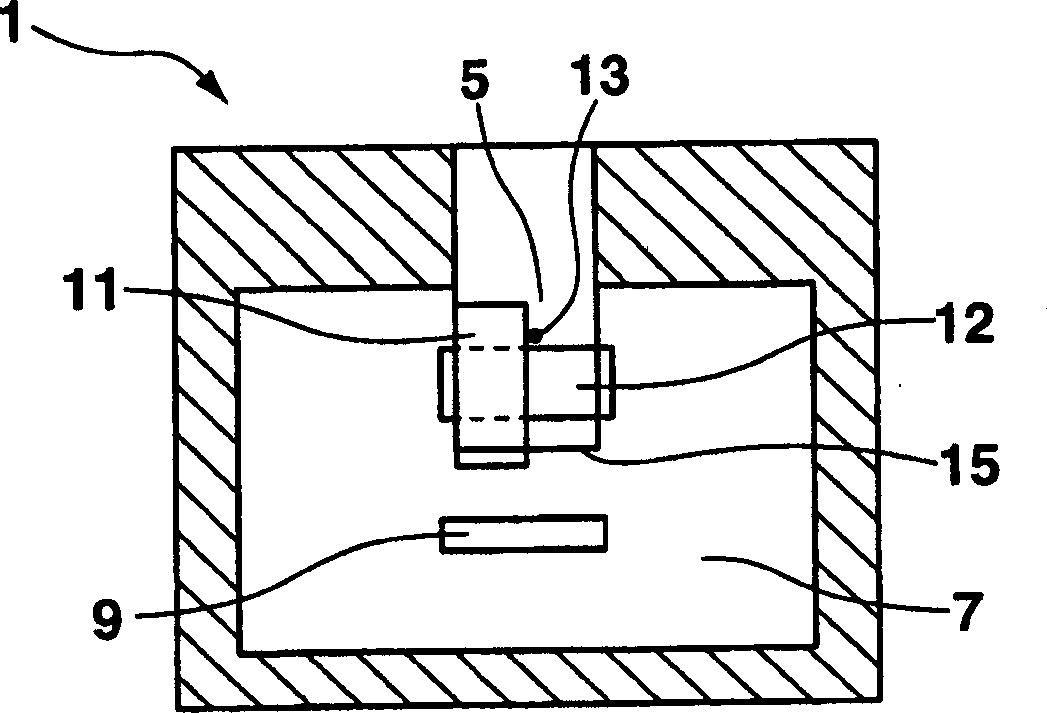

Spindle mechanism provided with core fixing device

InactiveCN104131377AReduce vibration amplitudeImprove fluencyTextiles and paperVibration amplitudeYarn

The invention discloses a spindle mechanism provided with a core fixing device. The spindle mechanism provided with the core fixing device comprises a spindle (10), a spindle seat (20), a bearing (30) and the core fixing device (40) mounted on the spindle seat (20). The core fixing device (40) comprises a fastening component (43) located above the spindle (10), a groove (431) is formed in the bottom end of the fastening component (43), and the groove (431) can cover the top end of the spindle (10), thus, when the spindle rotates, the amplitude of vibration of the spindle is limited by the groove. According to the technical scheme, the core fixing device belongs to a device attached to the spindle, the original structure of the spindle does not need to be changed, installation is convenient to carry out, occurrence of the yarn breaking situations generated due to oversize vibration amplitude during rotating of the spindle can be avoided, and smoothness of winding is improved.

