Selvage device in loom

A loom and weaving edge technology, which is applied in looms, fabrics, textiles, etc., can solve the problems of large-scale edge yarn opening mechanism, and achieve the effects of simplifying the structure, preventing yarn breakage, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

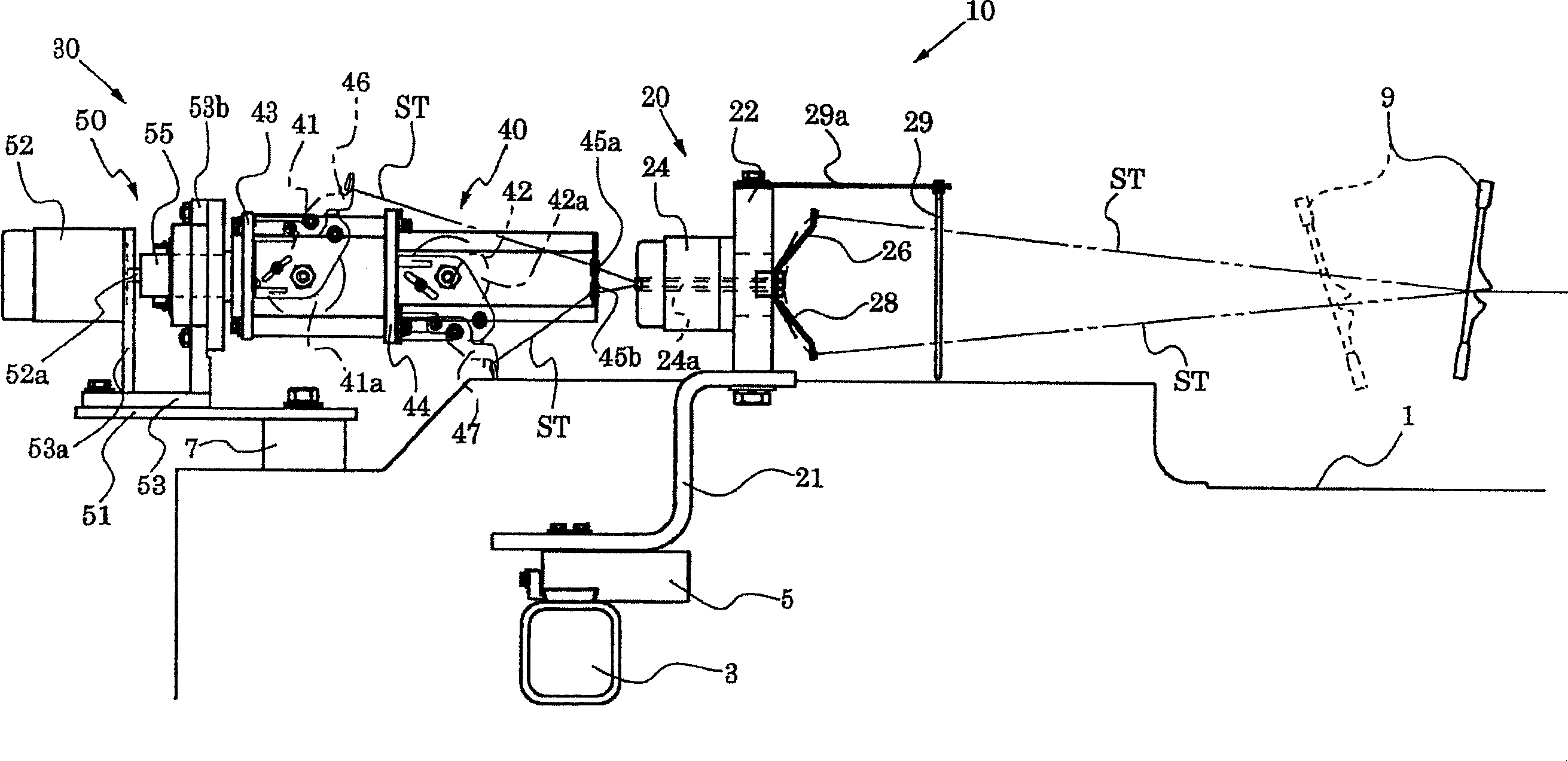

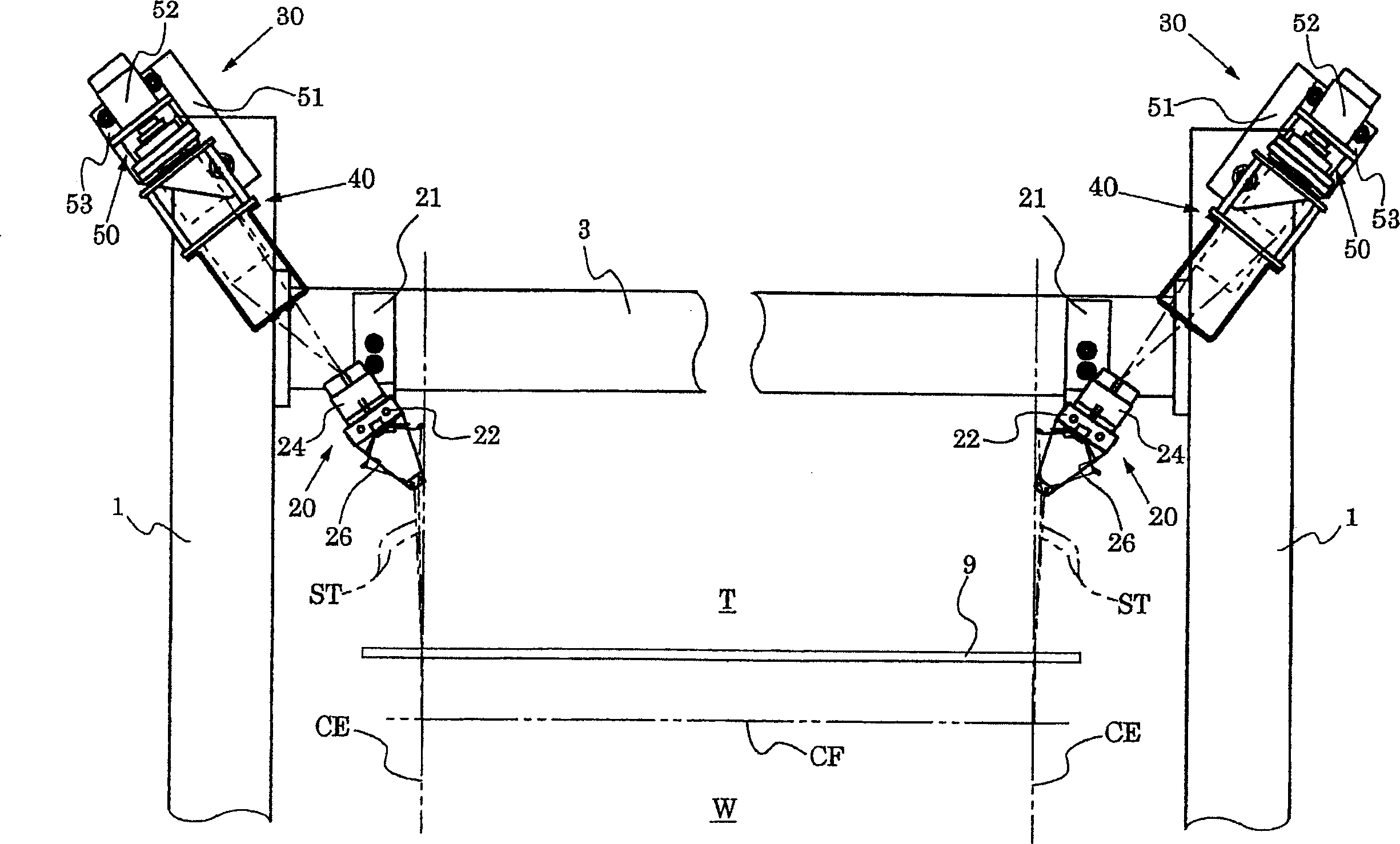

[0026] Figure 1~4 Shown is an embodiment of the present invention. The selvedge device 10 is composed of a side yarn shedding mechanism 20 and a side yarn supply mechanism 30. Such as figure 1 and 2 As shown, the side yarn shedding mechanism 20 is supported by a support block 5 and the like on a cross bar (beam) 3 erected between the side frames 1, 1 on both sides of the loom, and is arranged on a warp composed of multiple warps. Near column T. In addition, the side yarn supply mechanism 30 is supported on the side frames 1, 1 on both sides of the loom via the support block 7 and the like.

