Resilient disc sheet type solid compact spinning apparatus

A disc type and elastic disc technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve the problems of out-of-sync speed of compact spinning device, inability to eliminate yarn quality, high production cost, etc., to achieve The effects of shortening the twisting distance, avoiding yarn breakage and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

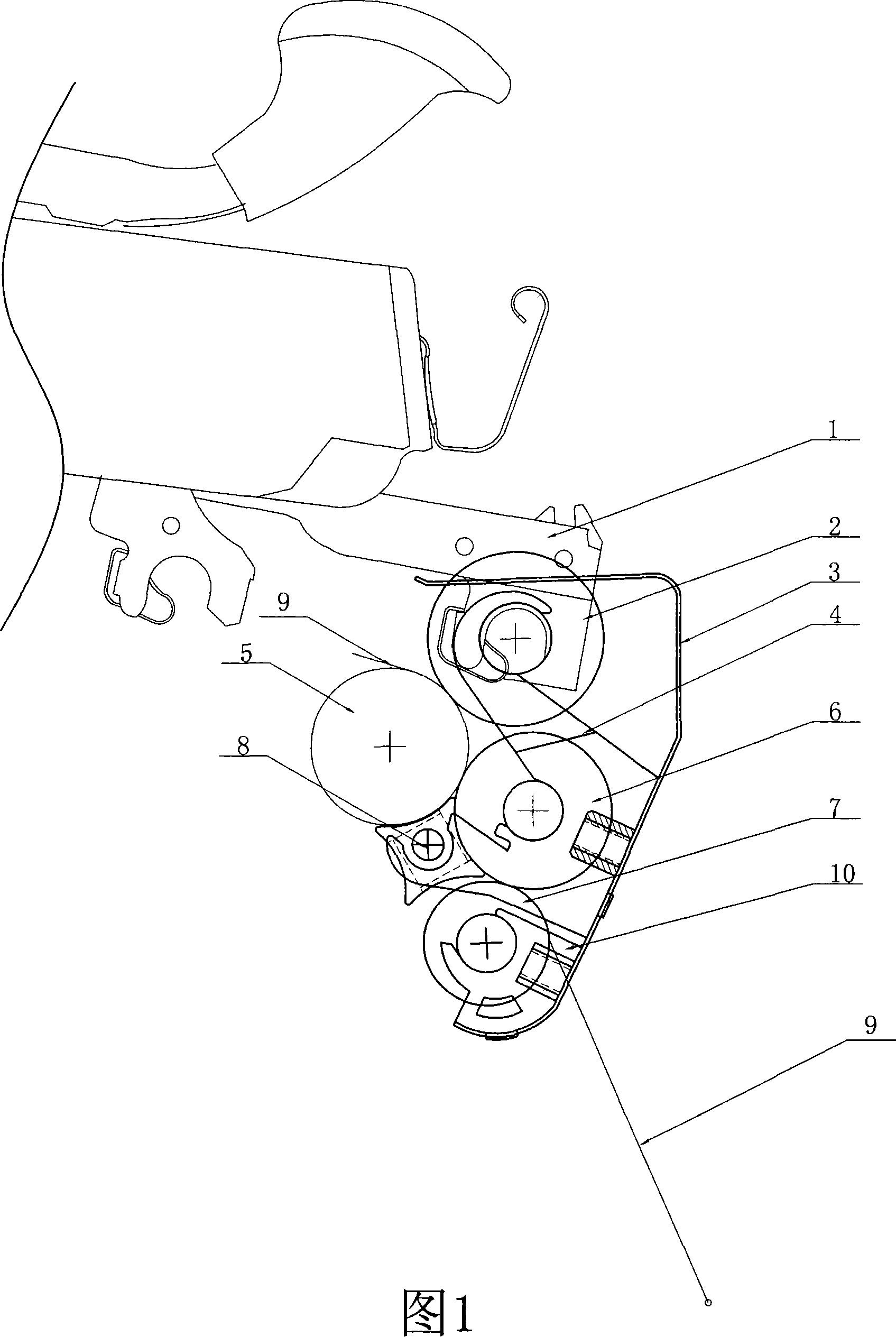

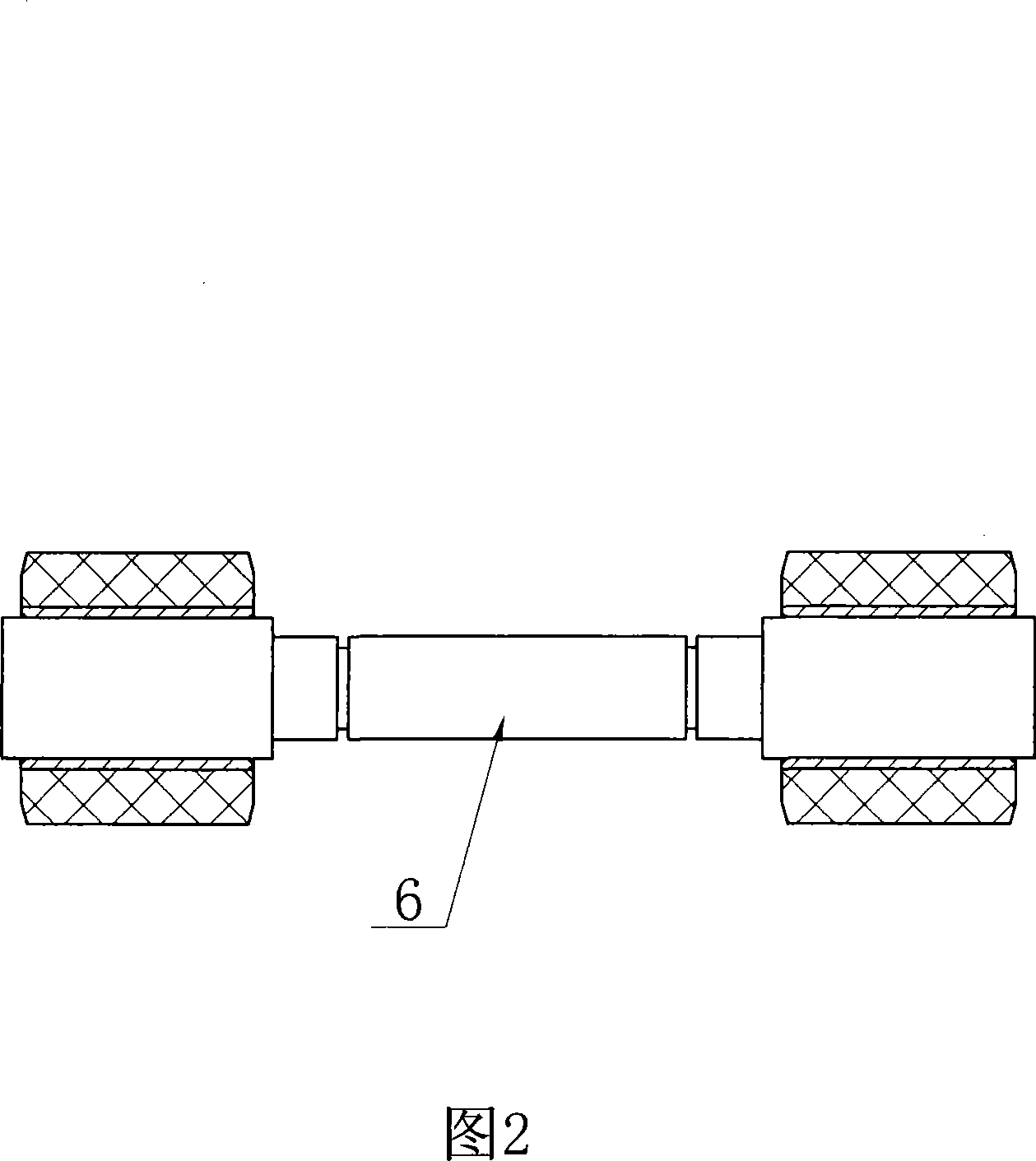

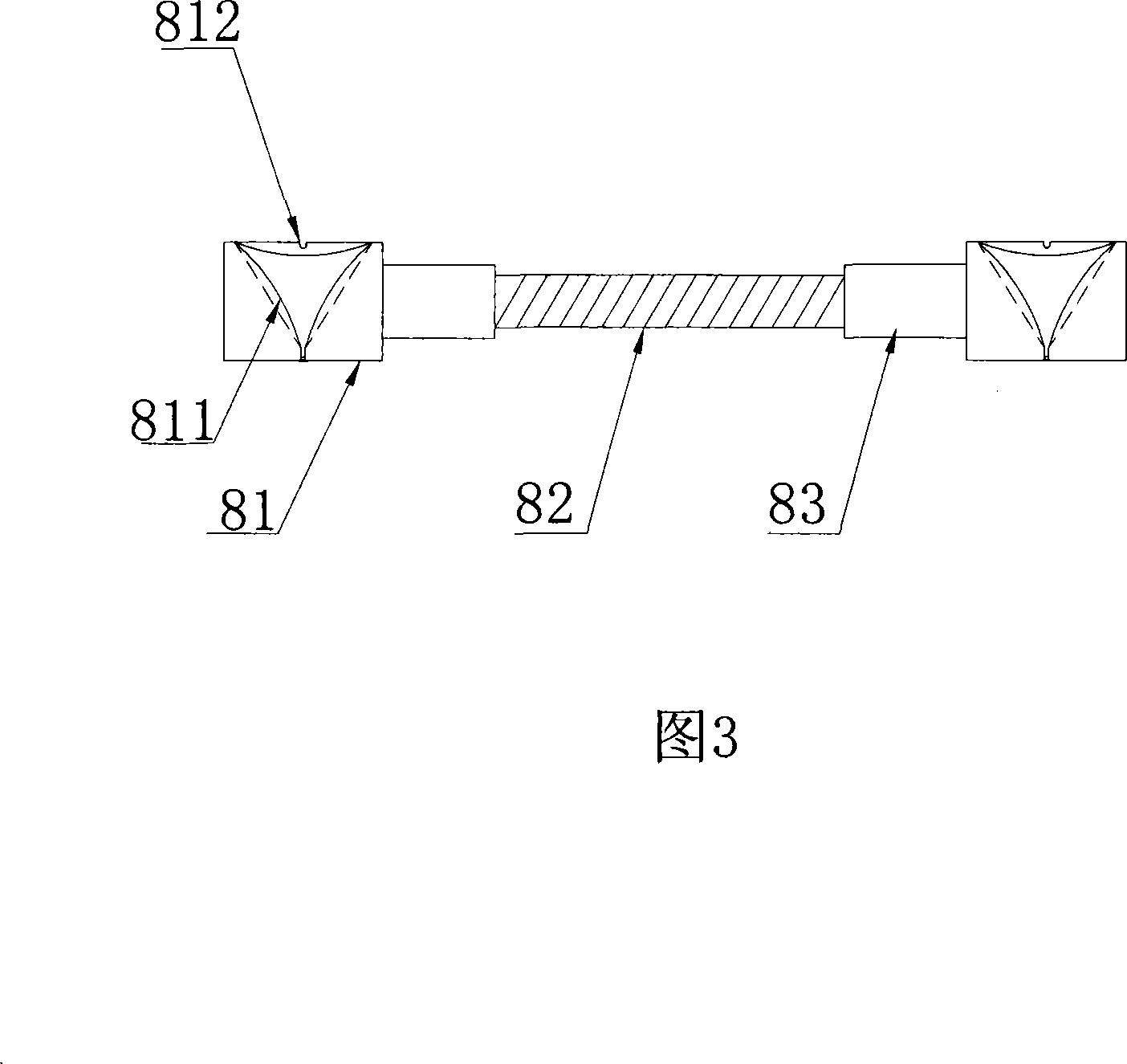

[0017] As shown in Fig. 1, Fig. 2 and Fig. 4, the lower top roller 2 is installed on the cradle 1 of the spinning frame, the bottom roller 5 is installed on the fuselage below the cradle 1, and the lower top roller 2 is pressed tightly On the roller 5, one end of the upper fixing seat 4 is connected to the shaft of the lower top roller 2, and the other end is installed on the spring plate 3, as shown in Figure 5 and Figure 6, the spring plate 3 is a bow-shaped plate with two ends bent, and the spring The upper end of the plate 3 is fixedly connected to the cradle 1, and a lower fixing seat 10 is installed on the lower end bending part of the spring plate 3, and a middle top roller 6 and an elastic disk 8 are installed on the upper fixing seat 4, and the middle top roller 6 is tightly fastened. Press on the bottom roller 5, and an elastic disk 8 is arranged between the middle top roller 6 and the bottom roller 5. One side of the elastic disk 8 is pressed on the bottom roller 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com