Triangular track structure of two-sided terry circular knitting machine

A technology of circular knitting machine and double-faced wool, which is applied to circular knitting machines with individual moving needles, weft knitting, textiles and papermaking, etc. It can solve problems such as broken yarns, burst holes, and failure to improve fabric quality. , to avoid yarn breakage and blast holes, and to achieve the same effect of pile length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

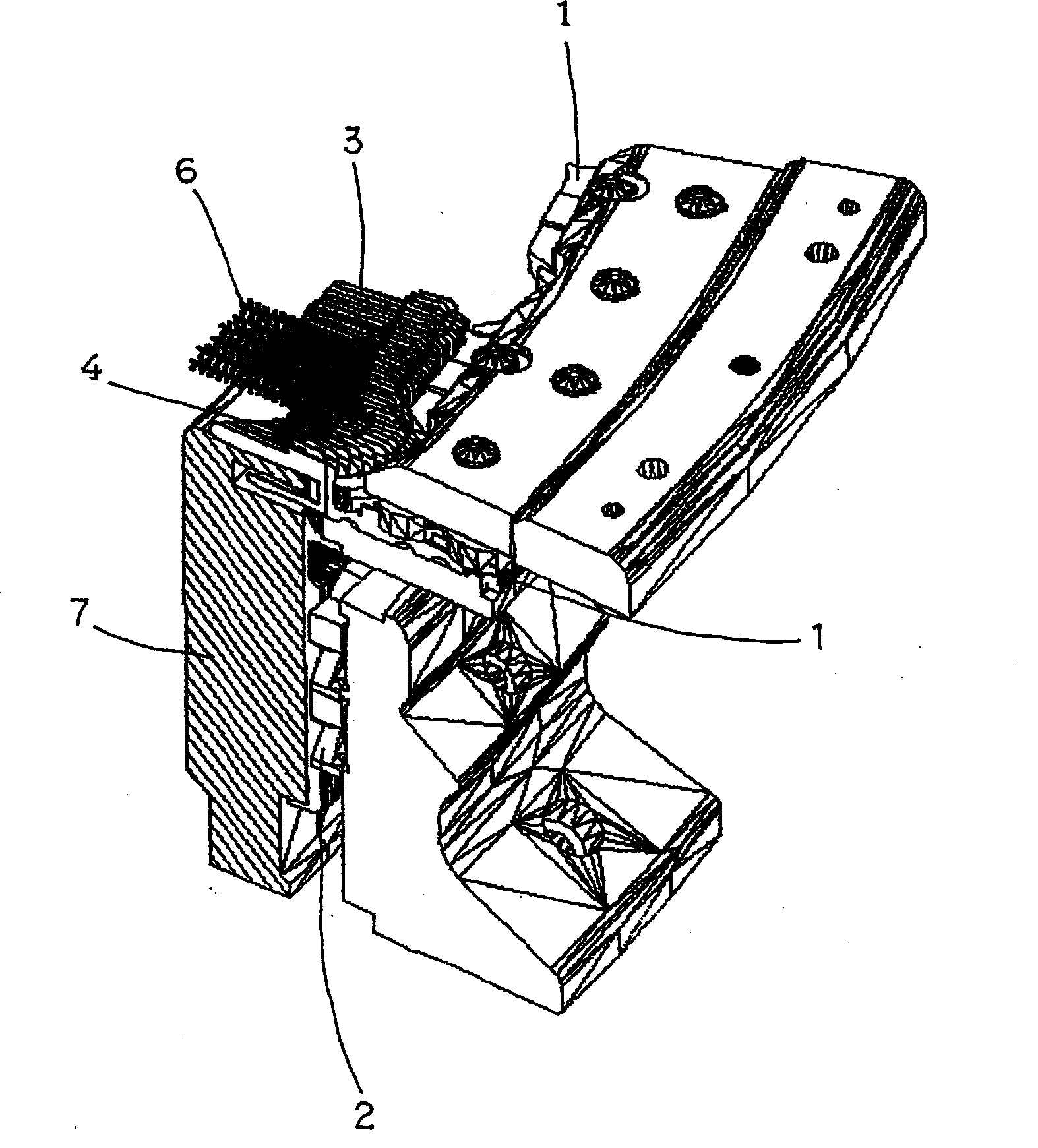