Owner:JIANGSU HAIYANG CHEM FIBERS

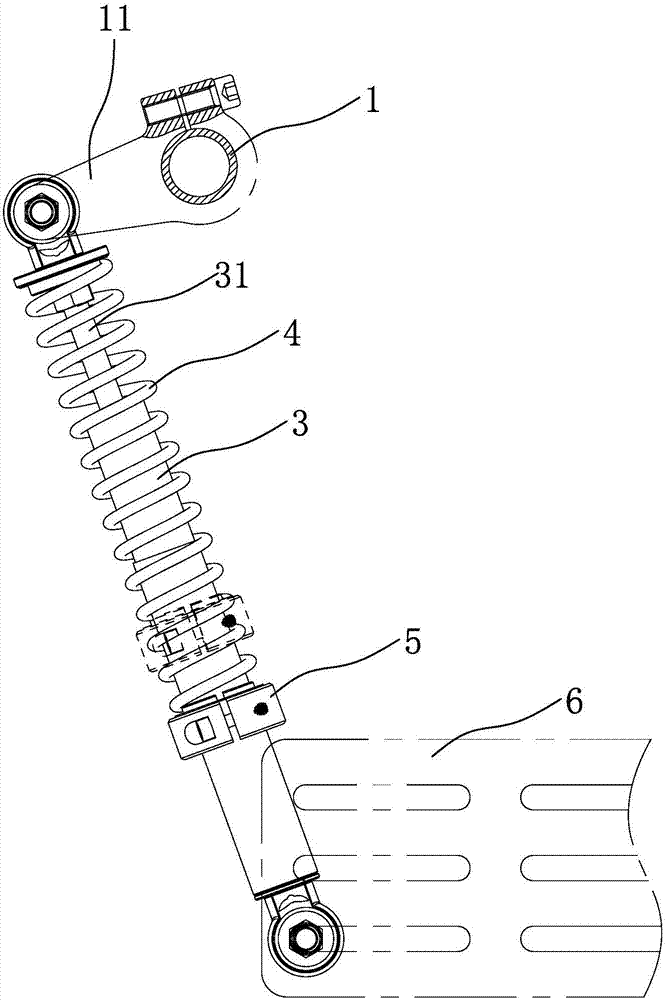

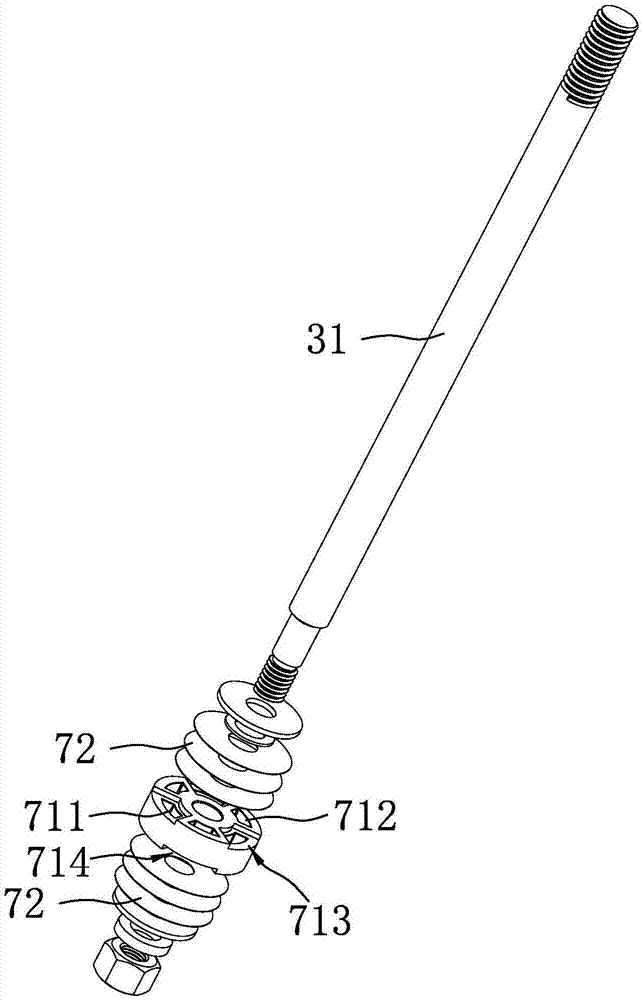

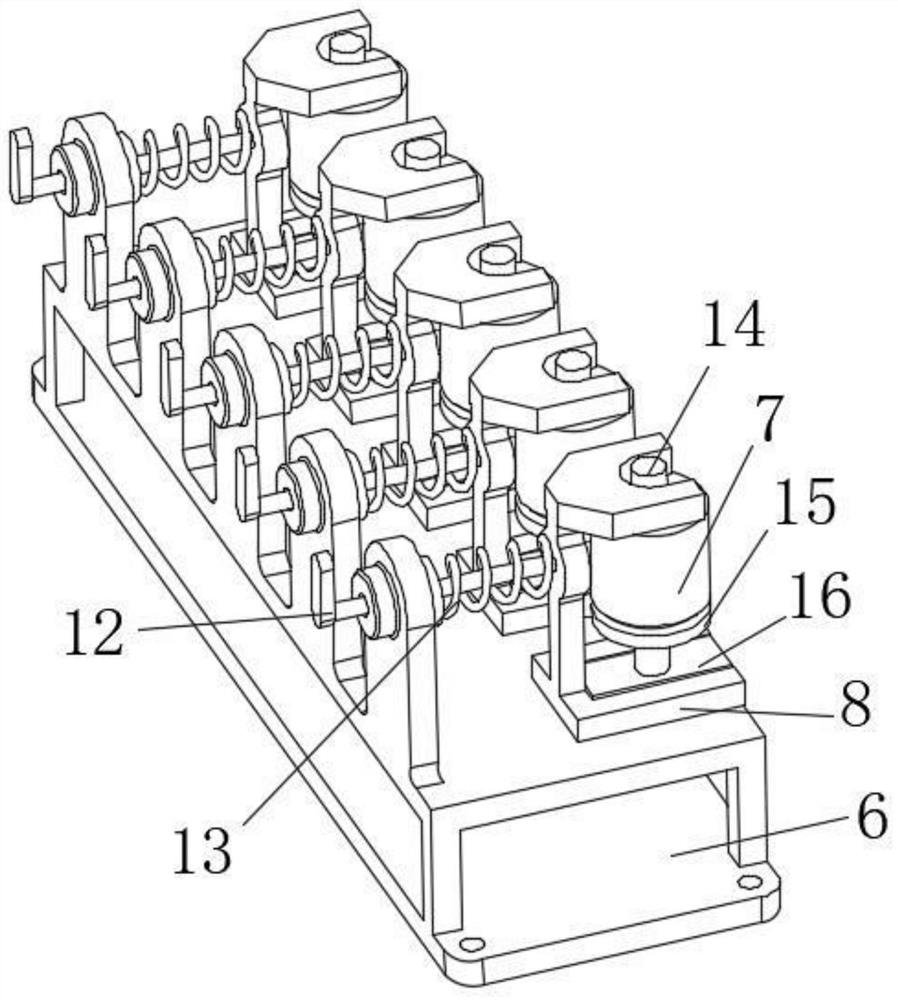

Yarn tension constant compensation device

The invention relates to a yarn tension constant compensation device. The device comprises a rack and multiple yarn guiding rods installed on the rack, a tension compensation mechanism is connected to each yarn guiding rod, each tension compensation mechanism comprises a damping cylinder, a spring arranged on the outer surface of the damping cylinder in a sleeving mode and a clamping ring, wherein one end of the damping cylinder is fixed to the rack, the other end of the damping cylinder is connected with the corresponding yarn guiding rod through a connecting plate, the spring is clamped between the end, connected to the connecting plate, of the damping cylinder and the clamping ring, the clamping ring is in threaded connection with the damping cylinder, a piston assembly inside the damping cylinder comprises a piston rod, a piston and a fixing part used for fixing the piston, the piston comprises a piston body and multiple piston sheets installed at the two ends of the piston body, the piston body is provided with multiple first oil channels and second oil channels which are cut through in the axial direction, and the first oil channels and the second oil channels are distributed at intervals in the circumference direction of the piston body. The yarn tension constant compensation device is applicable to damping and yarn-breaking-prevention of the yarn guiding rods on textile equipment.

Owner:JINJIANG PENGTAI MACHINERY TECH CO LTD

Yarn heater and its use

A yarn heater 1 is provided, in particular for a false twist texturing machine, comprising a heating zone 3 with a yarn channel 5, on which at least one heating wall 7 is arranged, a heating device 9 is provided for heating Said heating wall 7, arranges a yarn guide 11 in said yarn channel 5, wherein the yarn guide 11 is arranged such that the yarn course 13 predefined by the yarn guide 11 has a zigzag shape. This yarn heater is especially suitable for the false twist texturing process as a main heater for heating polyamide yarns.

Owner:萨罗瑞士麦特雷有限公司

Production technology of full-cotton face towel