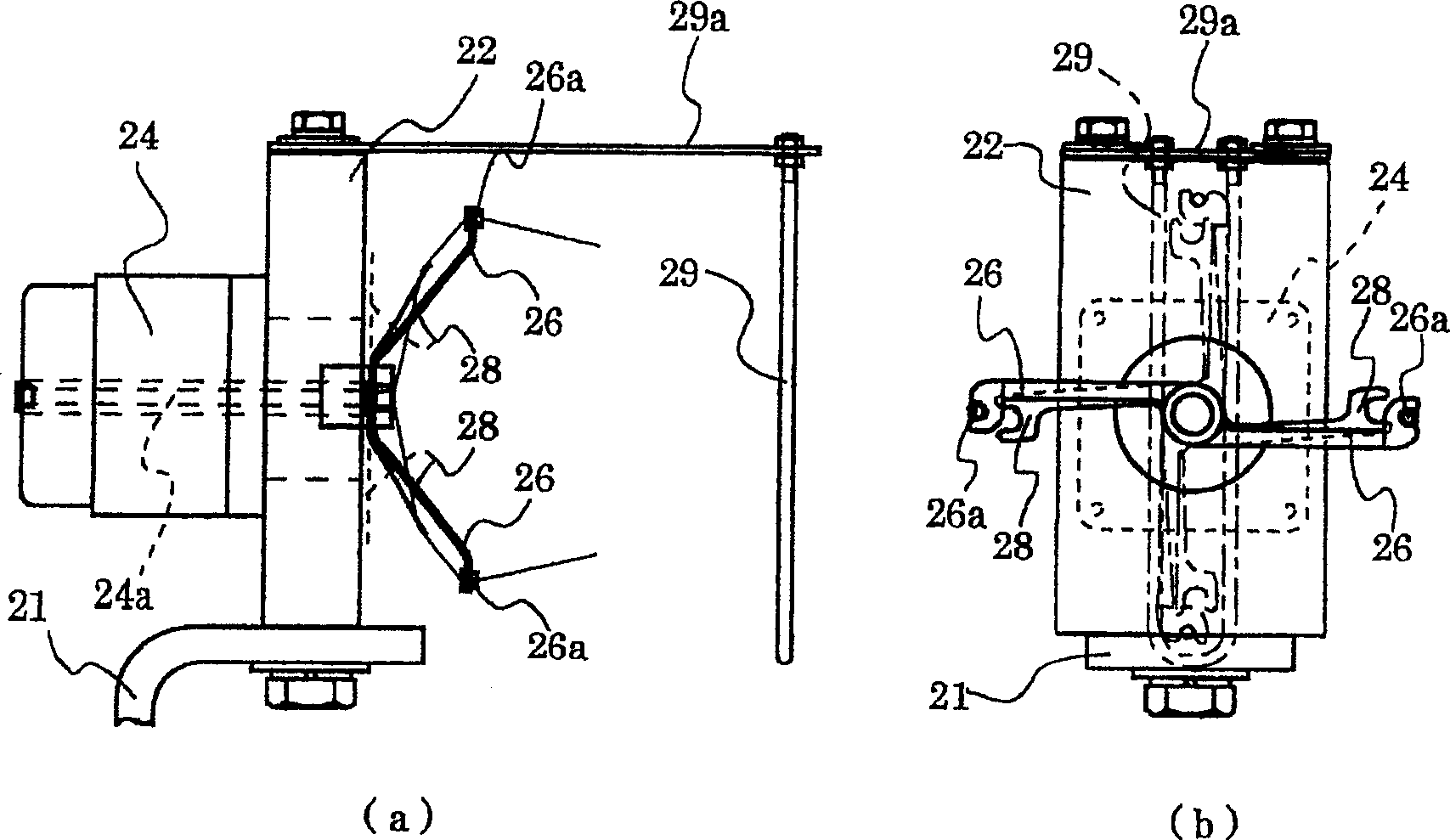

[0027] Such as Figure 1~3 As shown, the side yarn shedding mechanism 20 of this embodiment has a dedicated drive motor 24 as a drive source, and an arm 26 as a rotating body mounted on the output shaft 24a of the drive motor 24. In addition, the support block 5 on the cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com