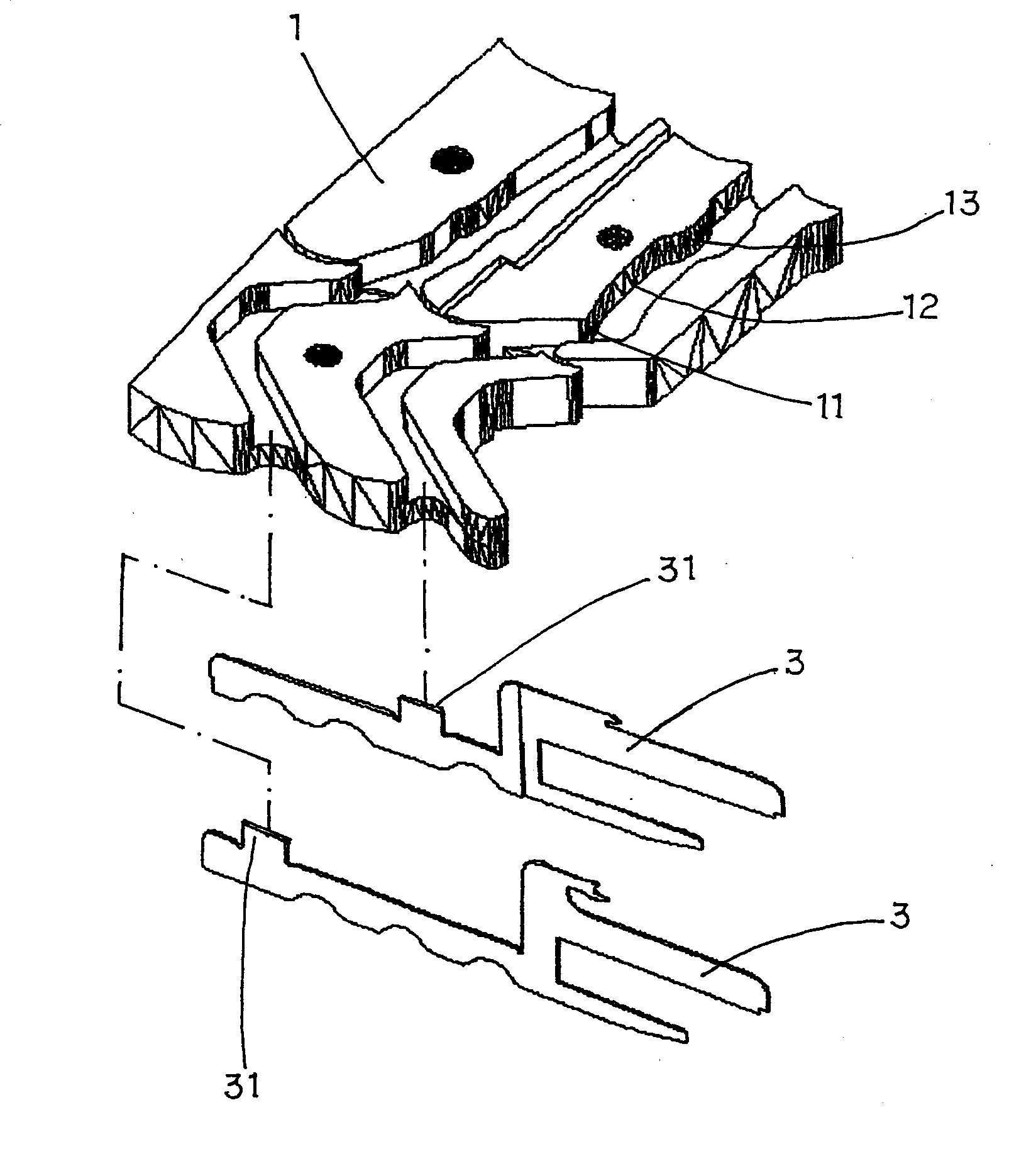

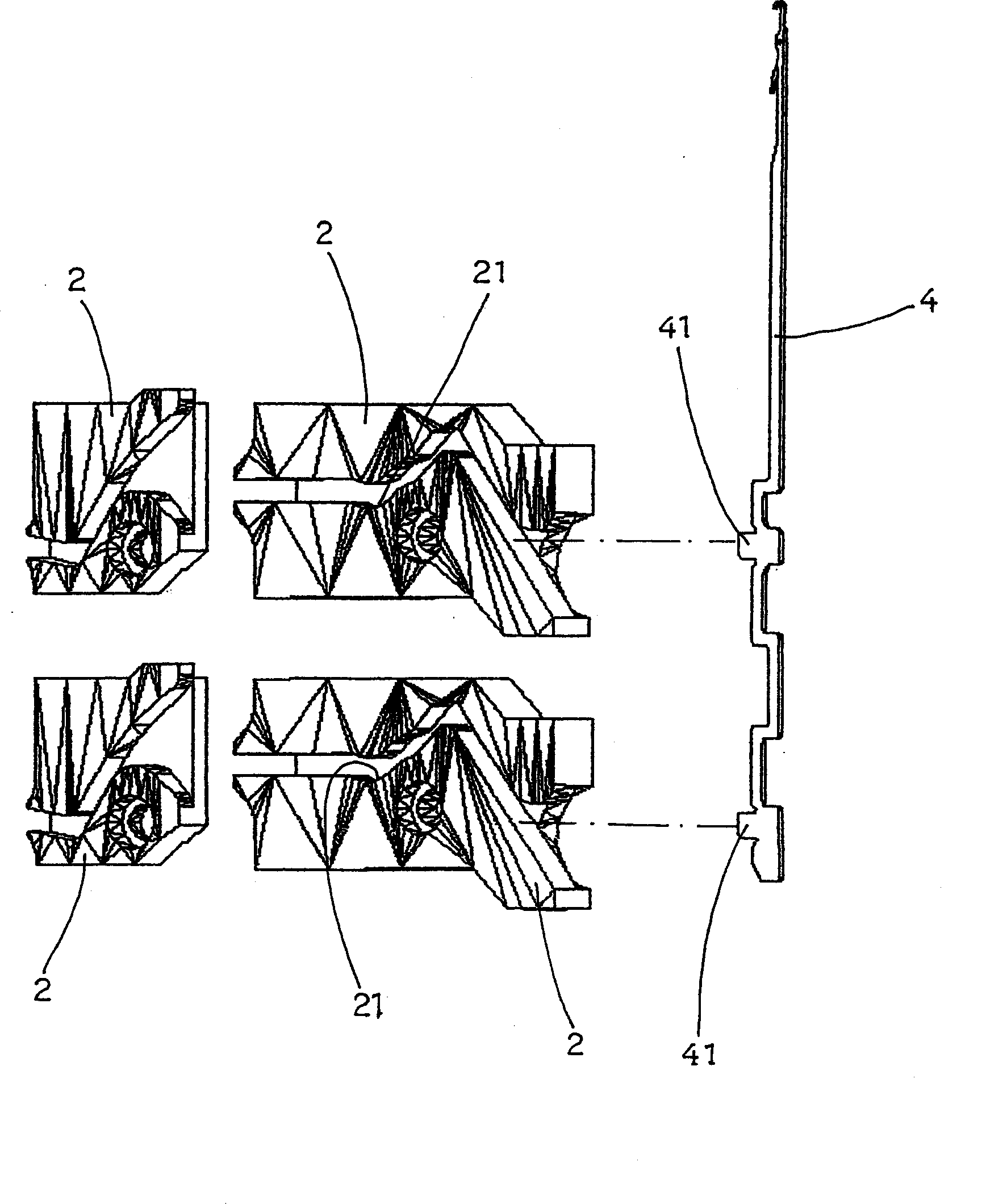

[0021] see Figure 1~3 , the accessories of the triangular track structure of the double-sided circular terry knitting machine of the present invention are the same as those of the generally known double-sided circular terry knitting machine. Sheet 3, and knitting needle 4 is installed in the knitting needle groove of needle cylinder 7, and upper and lower triangular tracks 1, 2 are respectively established on the outside of needle cylinder 7, and the sheet feet 31 and 2 of raw gram sheet 3 are The stitches 41 of the knitting needle 4 are respectively placed in the upper and lower triangular tracks 1 and 2, and the raw sheet 3 and the knitting needle 4 are driven by the rotation of the needle cylinder 7 and the tracks of the upper and lower triangular tracks 1 and 2 action, and cooperate with the yarn of the yarn feeder 5 to carry out the knitting needle hook yarn weaving cloth, and the present invention is mainly to drive the yarn eating section of the upper triangular track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com