InactiveCN107460636AAvoid yarn breakageHeating/cooling textile fabricsNon-woven fabricsCardingCotton pad

The invention discloses a production technology of a full-cotton face towel. ES cotton and viscose cotton are utilized as a main raw material of the face towel, working procedures of material mixing, dust removing, carding, cotton paving, compressing, knitting, shaping and after finishing are conducted in sequence, the produced face towel is the full-cotton face towel, the full-cotton face towel is high in moisture absorption property, breathability and intensity, fuzzing and linting do not occur, the hand feeling is good, and the full-cotton face towel is poisonless and harmless to the human skin, is washable and not prone to deformation at the same time, can be repeatedly utilized and is suitable for being further processed into sanitation supplies of napkins, towels, makeup cotton and the like.

Owner:邱宗坚

Yarn finishing device for textile machinery

The invention relates to the technical field of textile production, and specifically discloses a yarn finishing device for a textile machinery. The yarn finishing device for the textile machinery comprises a pedestal, a support frame is fixedly mounted at a left side of the pedestal through a bolt, moreover, at least three guide blocks arranged at equal distance are integrally formed on the support frame, a centering column is integrally formed on an upper end of each guide block, and a yarn cone for winding yarns is mounted on the centering column through sleeving connection. Beneficial effects: the yarn finishing device designed by the invention is convenient to use, can effectively sorting and ordering the yarns through ring-shaped yarn grooves on a traction roller and an adhesive roller, also can realize tensioning for the yarns through cooperation of a tensioning spring and the adhesive roller, and thus, can effectively avoid problems, such as breaking of the yarns caused by intertwining and friction among the yarns; moreover, the device also can effectively remove redundant fibers on the yarns through a vacuum pump and the adhesive roller, and consequently can effectively avoid interference on follow-up textile processing caused by the redundant fibers.

Owner:CHANGLE LITIAN KNITTING TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com